Alkaline cyanide-free silver plating electroplating liquid and silver plating method

A cyanide-free silver plating and electroplating solution technology, applied in the field of silver electroplating, can solve the problems of narrow cathode current density, weak bonding force between the coating and the substrate, and poor discoloration resistance of the silver coating, so as to achieve the appearance quality. Improve and enhance the anti-discoloration ability and the effect of dense crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

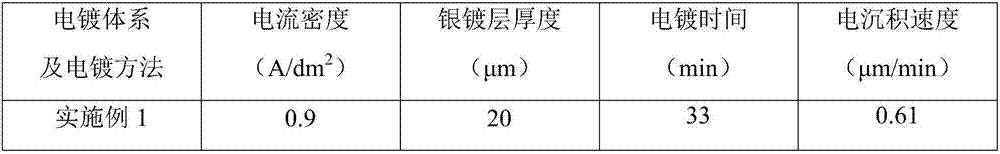

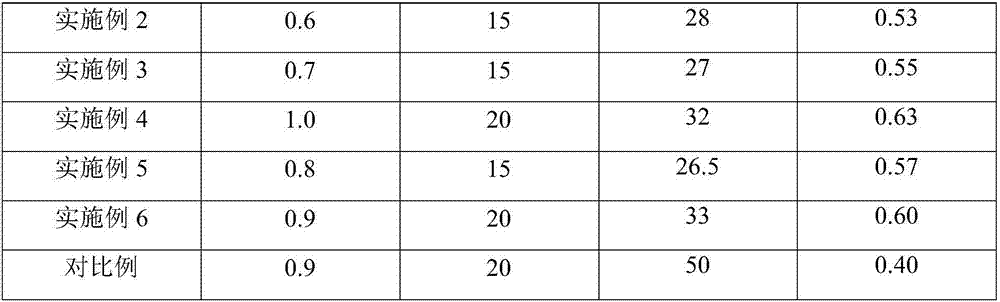

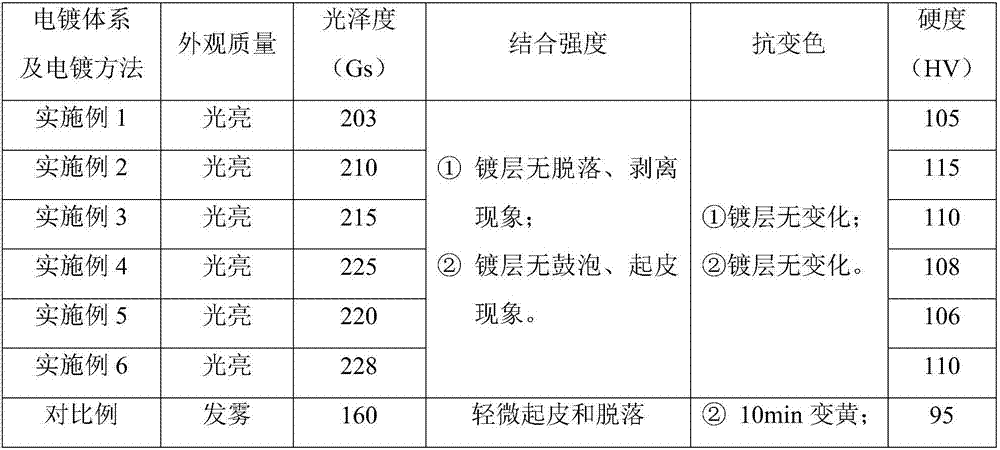

Examples

Embodiment 1

[0050] The alkaline cyanide-free silver plating solution of the present embodiment is made up of following components:

[0051] Main salt: silver nitrate 20g / L;

[0052] Complexing agent: 5,5-dimethylhydantoin 100g / L,

[0053] Potassium pyrophosphate 70g / L;

[0054] Composite brightener: sodium polydisulfide dipropane sulfonate 0.9g / L,

[0055] Benzotriazole 0.12g / L,

[0056] N,N'-Dioleoyl ethylenediamine diethylsulfonate sodium 10mg / L,

[0057] Polyethylene glycol 0.15g / L;

[0058] Potassium hydroxide is used as a pH regulator to make the pH of the system 9, and the balance is water.

[0059] The electroplating method that adopts above-mentioned alkaline cyanide-free silver-plating electroplating solution of the present embodiment may further comprise the steps:

[0060] 1) Use a water-based degreasing agent to remove the oil on the surface of the copper substrate, and then wash with water;

[0061] 2) Under room temperature conditions, use hydrochloric acid with a vol...

Embodiment 2

[0065] The alkaline cyanide-free silver plating solution of the present embodiment is made up of following components:

[0066] Main salt: silver nitrate 30g / L;

[0067] Complexing agent: 5,5-dimethylhydantoin 50g / L,

[0068] Potassium pyrophosphate 75g / L;

[0069] Composite brightener: sodium polydisulfide dipropane sulfonate 0.8g / L,

[0070] Benzotriazole 0.14g / L,

[0071] N,N'-Dioleoyl ethylenediamine diethylsulfonate sodium 12mg / L,

[0072] Polyethylene glycol 0.20g / L;

[0073] Potassium hydroxide is used as a pH regulator to make the pH of the system 9.5, and the balance is water.

[0074] The electroplating method that adopts above-mentioned alkaline cyanide-free silver-plating electroplating solution of the present embodiment may further comprise the steps:

[0075] 1) Use a water-based degreasing agent to remove the oil on the surface of the copper substrate, and then wash with water;

[0076] 2) Under room temperature conditions, use hydrochloric acid with a vo...

Embodiment 3

[0080] The alkaline cyanide-free silver plating solution of the present embodiment is made up of following components:

[0081] Main salt: silver nitrate 40g / L;

[0082] Complexing agent: 5,5-dimethylhydantoin 80g / L,

[0083] Potassium pyrophosphate 90g / L;

[0084] Composite brightener: sodium polydisulfide dipropane sulfonate 1.0g / L,

[0085] Benzotriazole 0.13g / L,

[0086] N,N'-Dioleoyl ethylenediamine diethylsulfonate sodium 14mg / L,

[0087] Polyethylene glycol 0.30g / L;

[0088] Potassium hydroxide is used as a pH regulator to make the pH of the system 10.5, and the balance is water.

[0089] The electroplating method that adopts above-mentioned alkaline cyanide-free silver-plating electroplating solution of the present embodiment may further comprise the steps:

[0090] 1) Use a water-based degreasing agent to remove the oil on the surface of the copper substrate, and then wash with water;

[0091] 2) Under room temperature conditions, use hydrochloric acid with a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com