A kind of imitation twisted stone enamel decorative plate and its preparation method

A technology of twisted stone and decorative boards, which is applied in chemical instruments and methods, laminating devices, and other household appliances, etc., can solve the problems that product quality cannot meet the use requirements, and enamel decorative boards cannot meet application requirements, etc., so as to facilitate industrialization Production, easy to achieve, fine glazed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

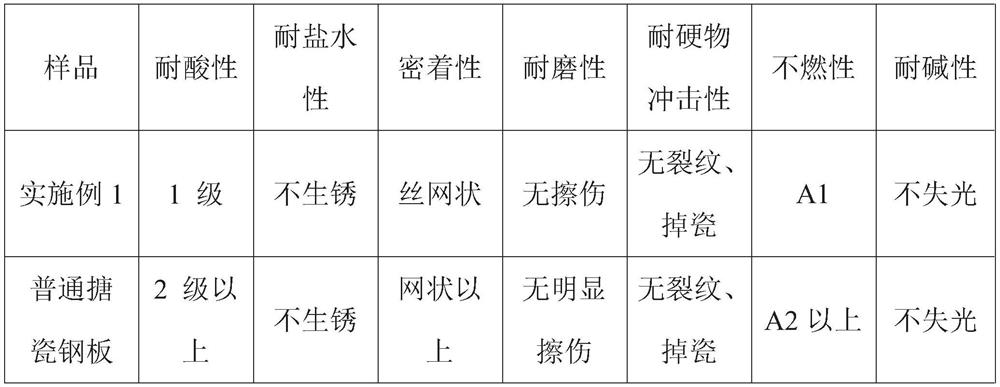

Examples

Embodiment 1

[0039] A preparation method of imitation twisted stone enamel decorative plate, comprising the following steps:

[0040] (1) CNC cutting, cutting and folding the special steel plate to be processed into the desired shape

[0041] (2) Carry out degreasing, derusting and secondary neutralization anti-rust treatment on the enamel special steel plate to be treated;

[0042] (3) The special steel plate for enamel after processing in the above-mentioned step (2) is sprayed with an electrostatic dry powder equipment for bottom glaze and top glaze;

[0043] (4) Sinter the enamel special-purpose steel plate sprayed in the above step (3) at 830° C. for 7 minutes. After sintering, the thickness of the bottom glaze and top glaze is 100 μ to obtain a white enamel steel plate substrate;

[0044] (5) The preparation process of the bottom color glaze of twisted stone is;

[0045] A: Take the following raw materials in parts by weight: 100 parts of titanium glaze, 5 parts of clay, 0.1 part o...

Embodiment 2

[0062] A preparation method of imitation twisted stone enamel decorative plate, comprising the following steps:

[0063] (1) CNC cutting, cutting and folding the special steel plate to be processed into the desired shape

[0064] (2) Carry out degreasing, derusting and secondary neutralization anti-rust treatment on the enamel special steel plate to be treated;

[0065] (3) The special steel plate for enamel after processing in the above-mentioned step (2) is sprayed with an electrostatic dry powder equipment for bottom glaze and top glaze;

[0066] (4) Sinter the enamel special steel plate sprayed in the above step (3) at 840° C. for 6 minutes. After sintering, the thickness of the bottom glaze and top glaze is 150 μ to obtain a white enamel steel plate substrate;

[0067] (5) The preparation process of the textured stone base color glaze is:

[0068] A: Take the following raw materials in parts by weight: 100 parts of titanium glaze, 7 parts of clay, 0.3 parts of bentonite...

Embodiment 3

[0085] A preparation method of imitation twisted stone enamel decorative plate, comprising the following steps:

[0086] (1) CNC cutting, cutting and folding the special steel plate to be processed into the desired shape

[0087] (2) Carry out degreasing, derusting and secondary neutralization anti-rust treatment on the enamel special steel plate to be treated;

[0088] (3) The special steel plate for enamel after processing in the above-mentioned step (2) is sprayed with an electrostatic dry powder equipment for bottom glaze and top glaze;

[0089] (4) Sinter the enamel special steel plate sprayed in the above step (3) at 850° C. for 5 minutes. After sintering, the thickness of the bottom glaze and top glaze is 180 μ to obtain a white enamel steel plate substrate;

[0090] (5) The preparation process of the textured stone base color glaze is:

[0091] A: Take the following raw materials in parts by weight: 100 parts of titanium glaze, 8 parts of clay, 0.5 part of bentonite,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com