Optical transparent member and optical system using the same

An optically transparent and optical system technology, applied in the field of optical systems, can solve the problems of high capital expenditure, insufficient anti-reflection performance, low throughput, etc., to achieve improved low-reflection properties, maintain anti-reflection performance, and good anti-reflection effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

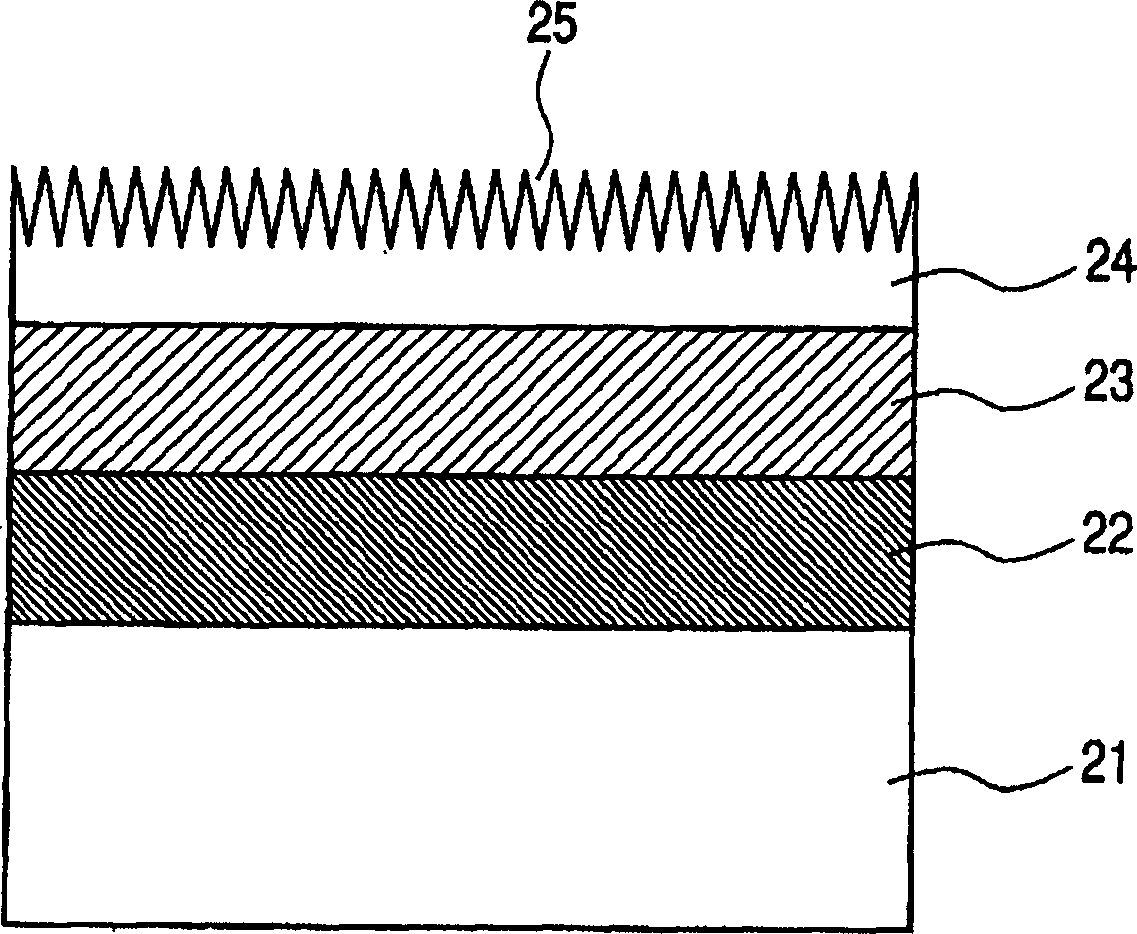

Method used

Image

Examples

example 1

[0084] A substrate of clear-float glass (composition: soda lime silicate type, refractive index ng=1.52) with a size of about 100 mm x 100 mm and a thickness of about 2 mm was ultrasonically cleaned with isopropanol, dried, And used as a glass substrate for coating.

[0085] Tetraethoxysilane (TEOS) was dissolved in ethanol (EtOH), 0.01 M phosphoric acid aqueous solution was added to the resulting solution as a catalyst, and the resulting mixture was stirred for 6 hours. At this time, the molar ratio of each component is TEOS: EtOH: H 3 PO 4 aq=1:40:2. Titanium n-butoxide (TBOT) was dissolved in ethanol, then ethyl acetoacetate (EAcAc) was added to the resulting solution as a stabilizer, and the resulting mixture was stirred at room temperature for 3 hours. The molar ratio of each component was TBOT:EtOH:EAcAc=1:20:1. TiO 2 The sol solution was added to the aforementioned SiO 2 sol solution, so that the SiO 2 :TiO 2 =95:5 molar ratio, and the resulting mixture was stir...

example 2

[0092] An S-TIH53 glass substrate (manufactured by OHARA Corporation, refractive index n=1.84) with a size of about 50 mm×50 mm and a thickness of about 1 mm was ultrasonically cleaned with isopropanol, dried, and used as a glass substrate for coating .

[0093] TiO 2 The sol solution was added to the aforementioned SiO 2 sol solution, so that the SiO 2 :TiO 2 =7:3 molar ratio, and the resulting mixture was stirred at room temperature for 2 hours, and then used as SiO 2 -TiO 2 Coating solution, as described in Example 1. Next, the aforementioned coated glass substrate was immersed in this coating solution, and a coating film was formed on the surface of the glass substrate by a dipping method (at a lifting speed of 0.5 mm / sec, and at 20° C. and 56% R.H.). The glass substrate was dried and then heat-treated by baking at 400 °C for one hour, and transparent amorphous SiO 2 / TiO 2 A film is coated thereon. The thickness and refractive index of the obtained film were meas...

example 3

[0099] The same S-TIH53 glass substrate (manufactured by OHARA Corporation, refractive index n=1.84) as in Example 2 was used as the glass substrate for coating.

[0100] Coated SiO 2 / TiO2 (7 / 3), followed by the formation of transparent amorphous SiO in the same manner as in Example 2 2 / TiO 2 membrane. The thickness and refractive index of the obtained film were measured, and the measurement results showed that the thickness was 28 nm and the refractive index n s is 1.67.

[0101] Aluminum sec-butoxide [Al(O-sec-Bu) 3 ] was dissolved in 2-propanol [IPA], ethyl acetoacetate [EAcAc] was added to the resulting solution as a stabilizer, and the resulting mixture was stirred at room temperature for about 3 hours to prepare Al 2 o 3 Sol solution. Here, the molar ratio of the solution is Al(O-sec-Bu) 3 :IPA:EAcAc=1:20:1. Titanium n-butoxide [Ti(O-n-Bu) 4 ] was also dissolved in IPA, EAcAc was added to the resulting solution, and the resulting mixture was stirred for appro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com