Water-based phenolic epoxy coating material and preparation method thereof

A water-based phenolic epoxy and coating technology, applied in the field of coatings, can solve the problems of hidden safety hazards and high VOC content, and achieve the effects of low VOC content, excellent comprehensive performance, and good chemical resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

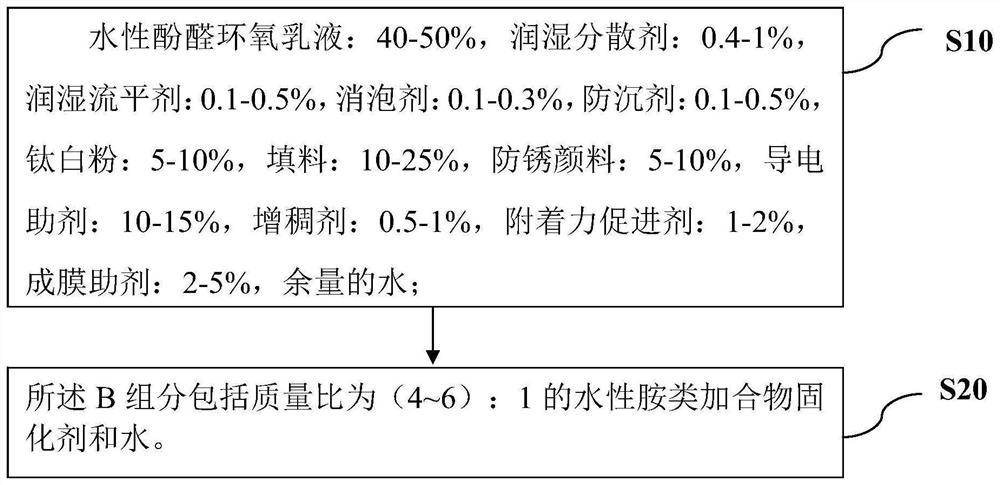

[0069] as attached figure 1 Shown, the second aspect of the embodiment of the present application provides a kind of preparation method of waterborne novolac epoxy coating, comprises the following steps:

[0070] S10. The water-based novolak epoxy emulsion with a mass percentage of 40-50%, 0.4-1% wetting and dispersing agent, 0.1-0.5% wetting and leveling agent, 0.1-0.3% defoaming agent, 0.1 -0.5% anti-settling agent, 5-10% titanium dioxide, 10-25% filler, 5-10% anti-rust pigment, 10-15% conductive additive, 0.5-1% thickener, 1-2% adhesion promoter, 2-5% film-forming aid and the rest of water are mixed to obtain component A;

[0071] S20. Dissolving the water-based amine adduct curing agent in water, the mass ratio of the water-based amine adduct curing agent to water is (4-6):1 to obtain component B.

[0072] The preparation method of the water-based novolac epoxy coating provided by the second aspect of the embodiment of the present application, the preparation method of t...

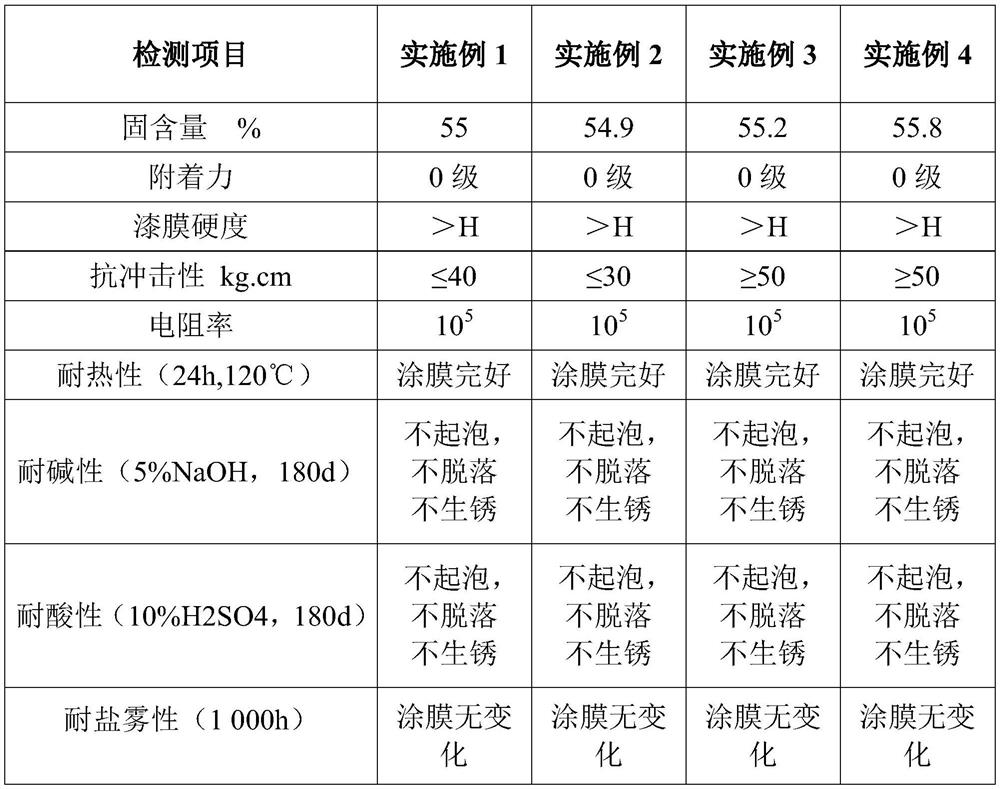

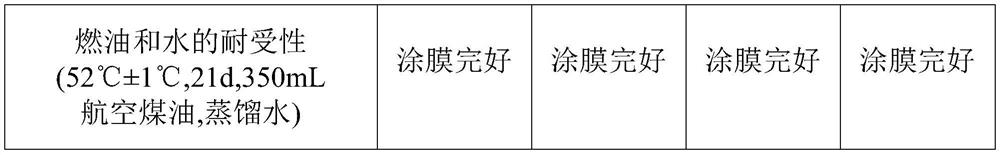

Embodiment 1

[0078] A kind of waterborne novolac epoxy paint, comprises A component and B component, wherein,

[0079] The preparation of component A includes steps: first add 11% deionized water, 1.2% wetting and dispersing agent DISPERBYK-190, and 0.1% defoamer BYK-028 into the material preparation container in sequence, and stir evenly; then add 0.2% anti-settling Agent bentonite powder EW, 15% titanium dioxide, 5% barium sulfate filler, 6% anti-rust pigment zinc phosphate, 6% conductive mica powder conductive additives were added to the above container in turn, stirred evenly again, and dispersed at high speed for 30 minutes to obtain the pre- Disperse the slurry; the obtained pre-dispersed slurry is ground to a fineness of less than or equal to 30 microns; finally, 1.5% silane coupling agent adhesion promoter, 50% water-based novolac epoxy emulsion, and 3.5% film-forming aid dipropylene glycol Add butyl ether and 0.1% leveling agent Tego Wet 270 into the qualified mill base, and use 0...

Embodiment 2

[0083] A kind of waterborne novolac epoxy paint, comprises A component and B component, wherein,

[0084] The preparation of component A includes steps: first add 12% deionized water, 1.3% wetting and dispersing agent DISPERBYK-194N, and 0.2% defoamer BYK-028 into the material preparation container in sequence, and stir evenly; then add 0.3% anti-settling Agent bentonite powder EW, 16% titanium dioxide, 4% barium sulfate filler, 6.5% anti-rust pigment zinc phosphate, 6.8% conductive mica powder conductive auxiliary agent were added to the above container in turn, stirred again, and dispersed at high speed for 30 minutes to obtain the pre- Disperse the slurry; the resulting pre-dispersed slurry is ground to a fineness of less than or equal to 30 microns; finally, 2% silane coupling agent adhesion promoter, 47% water-based novolac epoxy emulsion, and 3.3% film-forming aid dipropylene glycol Put butyl ether and 0.2% leveling agent BYK-333 into the qualified mill base, and use 0.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com