Preparing method for composite coating comprising metal organic frame MOF and polycaprolactone PCL and degrading surface of magnesium alloy

A metal-organic framework and composite coating technology, which can be applied to devices, coatings, special surfaces, etc. for coating liquids on the surface, which can solve problems such as damage, and achieve the effects of less equipment investment, less difficulty in implementation, and good compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

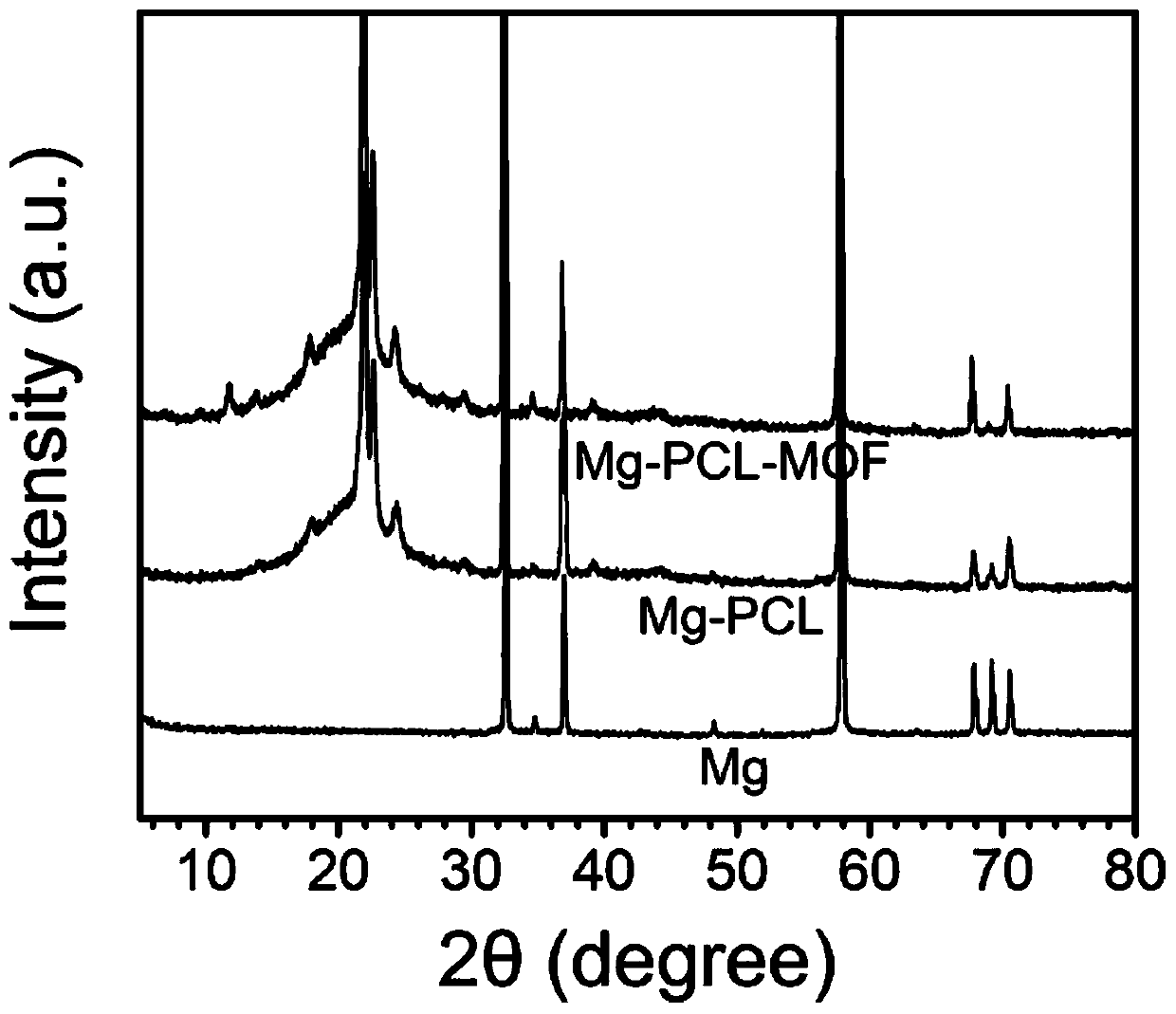

[0035] Step 1, magnesium alloy mechanical polishing

[0036] Grind the AZ31 magnesium alloy with 2400 grit sandpaper on a polishing machine until the surface is smooth with a mirror finish. Put the polished AZ31 magnesium alloy in absolute ethanol and ultrasonically clean it for 15 minutes, dry it naturally at room temperature, and set aside;

Embodiment 2

[0038] Step 1, magnesium alloy mechanical polishing

[0039] Grind the AZ31 magnesium alloy with 2400 grit sandpaper on a polishing machine until the surface is smooth with a mirror finish. Put the polished AZ31 magnesium alloy in absolute ethanol and ultrasonically clean it for 15 minutes, dry it naturally at room temperature, and set aside;

[0040] Step 2, preparing the PCL coating, the specific steps are:

[0041] 1) PCL is dissolved in dichloromethane to obtain a concentration of 6wt% solution

[0042] 2) The above solution was added dropwise on the surface of the magnesium alloy obtained in step 1, and dried in an oven at 37°C. After complete drying, the PCL solution was added dropwise on the surface of the magnesium alloy and dried to obtain a sample Mg-PCL. The volume of each dropwise solution was 50 μL.

Embodiment 3

[0044] Step 1, magnesium alloy mechanical polishing

[0045] Grind the AZ31 magnesium alloy with 2400 grit sandpaper on a polishing machine until the surface is smooth with a mirror finish. Put the polished AZ31 magnesium alloy in absolute ethanol and ultrasonically clean it for 15 minutes, dry it naturally at room temperature, and set aside;

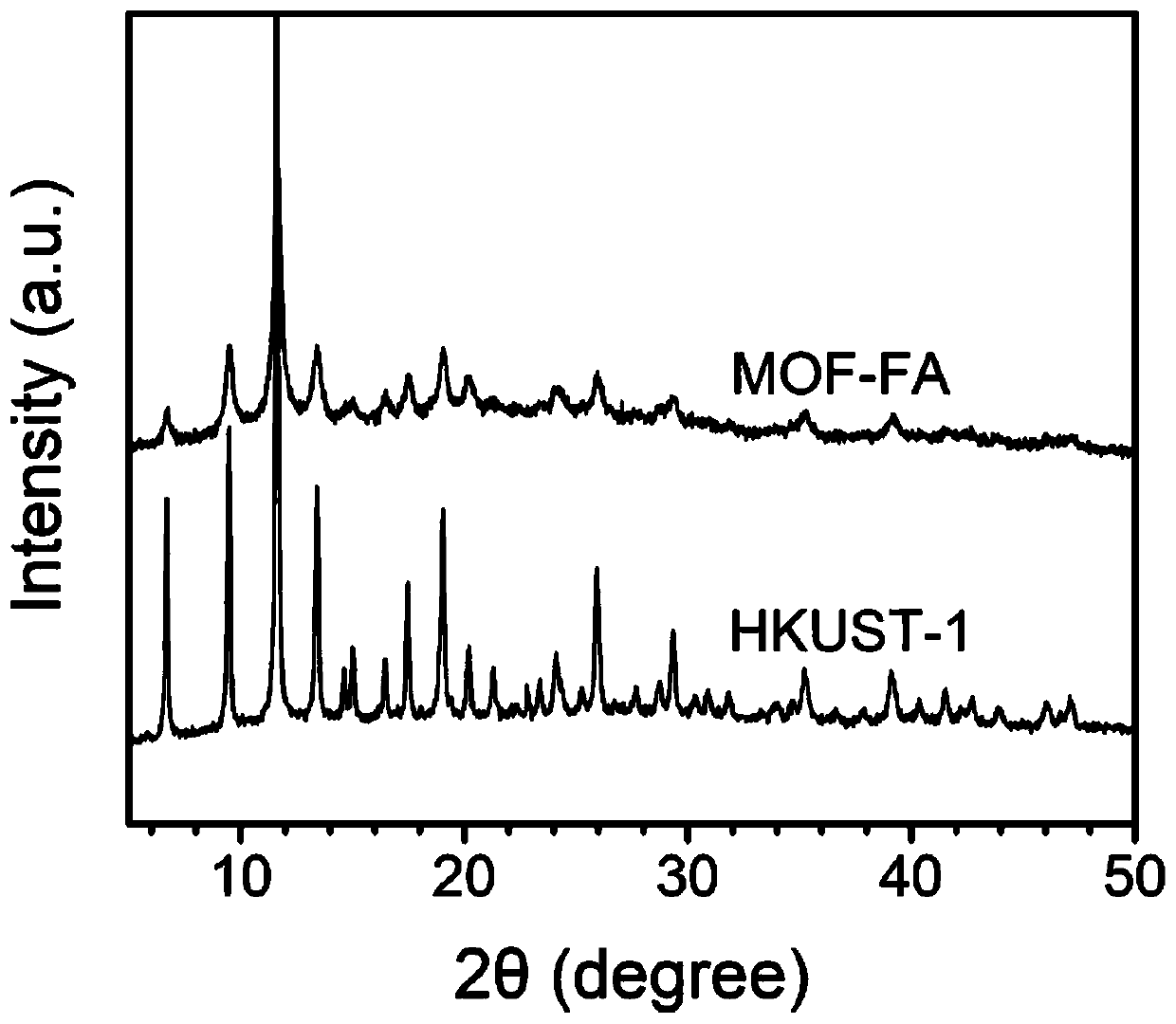

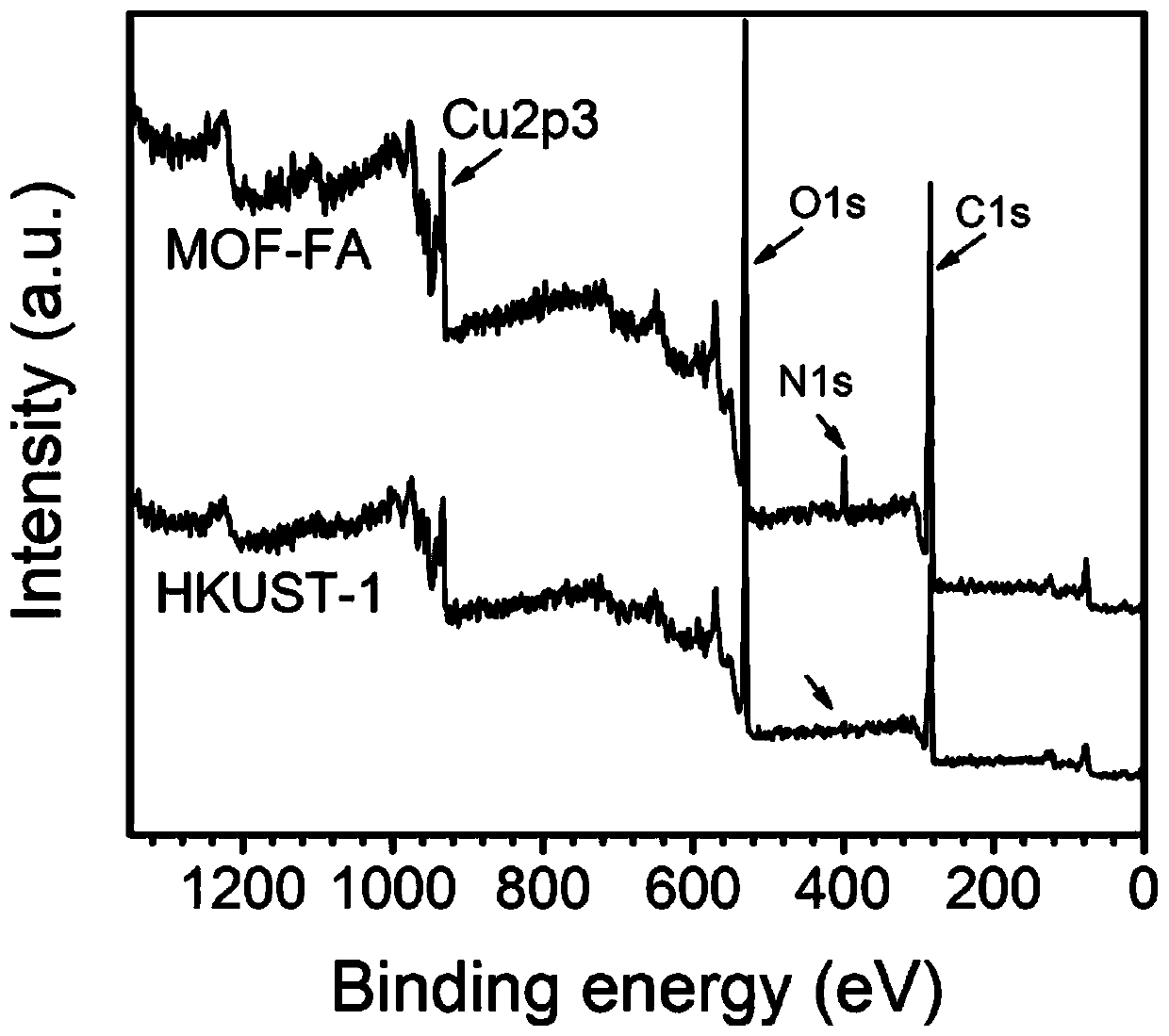

[0046] Step 2, preparing folic acid-modified MOF powder, the specific steps are:

[0047] 1) Dissolve 36mL of folic acid in dimethyl sulfoxide (concentration: 1.64mmol / L), stir and mix with 0.8mL of trimesic acid ethanol solution (concentration: 260mol / L), add 34mL of 50% ethanol, and 1 mL aqueous solution of copper acetate monohydrate (concentration: 375 mol / L) was added dropwise. The rotational speed was adjusted to 300 rpm, and the reaction was stirred for 40 minutes.

[0048] 2) The resulting solution was centrifuged at 8000 rpm for 2 minutes with a centrifuge, then washed three times with a mixed solvent of dimethyl sulfoxide, abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com