Preparation method of high corrosion resistant sintered NdFeB magnet

A technology with high corrosion resistance and magnets, which is applied in the manufacture of permanent magnets, inductors/transformers/magnets, coatings, etc., can solve the problems of high bonding force and high corrosion resistance on the surface of sintered NdFeB magnets, and improve the bonding force of the film base , long-term corrosion resistance, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A method for preparing a glass coating on the surface of a neodymium iron boron magnet, including the following steps:

[0031] The sintered NdFeB magnets with length, width, and height specifications of 20mm×10mm×3mm were mechanically polished, and then the polished sintered NdFeB magnet was cleaned with acetone solution to make the cleanliness of the sintered NdFeB magnet reach Sa4 level.

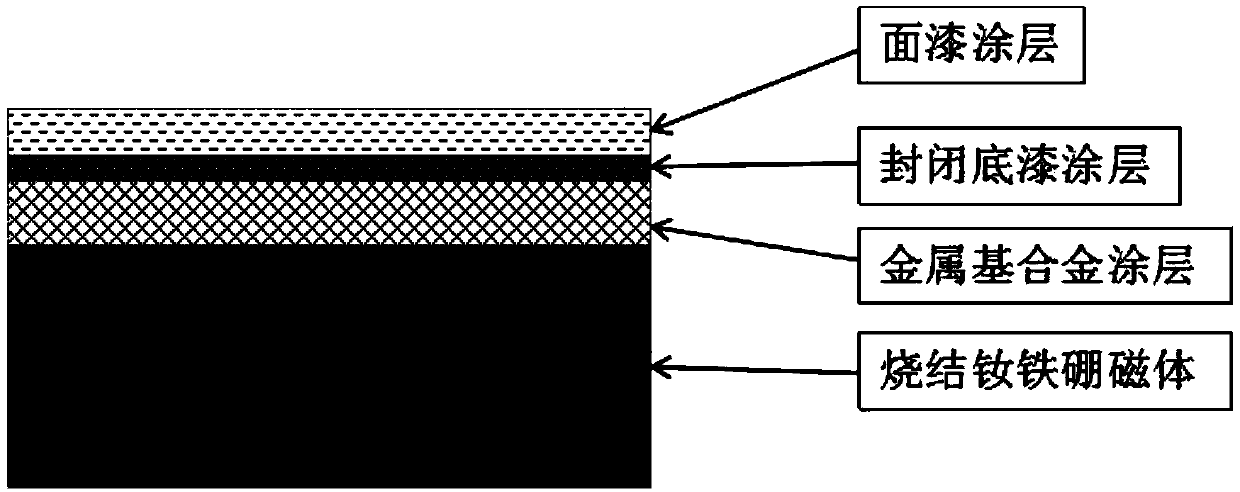

[0032] (1) Metal-based alloy coating treatment: the metal-based alloy coating is prepared on the surface of the sintered NdFeB magnet by arc spraying;

[0033] (2) Sealing primer coating treatment: coating siloxane paint on the surface of the metal-based alloy coating to form a closed primer coating;

[0034] (3) Topcoat coating treatment: apply topcoat paint on the surface of the closed primer coating to form a topcoat coating. The topcoat paint is prepared by the mass percentage of nanoparticles and modified acrylic epoxy resin. Nanoparticles The mass percentage of 5% is 5%...

Embodiment 2

[0042] Embodiment 2: A method for preparing a glass coating on the surface of a neodymium iron boron magnet, including the following steps:

[0043] The sintered NdFeB magnets with length, width, and height specifications of 20mm×10mm×3mm were mechanically polished, and then the polished sintered NdFeB magnet was cleaned with an acetone solution to make the cleanliness of the sintered NdFeB magnet reach Sa4 level.

[0044] (1) Metal-based alloy coating treatment: the metal-based alloy coating is prepared on the surface of the sintered NdFeB magnet by arc spraying;

[0045] (2) Sealing primer coating treatment: coating siloxane paint on the surface of the metal-based alloy coating to form a closed primer coating;

[0046] (3) Topcoat coating treatment: apply topcoat paint on the surface of the closed primer coating to form a topcoat coating. The topcoat coating is prepared by the mass percentage of nanoparticles and modified acrylic epoxy resin. The mass percentage is 15%, and the rest...

Embodiment 3

[0054] Embodiment 3: A method for preparing a glass coating on the surface of a neodymium iron boron magnet, including the following steps:

[0055] The sintered NdFeB magnets with length, width, and height specifications of 20mm×10mm×3mm were mechanically polished, and then the polished sintered NdFeB magnet was cleaned with an acetone solution to make the cleanliness of the sintered NdFeB magnet reach Sa4 level.

[0056] (1) Metal-based alloy coating treatment: the metal-based alloy coating is prepared on the surface of the sintered NdFeB magnet by arc spraying;

[0057] (2) Sealing primer coating treatment: coating siloxane paint on the surface of the metal-based alloy coating to form a closed primer coating;

[0058] (3) Topcoat coating treatment: apply topcoat paint on the surface of the closed primer coating to form a topcoat coating. The topcoat coating is prepared by the mass percentage of nanoparticles and modified acrylic epoxy resin. The mass percentage is 25%, and the rest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com