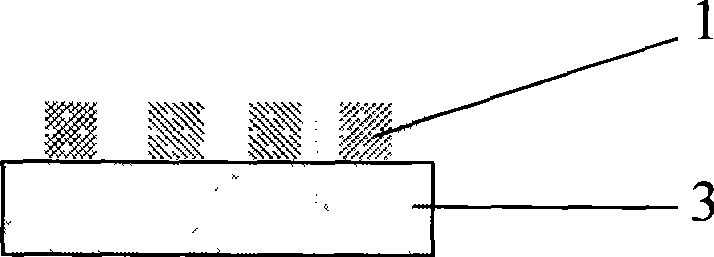

Patents

Literature

49results about How to "Long-term corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

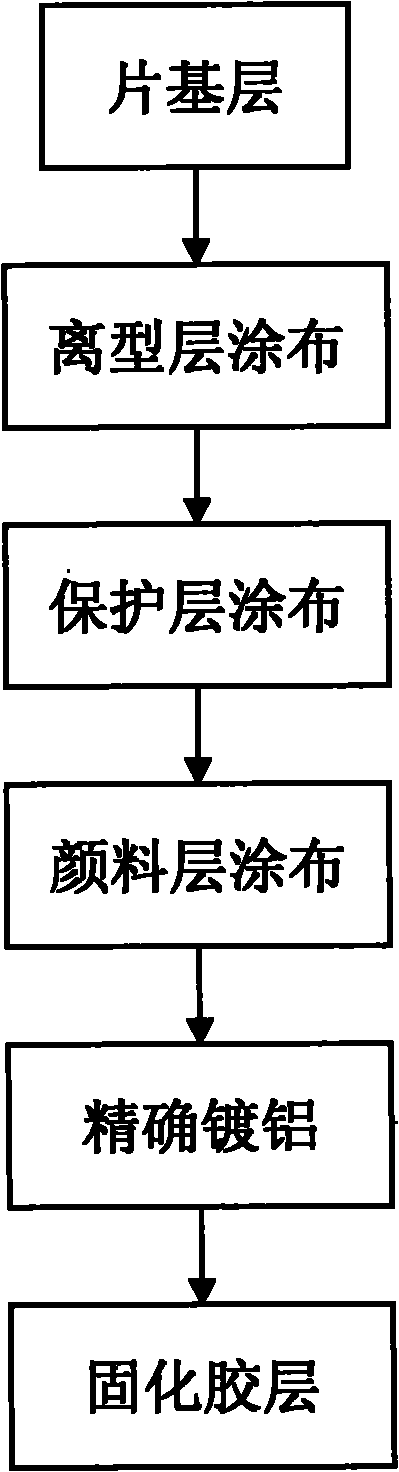

Production method of hot stamping foil

ActiveCN101879819ASolving Hot Stamping RequirementsEvenly paintedCoatingsThermographyPolyvinyl butyralHot stamping

The invention discloses a production method of hot stamping foil, which adopts six production process flows: release coating, protective layer coating, color layer coating, accurate aluminizing and curing glue layer coating. In the whole production process, water soluble glue, water soluble ink and water soluble gloss oil are used to realize the integrated production of the hot stamping foil, methacrylates and monomers which are emulsified and polymerized are mixed in a certain ratio, a dye leveler, thickener and the like are added in the mixture, the resulting product is coated and dried, polyvinyl butyral-based glue is coated, and the whole production of the hot stamping foil is finished. The hot stamping foil produced by the process has the characteristics of energy conservation, environmental protection and sanitation.

Owner:江苏卫星新材料股份有限公司

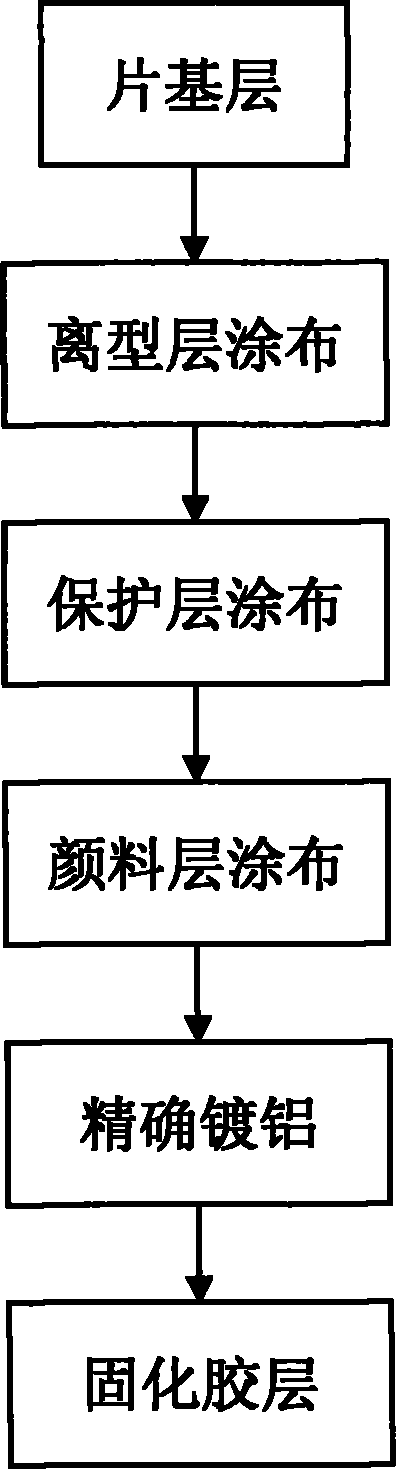

Optical transparent member and optical system using the same

InactiveCN1834693AImprove anti-reflection effectLong-term corrosion resistanceLayered productsRecord information storageMaterials scienceCrystal

It is an object to provide an optical transparent member capable of maintaining a high-performance antireflection effect for a base over a long period of time, and an optical system using the same, specifically an optical transparent member including on a base, a layer containing SiO 2 as a main component, a layer containing Al 2 O 3 as a main component, and a plate crystal layer formed from plate crystals containing Al 2 O 3 as a main component, wherein the surface of the plate crystal layer has a shape of irregularities, and an optical system using the same.

Owner:CANON KK +1

Method for treating magnesium-alloy workpiece, workpiece therefrom and composition therewith

InactiveCN101074479AHelp formImprove bindingLiquid/solution decomposition chemical coatingCleaning using liquidsSurface finishingElectroplated nickel

A method for treating magnesium-alloy work-piece surface, its work piece, its degrease surface treatment and non-electroplating nickel composition are disclosed. The process is carried out by forming displacing and activating layer containing nickel and metal M crystal seed on surface layer exposed with magnesium-alloy solid melt and heat treating. It has strong adhesion and long-period anti-corrosive function.

Owner:GREAT MAGTECH TECH CO LTD

High-efficiency antiseptic antifreezing agent for coal transportation and method for preparing same

InactiveCN1603380AImprove stabilityMeet the requirements of transportationOther chemical processesDepressantCoal

The invention provides a kind of coal transportation with highly effective to guard against corrosion the antifreeze, its component was: Glycol, calcium chloride, triethanolamine, with deionized water. The above coal transportation highly effective anticorrosion antifreeze preparation method includes: (1) solution configuration: The calcium chloride, joins in the deionized water, namely made has been ready to be used the fluid, (2) mixed the process: Joins the triethanolamine makes is ready to be used in the fluid, makes the reserve fluid, again glycol if in the reserve fluid, then continues to stir for a hour, causes the temperature drop to the room temperature, like this, has made the end product. The invention discloses testing many times in the foundation, screened pour point depressant, caused the antifreeze the solidification point greatly to reduce, had achieved -66deg.C, its anti- freezing temperatures has achieved -40deg.C, therefore had the fine low freezing point performance, also the stability was extremely good, has satisfied north the winter coal transportation request. After simultaneously in order to avoid pour point depressant oxidizing corrodes the freight car, but also has used the inhibitor technology, provides the long-term anticorrosion for the train freight car, has guarded against the rust function.

Owner:SHANXI YUNYAN PETROCHEM CO LTD

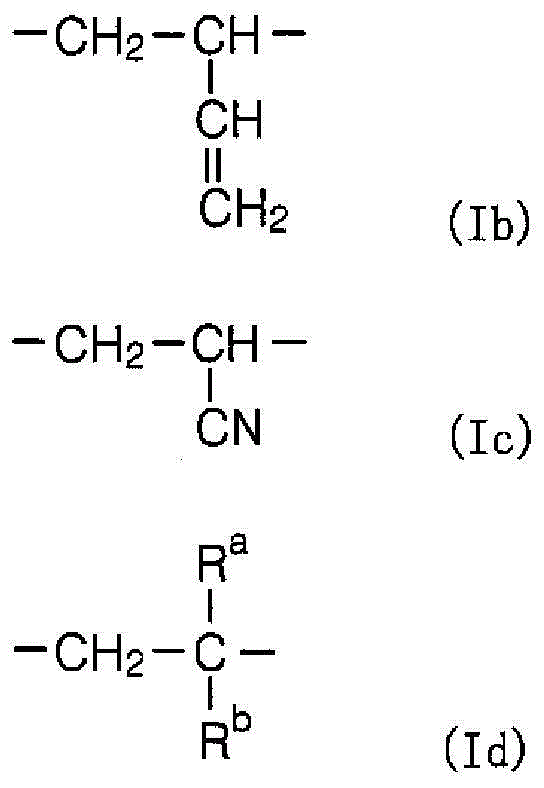

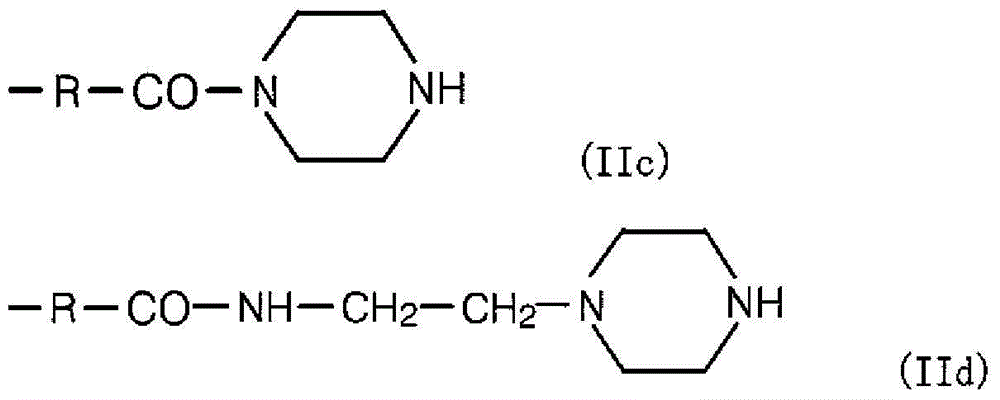

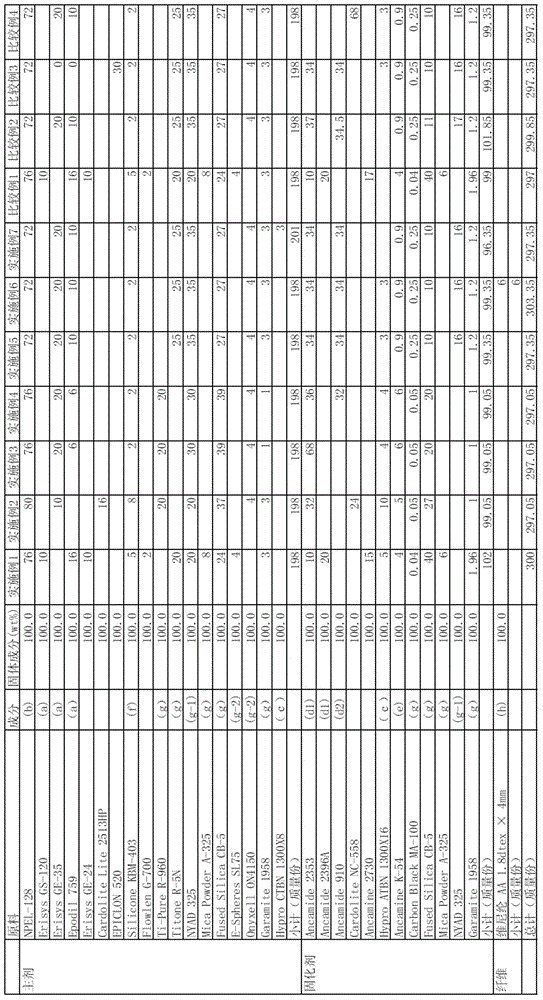

Epoxy resin composition

ActiveCN104449203AAchieve protectionLong-term corrosion resistanceConjugated diene hydrocarbon coatingsAnti-corrosive paintsEpoxyPolyamide

The invention relates to an epoxy resin composition which has epoxy resin (a) more than two functions derived from higher fatty acids or a derivative thereof, epoxy resin (b) other than the epoxy resin (a), end-reactive butadiene-acrylonitrile copolymer (c), and polyamide amine (d). According to the present invention, the epoxy resin composition can follow cracks and achieve protection of the concrete structure by a simple method using roller coating and brush coating paint in a wet surface. Further, the epoxy resin composition of the present invention has long-term corrosion resistance to seawater, and adhesion to concrete wet surfaces, rebars, steel, and rust surfaces.

Owner:CHUGOKU MARINE PAINTS

Low-VOC (volatile organic compound) full-solid-ingredient cavity anti-corrosion wax composition

ActiveCN106867321AImprove water resistanceImprove anti-corrosion performanceWax coatingsAnti-corrosive paintsVehicle frameSolvent

The invention relates to a low-VOC (volatile organic compound) full-solid-ingredient cavity anti-corrosion wax composition, which is prepared from the following ingredients in percentage by mass: 5 to 20 percent of wax materials, 5 to 20 percent of plant grease, 1 to 10 percent of oil-soluble anti-rust additives, 5 to 10 percent of anti-rust pigments, 1 to 5 percent of drying control agents, 0.1 to 1 percent of driers, 0.1 to 1 percent of silane coupling agents and 40 to 70 percent of basic oil. The anti-corrosion wax composition provided by the invention does not contain solvent ingredients; the ingredients are all solid ingredients; the low-VOC and environment-friendly effects are achieved; the flash point is high; the operation is safe; the low-VOC full-solid-ingredient cavity anti-corrosion wax composition can be used as anti-corrosion wax to be applied to coating of underpans, vehicle frames, hinges, vehicle door insides, window beam insides or other steel plate structures and components in automobile industry.

Owner:SHENYANG PARKERIZING

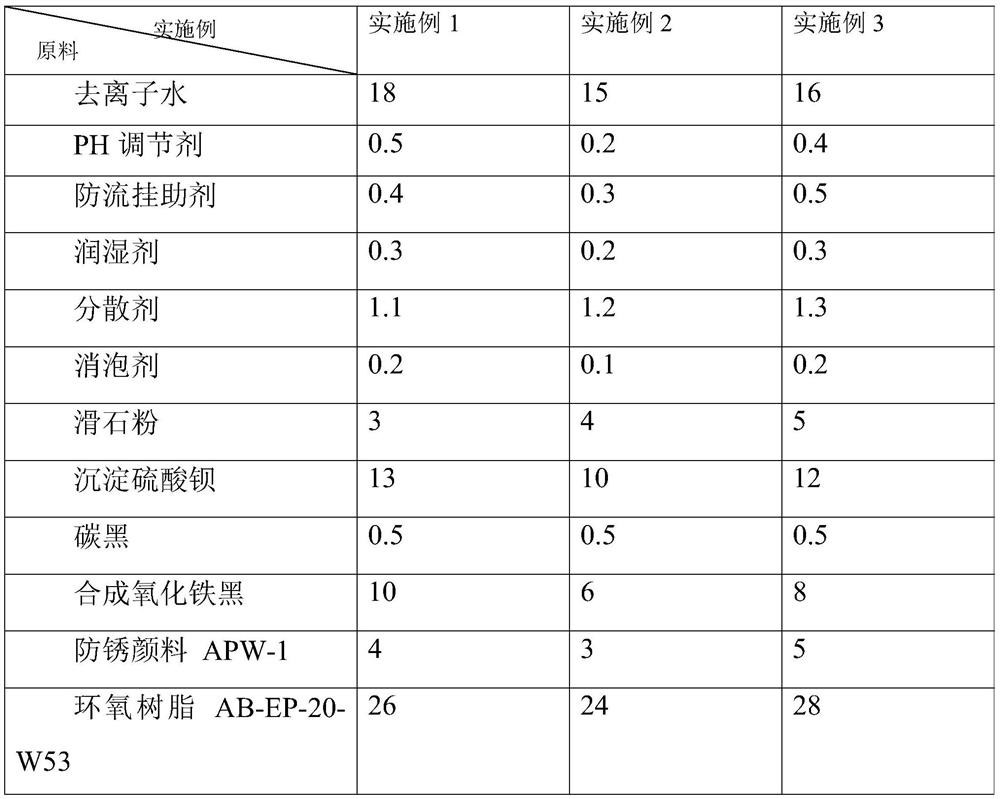

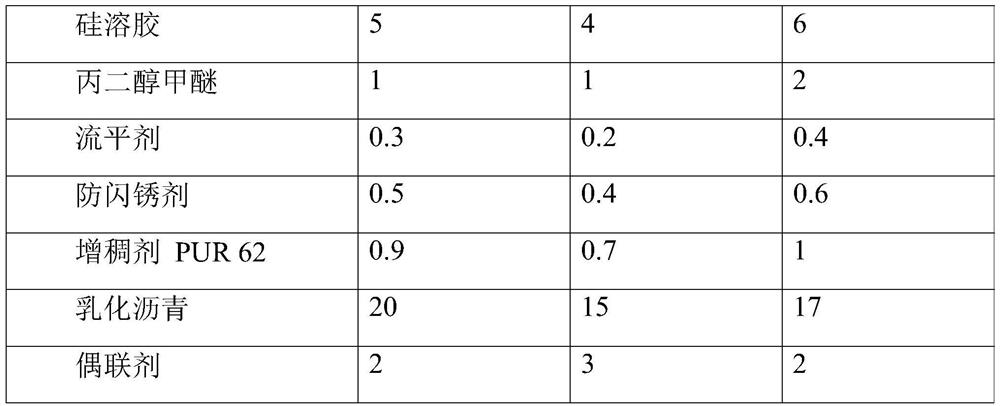

Waterborne epoxy asphalt coating and preparation method thereof

InactiveCN111978815AExcellent anti-corrosion performance and bonding performanceGood water resistanceAnti-corrosive paintsEpoxy resin coatingsPolyamideCorrosion resistant

The invention provides a waterborne epoxy asphalt coating. The coating comprises a component A and a component B. The component A is prepared from the following raw materials in parts by weight: 15-18parts of deionized water, 0.2-0.5 part of a pH regulator, 0.3-0.5 part of anti-sagging auxiliary agent, 0.2-0.3 part of a wetting agent, 1.1-1.3 parts of a dispersing agent, 0.1-0.2 part of a defoaming agent, 3-5 parts of talcum powder, 10-13 parts of precipitated barium sulfate, 0.5 part of carbon black, 6-10 parts of iron oxide black, 3-5 parts of antirust pigment, 24-28 parts of epoxy resin, 4-6 parts of silica sol, 1-2 parts of propylene glycol monomethyl ether, 0.2-0.4 part of a flatting agent, 0.4-0.6 part of a flash rust inhibitor, 0.7-1 part of a thickener, 15-20 parts of emulsified asphalt and 2-3 parts of a coupling agent. The component B is an aliphatic amine modified polyamide polymer. The mass ratio of the component A to the component B is 12:1. The thickness of a film formedby one-time spraying of the coating can reach 150 microns, and the coating has excellent corrosion resistance, sagging resistance and chemical resistance.

Owner:北京红狮科技发展有限公司

Method for preparing aluminum part surface zincing powder and method for coating aluminum part surface zincing powder

InactiveCN102002665AImprove corrosion resistanceAvoid direct contactSolid state diffusion coatingCorrosionZinc

The invention discloses a method for preparing aluminum part surface zincing powder and a method for coating the aluminum part surface zincing powder. The aluminum part surface zincing powder comprises the following components in percentage by weight: 14.9 to 84.5 percent of zinc powder, 84.9 to 14.5 percent of inert metal oxide powder, 0.1 to 0.5 percent of activating agent and 0.1 to 0.5 percent of auxiliary agent. The coating method of the aluminum part surface zincing powder comprises the following steps of: placing the aluminum part surface zincing powder prepared by the preparation method and an aluminum part to be zinced in the same sealed steel can; heating the steel can; controlling the temperature to 400 + / -10 DEG C; after keeping the temperature for 60 to 180 minutes, cooling to the room temperature; and zincing and coating the surface of the aluminum part. The corrosion resistance of an aluminum plate processed by the method is obviously improved, and particularly the marine atmospheric environment corrosion resistance is greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

Production method for high-temperature bearing composite material insulator especially for petroleum logger

ActiveCN101174488AHigh temperature resistantHas acid and alkali resistanceGlass making apparatusQuartz/glass/vitreous enamelsTemperature resistanceSilicon dioxide

The invention discloses a preparation method for special high-temperature pressure-bearing composite material insulator used for a petroleum logging tool. The preparation method is performed in the following steps: silanizing coupling pretreatment are first performed to high intensity glass fiber chopped strands, nano silicon dioxide and black carbon are added into the well treated glass fiber chopped strands or twistless roving or chopped strand mats in vacuum state, the components are positioned into a vacuum performing die for evacuation, crack resistant material and hydrophobic material are added into high-temperature resin glue to perform stirring and standing in the vacuum state; the sizing material after the standing is poured into a vacuum pressure pot, a valve is opened in order to ensure the sizing material to flow upward in countercurrent manner, in order to fill up the preforming die; the upper valve and the lower valve of the performing die are closed, the preforming die is positioned into oil to be heated, and then high temperature pressure bearing test is performed to measure the insulation value under the indexes of 175 DEG C and 140 MPa. The invention has the advantages of high temperature resistance, acid and alkali resistance, low cost, simple technology, and good insulation performance, and when the insulation value is higher than or equal to 500 M Omega, the insulator is determined to be qualified.

Owner:西安永兴科技发展有限公司

Six-color full-color soft printing ink and preparation method thereof

InactiveCN106349811AImprove performanceAddresses bugs that occur when mates dissolveInksDecabromodiphenyl etherAcrylic resin

The invention relates to practical printing ink, in particular to six-color full-color soft printing ink and a preparation method thereof. The six-color full-color soft printing ink is mainly prepared from 11.5 to 31.5 parts of dye, 57 to 77 parts of binder and 6 to 27 parts of accessory ingredient, wherein the dye contains an organic pigment, a inorganic pigment or a mixture of the organic pigment and the inorganic pigment; the binder mainly contains: water-soluble acrylic resin, polyether-modified acrylic acid polyurethane resin, cellulose acetate butyrate, rosin modified phenolic resin, polyvingakohol, glycerin, ethyl acetate, sodium diacetate, decabromodiphenyl ether, n-butyl acetate, polybasic acrylic copolymer resin and polyketone resin; the accessory ingredient is one or more of a color adjustment agent, a plasticizer, a thickener, an organic diluting solvent, a liquidity adjustment agent, a gel, an adhesion removal agent, a surface active agent or talcum powder. According to the six-color full-color soft printing ink and the preparation method thereof provided by the invention, the performances of the binder and the accessory ingredient are improved, so that the printing ink with a favorable performance is obtained, and an excellent printing effect is obtained when in use.

Owner:东莞市巨泓彩色印刷有限公司

One-step cover closing method of electronic paper micro-cup and cover closing material

InactiveCN101441382ASimple methodEasy to emulsifyNon-linear opticsIdentification meansDissolutionConductive materials

The invention relates to an electronic paper micro-cup, in particular to a method for the one-step sealing of the electronic paper micro-cup on flexible basal material in solvent with strong dissolution or swelling such as tetrachlorethylene, and sealing material thereof. According to the invention, unsaturated acrylic ester derivatives are taken as main material to prepare sealing glue liquor together with oligomers, monomers, a photoinitiator, a modifier, a surfactant and conductive material. The sealing glue liquor is mixed with pigment dispersing liquor according to certain proportion and is used for completing the sealing through emulsification and dispersion, delamination, and photo solidification. The sealing thickness can be accurately controlled through the volumetric ratio of the sealing glue liquor and the pigment dispersing liquor. The invention can not only be suitable for sealing electronic ink or liquid crystal to realize flexible or rigid plate display, but also be used for the micro-flow control, cell or tissue culture, synthesis and preparation in the fields of biology, medicine and chemistry.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

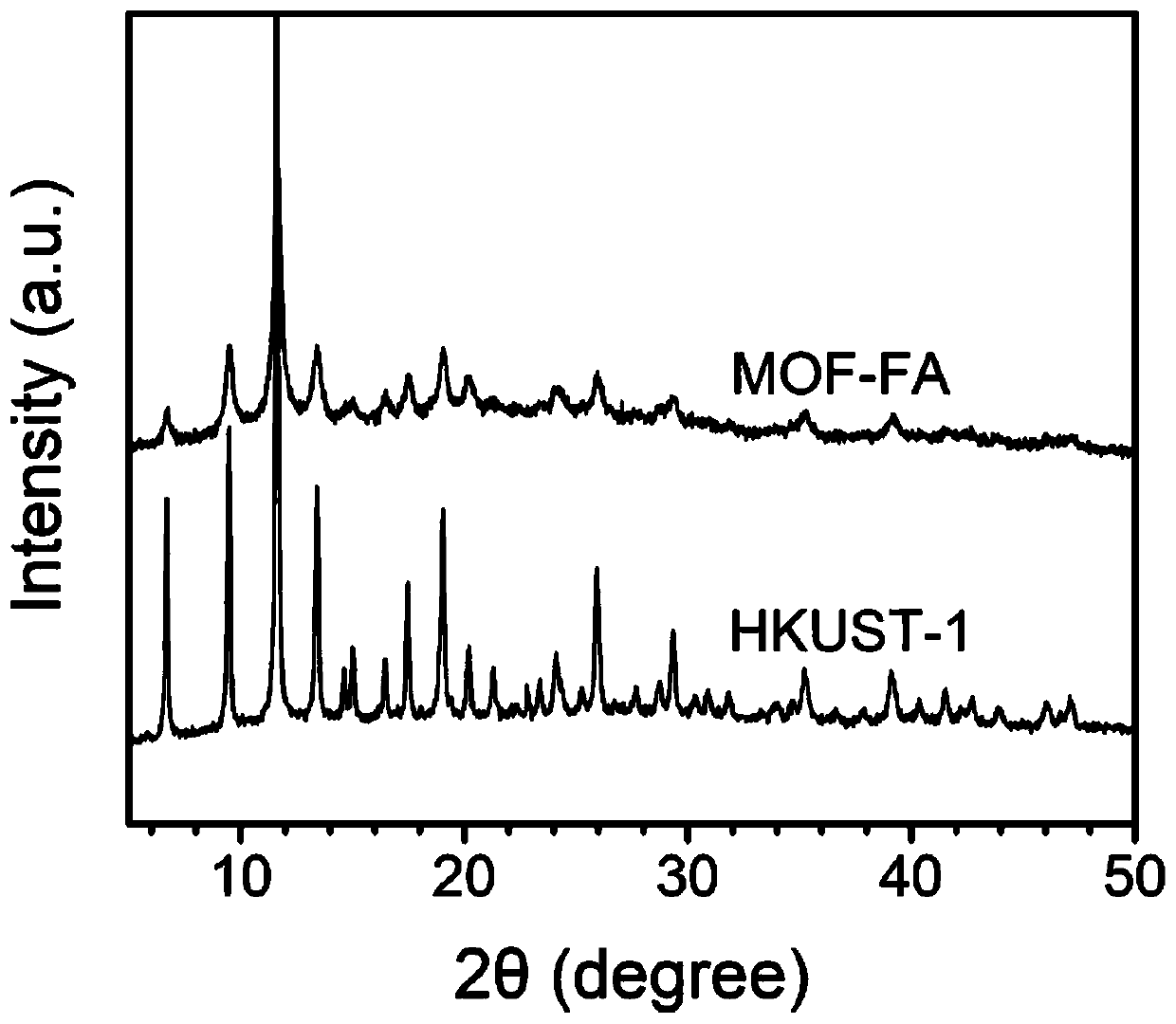

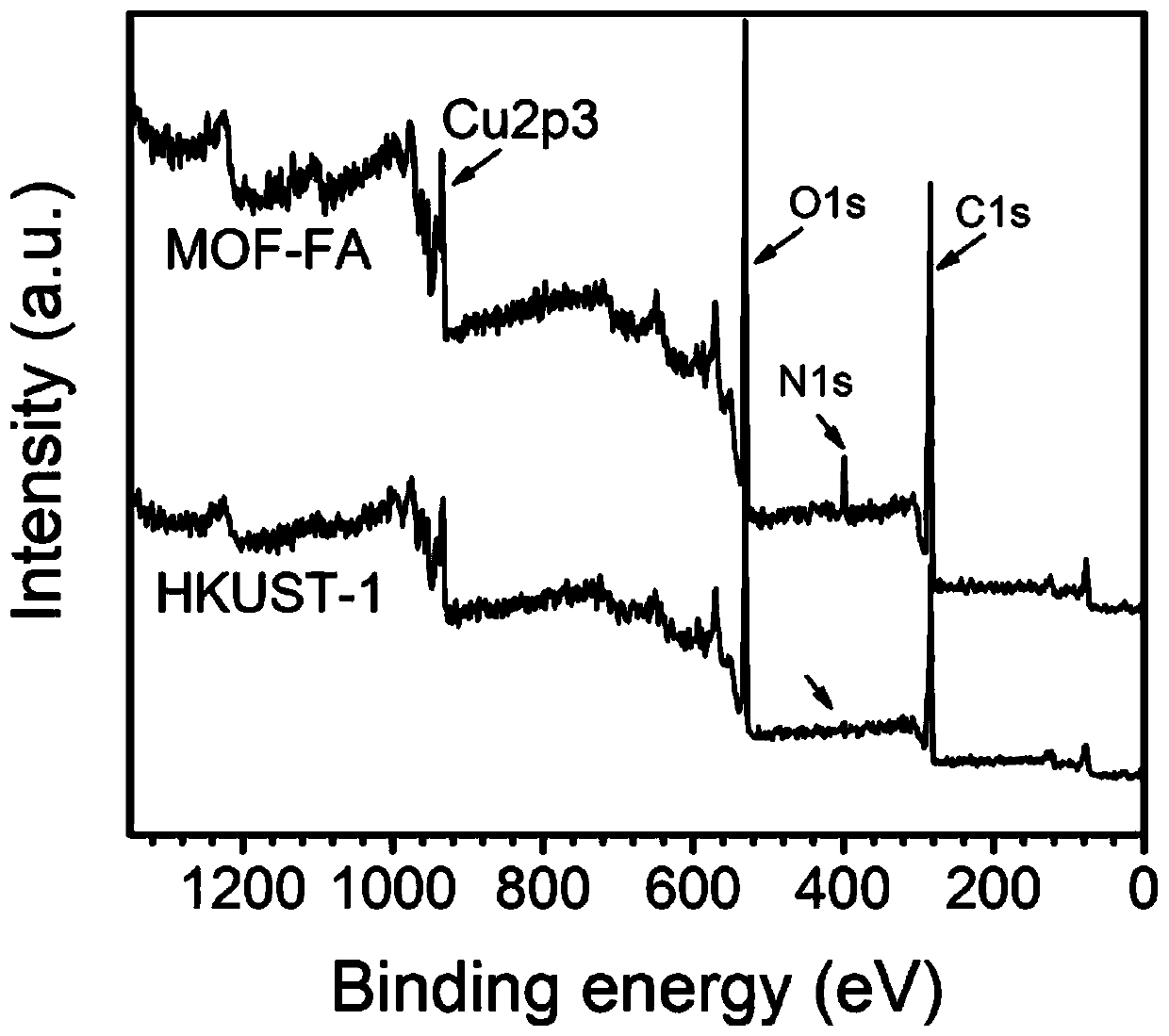

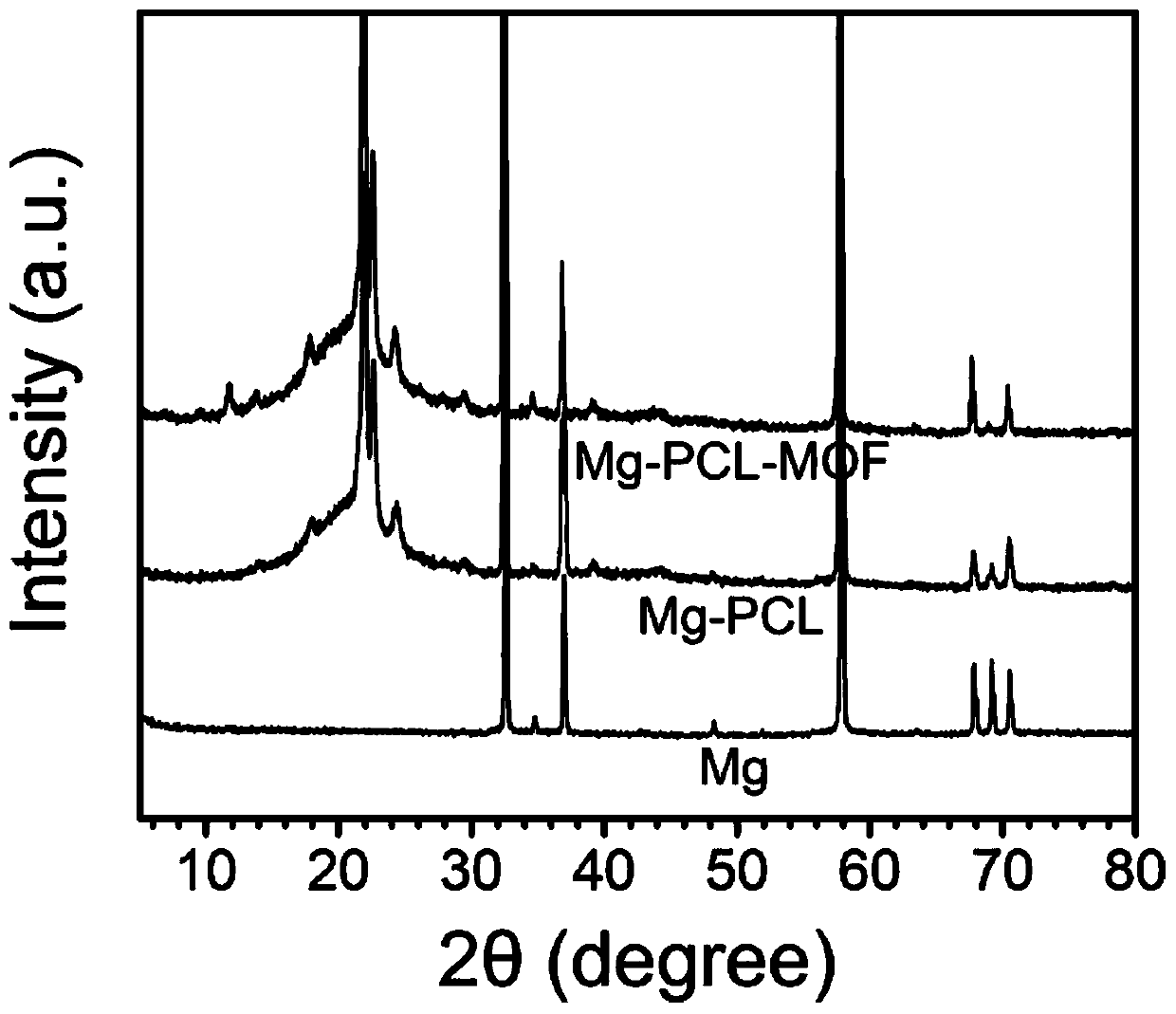

Preparing method for composite coating comprising metal organic frame MOF and polycaprolactone PCL and degrading surface of magnesium alloy

ActiveCN110665772AImprove compactnessLong-term corrosion resistancePretreated surfacesSpecial surfacesFolic acidBone cell

The invention provides a preparing method for a composite coating comprising a metal organic frame MOF and polycaprolactone PCL and degrading the surface of a magnesium alloy. The preparing method includes the following steps that firstly, mechanical polishing treatment of the magnesium alloy is conducted; secondly, folic acid modification MOF powder is prepared; and thirdly, the PCL-MOF compositecoating is prepared. By means of the preparing method, folic acid modification HKUST-1 (MOF-FA) and a PCL solution are mixed, and the mixed solution is dripped to the surface of the AZ31 magnesium alloy to form the composite coating (PCL-MOF). In the coating, a hydrogen bond can be formed between MOF and PCL, compactness of PCL is improved, and the effect of delaying magnesium alloy corrosion isachieved; and meanwhile, MOF-FA can also be adopted as the carrier of copper ions, the copper ions are released slowly in the coating degrading process, and proliferation and differentiation of bone cells are promoted.

Owner:HUBEI UNIV

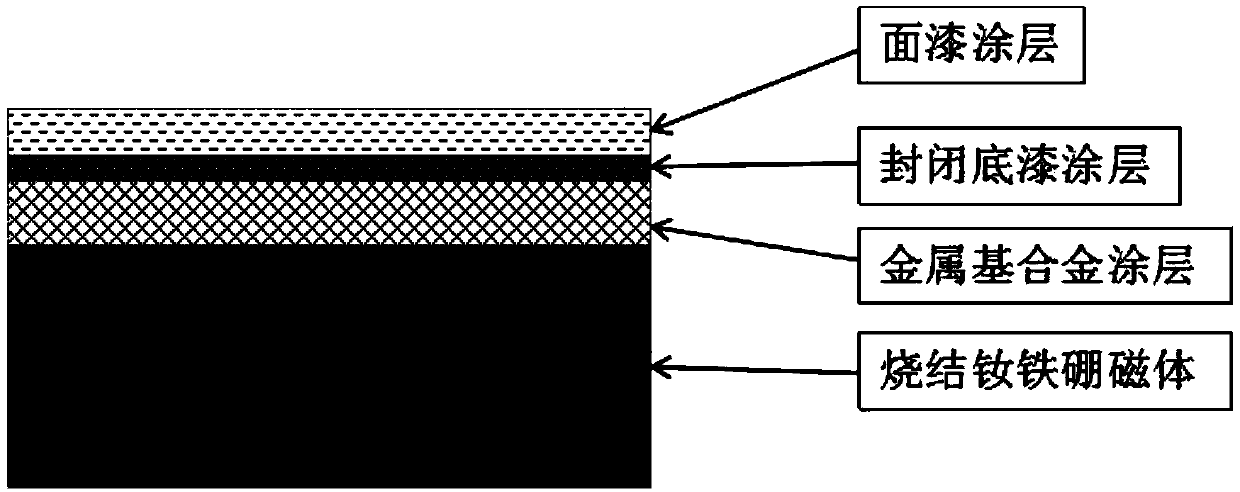

Preparation method of high corrosion resistant sintered NdFeB magnet

The invention discloses a preparation method of a high corrosion resistant sintered NdFeB magnet. The method is characterized by comprising the following steps of (1) metal-based alloy coating treatment: preparing a metal-based alloy coating on the surface of the sintered NdFeB magnet by adopting an arc spraying process; (2) closed primer coating treatment: coating the surface of the metal-based alloy coating with a silicone coating to form a closed primer coating; (3) topcoat coating treatment: coating the surface of the closed primer coating with a topcoat paint to form a topcoat coating prepared by nanometer particles and modified acrylic epoxy resin by mass, wherein the mass percentage of the nanoparticles is 5.25%, and the balance is the modified acrylic acid epoxy resin. The preparation method has high bonding strength and high corrosion resistance.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

Production method of high-gloss one-sided dual-color heat transfer anodized aluminum

InactiveCN102303440ARealize integrated productionExcellent adhesionSynthetic resin layered productsMetal layered productsFractionationEthyl acetate

The invention discloses a production method of high-gloss one-sided dual-color heat transfer anodized aluminum, which comprises the processes of release coating, color layer coating, heating and drying, accurate aluminizing and adhesive layer curing. In the processes, anatase metal powder enabling the gloss of the anodized aluminum to be increased is added in a color layer for spraying, and ethyl acetate is added in the anatase metal powder to be used as a developing agent of color chromatographic fractionation. By adopting an anodized aluminum production technology, printing and gold blocking effects are greatly improved, and especially, gloss of thermoprinted characters, patterns and lines is greatly increased.

Owner:江苏卫星新材料股份有限公司

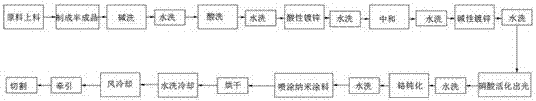

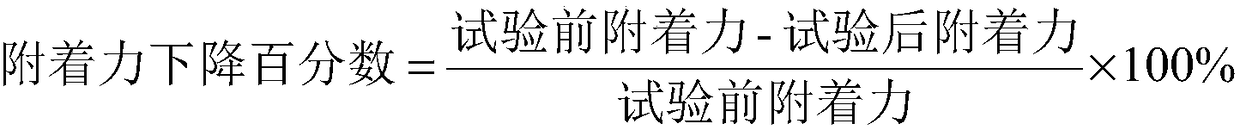

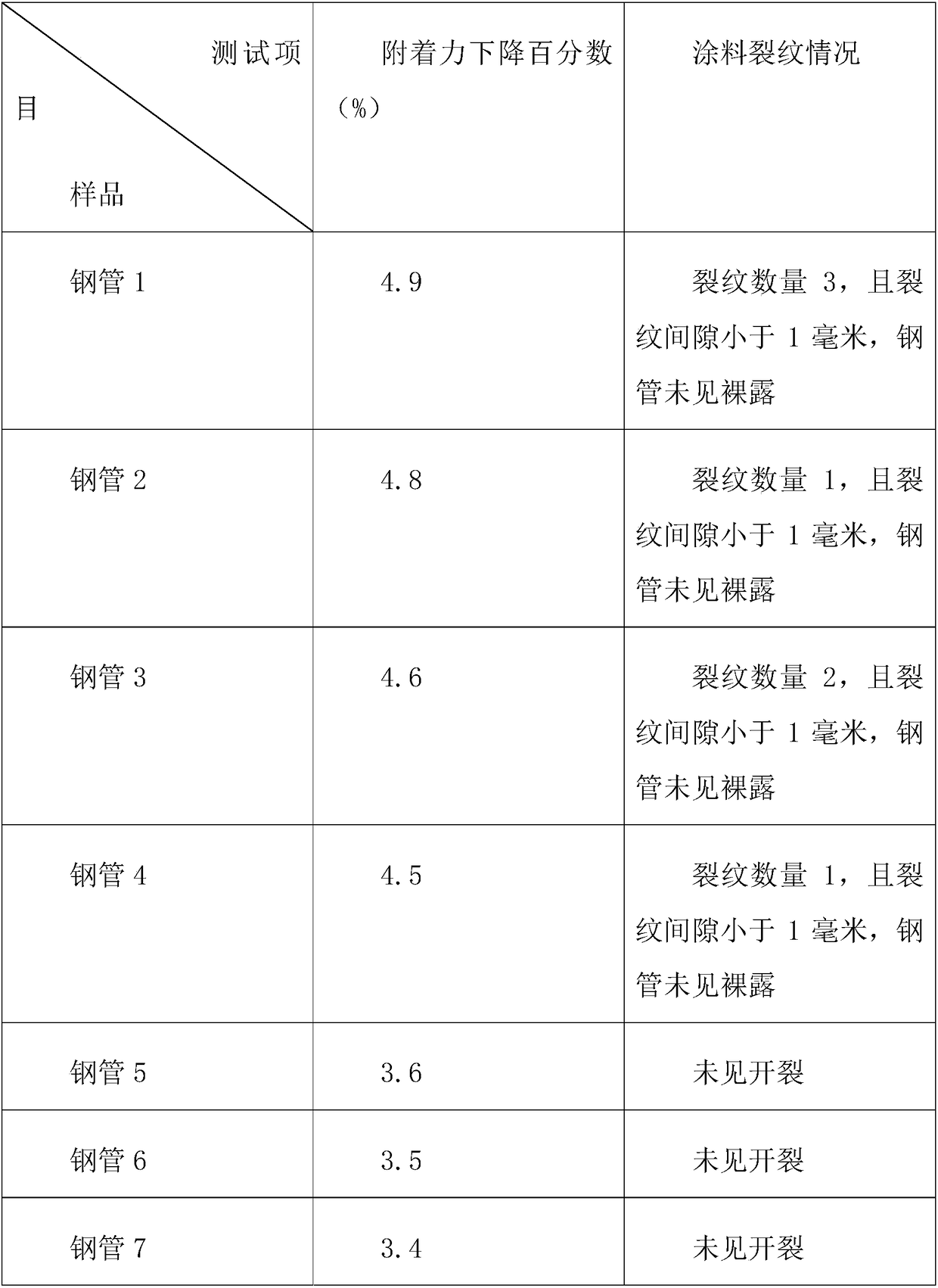

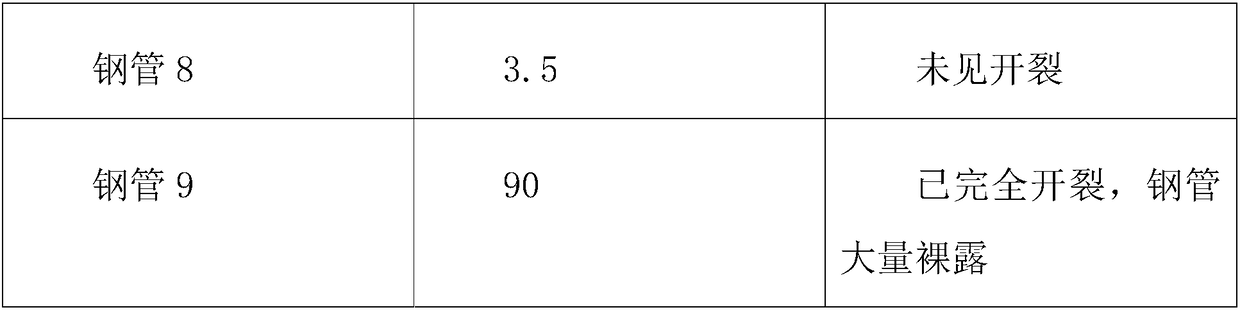

Production process for oil pipe used for automobile

InactiveCN106868506ALong-term corrosion resistanceImprove corrosion resistanceSuperimposed coating processCorrosion resistantWork in process

The invention discloses a production process of oil pipes for automobiles, which includes: (1) the step of making raw materials into semi-finished products; (2) the step of electrolytically galvanizing the semi-finished products; (3) the step of passivation treatment; (4) spraying nano Coating and post-processing steps. The invention can effectively maintain the anti-corrosion performance for a long time in harsh environment, has super high anti-corrosion performance, strong surface durability and higher quality.

Owner:江阴韩一钢铁有限公司

Antibacterial property treatment technology of wood

InactiveCN105538445ALong-acting antibacterialLong-term corrosion resistanceWood treatment detailsPressure impregnationEscherichia coliAspergillus niger

The invention discloses an antibacterial property treatment technology of wood. The technology comprises specific operation steps as follows: firstly, the wood is pretreated; then an antibacterial treating fluid is prepared: inoculation of strains and sterile water is performed in a sterile operation room, the strains comprise Aspergillus niger and Escherichia coli, the sterile water comprises water, tetraethyl titanate, chitin, diammonium phosphate and an isothiazolone derivative, the strains are required to be cultured for 3-5 days, and the required antibacterial treating fluid is prepared from the cultured strains and the sterile water through mixing; finally, the wood is placed in the sterile fluid for dipping treatment culture for 2-4 days and then taken out for light treatment, and the wood obtained after drying in the sun has the antibacterial property. The treatment technology has the advantages of simplicity, low energy consumption, environment-friendliness, safety, easiness in control and the like, and the treated wood has the lasting antibacterial property and corrosion resistance, has the higher moisture content and is applicable to occasions with high humidity and large temperature variations.

Owner:常熟市梅李镇赵市永宏红木家具厂

Wear-resistant anticorrosive coating, and preparation method and brushing method thereof

InactiveCN108165097ASimple and easy to prepareSimple methodFireproof paintsLiquid surface applicatorsFiberCarbon fibers

The invention provides a wear-resistant anticorrosive coating, and a preparation method and a brushing method thereof, and relates to the technical field of coatings. The wear-resistant anticorrosivecoating is mainly prepared from the following raw materials in parts by weight: 5 to 25 parts of carbon fiber, 5 to 25 parts of polyphenylene sulfide, 10 to 50 parts of an additive, 30 to 80 parts ofa first component, 50 to 100 parts of a second component and 20 to 50 parts of ceramic microspheres, wherein the additive comprises one or two selected from the group consisting of an inorganic additive and an organic additive; the first component comprises a curing agent and an aging-resistant auxiliary agent with a weight ratio of 1.5: (1-2); and the second component comprises a silane couplingagent, polyethylene glycol and epoxy resin with a weight ratio of 1: 2: (1.5-2.5). According to the invention, the stripe structure of the carbon fiber facilitates dispersing and absorbing the wear force to the coating, so the wear-resistant capacity of the coating is improved; the polyphenylene sulfide can be used as a protective layer of the carbon fiber, so bonding among carbon fibers is more stable; meanwhile, by utilization of the wear resistance of the polyphenylene sulfide, a protective layer to the carbon fiber can be constituted.

Owner:东方工建集团有限公司

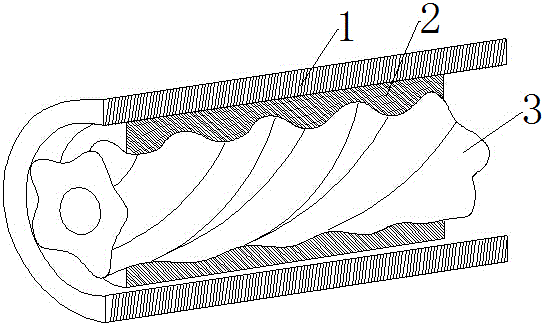

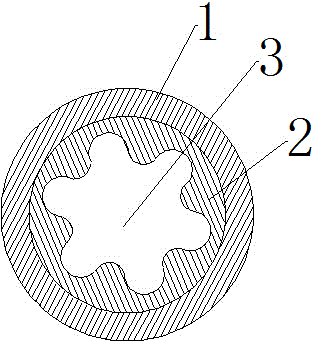

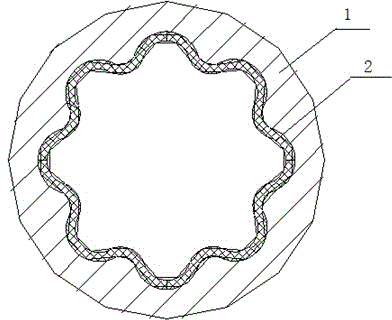

Screw drilling tool stator manufactured by using FEP and modified FEP applied to stator

ActiveCN104595182AImprove wear resistanceImprove flame retardant performanceRotary piston pumpsRotary piston liquid enginesMaterials sciencePolymer

The invention discloses a screw drilling tool stator manufactured by using FEP and modified FEP applied to the stator; the screw drilling tool stator mainly comprises a stator metal outer tube and a polymer layer from outside to inside successively, wherein the polymer layer is made of the FEP, and the modified FEP material is applied to the stator. The FEP is adopted for manufacturing the screw drilling tool stator, high-temperature resistance and abrasion resistance of the stator are greatly improved, the service life of a device is effectively extended, the adaptability to a harsh environment is good, the maintenance difficulty is low, the drilling operating efficiency is effectively improved, and the operating cost is significantly reduced.

Owner:ZHEJIANG GREEN NEW MATERIALS

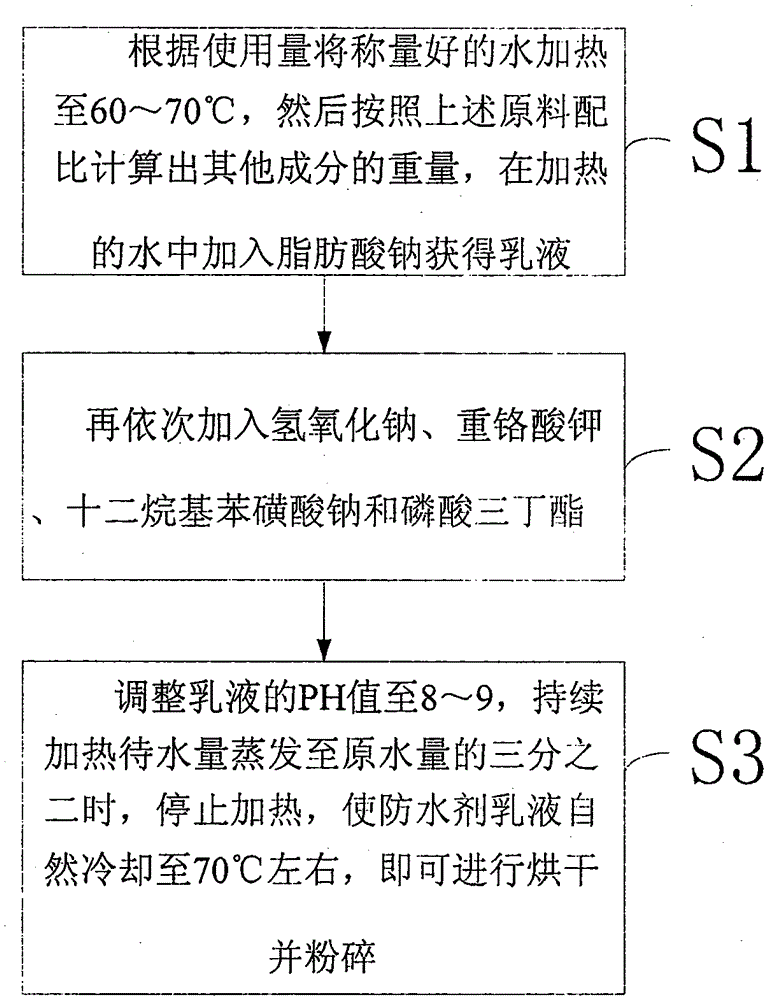

Preparation method of high-efficiency compound waterfroof agent for mortar and concrete

The invention discloses a preparation method of a high-efficiency compound waterfroof agent for mortar and concrete. The high-efficiency compound waterfroof agent comprises, by mass, 80-90 parts of sodium aliphatate, 0.3-0.4 parts of sodium hydroxide, 0.4-0.5 parts of potassium dichromate, 0.05-0.1 parts of sodium dodecyl benzene sulfonate, 0.3-0.5 parts of tributyl phosphate and the balance water. The preparation method comprises according to a use amount, heating weighed water to a temperature of 60-70 DEG C, calculating weights of other ingredients according to a raw material ratio, adding sodium aliphatate into the heated water to obtain an emulsion, orderly adding other raw materials into the emulsion, adjusting pH of the emulsion, and carrying out cooling, drying and crushing. Through use of the waterfroof agent in mortar or concrete, in cement hydration, the waterfroof agent, a cement hydration group, aggregates and uncompletely hydrated cement particles undergo complex chemical crosslinking reactions and physical riveting so that a building service life is prolonged and good waterproof effects are obtained.

Owner:HEBEI AOTELAI WATERPROOF MATERIAL CO LTD

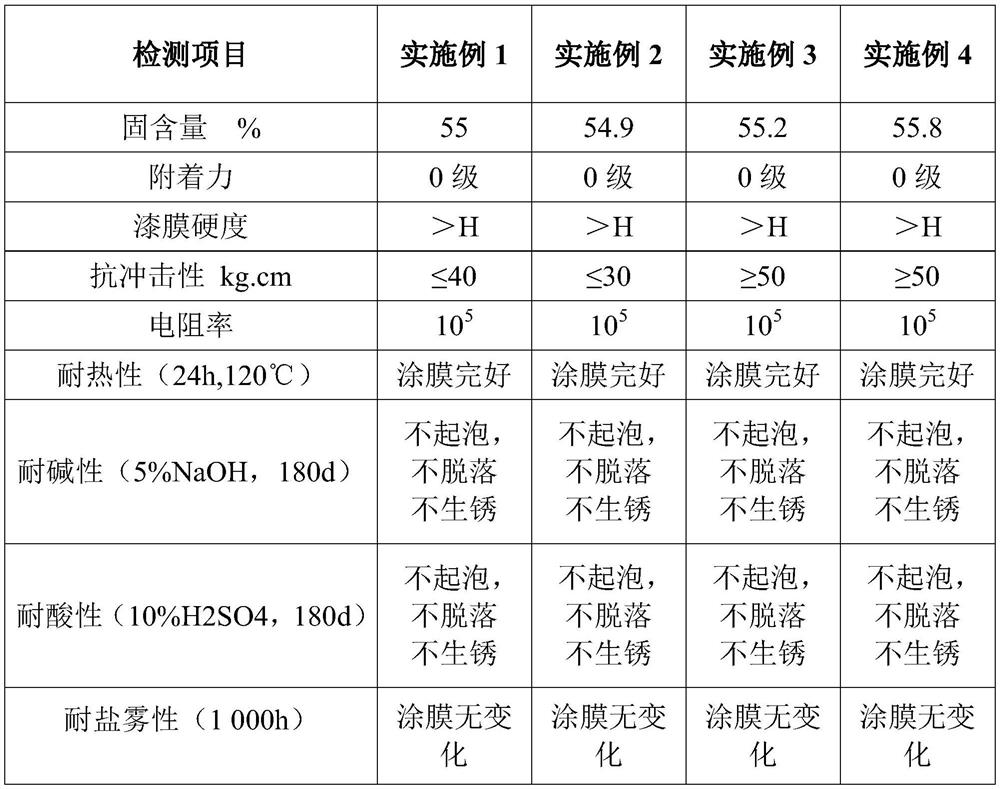

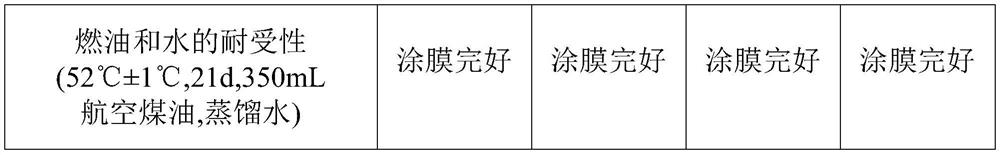

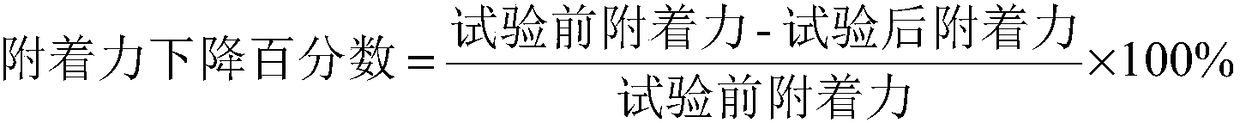

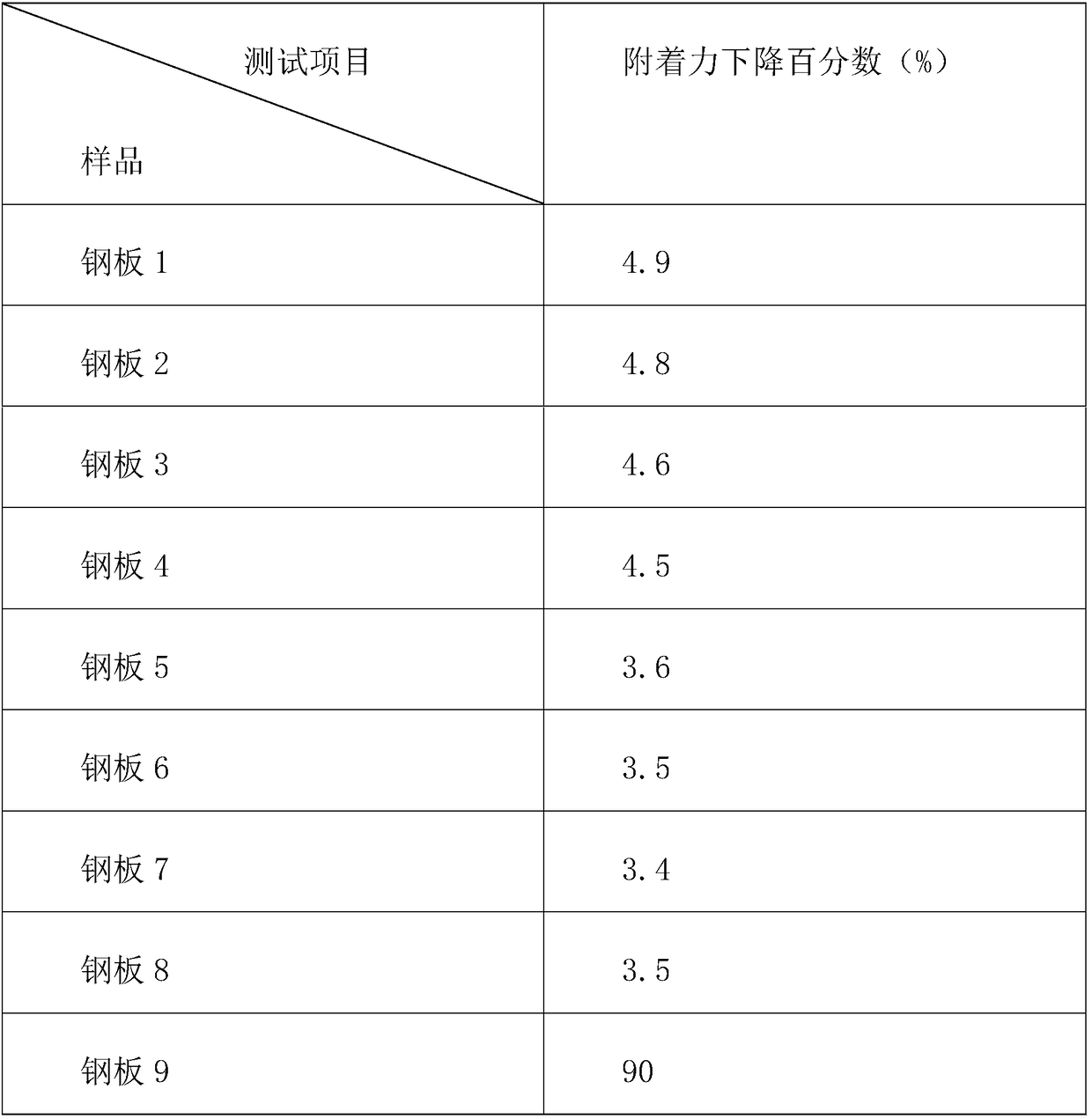

Preparation method for long-acting anticorrosive paint

InactiveCN108129956AGood chemical resistanceGood adhesionFireproof paintsAnti-corrosive paintsCross-linkFoaming agent

The invention discloses a preparation method for long-acting anticorrosive paint. The preparation method comprises the following steps: A, preparing a component A: putting bisphenol A epoxy resin, poly(epoxy chloropropane) polyepichlorohydrin epoxy resin and a reactive diluent into a mixer to mix at a uniform speed at a temperature of 42-62 DEG C, adding a dispersing agent, a de-foaming agent, antioxidant and a stabilizer to uniformly mix, performing high-speed dispersion, cooling to room temperature, grinding twice by a grinder while cooling the room temperature, detecting that the fineness to beis 20-50 [mu]m through a scraper fineness meter, and packaging after the fineness is detected to be qualifieddetecting is approved; and preparing a component B: adding glycidyl epoxy propyl alkylether amine, low molecular polyamide, trisphenol and benzyl alcohol into a vessel, heating to 28-45 DEG C to uniformly mix, cooling to the room temperature, and packaging after detecting to be qualifiedis approved. A cross-linked and cured paint film forms a cross-linking state which mutually penetrates a network, so that the product becomes an insoluble substance, shows very strong long-acting adhesion, long-acting chemical resistance, long-acting corrosion resistance and long-acting impact resistance, is non-toxic and harmless, and has fire resistance.

Owner:合肥威希特汽车配件加工有限公司

Anticorrosive inner coating film for inner layer of steel drum

InactiveCN113943517AAct as a physical shieldReduce corrosion rateAnti-corrosive paintsEpoxy resin coatingsActive agentFirming agent

The invention belongs to the technical field of anticorrosive coatings, and relates to an anticorrosive inner coating film for an inner layer of a steel drum. The anticorrosive inner coating film mainly comprises the following components in percentage by weight: 60-70% of modified epoxy resin emulsion; 1-5% of a coalescing agent; 3-15% of anticorrosive pigment and filler; 2-8% of a surfactant; 4-10% of a coupling agent; 10-15% of a curing agent; 0.1-2% of a defoaming agent; 0.1-2% of a leveling agent; 0.1%-0.6% of a corrosion inhibitor; and 10-50% of water. The modified epoxy resin emulsion is adopted, so that a formed coating plays a role in physically shielding various corrosive media; the corrosion inhibitor is added, so that the corrosion rate of steel is greatly reduced; and a pigment and filler are modified to form the anticorrosive pigment and filler, the dispersity of the pigment and filler in epoxy resin is improved, and a phase interface between the pigment and filler and the resin is eliminated, so that the shielding property and the corrosion resistance of a colored paint film are improved on the premise of ensuring high hardness and high adhesive force of the paint.

Owner:荆州市先隆包装制品有限公司

Method for preparing aluminum part surface zincing powder and method for coating aluminum part surface zincing powder

InactiveCN102002665BAvoid direct contactImprove corrosion resistanceSolid state diffusion coatingRoom temperatureZinc

The invention discloses a method for preparing aluminum part surface zincing powder and a method for coating the aluminum part surface zincing powder. The aluminum part surface zincing powder comprises the following components in percentage by weight: 14.9 to 84.5 percent of zinc powder, 84.9 to 14.5 percent of inert metal oxide powder, 0.1 to 0.5 percent of activating agent and 0.1 to 0.5 percent of auxiliary agent. The coating method of the aluminum part surface zincing powder comprises the following steps of: placing the aluminum part surface zincing powder prepared by the preparation method and an aluminum part to be zinced in the same sealed steel can; heating the steel can; controlling the temperature to 400 + / -10 DEG C; after keeping the temperature for 60 to 180 minutes, cooling to the room temperature; and zincing and coating the surface of the aluminum part. The corrosion resistance of an aluminum plate processed by the method is obviously improved, and particularly the marine atmospheric environment corrosion resistance is greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

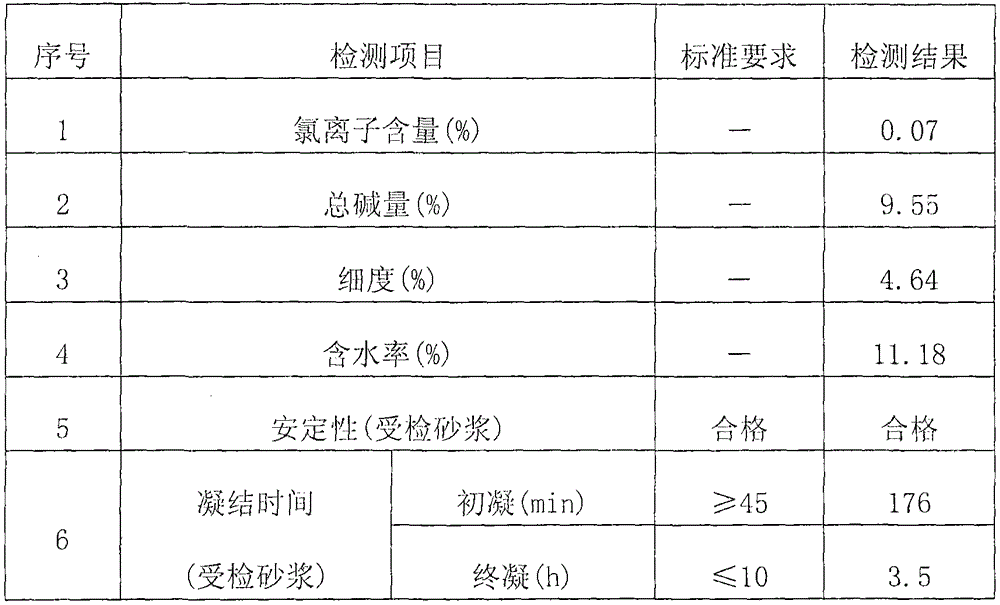

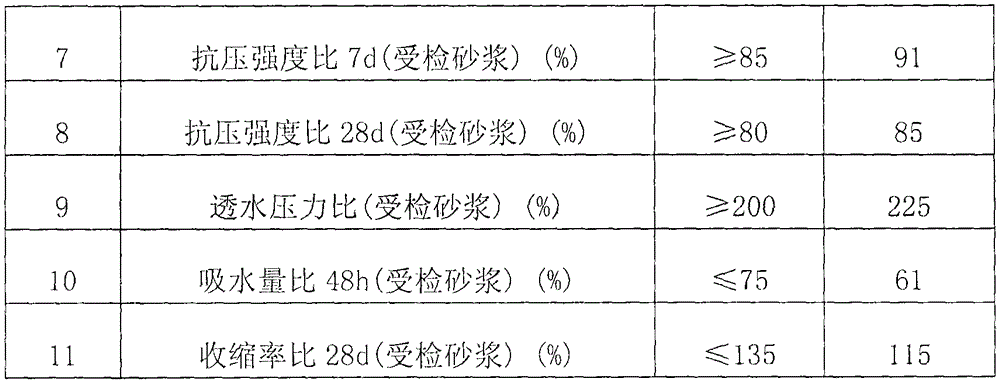

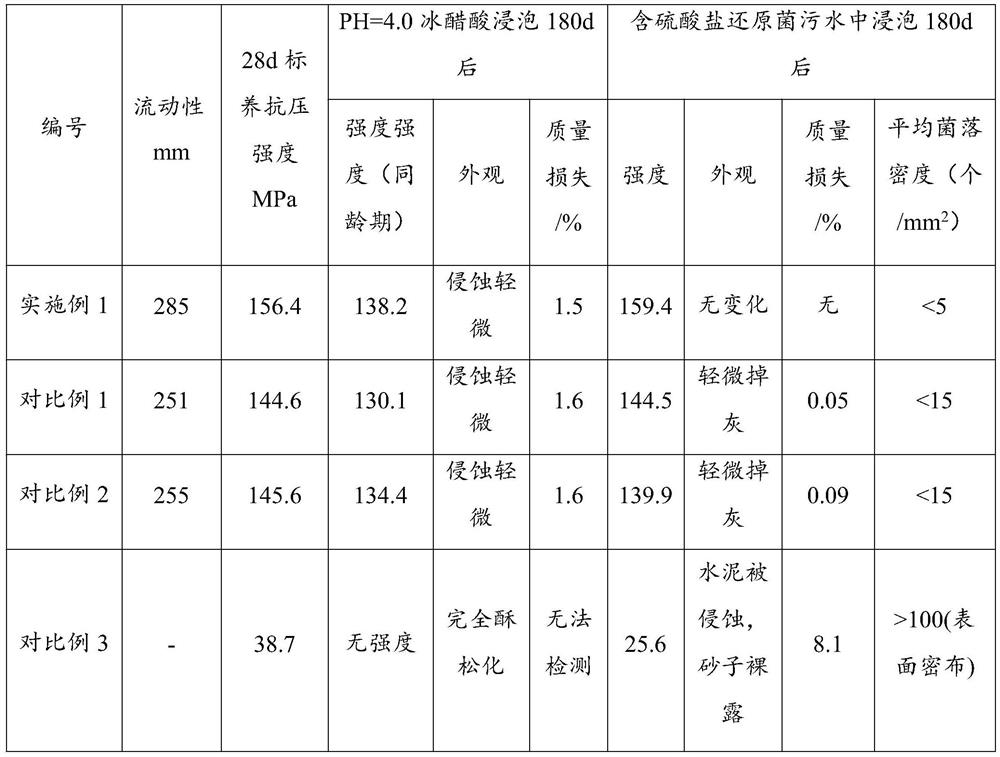

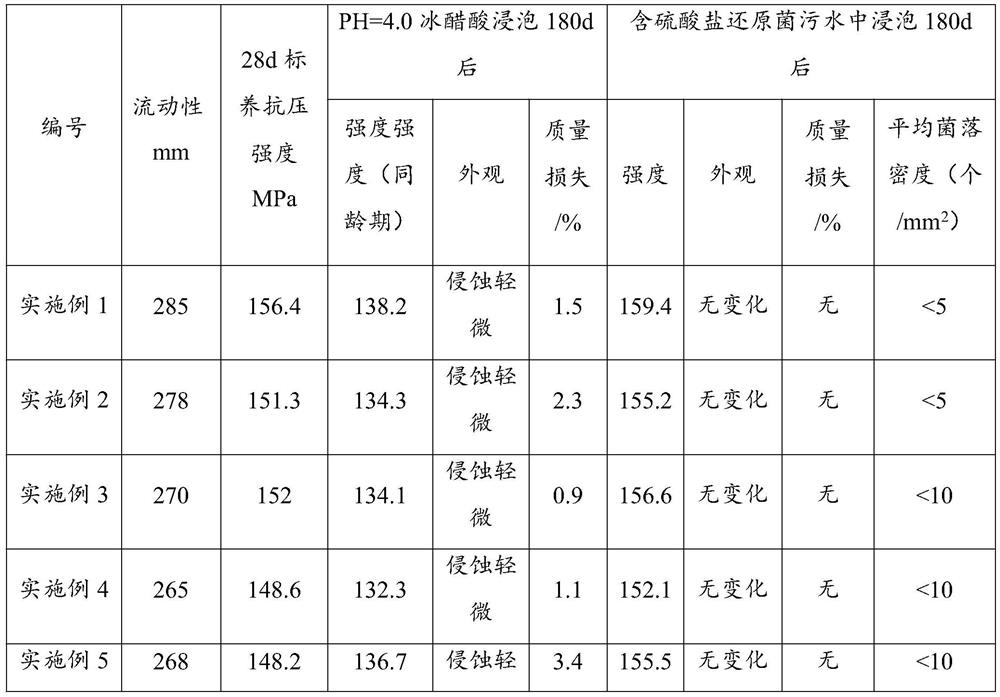

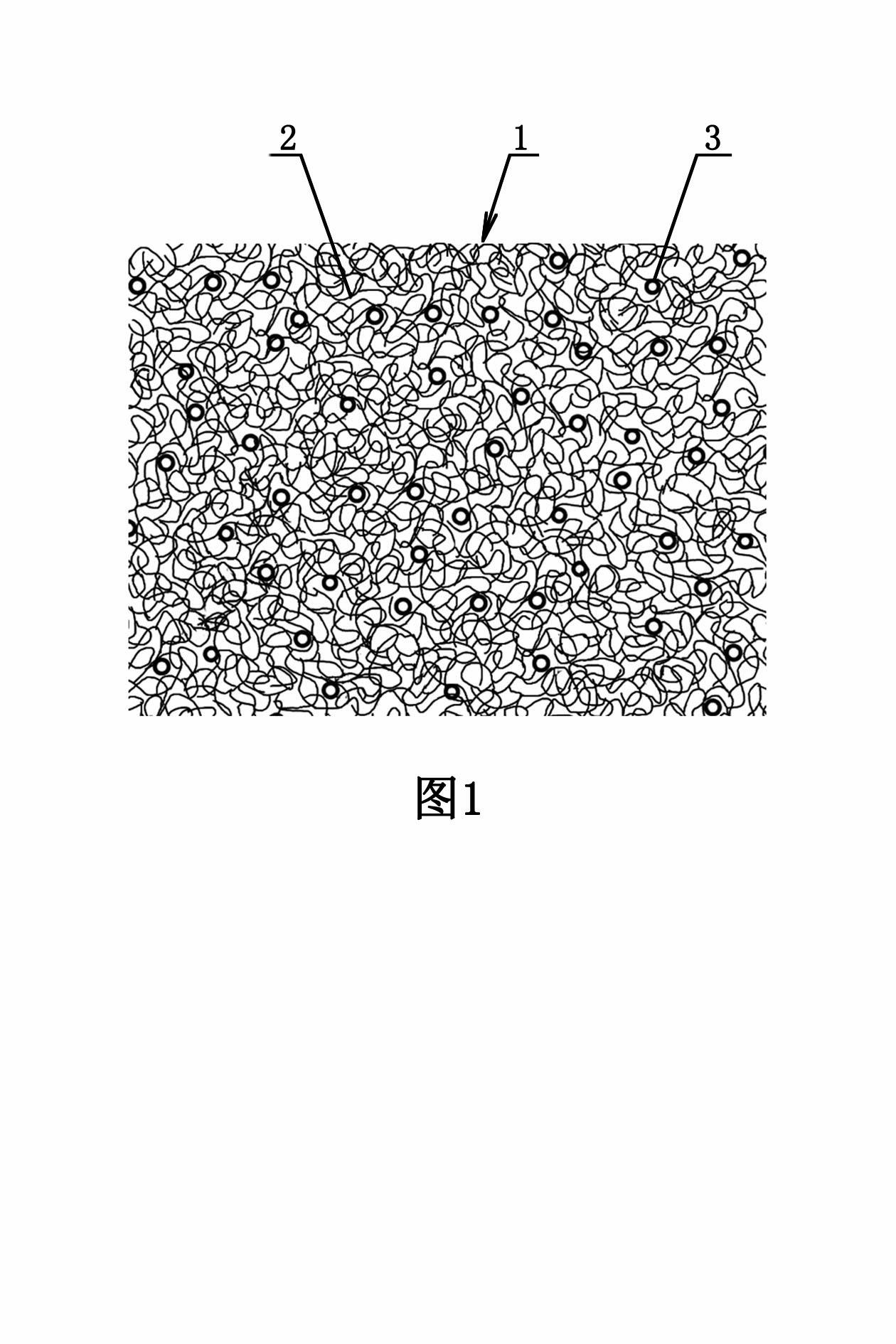

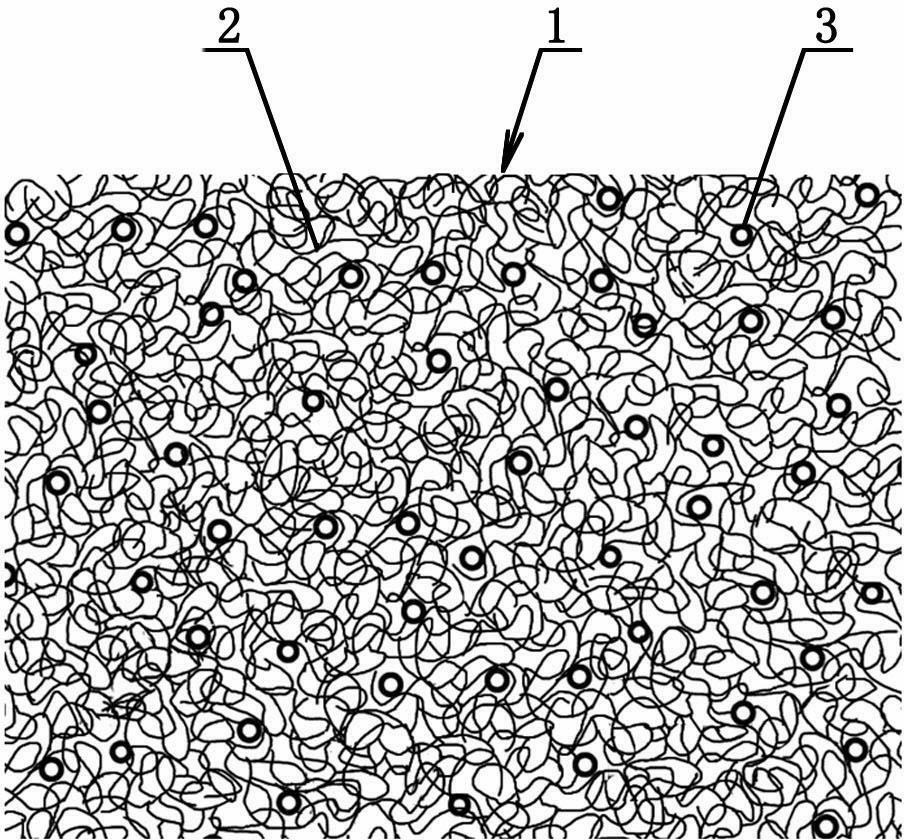

UHPC suitable for long-term sewage environment and preparation process thereof

PendingCN113896488AGood biocorrosionImproves strength and mobilityEnvironmental chemistrySilicate Cement

The invention provides UHPC suitable for a long-term sewage environment and a preparation process thereof. The UHPC comprises the following components: water, cement, fine aggregate, a mineral admixture, metal fibers, an additive and an antibacterial agent, wherein the antibacterial agent is beta-type phthalocyanine blue with a particle size of 0.005-0.015 [mu]m, and the cement is a mixture of ordinary Portland cement and calcium aluminate cement. According to the invention, the antibacterial agent phthalocyanine blue matched with UHPC is creatively introduced, and the high performance of the UHPC is combined, so that the material has good biological corrosion resistance, and the flowability and the strength of the material are improved; part of calcium aluminate cement is used for replacing ordinary Portland cement, so that the UHPC has a relatively low biological erosion rate, and the erosion-resistant period of the UHPC is further prolonged; and the UHPC is more suitable for serving under the working condition of sewage and waste treatment, the corrosion resistance of components can be greatly improved, the service life of the structure is prolonged, the later maintenance cost is reduced, and the UHPC has wide market prospects.

Owner:CHINA CONSTR THIRD BUREAU GREEN IND INVESTMENT CO LTD

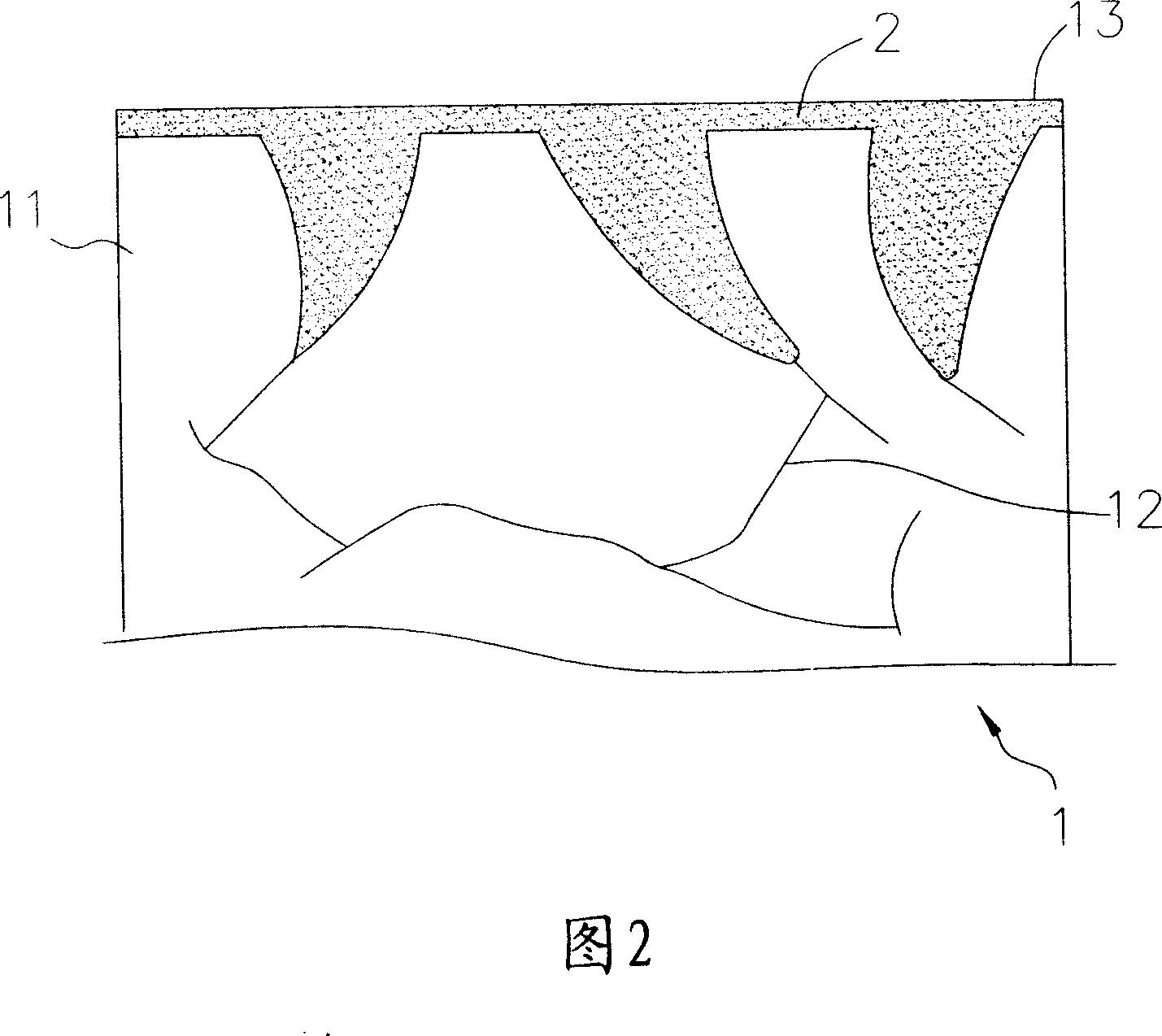

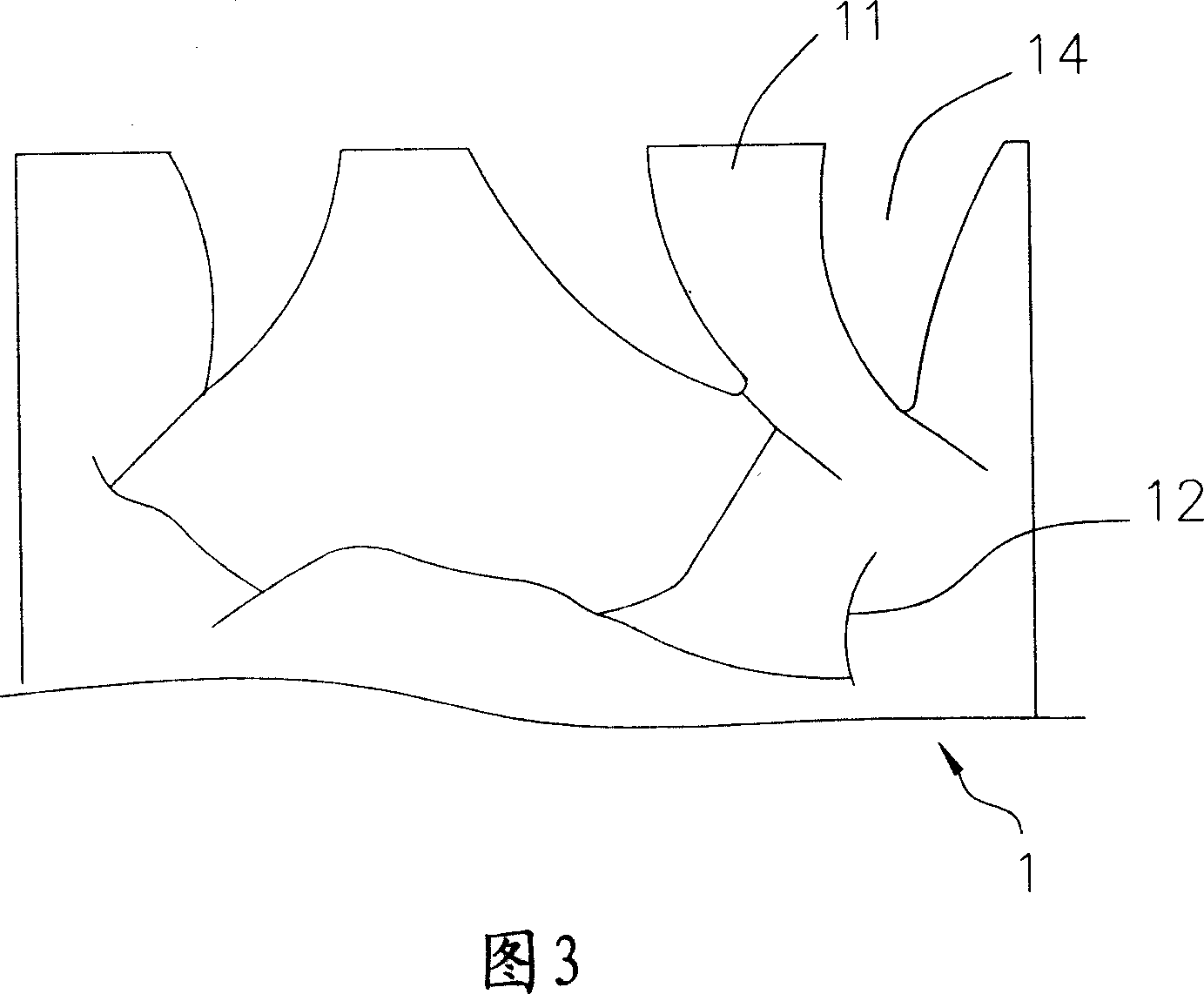

Acrylic resin culture medium for plant planting and preparation method thereof

InactiveCN102283091AGood light fastnessImprove outdoor aging performanceCultivating equipmentsSoilless cultivationMethacrylateAcrylic resin

The invention provides an acrylic resin culture medium for planting plants and a preparation method thereof. The glue cushion comprises a basic layer cushion body, wherein the basic layer cushion body is a wire flocculent structure formed by winding after hot melting and wire drawing are carried out on acrylic resin, the basic layer cushion body is internally distributed with water absorbent resin particles, and the water absorbent resin particles are fixed on acrylic resin wires. The acrylic resin is copolymerized by acrylate and methacrylate monomers. The water absorbent resin particles arestarch grafted acrylate copolymerization crosslinking particles, acrylamide-acrylate copolymerization crosslinking particles or mixture of the two particles. The acrylic resin culture medium for planting the plants provided by the invention has the advantages of simple structure, convenience in mounting and easiness in transportation, the adopted materials can be repeatedly used, and waste is reduced. When the acrylic resin culture medium for planting the plants is applied to three-dimensional greening, more irrigation water can be stored, transpiration loss of moisture and nutrient substances can be reduced, irrigation frequency can be reduced, soil erosion caused by soil plantation can be avoided, and pollution to ambient environment can be reduced.

Owner:重庆天开园林股份有限公司

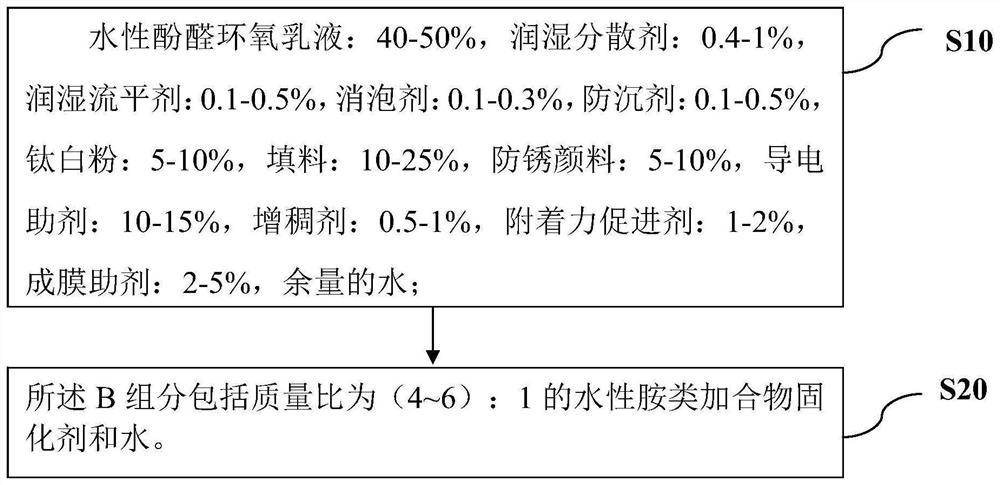

Water-based phenolic epoxy coating material and preparation method thereof

PendingCN113980550AGood chemical resistanceLow VOC contentAnti-corrosive paintsEpoxy resin coatingsDefoaming AgentsPetrochemical

The invention belongs to the technical field of coating materials, and particularly relates to a water-based phenolic epoxy coating material and a preparation method thereof. The water-based phenolic epoxy coating material comprises a component A and a component B, wherein the component A comprises the following components in percentage by mass: 40-50% of water-based phenolic epoxy emulsion, 0.4-1% of a wetting dispersant, 0.1-0.5% of a wetting leveling agent, 0.1-0.3% of a defoaming agent, 0.1-0.5% of an anti-settling agent, 5-10% of titanium dioxide, 10-25% of a filler, 5-10% of an anti-rust pigment, 10-15% of a conductive aid, 0.5-1% of a thickening agent, 1-2% of an adhesion promoter, 2-5% of a film forming aid, and the balance of water, and the component B comprises a water-based amine adduct curing agent and water in a mass ratio of (4-6): 1. The water-based phenolic epoxy coating material disclosed by the invention has chemical resistance and heat resistance, is low in VOC content and good in chemical stability, and has wide application prospects in the fields of petrochemical pipelines, storage tanks and the like.

Owner:珠海展辰新材料股份有限公司

Anticorrosive coating, and preparation method and brushing method thereof

InactiveCN108165129ASimple and easy to prepareSimple methodAnti-corrosive paintsPolyether coatingsEpoxyMicrosphere

The invention provides an anticorrosive coating, and a preparation method and a brushing method thereof, and relates to the technical field of coatings. The anticorrosive coating is mainly prepared from the following raw materials in parts by weight: 10 to 50 parts of an additive, 30 to 80 parts of a first component, 50 to 100 parts of a second component and 20 to 50 parts of ceramic microspheres,wherein the additive comprises one or two selected from the group consisting of an inorganic additive and an organic additive; the organic additive is one or two selected from the group consisting ofan ethylene-methacrylic acid copolymer and an ethylene-acrylic acid copolymer; the inorganic additive is one or more selected from the group consisting of TiO2, silicon-based oxides and A12O3; the first component comprises a curing agent and an aging-resistant auxiliary agent with a weight ratio of 1.5: (1-2); and the second component comprises a silane coupling agent, polyethylene glycol and epoxy resin with a weight ratio of 1: 2: (1.5-2.5). According to the invention, the epoxy resin is uniformly coated by a mesh structure, so the time of complete covering of a substrate with the coating is greatly prolonged, and the coating has more durable anticorrosive capacity.

Owner:东方工建集团有限公司

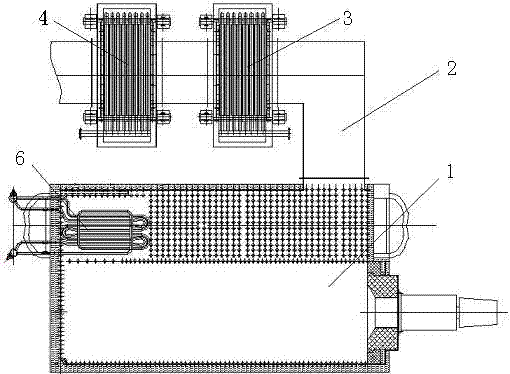

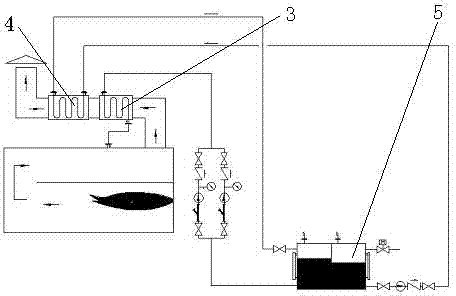

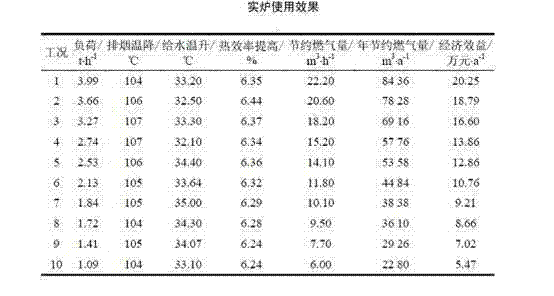

Water tube type condensation superheated steam boiler

The invention relates to a water tube type condensation superheated steam boiler, and belongs to the field of heating device. The water tube type condensation superheated steam boiler comprises a boiler body, a flue and a superheater. The flue is internally provided with two stages of heat exchanging devices, namely, an energy saver and a condenser. According to the water tube type condensation superheated steam boiler provided by the invention, two stages of heat exchange of the energy saver and the condenser which are arranged in the flue is adopted so that the discharge smoke heat can be adequately utilized, the consumption of fuel is reduced, and the total emission is reduced. The energy saver and the condenser provided by the invention are made of corrosion resisting materials so that the water tube type condensation superheated steam boiler can resist corrosion of flue gas for a long time.

Owner:ANYANG FANGKUAI BOILER

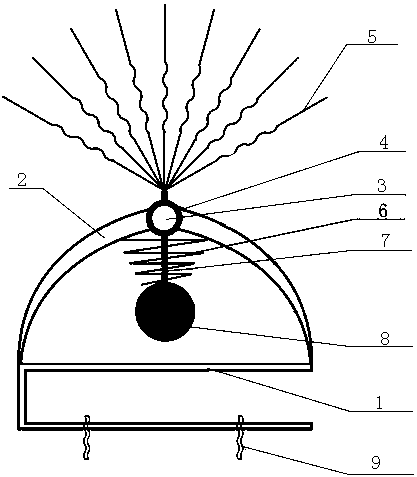

Pneumatic anti-bird thorn

ActiveCN105248408BImprove performanceSolve operational safety issuesAnimal repellantsWind drivenBird droppings

The invention discloses a wind-driven anti-bird thorn, comprising a fixed base, the fixed base is provided with a shield, the top of the shield is provided with a fixed shaft, and the fixed shaft is provided with a sliding ball seat for rotation, A plurality of needles are arranged above the sliding ball seat, and the needles are located above the shield to form an inverted umbrella structure, and a dynamic main shaft is located in the shield below the sliding ball seat, and the lower end of the dynamic main shaft is connected with The swing weight is provided with a stress spring between the shield and the swing weight, and the stress spring is sleeved on the dynamic main shaft. When a bird touches the anti-bird thorn, it will shake by itself when it is stressed, so that the bird cannot stay on the insulator, making it impossible to defecate and build a nest on the tower pole, which greatly improves the performance of the anti-bird thorn and has high reliability. , The installation is simple and easy to maintain, and it solves the safety problems of transmission lines mainly caused by guano flashover and bird's nest short-circuit faults.

Owner:胜利油田邦源电气有限责任公司

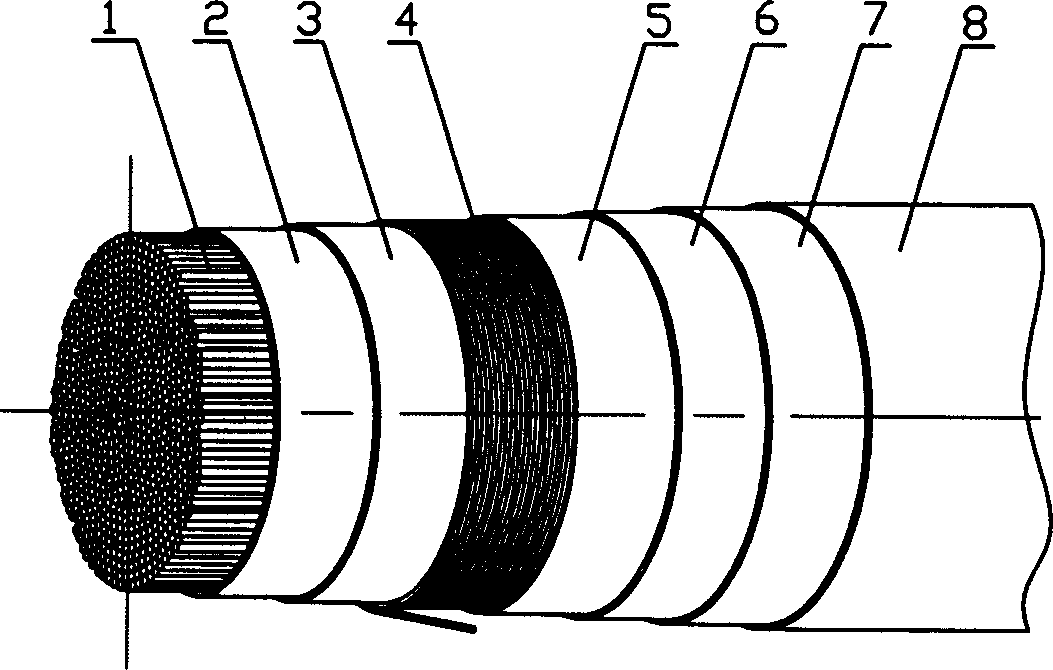

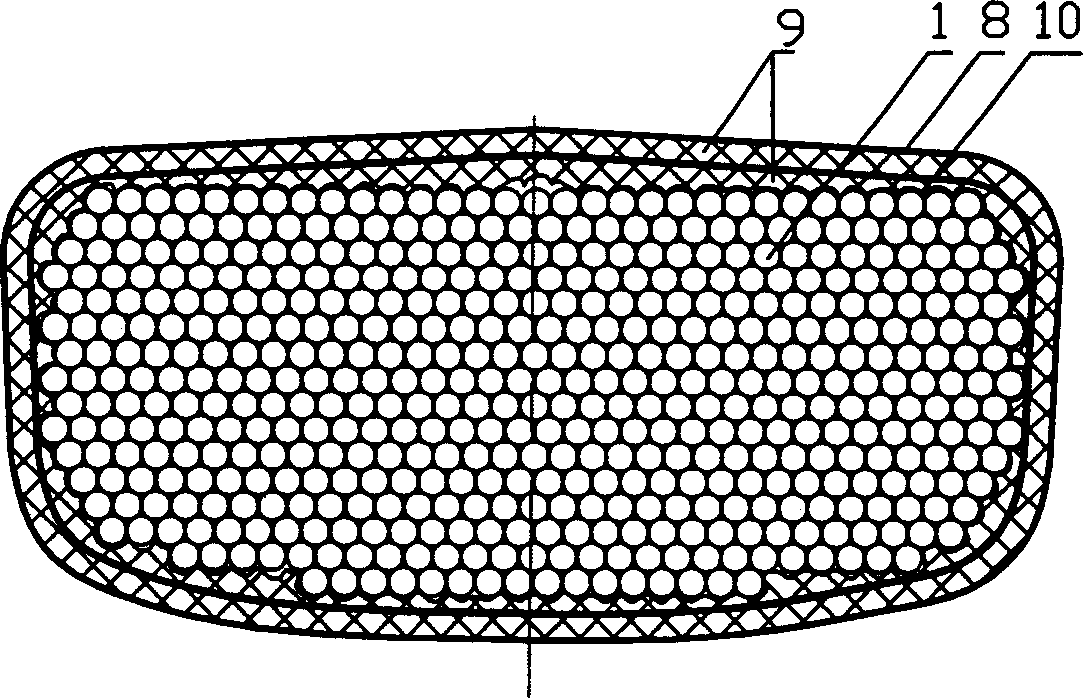

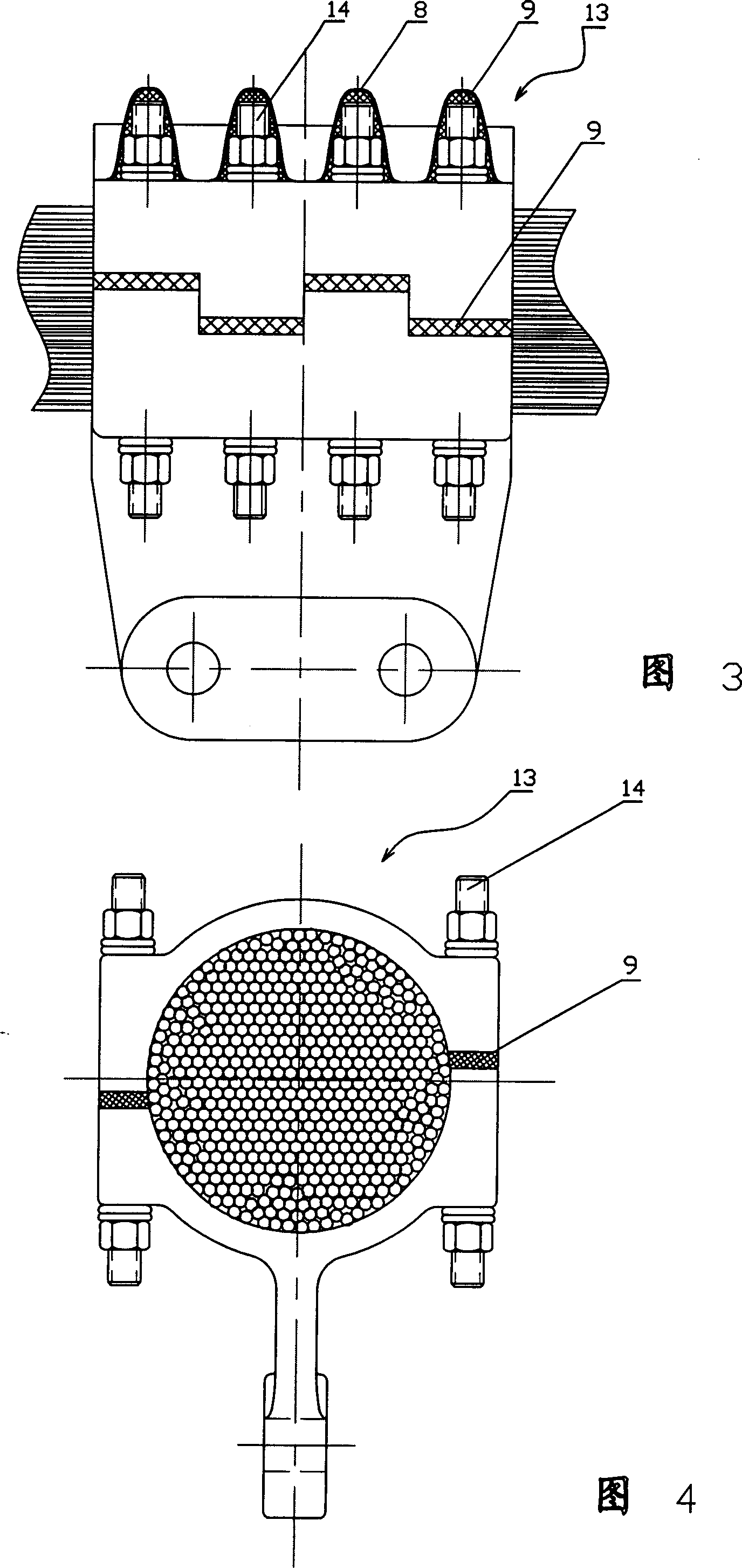

Method and structure for protecting primary cable system of suspension bridge

InactiveCN1110606CEffective protectionGood sealing and anti-corrosion performanceBridge structural detailsSuperimposed coating processStrip steelHigh intensity

A protecting structure for the main cable of suspension bridge is composed of main cable made up of multistrand high-strength zinc-plated steel wire bundles, multiple cable clampers fixed to the main cable and multiple suspension cables fixed to the cable clampers. After the external surface of main cable is anticorrosively treated, a layer of steel wire or strip steel is wound arount it and the external surface of wound layer is treated for protection. Said anticorrosion treatment of main cable is to coat unsulfurized non-drying sealing rubber paste on it. Said protective layer of main cable has same service life as the primary cable.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

A kind of low voc all solid cavity anticorrosion wax composition

ActiveCN106867321BImprove water resistanceImprove anti-corrosion performanceWax coatingsAnti-corrosive paintsOil and greaseVehicle frame

The invention relates to a low-VOC (volatile organic compound) full-solid-ingredient cavity anti-corrosion wax composition, which is prepared from the following ingredients in percentage by mass: 5 to 20 percent of wax materials, 5 to 20 percent of plant grease, 1 to 10 percent of oil-soluble anti-rust additives, 5 to 10 percent of anti-rust pigments, 1 to 5 percent of drying control agents, 0.1 to 1 percent of driers, 0.1 to 1 percent of silane coupling agents and 40 to 70 percent of basic oil. The anti-corrosion wax composition provided by the invention does not contain solvent ingredients; the ingredients are all solid ingredients; the low-VOC and environment-friendly effects are achieved; the flash point is high; the operation is safe; the low-VOC full-solid-ingredient cavity anti-corrosion wax composition can be used as anti-corrosion wax to be applied to coating of underpans, vehicle frames, hinges, vehicle door insides, window beam insides or other steel plate structures and components in automobile industry.

Owner:SHENYANG PARKERIZING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com