Environmental-protection interior wall latex paint

An interior wall latex paint, environmental protection technology, applied in the field of latex paint, can solve the problems of poor stability of latex paint, reduce human immunity, not easy to polish and stick sandpaper, etc., to achieve the effect of fresh decoration, maintaining gloss, and no fire hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

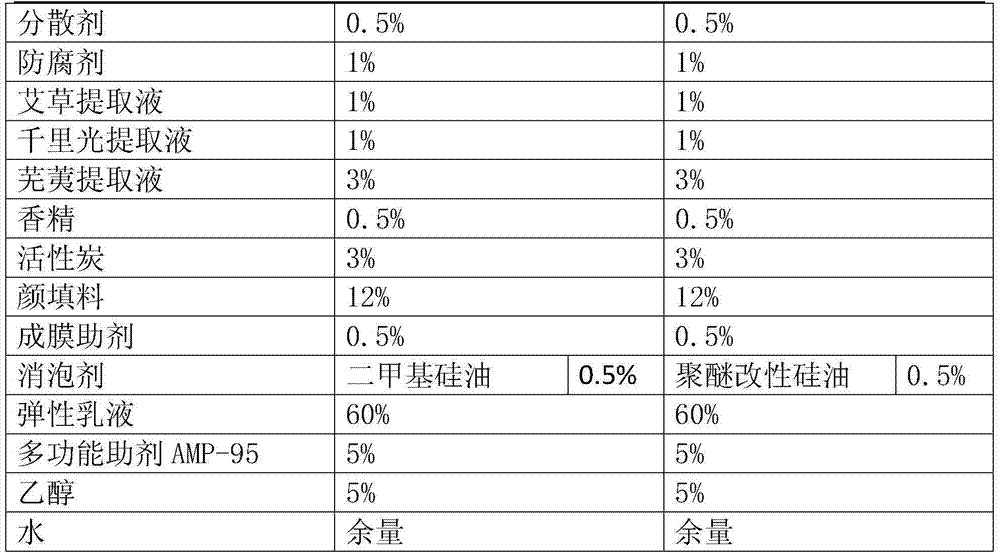

Examples

Embodiment 1

[0017] An environmentally friendly latex paint for interior walls, taking 100kg as an example, consists of the following raw materials in mass percentage: 0.5% dispersant, 1% allicin, 2% wormwood extract, 2% senecio extract, 4 turnip extract %, orange flavor 0.5%, activated carbon 4%, pigments and fillers 12%, film-forming aid 0.5%, defoamer 0.5%, elastic emulsion 60%, multifunctional additive AMP-955%, ethanol 5%, water volume composition.

[0018] Before adding the pigments and fillers, add water, dispersant and other additives to the reaction kettle, stir evenly and then add the pigments and fillers. Before that, stir at a low speed at 1000 rpm; after adding the pigments and fillers, turn to High-speed 3000 rpm; add the rest of the raw materials, after high-speed stirring, add film-forming aids and defoamers. After stirring, the finished product is obtained after testing.

Embodiment 2

[0020] An environmentally friendly latex paint for interior walls, taking 100kg as an example, consists of the following raw materials in mass percentage: 0.5% dispersant, 3% tea polyphenols, 2% wormwood extract, 2% senecio extract, 3 turnip extract %, lemon flavor essence 0.5%, activated carbon 3%, pigments and fillers 12%, film-forming aid 0.5%, defoamer 0.5%, elastic emulsion 55%, multifunctional additive AMP-955%, ethanol 5%, water volume composition.

[0021] Before adding the pigments and fillers, add water, dispersant and other additives to the reaction kettle, stir evenly and then add the pigments and fillers. Before that, stir at a low speed at 1000 rpm; after adding the pigments and fillers, turn to High-speed 3000 rpm; add the rest of the raw materials, after high-speed stirring, add film-forming aids and defoamers. After stirring, the finished product is obtained after testing.

Embodiment 3

[0023] An environmentally friendly latex paint for interior walls, taking 100kg as an example, consists of the following raw materials in mass percentage: 0.5% dispersant, 1% preservative, 1% wormwood extract, 1% senecio extract, 3 turnip extract %, apple flavor 0.5%, activated carbon 3%, pigments and fillers 12%, film-forming aid 0.5%, defoamer 0.5%, elastic emulsion 60%, multifunctional additive AMP-955%, ethanol 5%, water volume composition.

[0024] Before adding the pigments and fillers, add water, dispersant and other additives to the reaction kettle, stir evenly and then add the pigments and fillers. Before that, stir at a low speed at 1000 rpm; after adding the pigments and fillers, turn to High-speed 3000 rpm; add the rest of the raw materials, after high-speed stirring, add film-forming aids and defoamers. After stirring, the finished product is obtained after testing.

[0025] The construction process of interior wall latex paint, its basic procedure is: base trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com