Automatic film tearing machine

A film machine, automatic technology, applied in the field of film tearing machine, can solve the problems of easily damaged fingers, unfavorable processing, surface contamination of intermediate products, etc., to achieve the effect of simple and clear operation and stable running performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

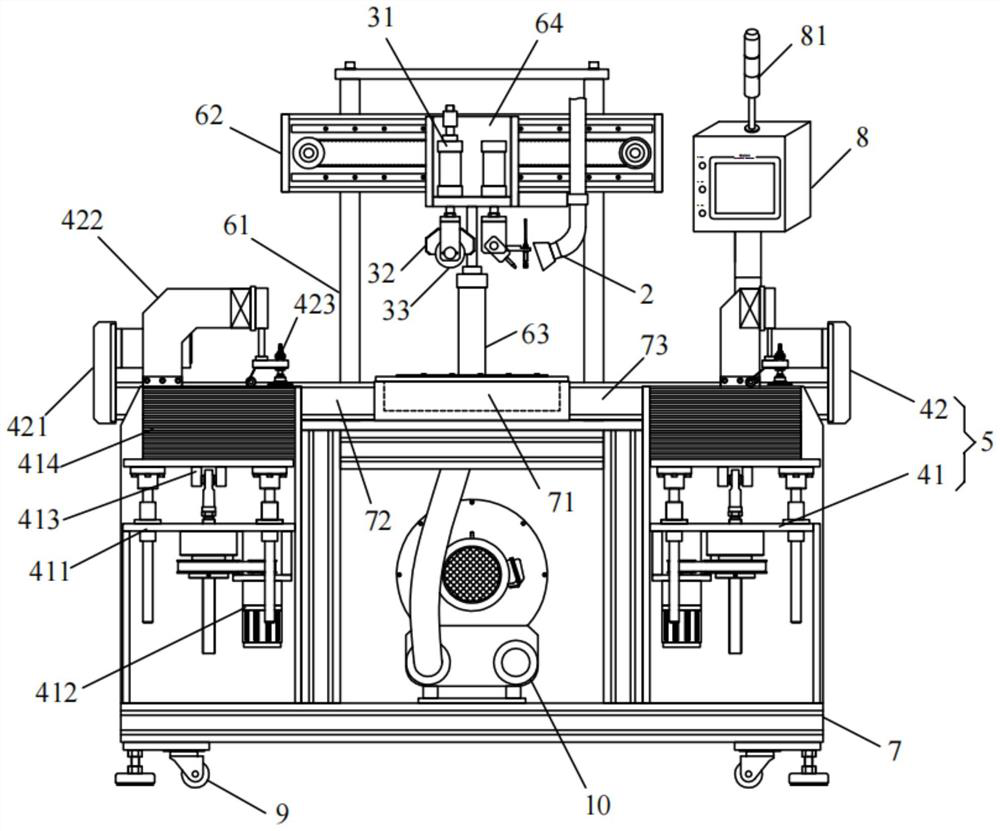

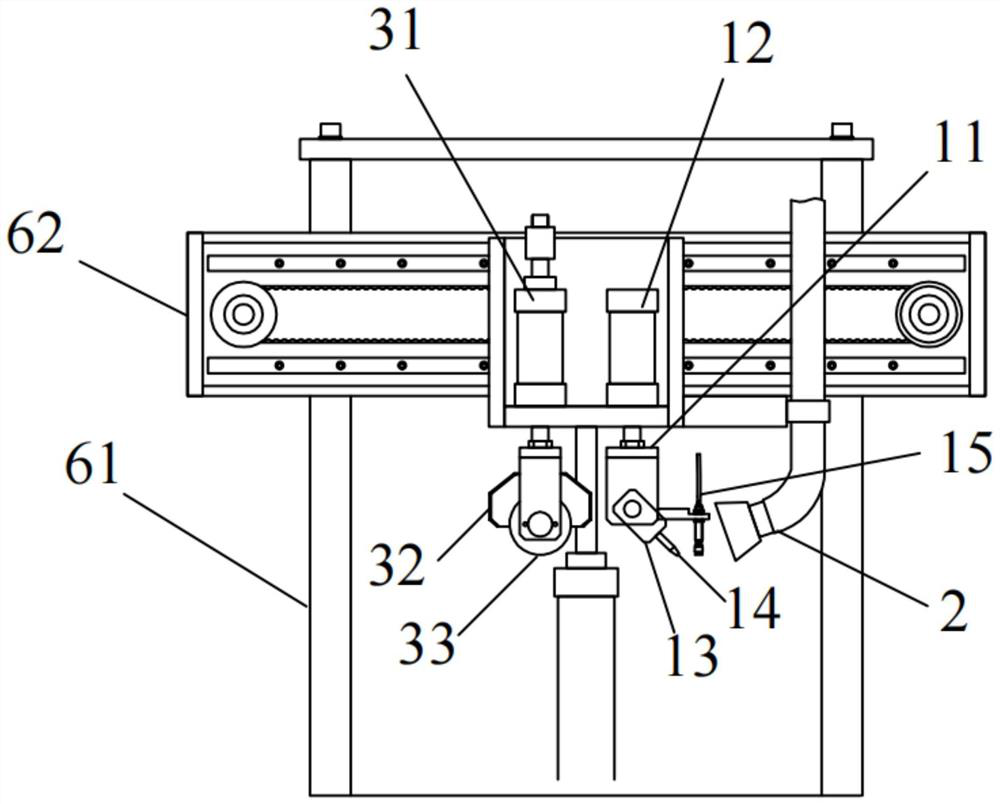

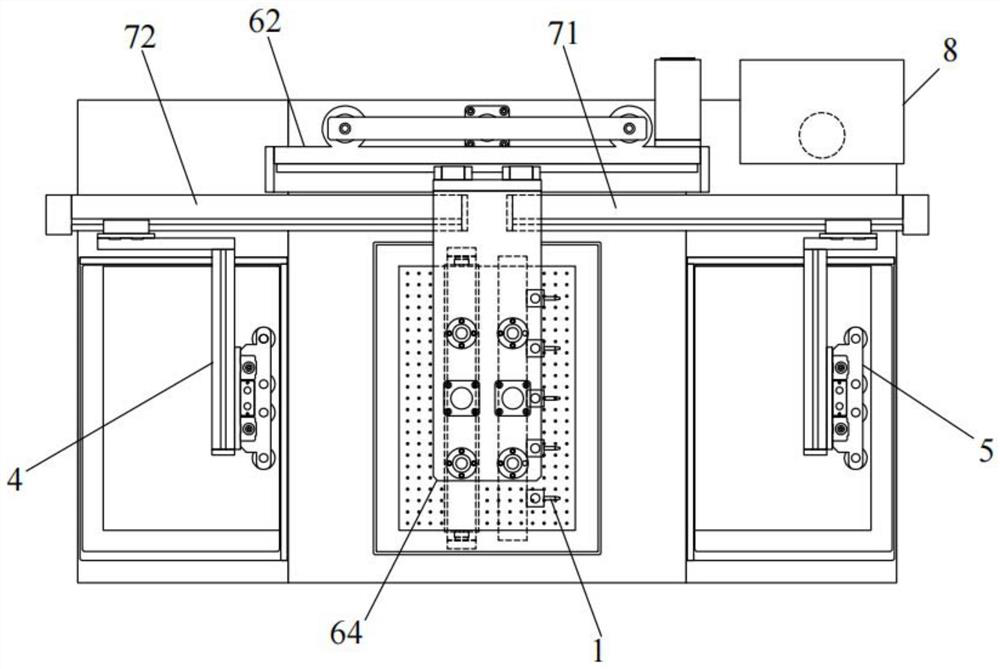

[0019] For the convenience of those skilled in the art to understand, below in conjunction with embodiment and appended Figure 1-3 To further illustrate the present invention, the content mentioned in the embodiment is not to limit the present invention.

[0020] See Figure 1-3 , an automatic film tearing machine, comprising an air blowing mechanism 1, a waste suction pipe 2, a hot pressing mechanism, an automatic feeding mechanism 4, an automatic unloading mechanism 5, a fixing mechanism and a frame 7, and the fixing mechanism includes a lifting frame 61, Lateral movement mechanism 62 and first lift cylinder 63, described lifting frame 61 is arranged on the upper end surface of described frame 7, and described lateral movement mechanism 62 is sleeved in described lifting frame 61, and the below of described lateral movement mechanism 62 A workbench 71 is provided, the automatic film tearing machine is provided with a horizontal X-axis moving path and a longitudinal Y-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com