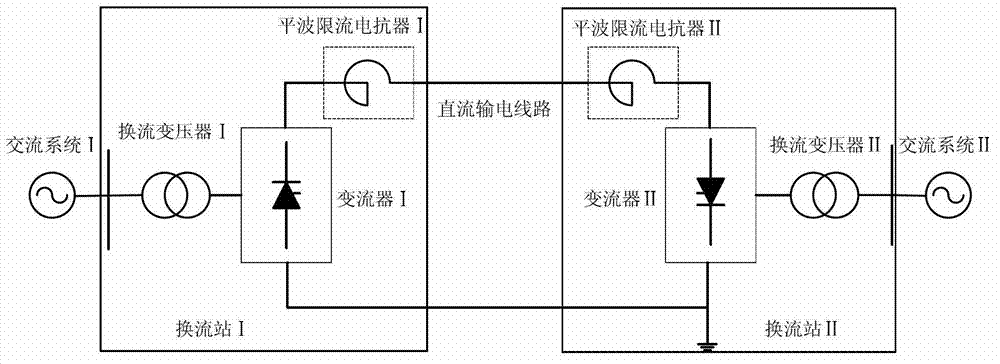

Superconductivity flat wave current limiting reactor applicable to high-voltage direct-current transmission

A technology of high-voltage DC transmission and current-limiting reactors, which is applied in transformer/inductor cores, transformers, superconducting magnets/coils, etc., and can solve the problem of high energy consumption of ordinary smoothing reactors and difficulty in breaking and short-circuiting of DC circuit breakers Current and other issues, to achieve the effect of no fire hazard, light weight, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

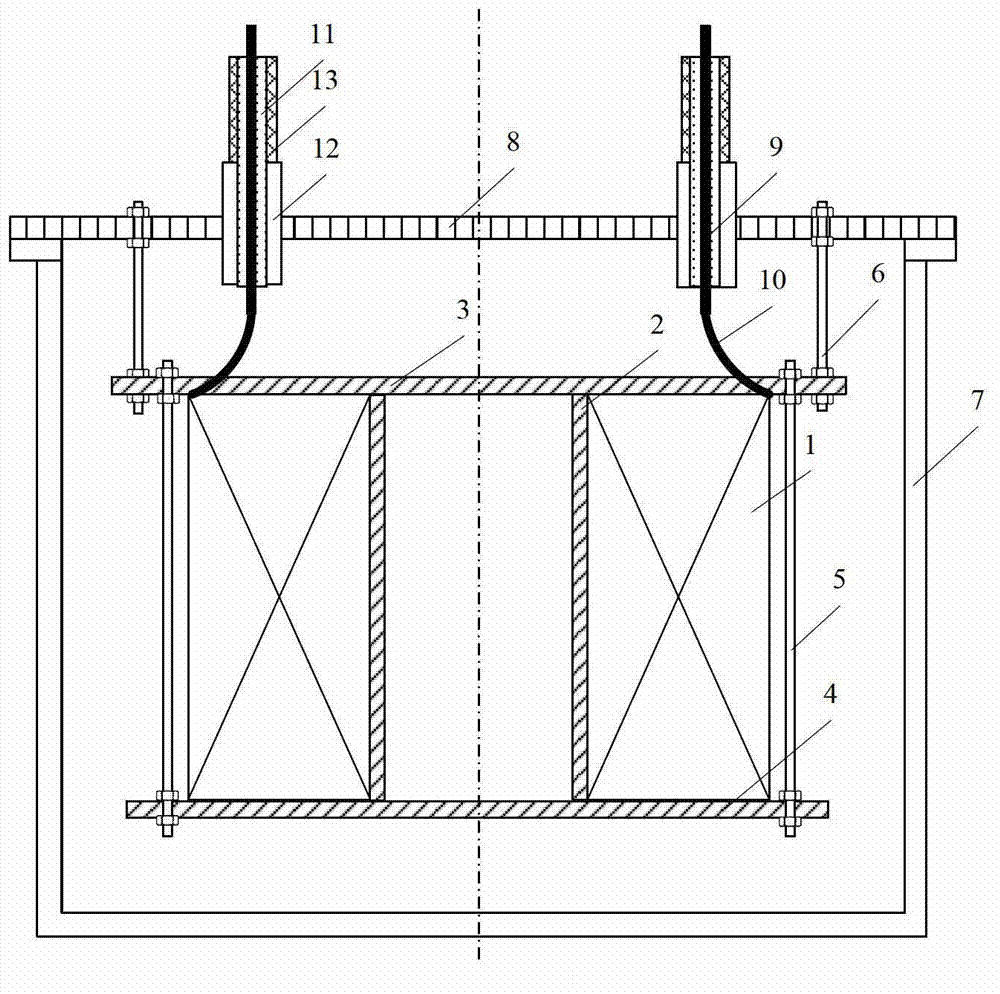

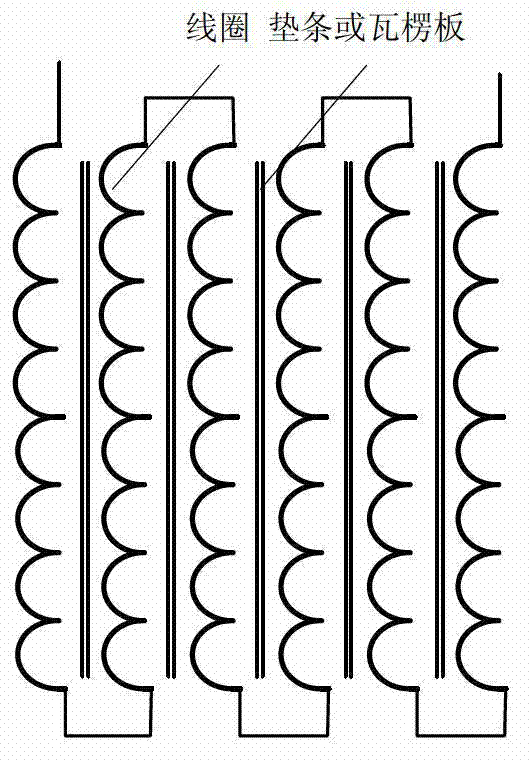

[0030] Embodiment 1 is a superconducting smoothing current-limiting reactor with an air-core structure. Such as figure 2 As shown, the superconducting flat-wave current-limiting reactor consists of a superconducting coil 1, a coil frame 2, a coil upper support plate 3, a coil lower support plate 4, a coil fastening screw 5, a pull rod 6, a low-temperature Dewar cylinder 7, and a low-temperature dewar Tile cover plate 8, current lead wire 9, transition line 10, sleeve insulation layer 11, sleeve low temperature insulation layer 12 and sleeve normal temperature insulation layer 13 are formed. A superconducting coil 1, a coil frame 2, an upper coil support plate 3, a coil lower support plate 4, and a coil fastening screw 5 form a superconducting magnet. The superconducting coil 1 is wound outside the bobbin 2 , the upper coil support plate 3 and the lower coil support plate 4 are respectively located at the upper and lower parts of the superconducting coil 1 , and the supercond...

Embodiment 2

[0033] Embodiment 2 The superconducting smoothing current-limiting reactor applied to high-voltage direct current transmission adopts an iron-core reactor structure with a gap. Such as Figure 6 As shown, the superconducting flat-wave current-limiting reactor consists of a superconducting coil 1, a coil frame 2, a coil upper support plate 3, a coil lower support plate 4, a coil fastening screw 5, a low-temperature Dewar cylinder 7, and a low-temperature Dewar upper cover Plate 8, current lead wire 9, transition line 10, sleeve insulation layer 11, sleeve low temperature insulation layer 12, sleeve normal temperature insulation layer 13, iron core 14, gap 15, coil upper pad 16, coil lower pad 17 and Block 18 under the iron core constitutes. A superconducting coil 1, a coil frame 2, an upper coil support plate 3, a coil lower support plate 4, and a coil fastening screw 5 form a superconducting magnet. The superconducting coil 1 is wound outside the bobbin 2 , the upper coil su...

Embodiment 3

[0035] Embodiment 3 is another iron core reactor structure with a gap used in the superconducting smoothing current-limiting reactor applied to HVDC transmission. Such as Figure 7 As shown, the superconducting flat-wave current-limiting reactor consists of a superconducting coil 1, a coil frame 2, a coil upper support plate 3, a coil lower support plate 4, a coil fastening screw 5, a low-temperature Dewar cylinder 7, and a low-temperature Dewar upper cover Plate 8, current lead wire 9, transition line 10, sleeve insulation layer 11, sleeve low temperature insulation layer 12, sleeve normal temperature insulation layer 13, iron core 14, gap 15 and iron core lower pad 18 constitute. A superconducting magnet is composed of a superconducting coil 1 , a coil frame 2 , an upper coil support plate 3 , a coil lower support plate 4 , and a coil fastening screw 5 .

[0036] Same as Embodiment 1, the superconducting coil 1 is wound outside the coil frame 2, the coil upper support plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com