Method for preparing zirconium silicate coated carbon nanosphere ceramic black pigment

A technology of nano-carbon spheres and black materials, applied in the direction of fibrous fillers, etc., can solve the problems of low wrapping rate, poor color rendering, grayish chroma, etc., and achieve high wrapping rate, dense wrapping layer, and pure hair color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

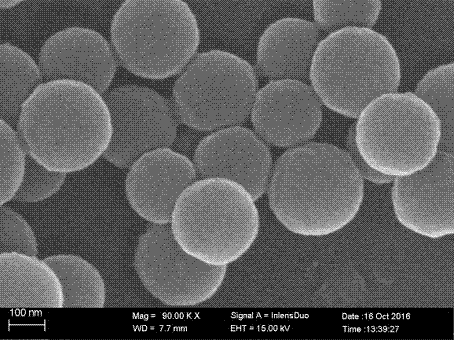

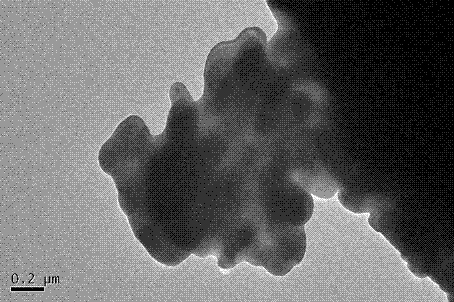

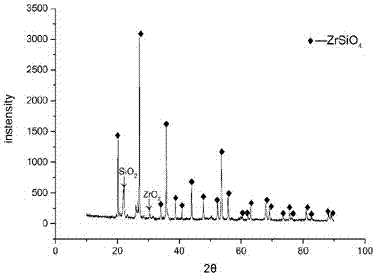

[0028] Dissolve 38g of glucose in 350ml of deionized water, stir evenly, pour the solution into a 400ml reaction kettle, then place it in an oven at 160°C for 10 hours, filter the reacted solution with ethanol and deionized water Wash three times to obtain carbon sphere particles, then disperse the carbon sphere particles in 1mol / L sodium hydroxide solution and stir at 38°C for 2.5h, then wash the pH value of the sodium hydroxide solution with deionized water to 7, and finally dry Obtain nano-carbon sphere powder; take 0.0733 g of the prepared nano-carbon sphere powder and add it to 14.66 g of ammonia water with a mass fraction of 20%, and disperse into a carbon sphere suspension by ultrasonication for 30 minutes. Weigh 0.744g ethyl orthosilicate and dissolve in 20ml ethanol and 20ml water, stir at room temperature for 1.5h, add 0.826g zirconyl nitrate and continue stirring at room temperature for 1h. The fully stirred silicon-zirconium mixed solution was added dropwise to the...

Embodiment 2

[0031] Dissolve 45g of starch in 350ml of deionized water, stir evenly, pour the solution into a 400ml reaction kettle, then place it in an oven at 180°C for 8 hours, filter the reacted solution with ethanol and deionized water Wash three times to obtain carbon sphere particles, then disperse the carbon sphere particles in 1mol / L sodium hydroxide solution and stir at 50°C for 4 hours, then wash the pH value of the sodium hydroxide solution with deionized water to 7, and finally dry to obtain Nano-carbon sphere powder; after drying, obtain nano-carbon sphere powder; take 0.0814 g of the prepared nano-carbon sphere powder and add it to 16.3 g of ammonia water with a mass fraction of 25%, and disperse it into a carbon sphere suspension by ultrasonication for 30 minutes. Weigh 0.625g ethyl orthosilicate and dissolve in 20ml ethanol and 20ml water, stir at room temperature for 3h, add 0.644g zirconium oxychloride and continue stirring at room temperature for 3h. The fully stirred s...

Embodiment 3

[0034] Dissolve 56g of fructose in 350ml of deionized water, stir evenly, pour the solution into a 400ml reaction kettle, then place it in an oven at 200°C for 6 hours, filter the reacted solution with ethanol and deionized water Wash three times to obtain carbon sphere particles, then disperse the carbon sphere particles in 1mol / L potassium hydroxide solution and stir at 65°C for 6 hours, then wash the pH value of the potassium hydroxide solution with deionized water to 7, and finally dry to obtain Nano-carbon sphere powder; obtain nano-carbon sphere powder after drying; take 0.9165 g of the prepared nano-carbon sphere powder and add it to 18.33 g of ammonia water with a mass fraction of 20%, and disperse it into a carbon sphere suspension by ultrasonication for 30 minutes. Weigh 0.833g ethyl orthosilicate and dissolve in 20ml ethanol and 20ml water, stir at room temperature for 6h, add 0.862g zirconium oxychloride and continue stirring at room temperature for 5h. The fully s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com