Shell removing machine for chinese chestnuts

A delinting machine and delinting technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of waste, increased labor intensity, incomplete consideration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

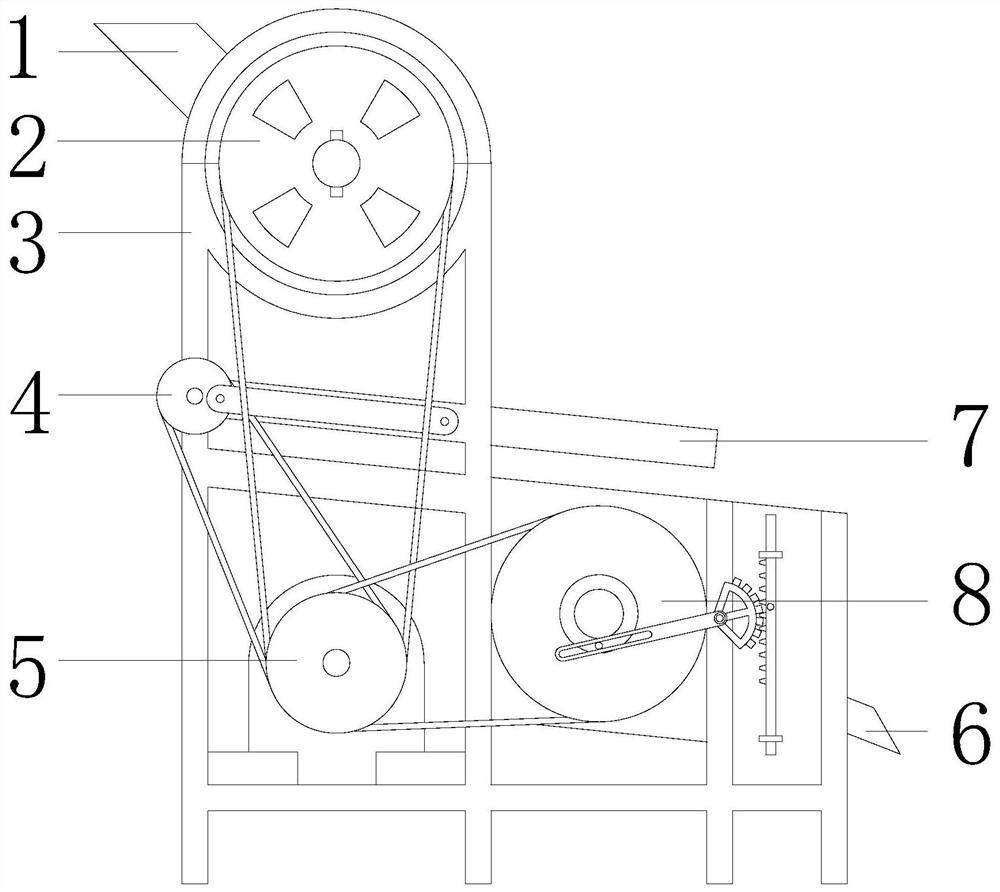

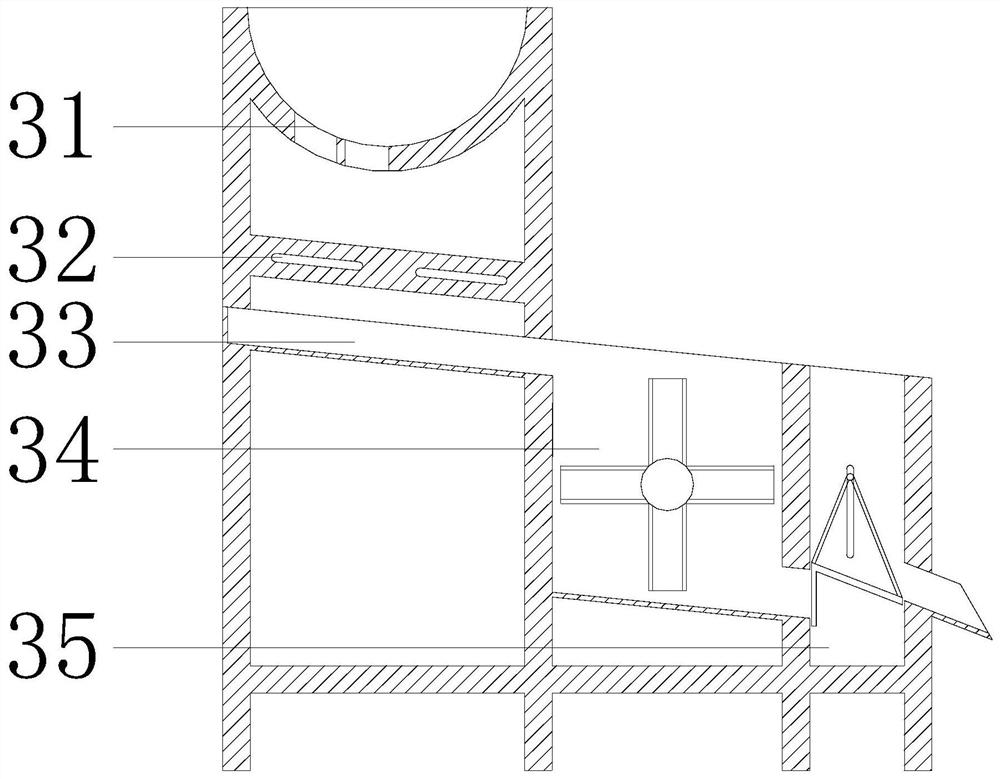

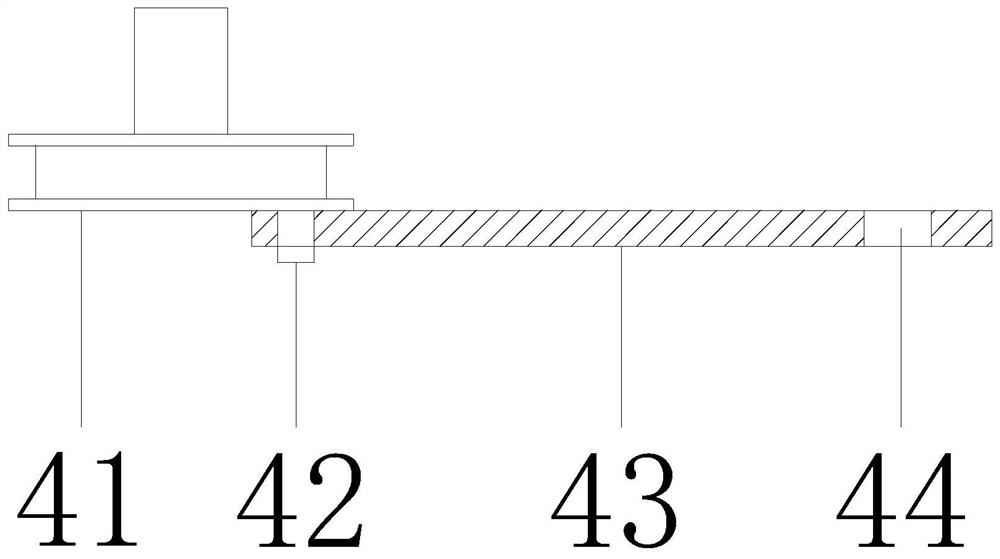

[0030] see Figure 1-Figure 6 , the present invention provides a chestnut delinting machine, which includes a feed hopper 1, rolling rollers 2, a steel frame 3 of the delinting machine, a vibration mechanism 4, a pulley motor 5, a hopper 6, a vibrating screen 7, and a roller brush for conveying Mechanism 8, the feed hopper 1 is located at the inner top of the rolling roller 2, the feeding hopper 1 is fixedly connected with the rolling roller 2, and the rolling roller 2 is arranged at the inner top of the steel frame 3 of the awning machine, the rolling roller The pressure roller 2 is movably connected with the steel frame 3 of the tenting machine, and the front surface of the steel frame 3 of the stripping machine is provided with a vibration mechanism 4, and the vibration mechanism 4 is connected with the steel frame 3 of the stripping machine, and the pulley motor 5 is located at The inner bottom of the delinting machine steel frame 3, the pulley motor 5 is threaded with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com