Epoxy resin composition

A technology of epoxy resin and composition, which is applied in the direction of epoxy resin coating, coating, anti-corrosion coating, etc., can solve the problems such as inability to construct, and achieve the effect of excellent natural environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

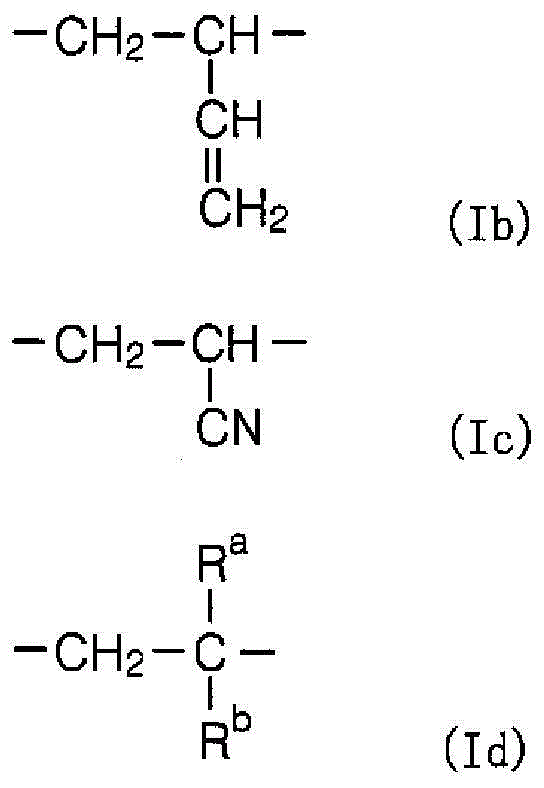

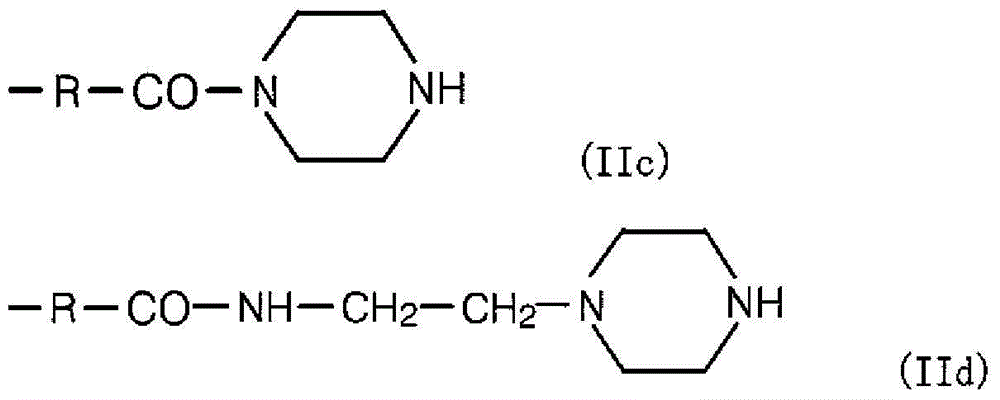

Method used

Image

Examples

preparation example Construction

[0116]

[0117] The epoxy resin composition of the present invention can be prepared by mixing the above components.

[0118] The epoxy resin composition of the present invention is suitably used as a two-liquid mixing type epoxy resin composition. A preferred embodiment is a form in which a main ingredient containing components (a) and (b) and a curing agent containing components (c) and (d) are mixed before use. In the case of using the epoxy resin composition of the present invention as a two-component mixed epoxy resin composition, it can be heat-cured by appropriately selecting a curing agent, or it can be left at ambient temperature without heating. curing method.

[0119] Furthermore, the liquid epoxy resin composition of the present invention may be used as a one-component epoxy resin composition by further blending a thermally active curing agent with components (a) and (b). In this case, it is mainly used in the method of heat curing.

[0120] When the epoxy res...

Embodiment 1~5、7

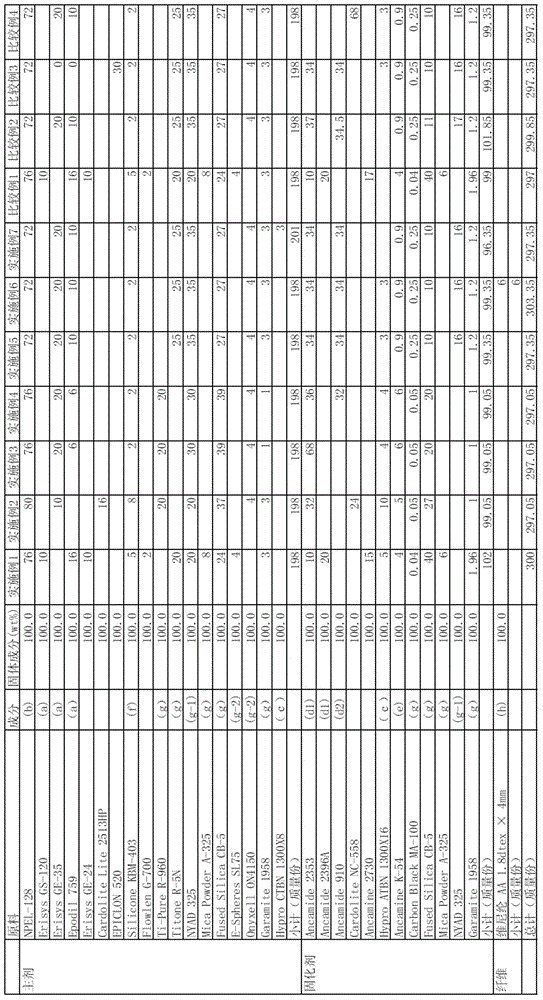

[0130] [Examples 1-5, 7, Comparative Examples 1-4]

[0131] (preparation of main ingredient)

[0132] The main ingredients used in Examples and Comparative Examples were prepared by mixing the raw materials shown in "Main ingredient" in Table 1 at the blending ratio (mass ratio) shown in Table 1, and stirring with a high-speed disperser.

[0133] (preparation of curing agent)

[0134] The respective raw materials shown in "curing agent" in Table 1 were mixed according to the blending ratio (mass ratio) shown in Table 1, and stirred with a high-speed disperser to prepare curing agents used in Examples and Comparative Examples.

[0135] (Preparation of epoxy resin composition)

[0136] Just before being tested in the test, the main agent prepared by the above method and the curing agent were mixed according to the mixing ratio (mass ratio) expressed in the subtotal amount in Table 1 using a disperser to prepare the epoxy resin composition. This epoxy resin composition was use...

Embodiment 6

[0139] In the same manner as above, each raw material shown in Table 1 was mixed at the blending ratio (mass ratio) shown in Table 1, and stirred with a high-speed disperser to prepare a main ingredient and a curing agent. Use a disperser to mix the main agent and curing agent according to the mixing ratio (mass ratio) expressed in the subtotal amount in Table 1, and then use an electric mixer to mix the fibers (h) shown in Table 1 in the subtotal amount Shown mixing ratio (mass ratio) was mixed to prepare an epoxy resin composition. This epoxy resin composition was used for the following test.

[0140] The test results are shown in Table 2.

[0141] Table 3 summarizes the raw materials used in Examples and Comparative Examples.

[0142]

[0143] After the concrete paving slab (base material) of 300 mm x 300 mm x 60 mm specified in JIS A5371 was completely immersed in water at 23° C. for 24 hours, it was taken out of the water. Thereafter, the above-mentioned epoxy resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com