Composite type modified steel reinforced concrete self-insulating wall material and preparation method thereof

A reinforced concrete and self-insulation technology, applied in the direction of insulation and building components, can solve the problems of short service life of the insulation layer, increase labor costs, increase construction procedures, etc., to reduce heat transfer, have no fire hazards, and ensure overall rigidity Effect

Inactive Publication Date: 2010-08-25

周智民

View PDF6 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to meet the energy-saving requirements of buildings, at present, the main method of energy-saving exterior walls is to add insulation layers to the exterior walls. This method not only increases the construction process, but also increases a lot of labor costs, and the service life of the insulation layer is short, which is easy to cause fire , causing a safety accident

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Login to View More

Abstract

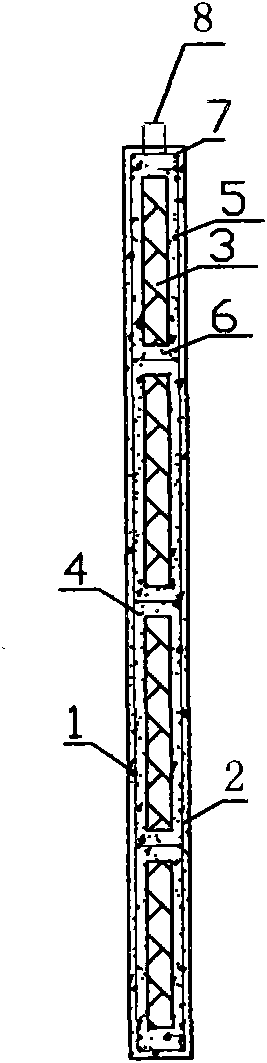

The invention relates to a composite type modified steel reinforced concrete self-insulating wall material, comprising an upper modified concrete layer, a lower modified concrete layer and a middle sandwich insulating board layer; the upper modified concrete layer is internally provided with an upper steel bar net piece layer; the lower modified concrete layer is internally provided with a lower steel bar net piece layer; the middle sandwich insulating board layer is provided with connecting holes which are internally penetrated with steel bars; the upper modified concrete layer, the middle sandwich insulating board layer and the lower modified concrete layer are connected into a whole by modified reinforced concrete formed in the connecting holes; the peripheries of the lower steel bar net piece layer and the upper steel bar net piece layer are provided with closed frame reinforced concrete beams consisting of frame steel bars and casting modified concrete, and the frame steel bar concrete beams are provided with lifting rings; and the lower steel bar net piece layer can be provided with hooks capable of containing the frame steel bars. The wall material can meet the building requirements and has the characteristics of fire prevention, insulation and energy conservation.

Description

technical field The invention belongs to the technical field of building energy-saving materials, and in particular relates to a composite modified reinforced concrete self-insulating wall material and a preparation method thereof. Background technique With the development of my country's economy, the energy-saving requirements for building exterior walls are getting higher and higher. According to relevant regulations: the average heat transfer coefficient of external walls of public Class A buildings should reach 0.7W / (m 2 .K) or less; the energy-saving requirements for the external walls of public Class B buildings require an average heat transfer coefficient of 1W / (m 2 .K) or less; the energy-saving requirements for the external walls of public Category C buildings require an average heat transfer coefficient of 1.5W / (m 2 .K) or less; the energy-saving exterior walls of residential buildings require an average heat transfer coefficient of 1.5W / (m 2 .K) below. In orde...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04B1/80

Inventor 周智民

Owner 周智民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com