A kind of low voc all solid cavity anticorrosion wax composition

An all-solid, anti-corrosion wax technology, used in anti-corrosion coatings, wax coatings, coatings, etc., can solve the problems of freezing, film formation, easy to be washed, and difficult to form film, etc., to achieve safe operation, good for the environment and safety, and good water resistance. The effect of resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

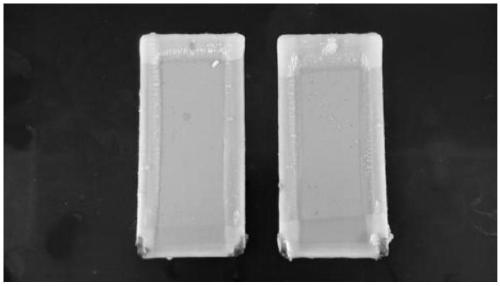

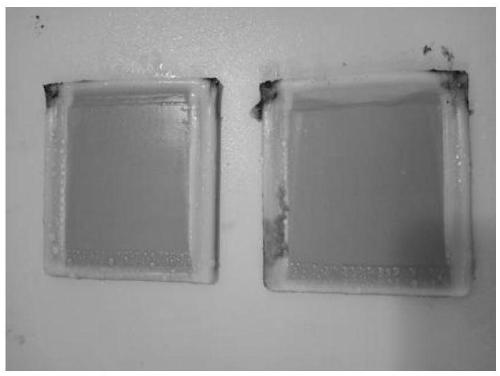

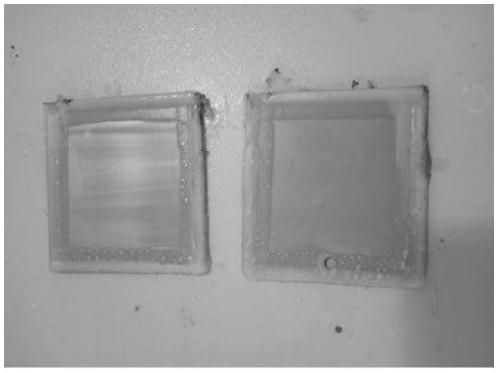

Image

Examples

Embodiment 1

[0029] The mass fraction of each component in the anti-corrosion wax: the waxy material is No. 58 fully refined paraffin wax 5.2%, No. 85 microcrystalline wax 12.5%, vegetable oil is linseed oil 6.5%, tung oil 1.2%, antirust pigment is zinc tripolyphosphate 3.5%, aluminum phosphate 1.8%, oil-soluble anti-rust additive is N oleoyl sarcosine octadecyl ammonium salt 8.2%, lanolin 1.0%, base oil is polyalphaolefin 25 58.5%, drier is cobalt isooctanoate 0.2 %, the drying control agent is 0.5% of dialkyl thiodipropionic acid, and the silane coupling agent is 0.9% of polymethyltriethoxysilane.

[0030] Preparation of anti-corrosion wax composition:

[0031] Add zinc tripolyphosphate and aluminum phosphate to linseed oil and tung oil, disperse at a high speed of 800 rpm, disperse and stir for 10 minutes; add No. 58 fully refined paraffin wax, No. 85 microcrystalline wax, and N-oleoyl sarcosine in sequence Octadecylamine salt, lanolin, high-speed stirring speed 1200 rpm, stirring for ...

Embodiment 2

[0035]The mass fraction of each component in the anticorrosion wax: the waxy material is polyethylene wax 3.0%, Montan wax 8.8%, vegetable oil is soybean oil 10.2%, polymerized sunflower oil 3.6%, antirust pigment is strontium aluminum phosphate 6.8% , zirconia 2.2%, oil-soluble anti-rust additive is lanolin magnesium soap 3.5%, zinc dinonyl naphthalene sulfonate 6.0%, base oil is No. 26 white mineral oil 43%, 500SN 10.9%, drier is cyclo 0.8% cobalt alkanoate, 0.2% di-tert-butyl p-cresol as the drying control agent, and 1.0% aminopropylmethyldiethoxysilane as the silane coupling agent.

[0036] Preparation of anti-corrosion wax composition:

[0037] Add strontium aluminum phosphate and zirconia into soybean oil and polymerized sunflower oil, disperse and stir for 30 minutes at 1000 rpm; add polyethylene wax, Montan wax, lanolin magnesium soap, dinonyl naphthalene sulfonic acid in sequence Zinc, high-speed stirring speed 1500 rpm, stirring for 1.5h; then add cobalt naphthenate...

Embodiment 3

[0042] The mass fractions of each component in the anticorrosion wax: the waxy material is pentaerythritol isooctanoate magnesium soap 2.0%, No. 70 microcrystalline wax 5.8%, vegetable oil is blown linseed oil 6.3%, soybean oil 2.6%, and the antirust pigment is Zinc aluminum orthophosphate 5.5%, strontium aluminum phosphate 3.1%, oil-soluble anti-rust additive is perbasic value sulfonate 6.7%, oxidized petroleum grease 2.2%, base oil is No. 26 adipate 51.35%, 150BS 16.0% , the drying agent is 0.1% of zirconium isooctanoate, 0.2% of rare earth cobalt zirconium salt, and the drying control agent is 0.05% of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 0.3% of trinonylated phenyl phosphite, and 0.8% of 3-aminopropyltriethoxysilane as the silane coupling agent.

[0043] Preparation of anti-corrosion wax composition:

[0044] Add strontium aluminum phosphate, zinc aluminum orthophosphate to blown linseed oil and soybean oil, disperse and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com