Utilization method of tertiary butyl alcohol coproduced by using device for producing epoxypropane by using propene and iso-butane cooxidation method

A co-oxidation method, propylene oxide technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as affecting product economy, tert-butanol cannot be directly used, and large costs are increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

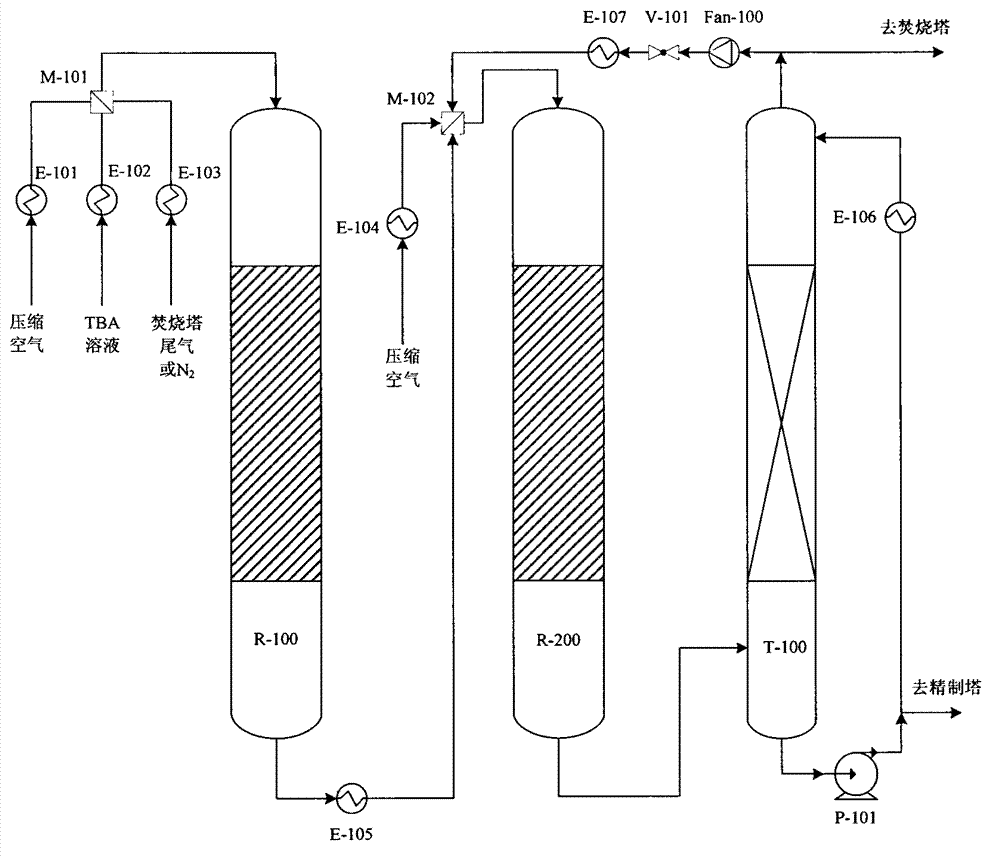

Method used

Image

Examples

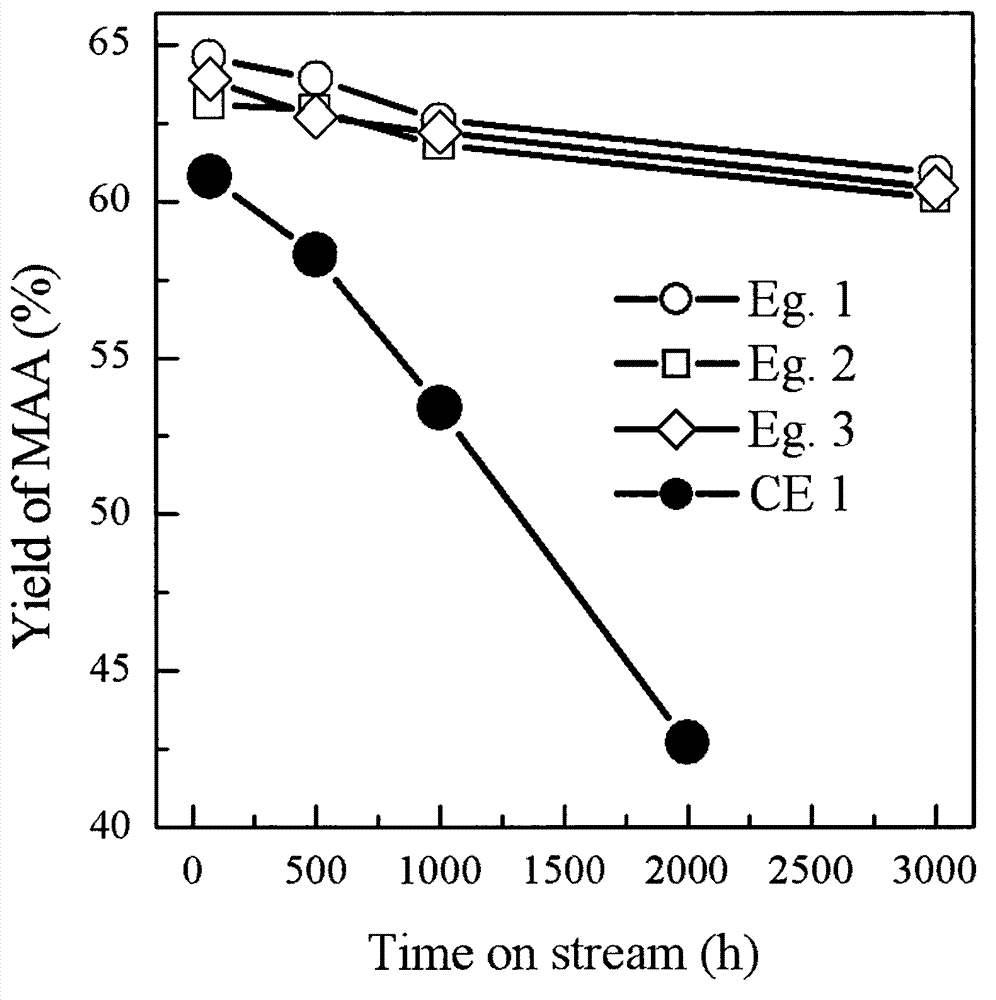

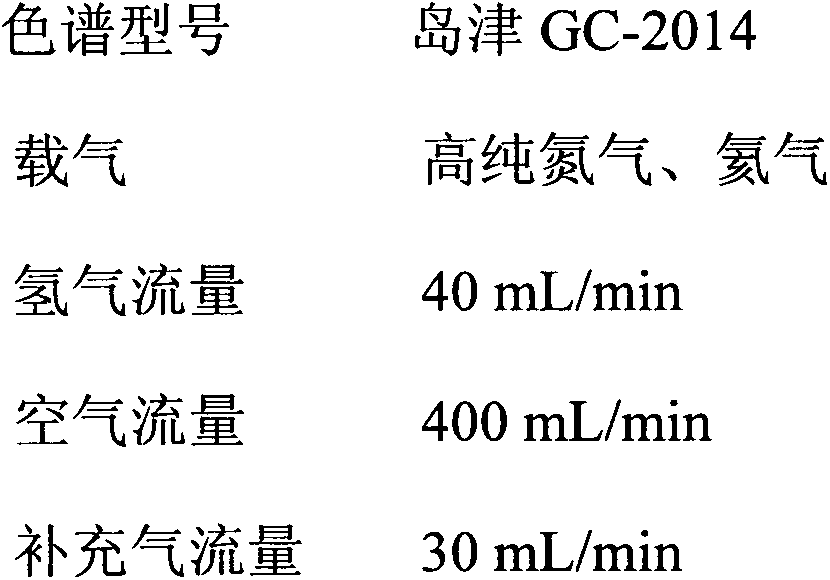

Embodiment 1

[0058] Preparation of catalyst:

[0059] Preparation of the first stage catalyst:

[0060] To 750 parts of deionized water, add 449 parts of ammonium heptamolybdate ((NH 4 ) 6 Mo 7 O 24 ·4H 2 O, molecular weight 1236) and 22.3 parts of ammonium metavanadate (NH 4 VO 3 , Molecular weight: 117), while stirring, the temperature is raised to 80°C, and 339 parts of bismuth nitrate (Bi(NO 3 ) 3 .5H 2 O, molecular weight 485), 317 parts of iron nitrate (Fe(NO 3 ) 3 ·9H 2 O, molecular weight 404), 111 parts of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O, molecular weight 291), 20.5 parts of copper nitrate (Cu(NO 3 ) 2 ·3H 2 O, molecular weight 242) and 20.7 parts of cesium carbonate (Cs 2 CO 3 , Molecular weight 326) was dissolved in 370 parts of nitric acid solution with a mass concentration of 10%. After stirring for 30 minutes, ammonia water was added to adjust the pH to 3.0. After aging the slurry for 10 hours, it was placed in a 90℃ blast drying oven for 12 hours. Finally, the catalyst After b...

Embodiment 2

[0076] Preparation of catalyst:

[0077] Preparation of the first stage catalyst:

[0078] To 750 parts of deionized water, add 449 parts of ammonium heptamolybdate ((NH 4 ) 6 Mo 7 O 24 ·4H 2 O, molecular weight 1236), 11.2 parts of niobium pentoxide (Nb 2 O 5 , Molecular weight: 265.8) and 7.4 parts of ammonium metavanadate (NH 4 VO 3 , Molecular weight: 117), while stirring, the temperature is raised to 80°C, and 102.7 parts of bismuth nitrate (Bi(NO 3 ) 3 .5H 2 O, molecular weight 485), 599 parts of iron nitrate (Fe(NO 3 ) 3 ·9H 2 O, molecular weight 404), 123.3 parts of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O, molecular weight 291), 102.5 parts of copper nitrate (Cu(NO 3 ) 2 ·3H 2 O, molecular weight 242) and 13.8 parts of cesium carbonate (Cs 2 CO 3 , Molecular weight 326) was dissolved in 370 parts of nitric acid solution with a mass concentration of 10%. After stirring for 30 minutes, ammonia water was added to adjust the pH to 3.0. After aging the slurry for 10 hours, it was plac...

Embodiment 3

[0095] Preparation of catalyst:

[0096] Preparation of the first stage catalyst:

[0097] Add 449 parts by weight of ammonium heptamolybdate ((NH 4 ) 6 Mo 7 O 24 ·4H 2 O, molecular weight 1236), 5.6 parts of niobium pentoxide (Nb 2 O 5 , Molecular weight: 265.8) and 99.0 parts of ammonium metavanadate (NH 4 VO 3 , Molecular weight: 117), heat to 80℃ while stirring, add 152.5 parts of bismuth nitrate (Bi(NO 3 ) 3 .5H 2 O, molecular weight 485), 171.2 parts of iron nitrate (Fe(NO 3 ) 3 ·9H 2 O, molecular weight 404), 246.4 parts of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O, molecular weight 291), 76.9 parts of copper nitrate (Cu(NO 3 ) 2 ·3H 2 O, molecular weight 242) and 51.8 parts of cesium carbonate (Cs 2 CO 3 , Molecular weight 326) was dissolved in 370 parts of nitric acid solution with a mass concentration of 10%. After stirring for 30 minutes, ammonia water was added to adjust the pH to 3.0. After aging the slurry for 10 hours, it was placed in a 90℃ blast drying oven for 12 hours. F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com