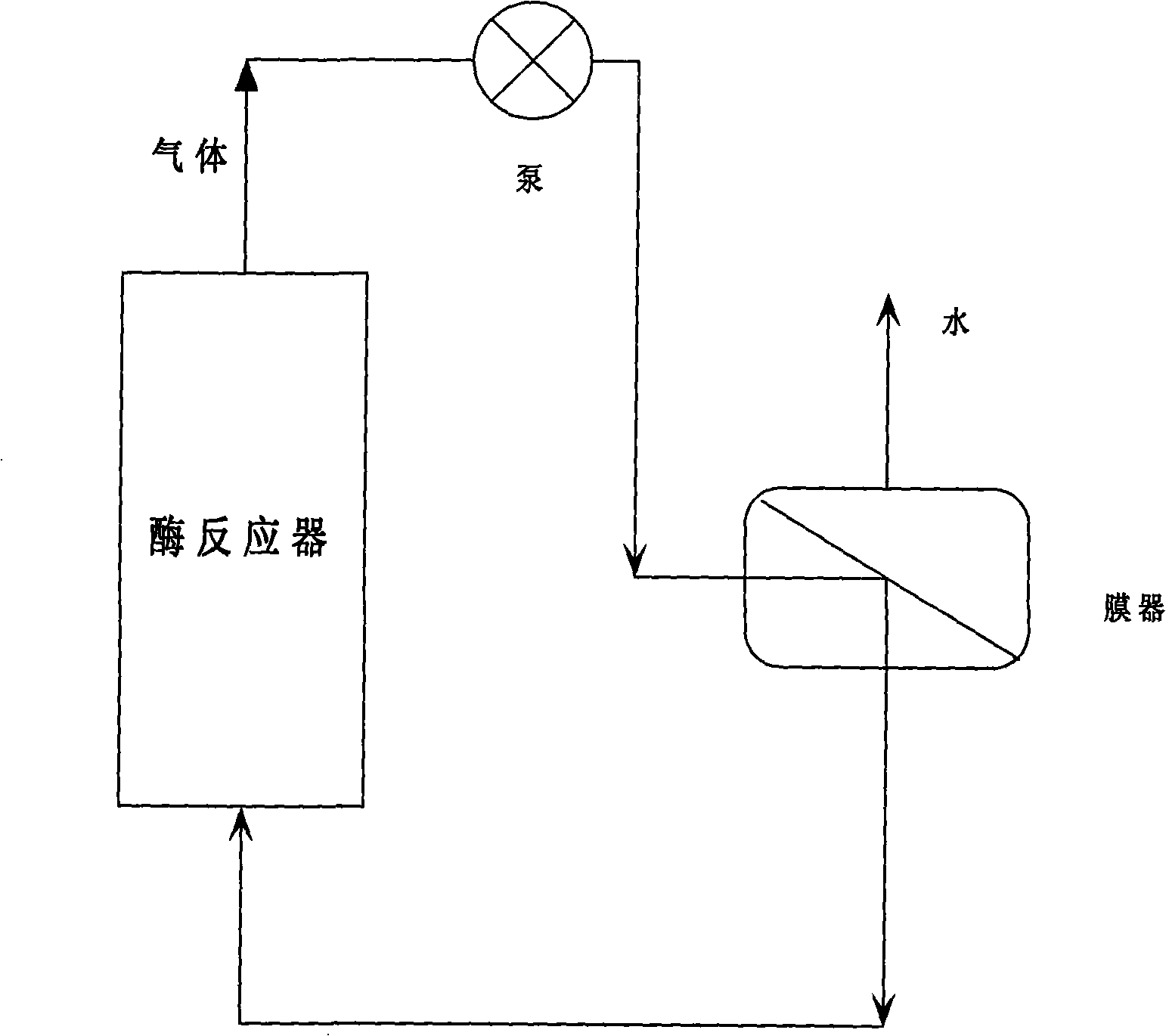

Bio diesel oil preparation technique using enzyme method of membrane on-line dehydration

A technology for biodiesel and enzymatic preparation, which is used in the preparation of liquid hydrocarbon mixtures, petroleum industry, biological raw materials, etc., to achieve the effect of improving the efficiency of enzymatic reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The airlift loop reactor is equipped with methanol and rapeseed acidified oil (acid value of 120) in a molar ratio of 4:1, and 60% tert-butanol based on the volume of the fat. The temperature is controlled at 50°C. Immobilized lipase Lipozyme TL with 3% mass and Novozym 435 with 2% oil mass. The volatile gas tert-butanol and methanol are used as the circulation force of the liquid in the reactor to entrain the water generated in real time during the reaction. Pass through a ceramic membrane that can selectively permeate water, and then return to the enzyme reactor, and so on. After passing through the membrane, the water permeability can reach 90%, and the permeability of tert-butanol and methanol is 5%. After 5 hours of reaction, the yield of biodiesel reached more than 90%.

Embodiment 2

[0016] The airlift loop reactor is equipped with 5:1 molar ratio of ethanol and soybean acidified oil (acid value of 60), and 80% tert-butanol based on the volume of fat. The temperature is controlled at 50°C. 3% immobilized lipase Lipozyme TL and 2% immobilized lipase Novozym 435 based on the mass of oil. The volatile gas tert-butanol and methanol are used as the circulation force of the liquid in the reactor to entrain the water generated in real time during the reaction. A ceramic membrane that can selectively permeate water, and then return to the enzyme reactor, and so on. After passing through the membrane, the water permeability can reach 92%, and the permeability of tert-butanol and ethanol is 1%. After 6 hours of reaction, the yield of biodiesel reached more than 90%.

Embodiment 3

[0018] The airlift loop reactor is equipped with 6:1 molar ratio of propanol and soybean acidified oil (acid value of 100), and 60% tert-butanol based on the volume of fat. The temperature is controlled at 50℃. 3% immobilized lipase Lipozyme TL and 2% immobilized lipase Novozym 435 based on the mass of oil. The volatile gas tert-butanol and methanol are used as the circulation force of the liquid in the reactor to entrain the water generated in real time during the reaction. An organic membrane that can selectively permeate water, and then return to the enzyme reactor, and so on. After passing through the membrane, the water permeability can reach 98%, and tert-butanol and propanol are almost impermeable. After 5 hours of reaction, the yield of biodiesel reached more than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com