Acrylic adhesive composition, acrylic adhesive sheet, and method for bonding the adhesive sheet to coated surface of automobile

An acrylic, composition technology, applied in the direction of bonding method, adhesive type, ester copolymer adhesive, etc., can solve the problems of reduced adhesive force, reduced adhesiveness, and unobtainable adhesive sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

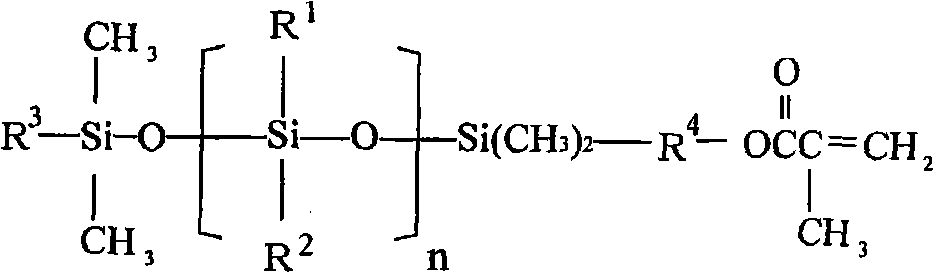

[0167](Synthesis of Copolymerized Oligomer (B1))

[0168] 148.5 parts by weight of cyclohexyl methacrylate, 1.5 parts by weight of single-end modified silicone oil ("X-22-2426" produced by Shin-Etsu Silicone Co., Ltd.), 4.5 parts by weight of 2-mercapto Ethanol, 0.3 parts by weight of 2,2'-azobisisobutyronitrile (AIBN), and 154.5 parts by weight of toluene were put into the flask. Polymerization was carried out at 70°C for 2 hours, followed by further aging at 80°C for 1 hour. Thereafter, toluene was distilled off from the reaction liquid, and it was further dried with a reduced-pressure drier to obtain a copolymerized oligomer (B1).

[0169] According to GPC (gel permeation chromatography), the copolymerized oligomer (B 1) had a polystyrene-equivalent weight-average molecular weight (the same applies hereinafter) of 4000, and a Tg (theoretical value) of 64°C.

[0170] (Preparation of Alkyl (Meth)acrylate Partial Polymer (A1) (UV Paste))

[0171] 0.05 parts by weight of tra...

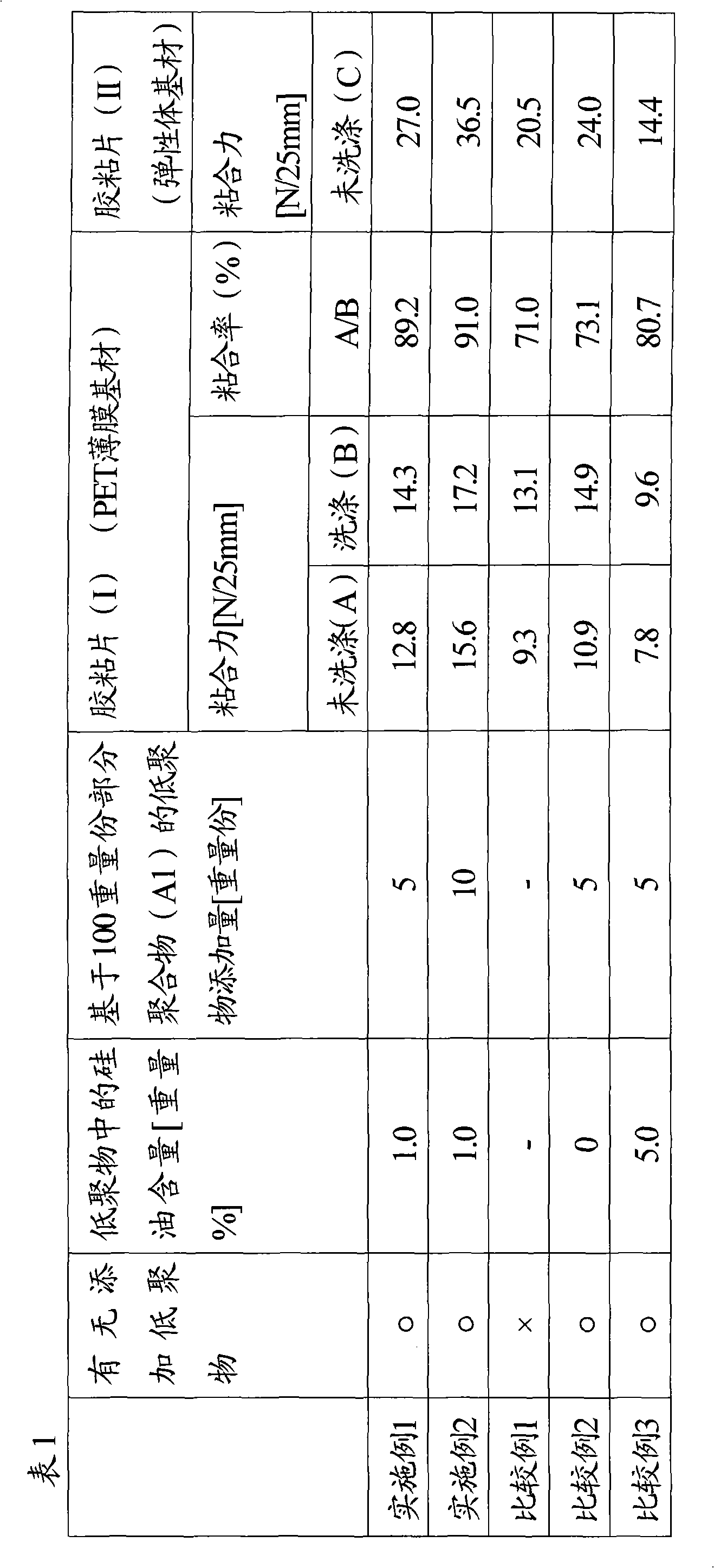

Embodiment 2

[0184] Except that the acrylic adhesive composition was prepared by adding 10 parts by weight of the copolymerized oligomer (B1), the PET film-based acrylic adhesive sheet (I-d) and the acrylic foam-based adhesive sheet were obtained in the same manner as in Example 1. material acrylic adhesive sheet (II-d).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| gel fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com