Binder for electrodes of lithium secondary batteries, and lithium secondary battery which uses electrode produced using binder for electrodes of lithium secondary batteries

A lithium secondary battery and binder technology, applied in battery electrodes, lithium storage batteries, batteries, etc., can solve the problems of inability to obtain charge-discharge cycle characteristics, reduced battery capacity retention rate, and low flexibility of electrode layers, achieving Excellent charge and discharge characteristics, excellent adhesion and electrolyte resistance, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] Next, examples and comparative examples of the present invention will be described. However, the present invention is not limited by these Examples. In addition, when "part" and "%" etc. appear below, unless otherwise specified, it is a mass basis.

[0102]

Synthetic example 1-1

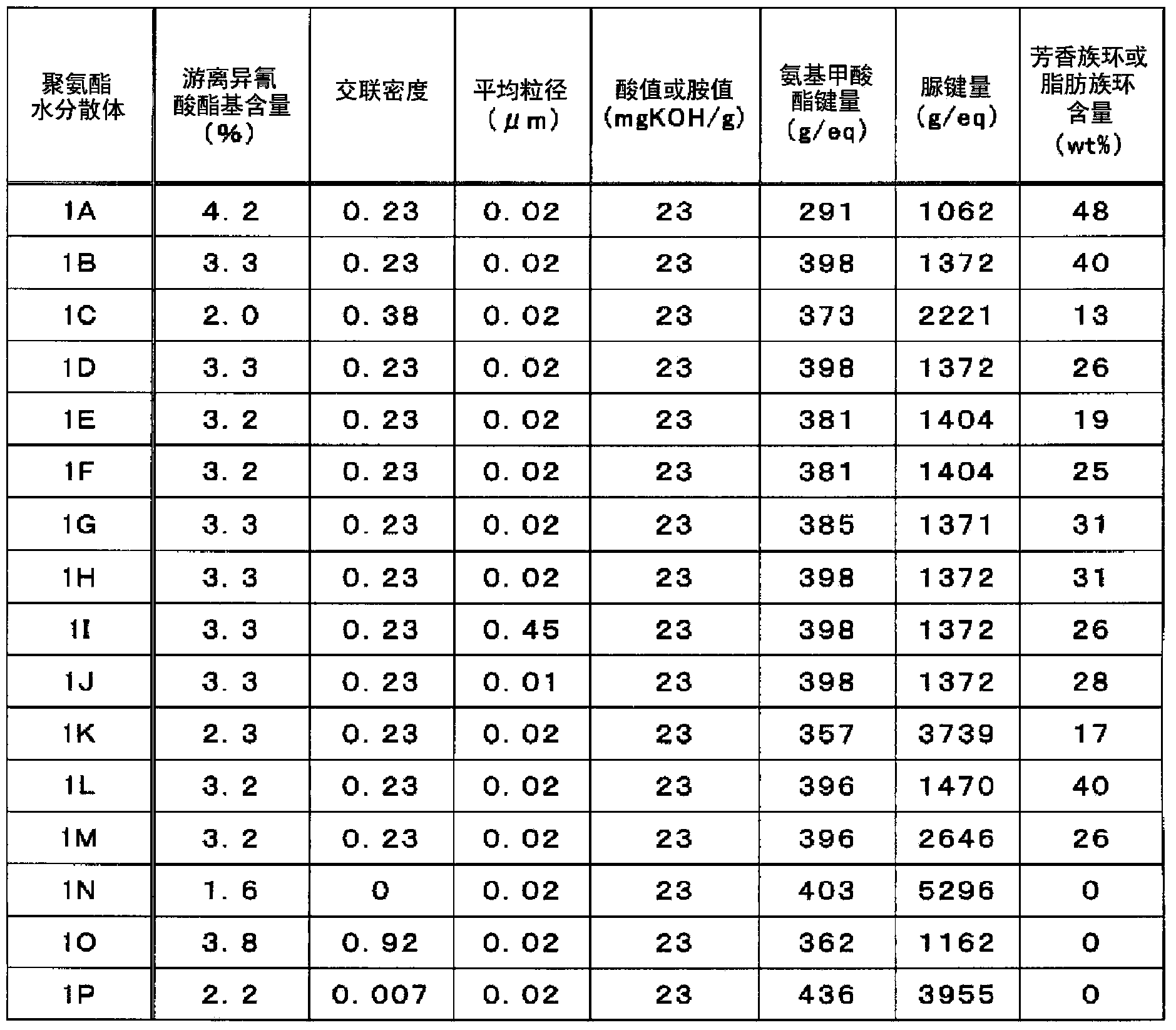

[0104] Into a four-necked flask equipped with a stirrer, a reflux cooling tube, a thermometer, and a nitrogen blowing tube, Newpol BPE-20NK (manufactured by Sanyo Chemical Co., Ltd., an ethylene oxide adduct of bisphenol A, an average hydroxyl value of 360 mgKOH / g, and active hydrogen Radix 2) 100 parts by mass, trimethylolpropane (active hydrogen radical number 3) 9.5 mass parts, dimethylol propionic acid (active hydrogen radical number 2) 16.3 mass parts, dicyclohexylmethane diisocyanate 174.2 mass parts, methyl ethyl ketone 200 Parts by mass were reacted at 75° C. for 4 hours to obtain a methyl ethyl ketone solution of a urethane prepolymer having a free isocyanate group content of 4.2% with respect to the non-volatile matter. This solution was cooled to 45° C., and 12.3 parts by mass of triethylamine was added for neutralization, then 900 parts by mass of water was slowly added, and emulsified dispersion was performed using a homogenizer. Next, an aqueous amine solution ob...

Synthetic example 1-2

[0106] Change 100 parts by mass of Newpol BPE-20NK to Kuraray Polyol P-1020 (manufactured by Kuraray Co., Ltd., polyester polyol composed of 3-methyl-1,5-pentanediol and terephthalic acid, average hydroxyl value 110mgKOH / g, active hydrogen group 2) 145.2 parts by mass, dicyclohexylmethane diisocyanate added to 129.0 parts by mass, ethylenediamine (active hydrogen group 2) added to 6.2 parts by mass, and It produced similarly to the synthesis example 1-1, and obtained the polyurethane aqueous dispersion 1B of about 30% of non-volatile matter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com