Water tube type condensation superheated steam boiler

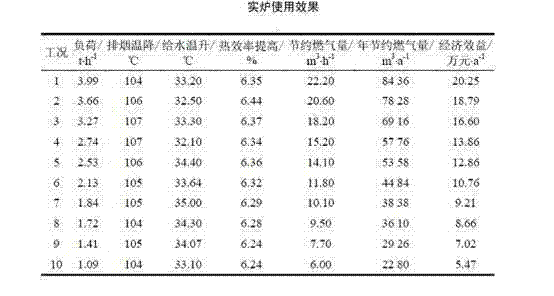

A superheated steam and water tube technology, applied in steam boilers, steam generation, lighting and heating equipment, etc., can solve the problems of untimely and convenient use of waste heat, decrease of overall boiler efficiency, and increase of boiler operating costs, so as to reduce emissions and improve Economic and environmental benefits, thermal efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to fully explain the implementation of the present invention, a specific embodiment of the present invention is provided. This embodiment is only an illustration and explanation of the present invention, and does not limit the scope of the present invention.

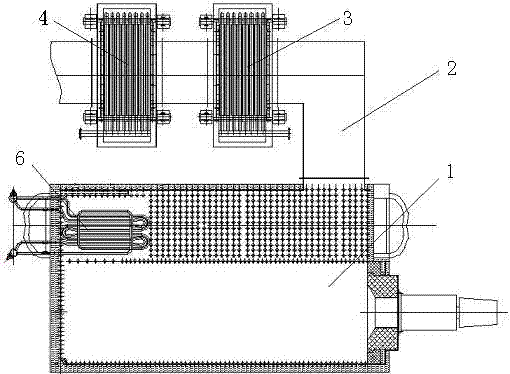

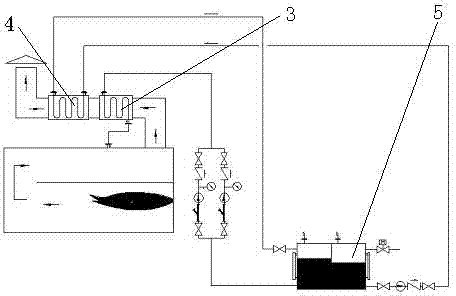

[0009] as attached figure 1 As shown, the boiler can be a superheated steam boiler with double-drum vertical arrangement, full-membrane water-cooled wall, D-shaped furnace natural circulation, and slight positive pressure combustion. The burner is arranged on the front wall. 90° into the convection tube bank, the high temperature part of the convection tube bank is equipped with a horizontal superheater 6, and then the low-temperature convection tube bank flue gas flows from the convection tube bank through the flue into the economizer 3 and the condenser 4, and then enters the chimney for discharge. Explosion-proof door, economizer 3 is composed of finned tubes, which are processed by high-frequency weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com