One-step cover closing method of electronic paper micro-cup and cover closing material

A technology of electronic paper and conductive materials, applied in identification devices, nonlinear optics, instruments, etc., can solve the problems of difficult implementation, fragile microcup structure, inapplicability, etc., and achieve the effect of cheap equipment, simple and fast method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

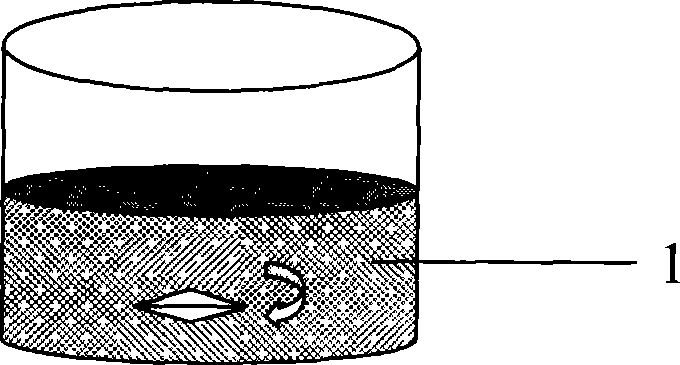

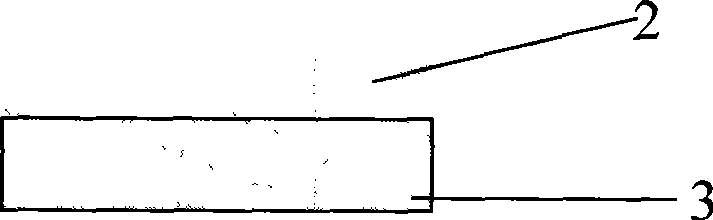

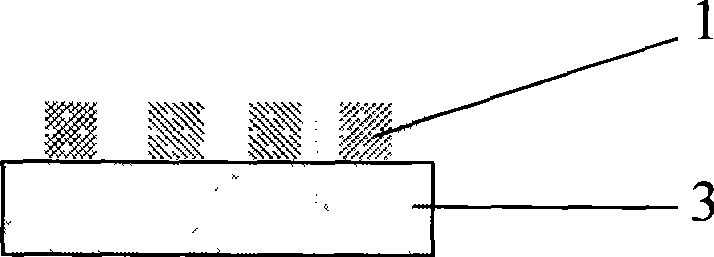

[0058] See Figure 1~5 .

[0059] In the capping glue: photoinitiator: 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, the concentration is 0.5wt%, 2-(4-(2-hydroxyl-2-methylpropane Oxy)phenoxy)acetic acid at a concentration of 0.5 wt%, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide at a concentration of 1 wt%, monomer: maleic anhydride modified Methacrylate at 8 wt%, Methacrylate Phosphate at 3 wt%, Polyethylene Glycol (600) Acrylate at 2 wt%, Ditrimethylol Propylene Tetraacrylate at 2 wt% %, oligomer: SB401 (aromatic acid methacrylic acid half ester) (Sartomer Company, U.S.), concentration is 5wt%, CN966 (amino ester / acrylic acid ester) (Sartomer Company, U.S.), concentration is 10wt%, Conductive material: 5 μm flake-shaped hollow aluminum powder, concentration is 50wt%, surfactant: CD9051 (acrylic acid ester containing three unsaturated carbon-carbon double bonds) (Sartomer, USA), concentration is 4wt%, BYK115 ( High-molecular-weight block copolymer solution with a molecu...

Embodiment 2

[0064] See Figure 1~5 .

[0065] In the capping glue: photoinitiator: 2-hydroxyl-1-(4-(2-hydroxyethoxy)phenyl)-2-methylpropyl-1-one, the concentration is 0.5wt%, 1- Hydroxycyclohexyl phenyl ketone, the concentration is 0.5wt%, monomer: polyethylene glycol (200) acrylate, the concentration is 5wt%, triglycerol triacrylate, the concentration is 3wt%, ethylene glycol bis Methacrylate, concentration is 2wt%, oligomer: EB2002 (water-soluble urethane acrylate, U.S. Cytec), concentration is 30wt%, CN2256 (water-soluble polyester acrylic acid, U.S. Sartomer Company), concentration is 10wt%, CN972 (aromatic amino ester acrylate) (Sartomer, U.S.), concentration is 10wt%, conductive material: 500nm flake silver-coated silica ball, concentration is 10wt%, polyaniline, concentration is 10wt% %, surfactant: silane coupling agent 570, concentration is 1wt%, BYK110 (Germany BYK chemical company), concentration is 2wt%, BYK154 (molecular weight is greater than the ammonium salt solution of ...

Embodiment 3

[0070] See Figure 1~5 .

[0071] In the capping glue solution: photoinitiator: benzoin dimethyl ether, the concentration is 1wt%, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, the concentration is 1wt%, monomer: acrylic acid modified Acrylate, concentration is 10wt%, isobornyl acrylate, concentration is 15wt%, ditrimethylol propylene tetraacrylate, concentration is 20wt%, oligomer: PE55WN (water-soluble polyester acrylate, Germany BASF company ), concentration is 25wt%, CN988 (Sartomer Company of the U.S.), concentration is 7wt%, surfactant: CD9051 (acrylic acid ester containing three unsaturated carbon-carbon double bonds in the molecule) (Sartomer Company of the United States), Concentration is 1wt%, BYK115 (Germany BYK chemical company), concentration is 2wt%, BYK181 (having the molecular weight of anionic / non-ionic character is greater than the solution of the alkanolammonium salt polymer of 10000 less than 3000000) (Germany BYK chemical company) , concentration is 5w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com