Raw material matting glaze

A matte glaze and raw material technology, applied in the field of ceramic glazes, to achieve the effect of fine glaze, wide firing range, and solve the problems of gloss and texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

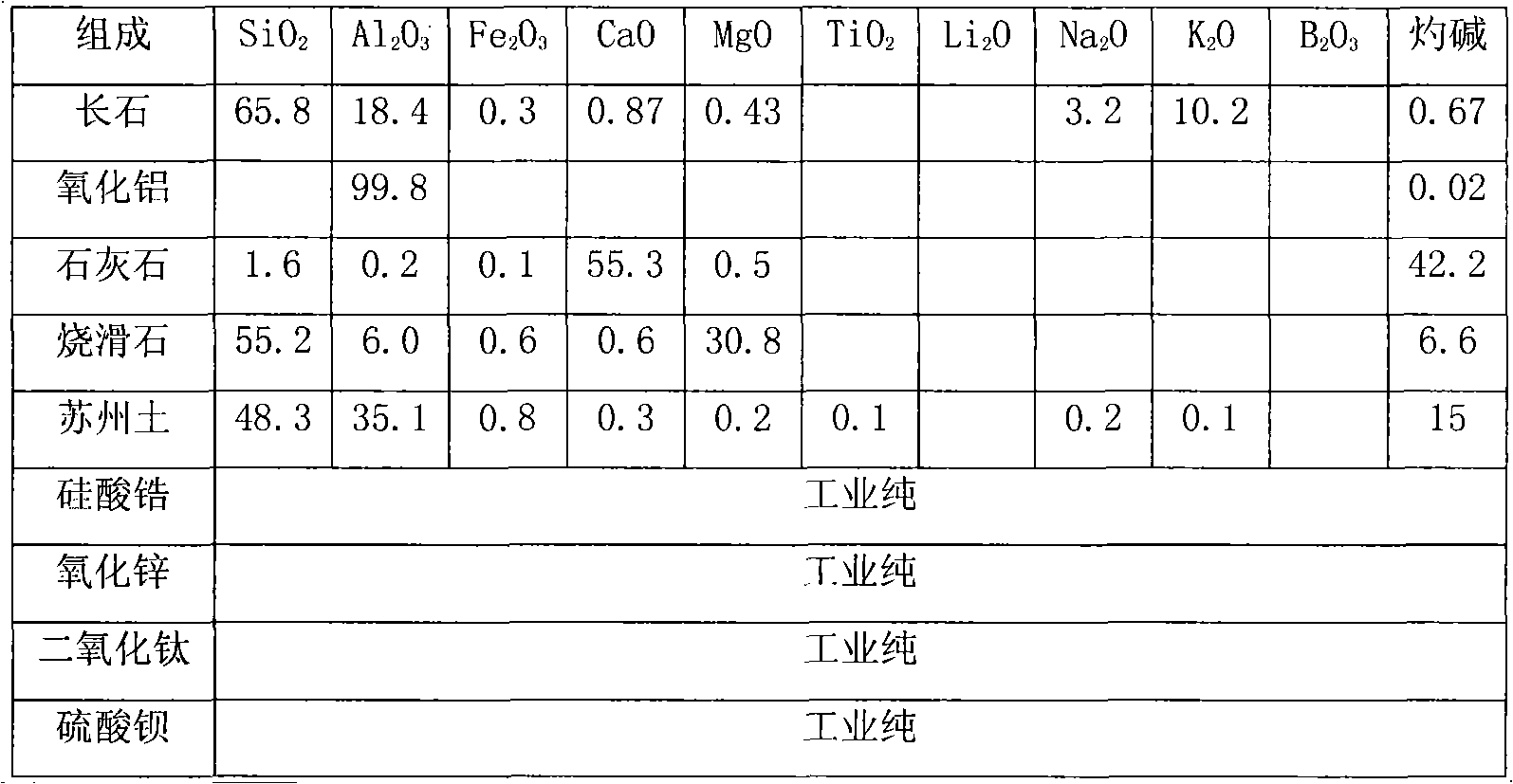

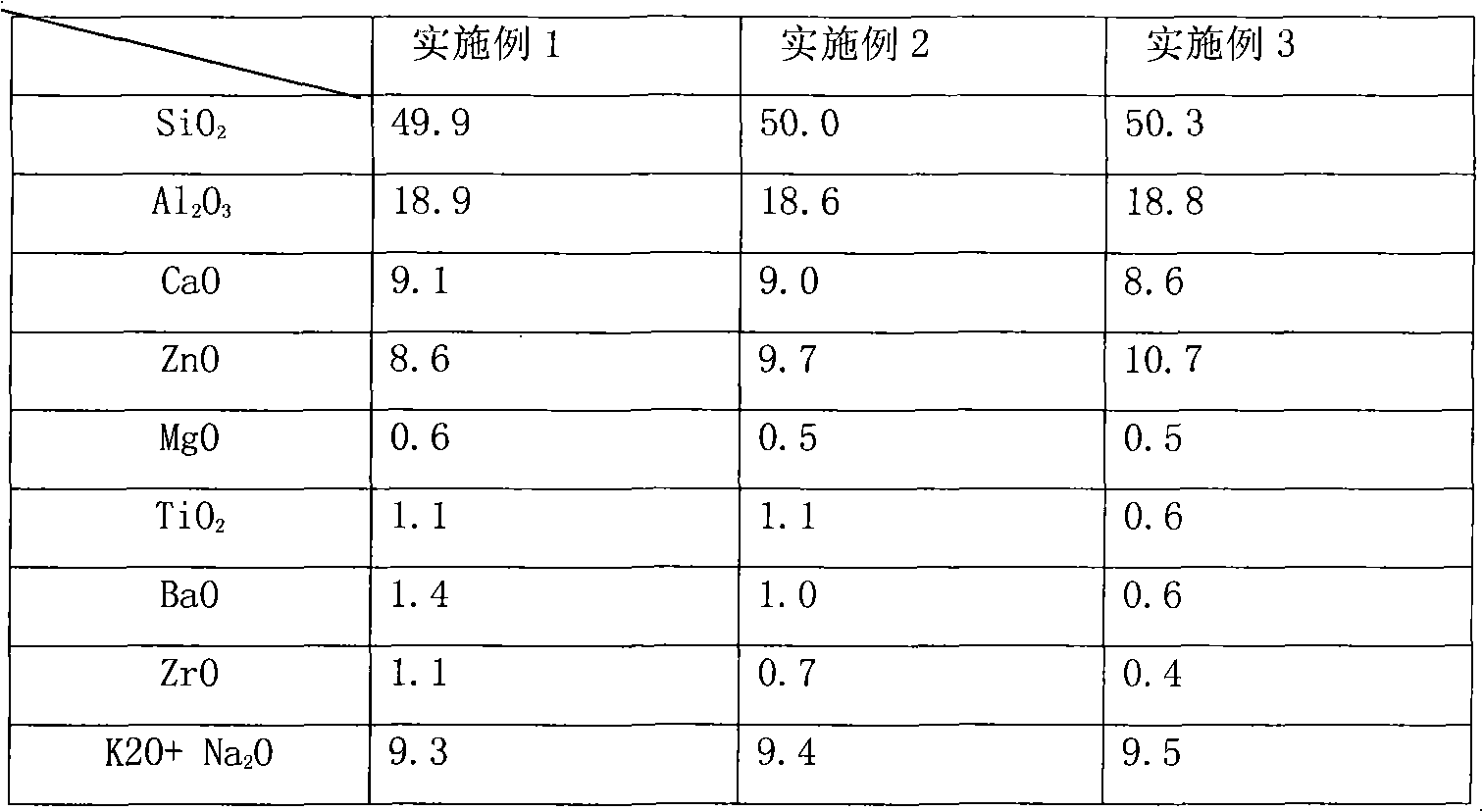

[0028] The raw matte glaze described in Example 1 is prepared from the following raw materials by weight percentage:

[0029] Feldspar 64.0%, alumina 4.5%, zinc oxide 8.0%, limestone 14.0%, calcined talc 1.5%, titanium dioxide 1.0%, zirconium silicate 1.5%, barium carbonate 1.5%, and Suzhou soil 4.0%.

[0030] Firstly, various raw materials are weighed according to the above-mentioned ratio; secondly, they are added into a ball mill at the ratio of batch material: ball stone: water=1:2:1, and then 0.05% of the dispersant CMC is added to make a glaze slurry. The size of the glaze slurry is controlled to be less than 10 μm. The particles with a particle size of 80 to 87% are made into a slurry that is aged for 48 hours for use.

[0031] The prepared glaze slurry is applied to the unfired bone china greenware and fired at a temperature of 1120-1150°C to obtain a high-quality matte bone china product. The porcelain surface of the product is as polished as wax, and it has a smooth, delic...

Embodiment 2

[0033] The raw matte glaze described in Example 2 is prepared from the following raw materials by weight percentage:

[0034] Feldspar 64.5%, alumina 4.0%, zinc oxide 9.0%, limestone 14.0%, calcined talc 1.0%, titanium dioxide 1.0%, zirconium silicate 1.0%, barium carbonate 1.0%, and Suzhou soil 4.5%.

[0035] Firstly, various raw materials are weighed according to the above-mentioned ratio; secondly, they are added into a ball mill at the ratio of batch material: ball stone: water=1:2:1, and then 0.05% of the dispersant CMC is added to make a glaze slurry. The size of the glaze slurry is controlled to be less than 10 μm. The particles with a particle size of 80 to 87% are made into a slurry that is aged for 48 hours for use.

[0036] The prepared glaze slurry is applied to the unfired bone china greenware and fired at a temperature of 1130-1170°C to obtain a high-quality matte bone china product. The porcelain surface of the product is as polished as wax, and it has a smooth, delic...

Embodiment 3

[0038] The raw material matte glaze described in Example 3 is prepared from the following raw materials by weight percentage:

[0039] Feldspar 65.0%, alumina 4.0%, zinc oxide 10.0%, limestone 13.5%, calcined talc 1.0%, titanium dioxide 0.5%, zirconium silicate 0.5%, barium carbonate 0.5%, Suzhou soil 5.0%.

[0040] Firstly, various raw materials are weighed according to the above-mentioned ratio; secondly, they are added into a ball mill at the ratio of batch material: ball stone: water=1:2:1, and then 0.05% of the dispersant CMC is added to make a glaze slurry. The size of the glaze slurry is controlled to be less than 10 μm. The particles with a particle size of 80 to 87% are made into a slurry that is aged for 48 hours for use.

[0041] The prepared glaze slurry is applied to the unfired bone china greenware and fired at a temperature of 1140-1180°C to obtain a high-quality matte bone china product. The porcelain surface of the product is as polished as wax, and it has a smooth,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com