Waterborne epoxy asphalt coating and preparation method thereof

A water-based epoxy asphalt and coating technology, which is applied in asphalt coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve environmental pollution and other problems, and achieve excellent mechanical properties, excellent construction viscosity and anti-sag performance, and high hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

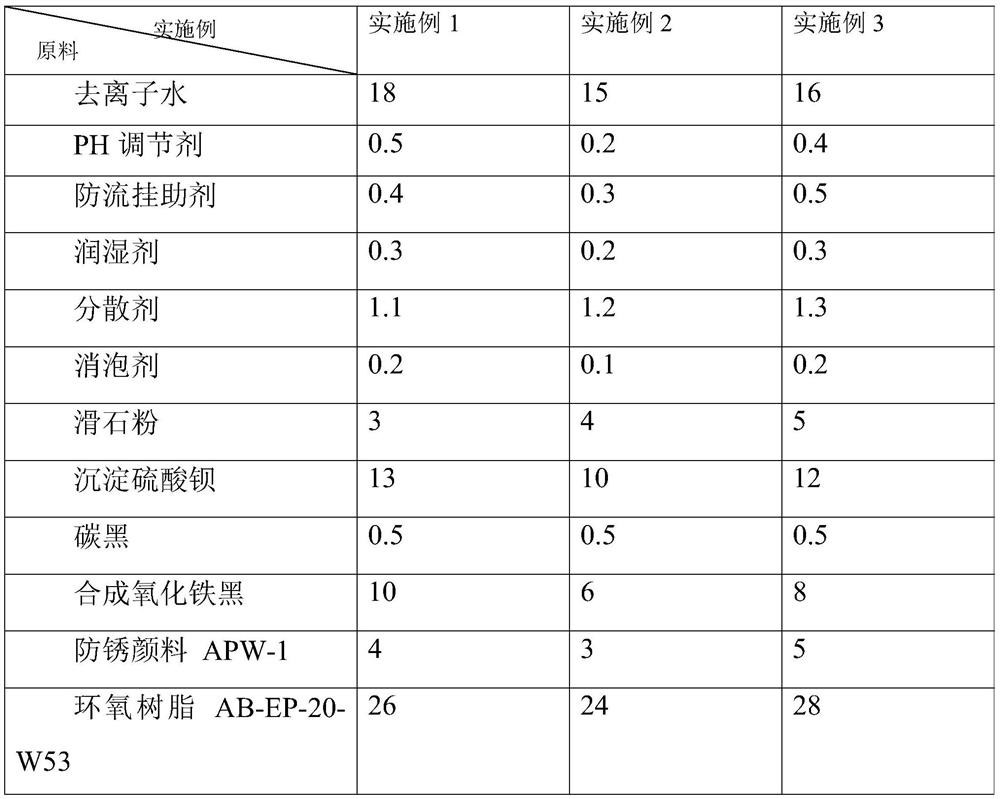

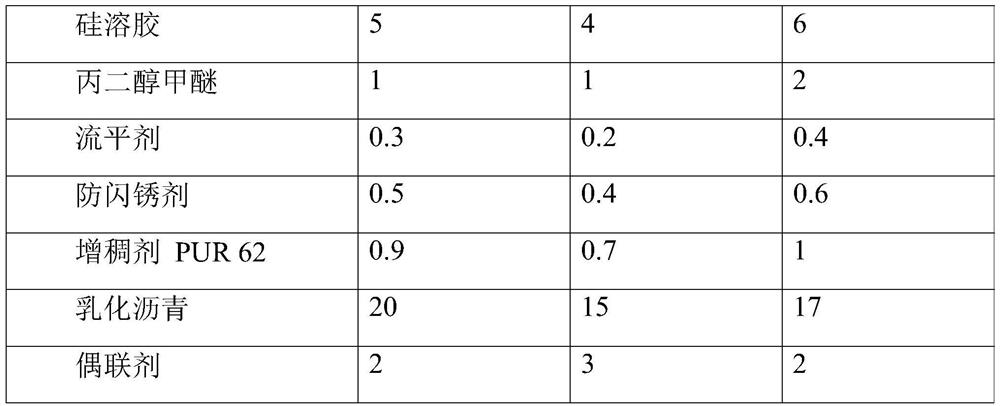

[0026] Waterborne epoxy asphalt paint component A raw material weight composition is shown in the following table:

[0027]

[0028]

[0029] The anti-sag additive is The wetting agent is GS 850, the dispersant is Clariant quaternary ammonium salt dispersant XW330, the defoamer is TEGO AIRES 901W, the leveling agent is TEGO TWIN4100, and the anti-flash rust agent is Raybo 60, the coupling agent is γ-glycidyl etheroxypropyltrimethoxysilane.

[0030] Component B of the waterborne epoxy asphalt coating is aliphatic amine-modified polyamide polymer (ARADER3986) from Huntsman Company of the United States.

[0031] Mix component A and component B fatty amine-modified polyamide polymer (ARADUR 3986) at a mass ratio of 12:1 and mix evenly.

[0032] Above-mentioned water-based epoxy asphalt coating adopts following method to prepare:

[0033] Add deionized water, PH regulator, anti-sag additive, wetting agent, dispersant, and defoamer into the mixing tank in sequence accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com