Hot melt adhesion technique

A hot-melt bonding and hot-pressing technology, applied in the field of bonding technology, can solve problems such as the failure of connecting parts to meet the requirements, uneven distribution of bonding materials, unstable process, etc., saving operation time and shortening bonding completion time. , process stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention provides a hot-melt bonding process with stable and reliable process, short time and high final bonding quality.

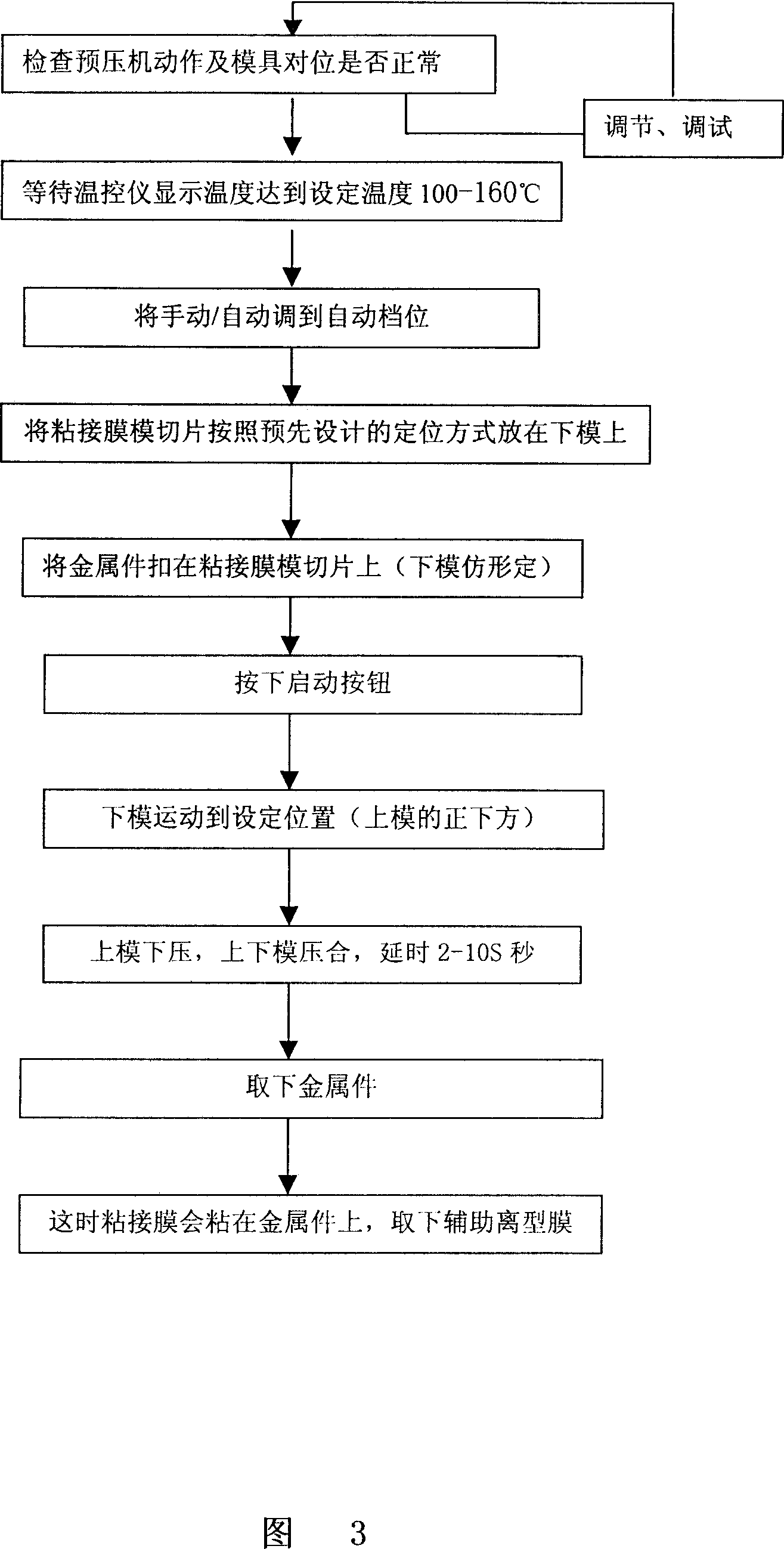

[0038] The structural features and advantages of the present invention will be described in detail below by taking the application of this process to bond a metal ring on the shell of a mobile phone as an example.

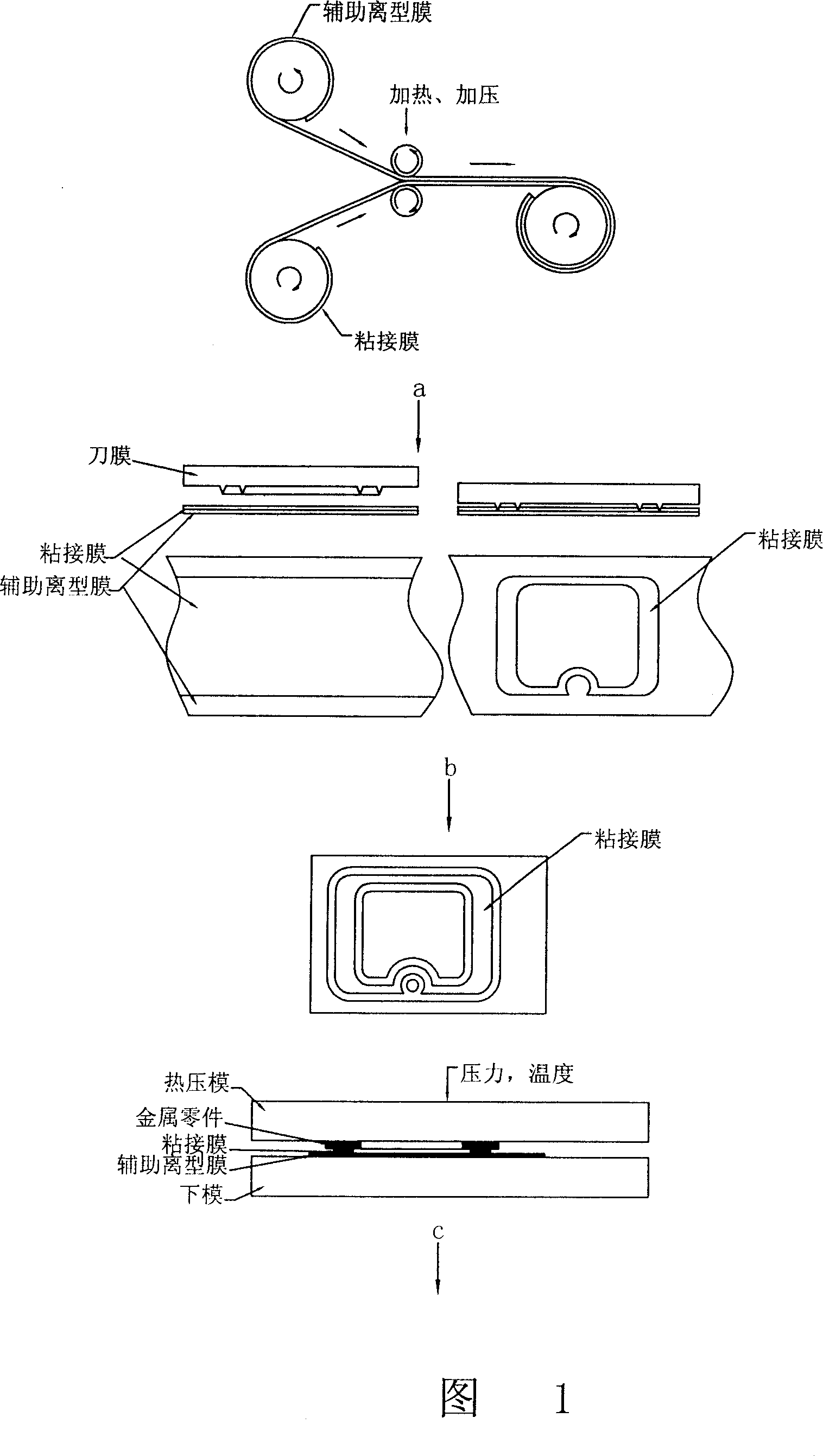

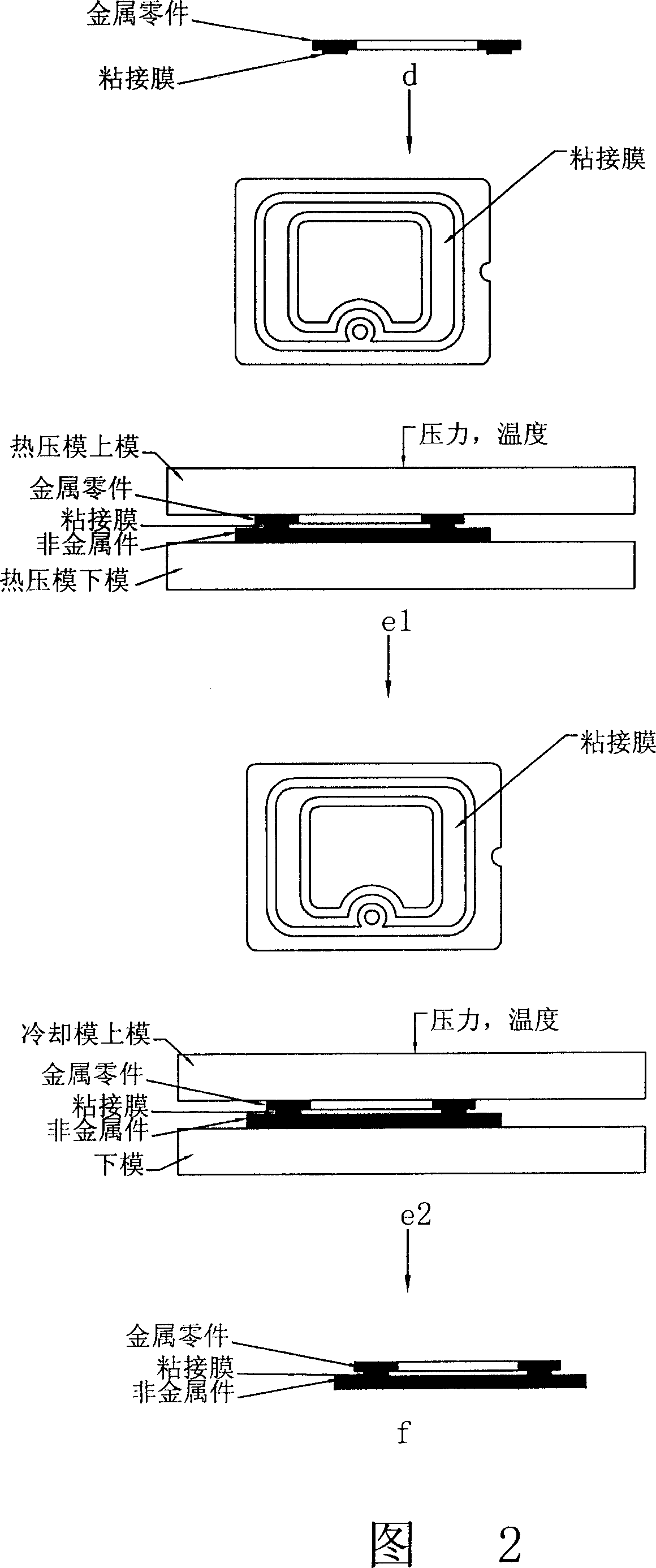

[0039] The invention relates to a hot-melt bonding hot-pressing process, which is to heat the thermoplastic polymer film material of the fiber-reinforced structure without hardening treatment as an adhesive film to a molten state, and in this state, the adhesive film serves as a connecting link with the adhesive film. The two parts to be bonded are welded, and when cooled to normal temperature, the adhesive film in the molten state solidifies and hardens, and is firmly bonded to the parts to be bonded, thereby forming a connection between the two parts to be bonded. As shown in Figure 1 and Figure 2, the present invention mainly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com