Method for preparing catalyst applied to low-carbon olefin selective oxidization for undersaturation aldehyde preparation

一种选择氧化、低碳烯烃的技术,应用在碳基化合物制备、化学仪器和方法、有机化合物的制备等方向,能够解决催化剂性能变差、催化剂组分不均匀、催化剂高转化率与高选择性高稳定性不能兼得等问题,达到选择性好、活性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

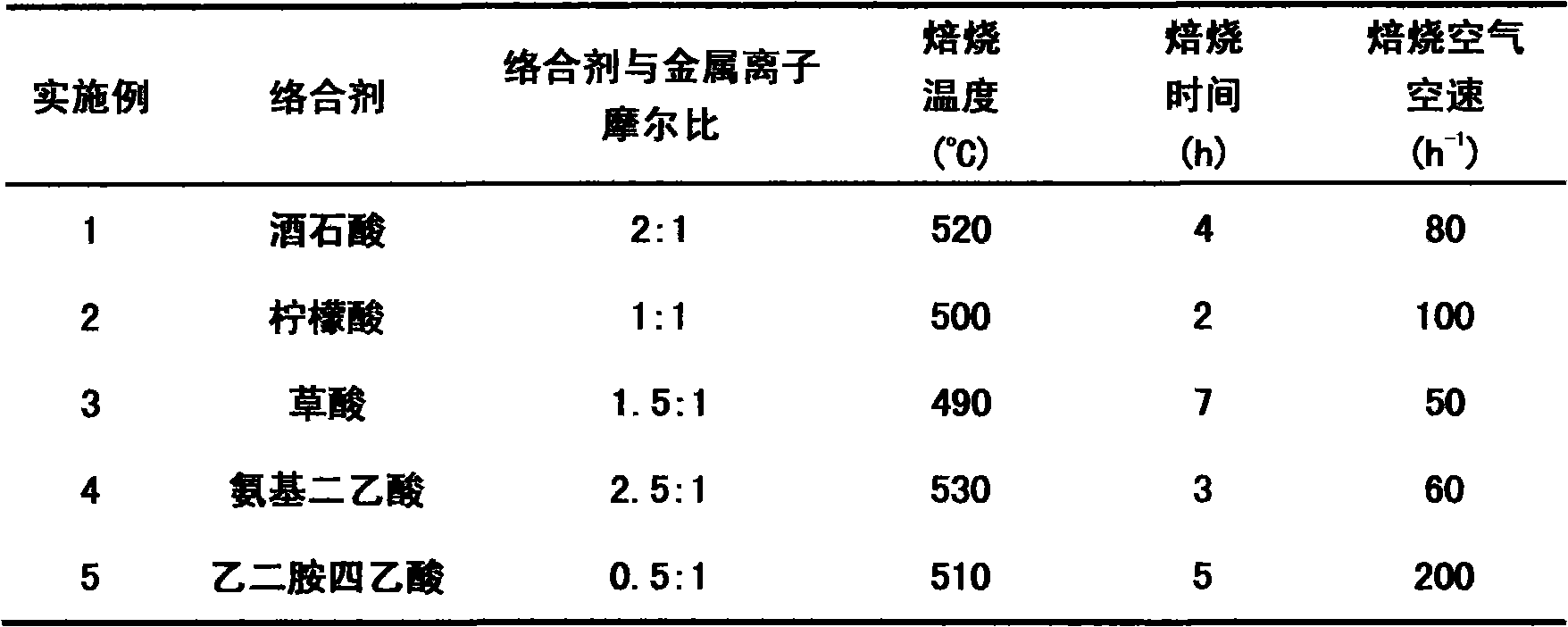

Embodiment 1~5

[0024] Dissolve 1000 grams of ammonium paramolybdate tetrahydrate in 2 liters of distilled water, and record it as solution A; 297.6 grams of bismuth nitrate pentahydrate, 192.6 grams of iron nitrate nonahydrate, 755.5 grams of cobalt nitrate hexahydrate, 27.5 grams of nickel nitrate hexahydrate, Dissolve 9.5 grams of potassium nitrate and 5.5 grams of cesium nitrate in 1.5 liters of distilled water, and record it as solution B. Add solution B to solution A under stirring, and add a complexing agent to the above mixed solution, and continue stirring at 60° C. for 5 hours. Afterwards, the above slurry was transferred to an oven at 100° C. for 18 hours to dry to obtain a dry slurry. Take 70 grams of dry slurry and 30 grams of SiC powder, mix them uniformly, and punch them into hollow columnar particles with an outer diameter of 5 mm, an inner diameter of 2 mm, and a length of 5 mm. The catalyst particles obtained are roasted in air to obtain a composition of 70 (Mo 12 Bi 1.3 F...

Embodiment 6~8

[0032] Dissolve 1000 grams of ammonium paramolybdate tetrahydrate and a certain amount of citric acid in 1 liter of distilled water, and record it as solution A; add an appropriate amount of bismuth nitrate pentahydrate, iron nitrate nonahydrate, cobalt nitrate hexahydrate and other components of the precursor Body salts were dissolved in 1 liter of distilled water, and recorded as solution B. Solution B was added to solution A with stirring, and stirring was continued at 70° C. for 4 hours. Then transfer the above slurry to an oven for 12 hours at 170°C to dry to obtain a dry slurry; take the above dry slurry and mix it with an appropriate amount of heat-conducting agent powder mechanically, and form it into a hollow column with an outer diameter of 5 mm, an inner diameter of 2 mm, and a height of 3 mm. particles, and then put the catalyst particles in the air to roast to obtain the catalyst. When roasting, the volume space velocity of the air relative to the catalyst is 100...

Embodiment 9~10

[0040] Dissolve 1000 grams of ammonium paramolybdate tetrahydrate in 3 liters of distilled water, and record it as solution A; dissolve an appropriate amount of bismuth nitrate pentahydrate, ferric nitrate nonahydrate, cobalt nitrate hexahydrate and other components of the precursor salt and tartaric acid in 0.5 liters of distilled water, recorded as solution B, wherein the molar ratio of tartaric acid to metal ions is 2:1. Solution A was added to solution B with stirring, and stirring was continued at 40° C. for 6 hours. Afterwards, transfer the above slurry to an oven for 24 hours at 70°C to obtain a dry slurry; add a certain amount of heat-conducting agent powder to the above dry slurry, mix it evenly by mechanical means, and slice it into pieces with an outer diameter of 5mm, an inner diameter of 2mm, Hollow columnar particles with a height of 3 mm, and then the hollow particles were calcined in air for 5 hours to obtain a catalyst. Air volume space velocity is 500h durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com