Method and structure for protecting primary cable system of suspension bridge

A technology for protective structures and suspension bridges, used in bridges, bridge parts, bridge construction, etc., can solve the problems of loss of metal adhesion, reduced corrosion resistance, cracks, etc., and achieve excellent resistance to ultraviolet aging, reduced maintenance costs, and good water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

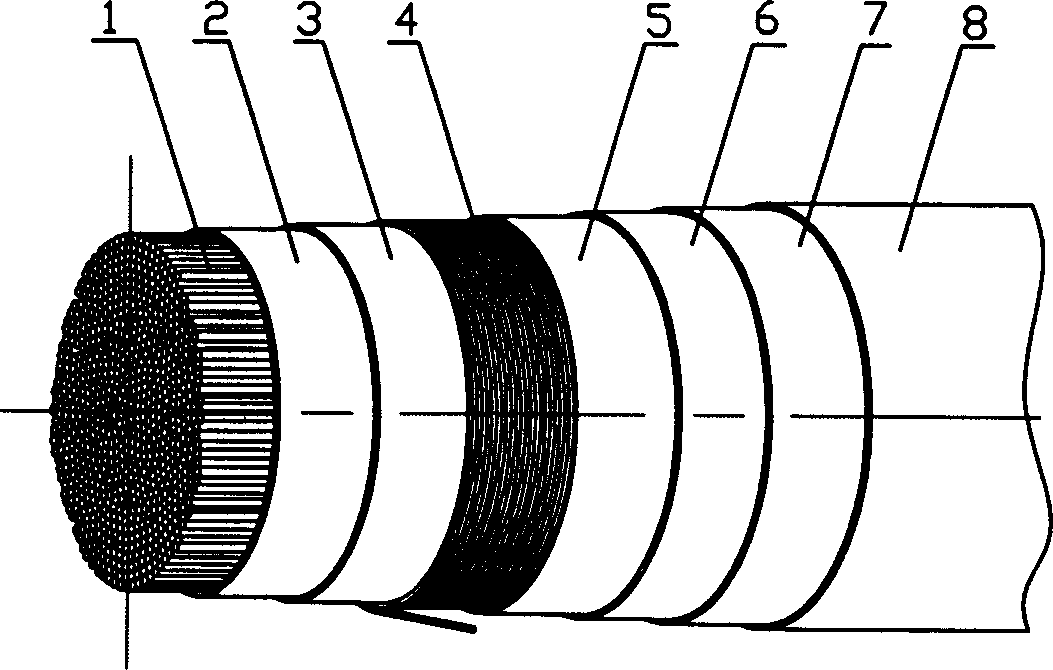

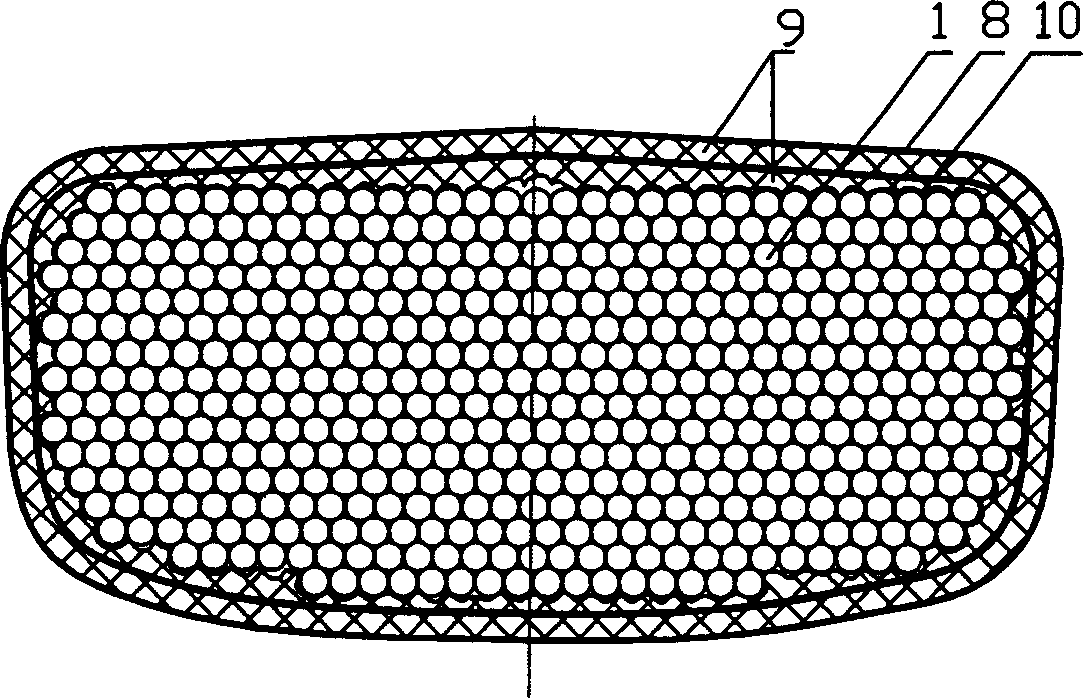

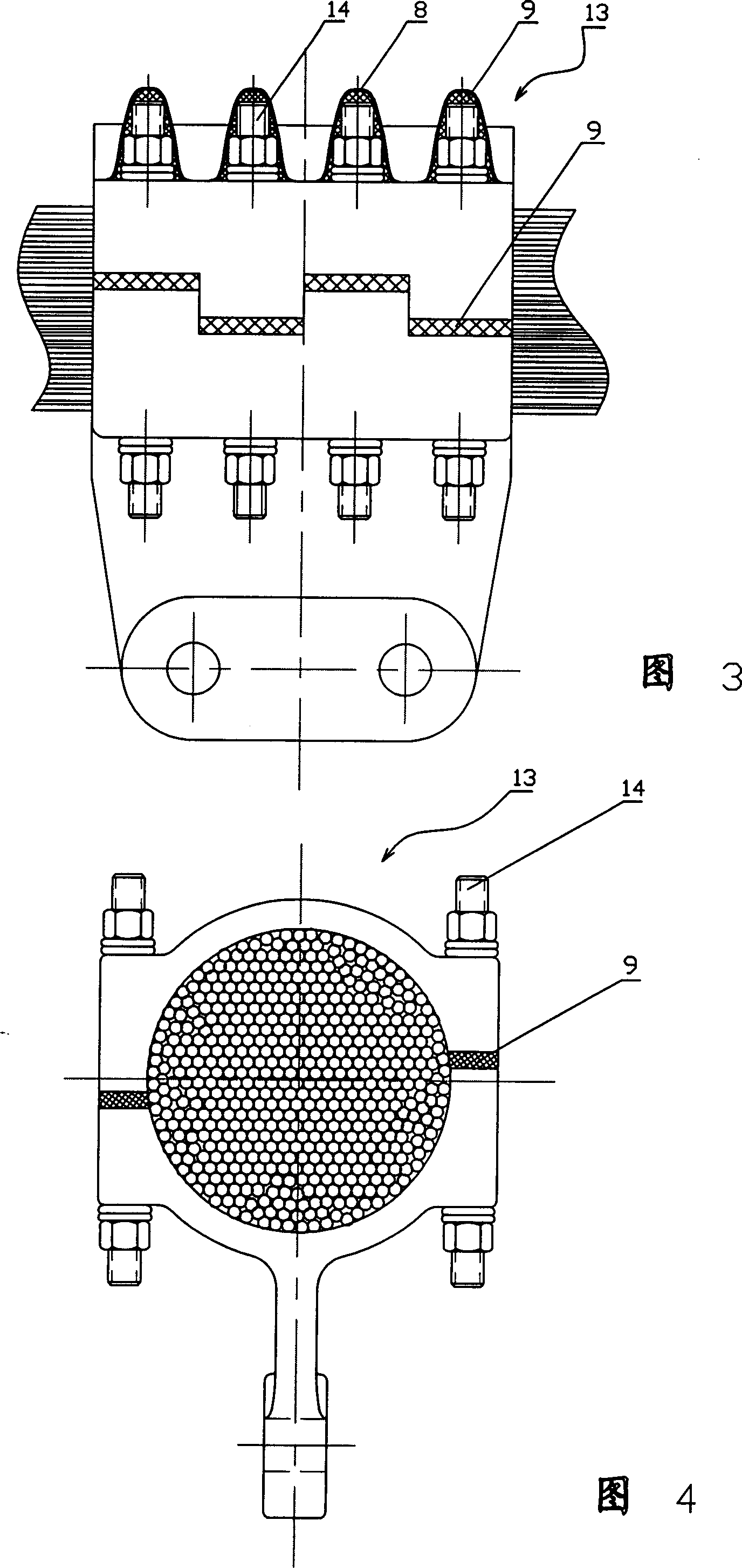

[0017] figure 1 A preferred embodiment of the main cable protective coating structure of the suspension bridge of the present invention is schematically shown. Wherein the main cable 1 is composed of multiple strands of high-strength galvanized steel wires, through a plurality of clamps (not shown in the figure) fixed on the main cable to form a steel wire bundle with a generally circular cross-section. According to the method for protecting the main cable system of the present invention, the surface of the main cable 1 is routinely cleaned to remove rust and other dirt, and then a layer of phosphating primer 2 is firstly applied. The phosphating primer 2 can adopt the XF06-2 type phosphating primer developed by the applicant, which is composed of polyvinyl butyral resin, zinc chromate antirust pigment, solvent and phosphating solution. The phosphating primer has excellent antirust ability, has phosphating and repairing functions on the mechanical damage of the galvanized ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com