Black ceramic and preparation method thereof

A technology for black ceramics and ceramic bodies, applied in the field of ceramic materials, can solve the problems of high cost and product color fluctuation, and achieve the effects of high density, stable black color development and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

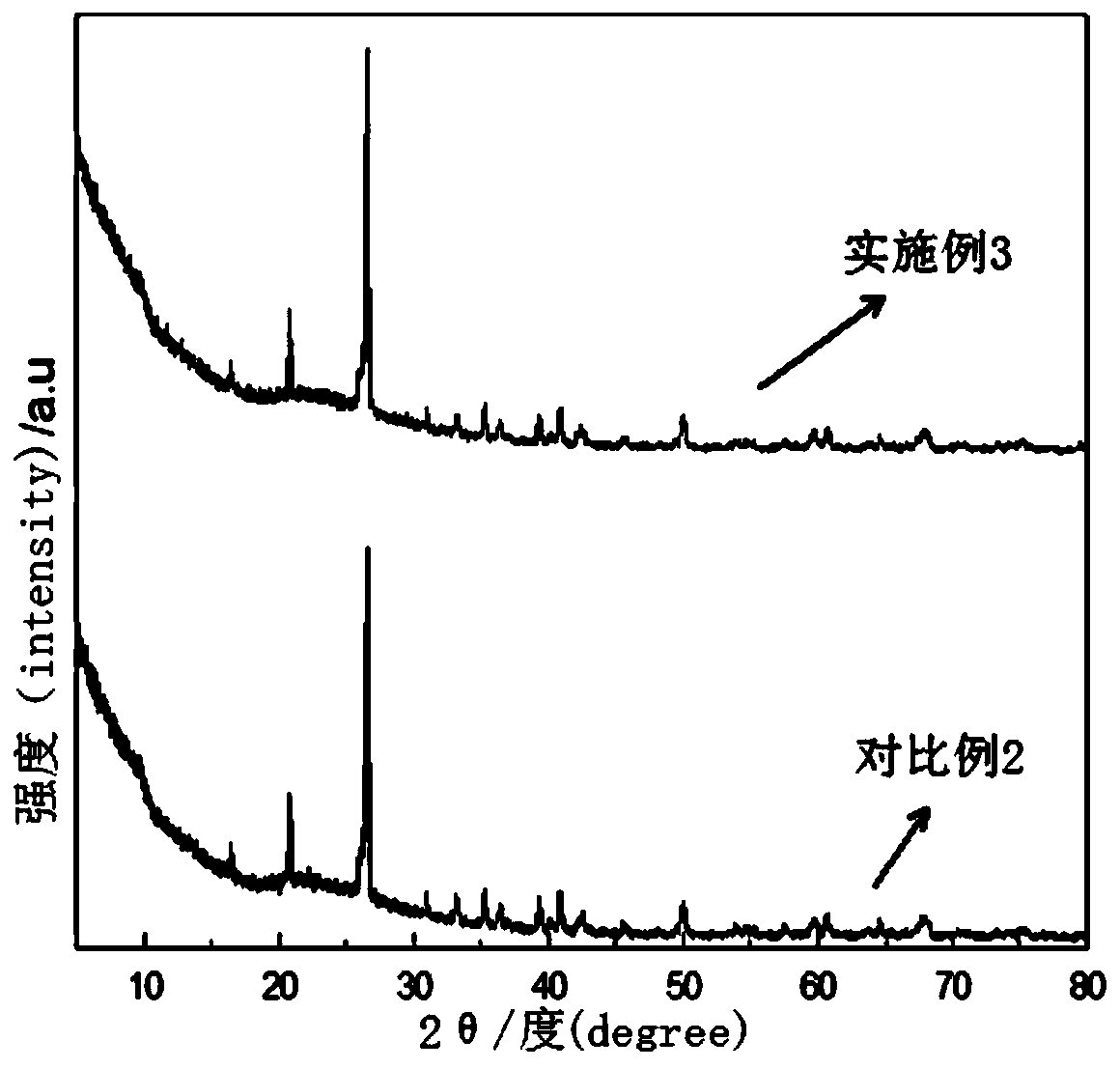

[0044] This embodiment provides a method for preparing black ceramics, which includes the following steps: sintering a ceramic body and carbon black in a closed environment to obtain the black ceramics.

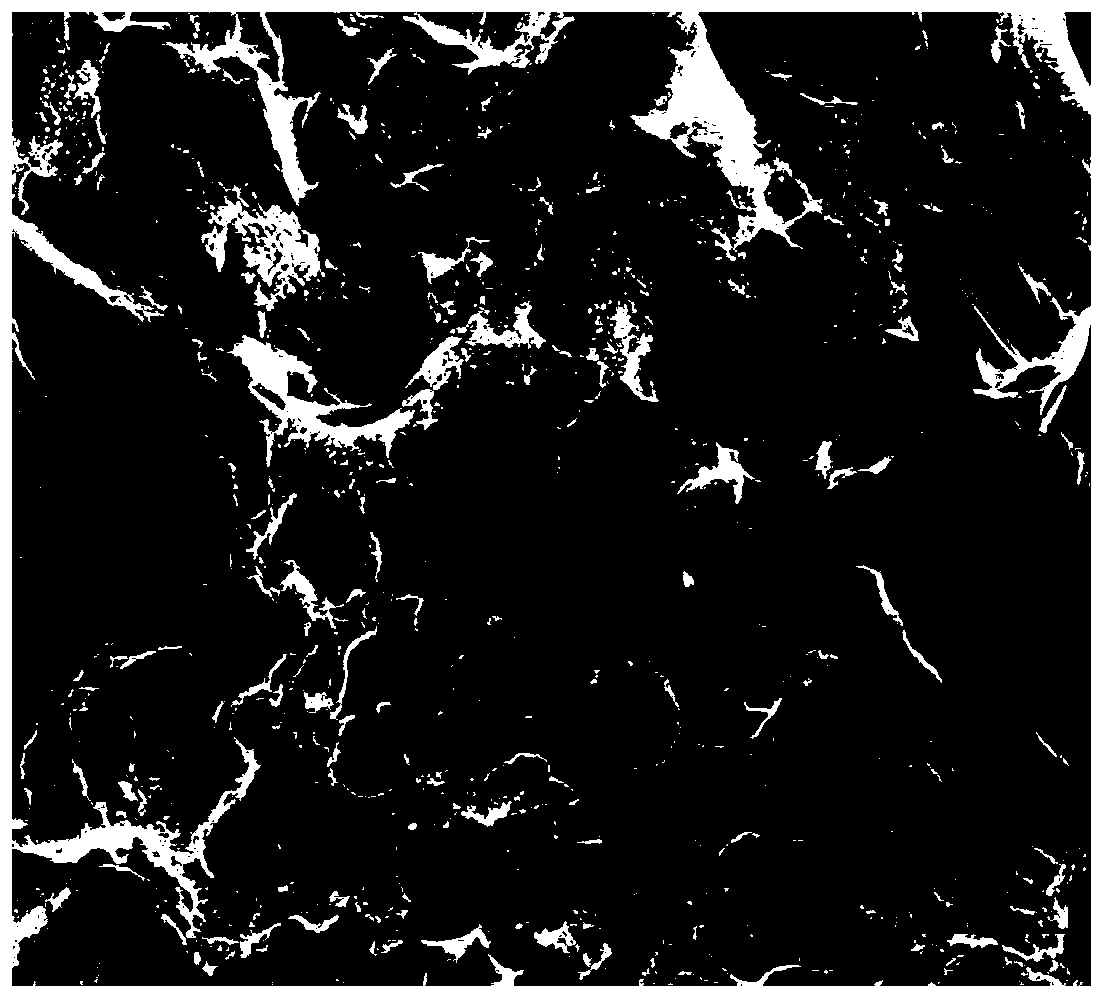

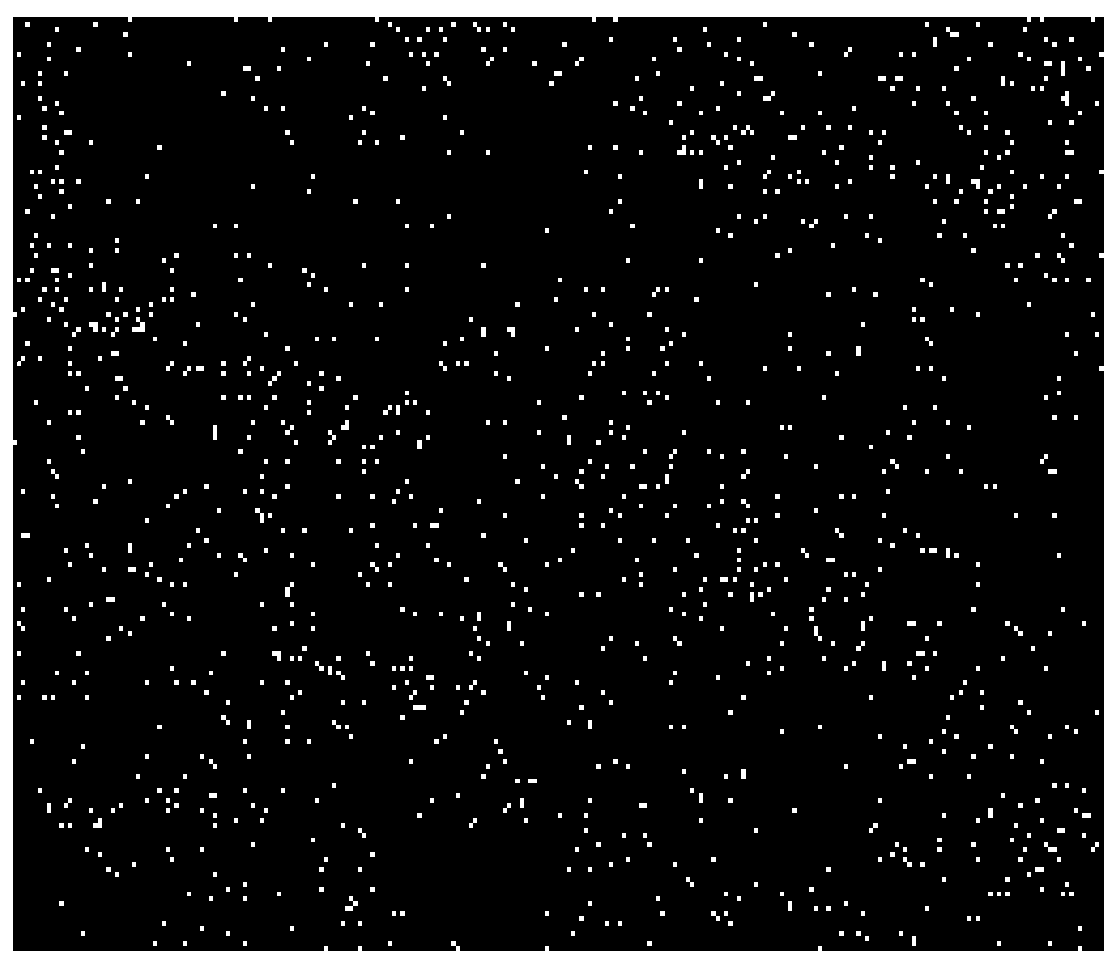

[0045]The invention utilizes the characteristics of high specific surface area and high activity of carbon black to sinter the ceramic body and carbon black at high temperature in a closed environment, and under the action of high-temperature self-infiltration of C element in carbon black, calcine to obtain pure black color ceramics.

[0046] What the inventor needs to explain is that carbon black is different from other carbon-containing substances (such as graphite), and its crystallization is very incomplete, with many defects and high activity. , heavy oil, fuel oil, etc.) are the products obtained by incomplete combustion or thermal decomposition under the condition of insufficient air. Carbon black, as a light, loose and extremely fine black powder, has a very large su...

Embodiment 1

[0069] The present embodiment provides a kind of preparation method of black ceramic, comprises the steps:

[0070] 1) Preparation of ceramic green body: in terms of mass fraction, the chemical composition is 70.5% SiO 2 , 19.08%Al 2 o 3 , 0.2% CaO, 0.6% MgO, 2.62% K 2 O, 0.75% Na 2 O, 0.25% Fe 2 o 3 And the ceramic green body with 6% loss on ignition is molded and dried, and then calcined at a low temperature of 750° C. to obtain a ceramic green body;

[0071] 2) Lay a layer of carbon black on the bottom of the sealable alumina crucible, that is, the first carbon black layer, and then place the ceramic green body obtained in step 1) on the first carbon black layer, and the ceramic green body The green body is located in the center of the crucible, and the central axis of the ceramic green body coincides with the central axis of the crucible;

[0072] 3) filling carbon black in the inner cavity of the ceramic green body and around the ceramic green body so that the carb...

Embodiment 2

[0080] The present embodiment provides a kind of preparation method of black ceramic, comprises the steps:

[0081] 1) Preparation of ceramic green body: in terms of mass fraction, the chemical composition is 70.5% SiO 2 , 19.08%Al 2 o 3 , 0.2% CaO, 0.6% MgO, 2.62% K 2 O, 0.75% Na 2 O, 0.25% Fe 2 o 3 And the ceramic green body with 6% loss on ignition is molded and dried, and then calcined at a low temperature of 750° C. to obtain a ceramic green body;

[0082] 2) Lay a layer of carbon black on the bottom of the sealable alumina crucible, that is, the first carbon black layer, and then place the ceramic green body obtained in step 1) on the first carbon black layer, and the ceramic green body The green body is located in the center of the crucible, and the central axis of the ceramic green body coincides with the central axis of the crucible;

[0083] 3) filling carbon black in the inner cavity of the ceramic green body and around the ceramic green body so that the carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com