Procedure for manufacturing ladderproof fabrics

a technology for ladderproof fabrics and manufacturing procedures, which is applied in the field of ladderproof fabric manufacturing procedures, can solve the problems of difficult dyeing and unattractiveness, negative fallout on the appearance and feel of fabrics, and hidden elastic yarns in such fabrics, so as to improve the appearance and surface feel, improve the appearance and feel, and improve the effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

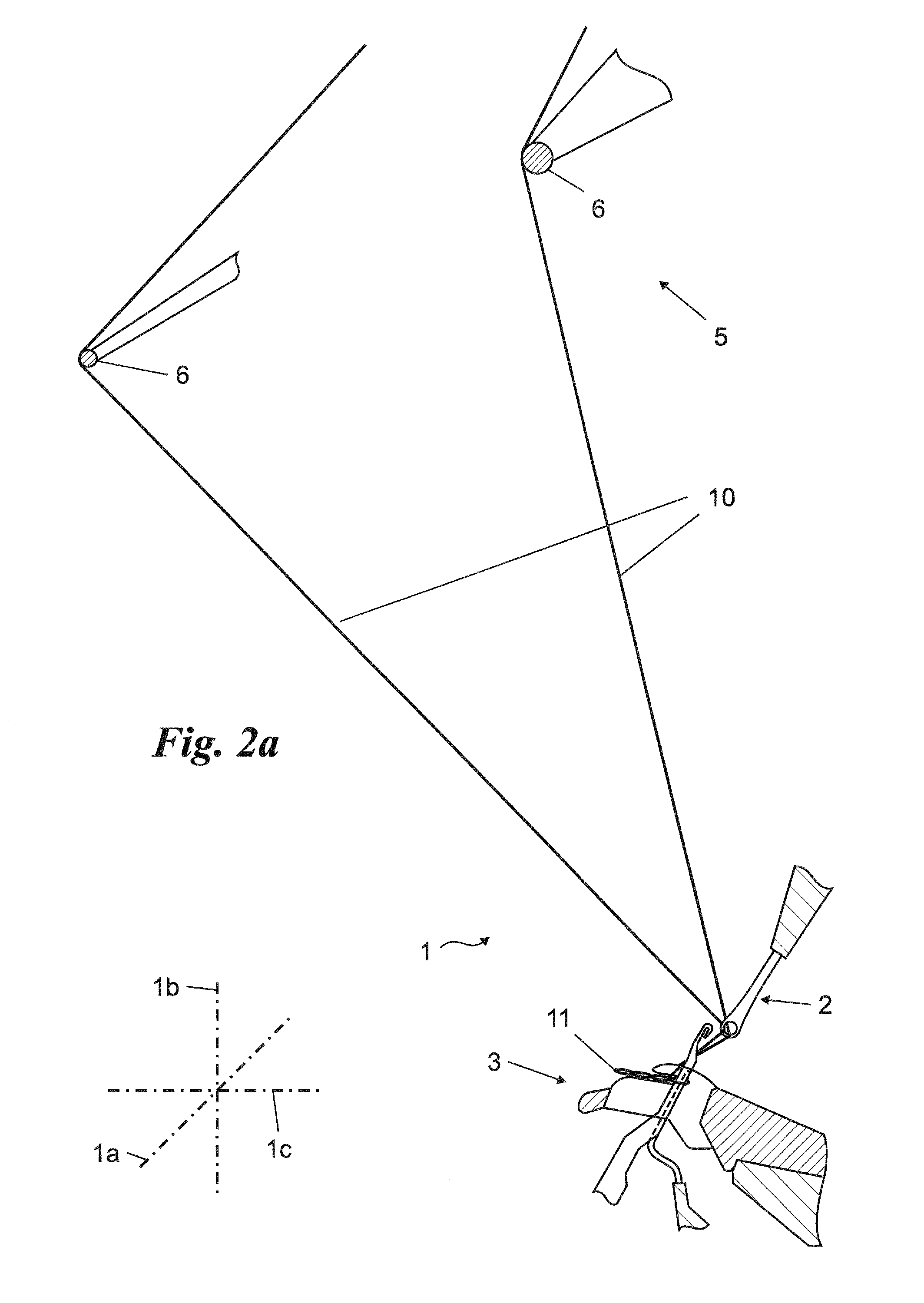

[0028]With reference to the attached figures, the knitting machine for implementing the procedure according to the invention is globally indicated by the numeral 1.

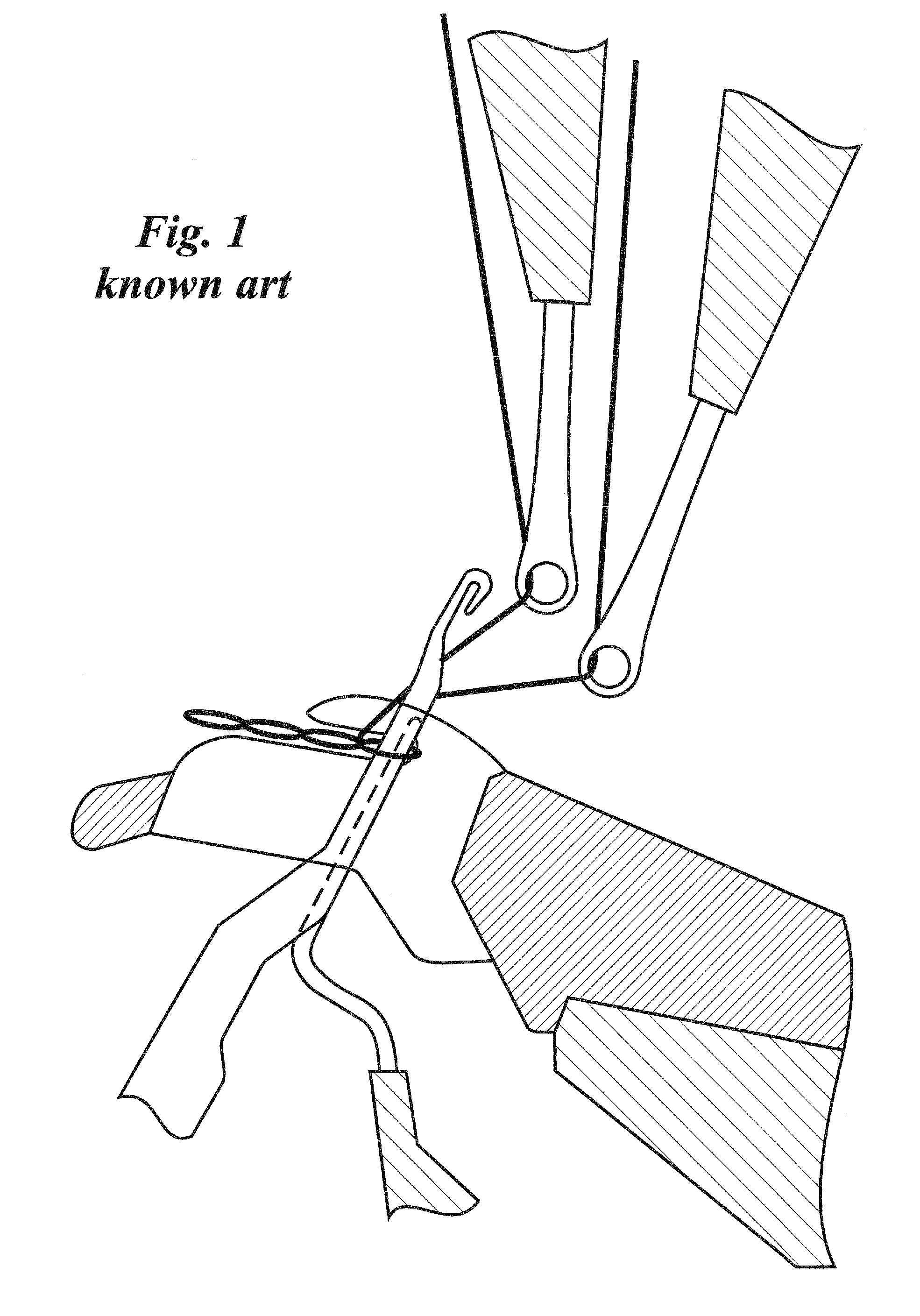

[0029]It substantially and preferably comprises a loom of the single needle bed, ladderproof type, shown in FIG. 1.

[0030]These machines are partially known and are supplied, for instance, by the German company LIBA Maschinenfabrik GmbH, going by the name of Copcentra.

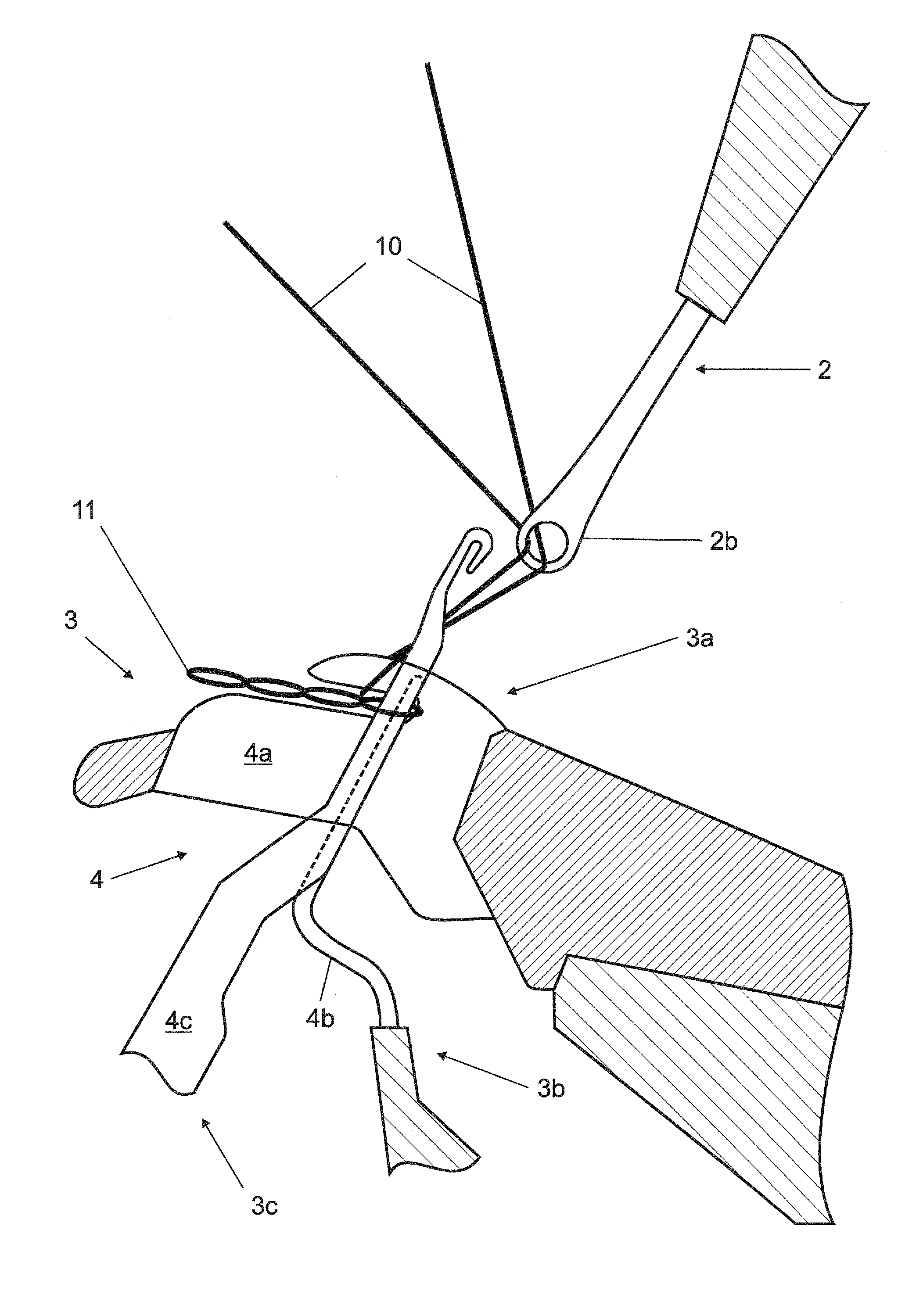

[0031]The wrap knitting machine 1 comprises at least one guide bar 2, a system of stitch-forming members 3, and a yarn conveyor system 5.

[0032]In particular, each guide bar 2 comprises a plurality of guides 2a in a recurrent arrangement and parallel to one another in the longitudinal direction 1a, perpendicular to the plane of the cross-section shown in FIG. 2a, and to the vertical 1b and crosswise 1c directions. The system of stitch-forming members 3 is of the known type and basically comprises a sinker bar 3a, a slider bar 3b and a needle bar 3c suitable fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com