Method for harvesting dunaliella salina by using waste spirulina culture liquid

A technology of spirulina and salina, which is applied in the field of harvesting salina by using spirulina culture waste liquid, can solve the problems of high cost, low flocculation efficiency, poor performance, etc., and achieve the effect of reducing production cost and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

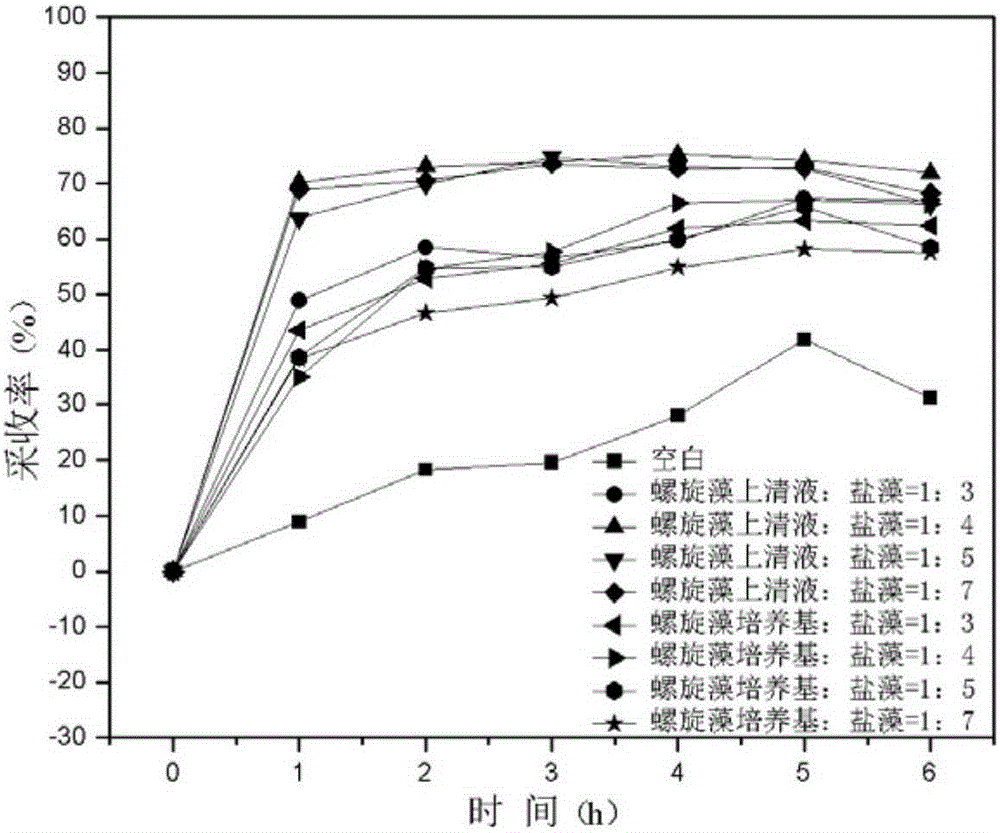

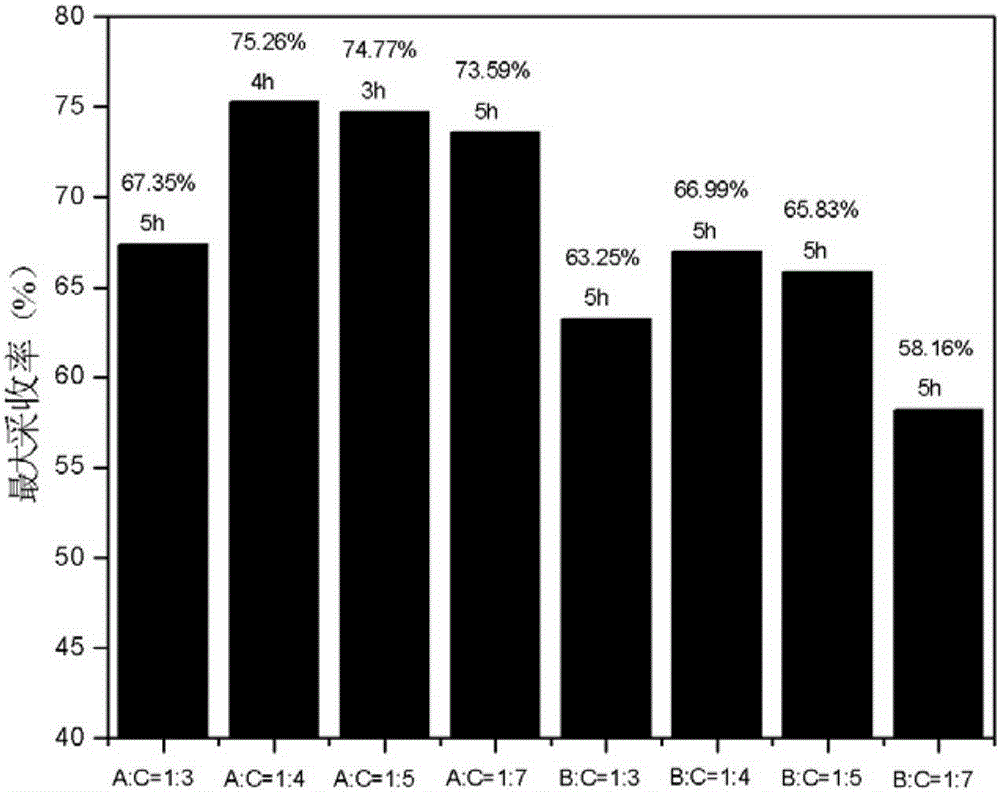

[0020] 1. Take 50ml of spirulina liquid that has been cultivated to the logarithmic phase, centrifuge it in a centrifuge at 4000rpm for 5min, take 20ml of the supernatant and add it to 80ml of salina algae liquid, stir at 150rpm for 3min, let stand for 4h, every hour Determination of absorbance OD 630 , the determination formula is (OD 630初始 -OD 630测定 ) / OD 630初始 , the maximum recovery rate is 75.26%. The algae liquid cultured for 7-10 days can be used, and the pH of the algae liquid is in the alkaline range.

[0021] 2. Take 20ml of fresh spirulina culture medium and add it to 80ml of salina algae liquid, stir for 3min with a magnet at 150rpm, as a comparative experiment, let it stand for 5h, and measure the absorbance OD every hour 630 , the determination formula is (OD 630初始 -OD 630测定 ) / OD 630初始 , the maximum recovery rate is 66.99%.

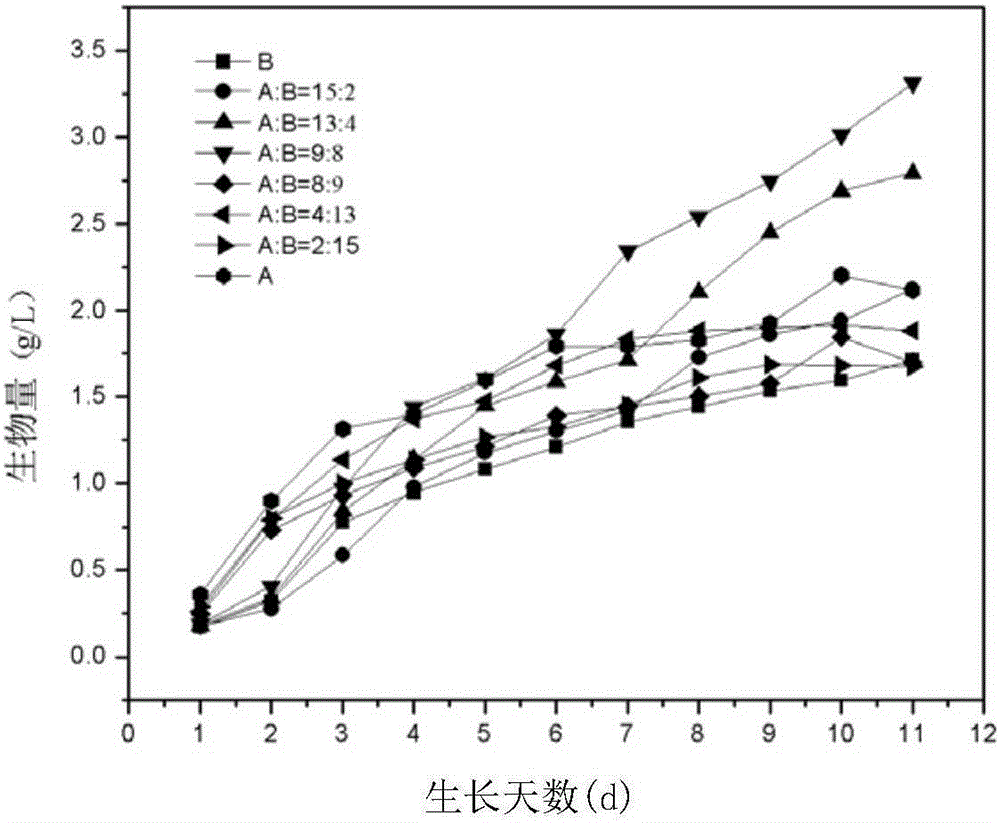

[0022] 3. Take the supernatant after flocculation in step 1 and fresh medium according to the ratio of 85:0, 2:15, 4:13, 8:9, 9:8, 13...

Embodiment 2

[0024] 1. Take 50ml of spirulina liquid that has been cultivated to the logarithmic phase, centrifuge it in a centrifuge at 4000rpm for 5min, take 17ml of the supernatant and add it to 83ml of salina liquid, stir with a magnet at 150rpm for 3min, let it stand for 3h, every hour Determination of absorbance OD 630 , the determination formula is (OD 630初始 -OD 630测定 ) / OD 630初始 , the maximum recovery rate is 74.77%.

[0025] 2. Take 17ml of fresh spirulina medium and add it to 83ml of salina algae liquid, stir for 3min at 150rpm with a magnet, let stand for 5h, measure the absorbance OD every hour 630 , the determination formula is (OD 630初始 -OD 630测定 ) / OD 630初始 , the maximum recovery rate is 65.83%.

Embodiment 3

[0027] 1. Take 50ml of the spirulina liquid that has been cultivated to the logarithmic phase, centrifuge it in a centrifuge at 4000rpm for 5min, take 12.5ml of the supernatant and add it to 87.5ml of the salina algae liquid, stir it at 150rpm for 3min, and let it stand for 5h. Measure the absorbance OD every hour 630 , the determination formula is (OD 630初始 -OD 630测定 ) / OD 630初始 , the maximum recovery rate is 73.59%.

[0028] 2. Take 12.5ml of fresh spirulina medium and add it to 87.5ml of salina algae liquid, stir for 3min with a magnet at 150rpm, let it stand for 5h, and measure the absorbance OD every hour 630 , the determination formula is (OD 630初始 -OD 630测定 ) / OD 630初始 , the maximum recovery rate is 58.16%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com