Production device and production method of caprolactam

A caprolactam, production device technology, applied to the preparation of lactam, separation/purification of lactam, chemical instruments and methods, etc., can solve the problem of low conversion rate of cyclohexanone oxime, easy deactivation of catalyst, catalyst replacement and device shutdown risk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

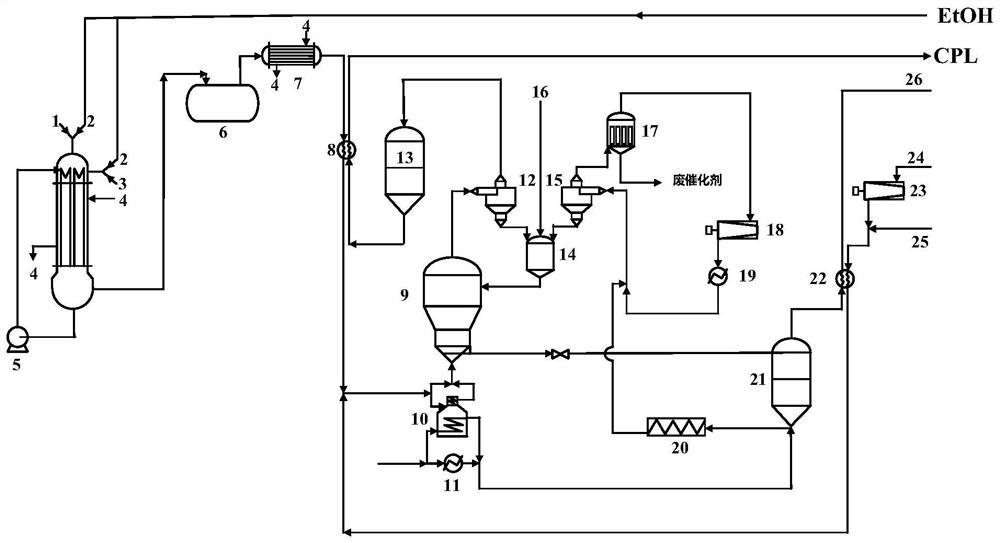

[0089] According to a preferred embodiment provided by the present invention, the production device of the caprolactam, such as figure 1 As shown, it includes: cyclohexanone oxime evaporation gasification system 4, mist separation system, fluidized bed reaction system, moving bed reaction system 13 connected in series;

[0090] The device also includes a reaction solvent recovery circulation system and a carrier gas recovery circulation system, the reaction solvent recovery circulation system is used to recover the solvent, and the carrier gas recovery circulation system is used to recover the carrier gas;

[0091] The cyclohexanone oxime evaporation gasification system 4 is provided with a carrier gas inlet 1, an ethanol inlet 2 and a cyclohexanone oxime inlet 3; the ethanol inlet 2 includes a first ethanol inlet and a second ethanol inlet, and the first ethanol The inlet and the carrier gas inlet 1 are set to the same inlet so that part of the ethanol and the carrier gas are...

specific Embodiment approach

[0130] The present invention has a wide selection range for the content of silicon and oxygen in the molecular sieve. In a specific embodiment, based on the total amount of molecular sieve, in the molecular sieve, the content of silicon, oxygen and metal The sum of the contents of the elements is 100%.

[0131] According to a preferred embodiment of the present invention, based on the total amount of molecular sieves, the content of the metal elements in the molecular sieves is 6-90 μg / g, preferably 30-80 μg / g. Specifically, for example, 30 μg / g, 35 μg / g, 40 μg / g, 45 μg / g, 50 μg / g, 55 μg / g, 60 μg / g, 70 μg / g, 75 μg / g, 80 μg / g, and among these values Any value in the range formed by any two of . In this preferred embodiment, the catalytic performance of the catalyst is better, which is more conducive to improving the conversion rate of cyclohexanone oxime and the selectivity of caprolactam. In the present invention, if the content of the metal element is too much, it is possib...

preparation example 1

[0261] Preparation example 1 (spray molding)

[0262] (1) 482kg content is that the ethanol of 95% by weight and the tetrapropyl ammonium hydroxide aqueous solution that 302kg content is 22.5% by weight are added respectively to 2M 3 In the stainless steel reaction kettle, stir, then add 347kg orthosilicate ethyl ester, continue to stir, then add 332kg water and 38.6 grams of Fe(NO 3 ) 3 9H 2 O, continue stirring for 4 hours at room temperature to obtain a colloidal mixture; wherein, SiO 2 The molar ratio of ethyl orthosilicate: ethanol: tetrapropylammonium hydroxide: water is 1:10:0.2:20; 2 The weight ratio of tetraethyl orthosilicate in terms of metal elements to the metal source in terms of metal elements is 18666:1;

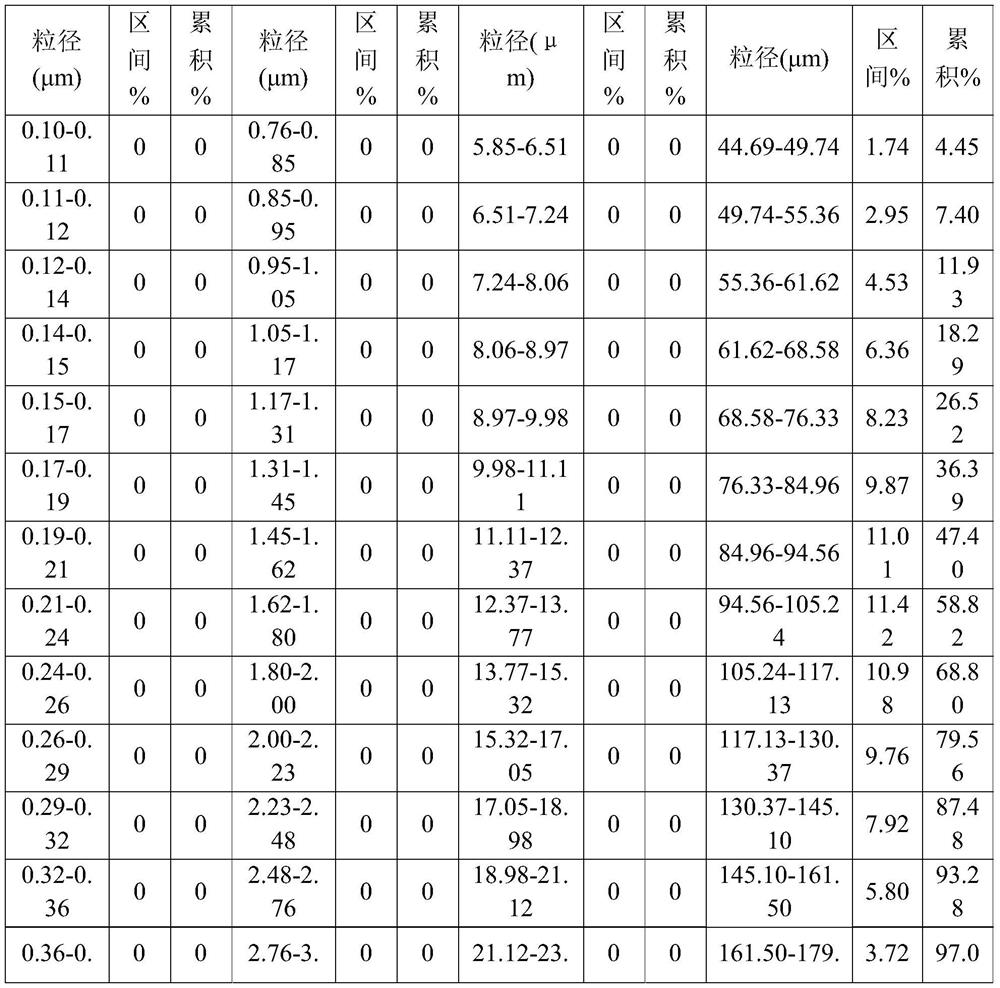

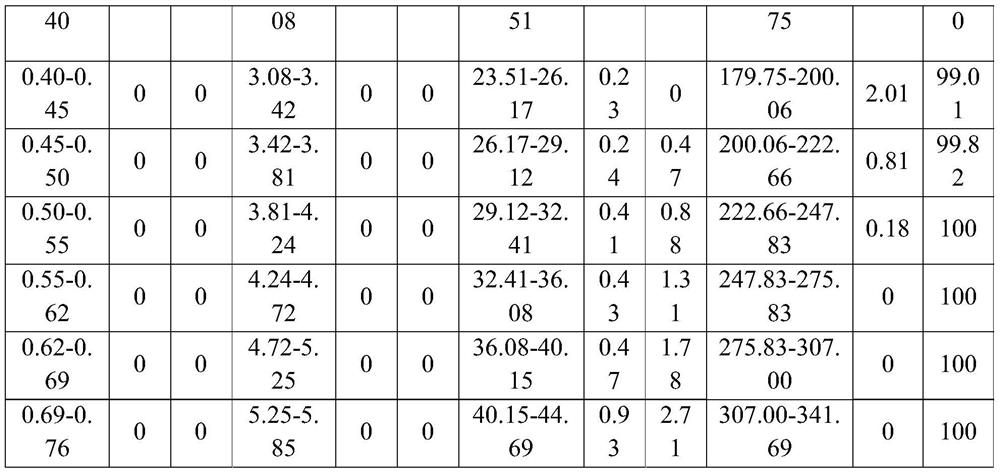

[0263] (2) The above-mentioned colloidal mixture is subjected to ethanol-hydrothermal system crystallization, and the conditions of the crystallization include: first crystallize at 70°C for 1 day, and then crystallize at 100°C for 2 days; obtain crystall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| External specific surface area | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com