Patents

Literature

35results about How to "Will not affect stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

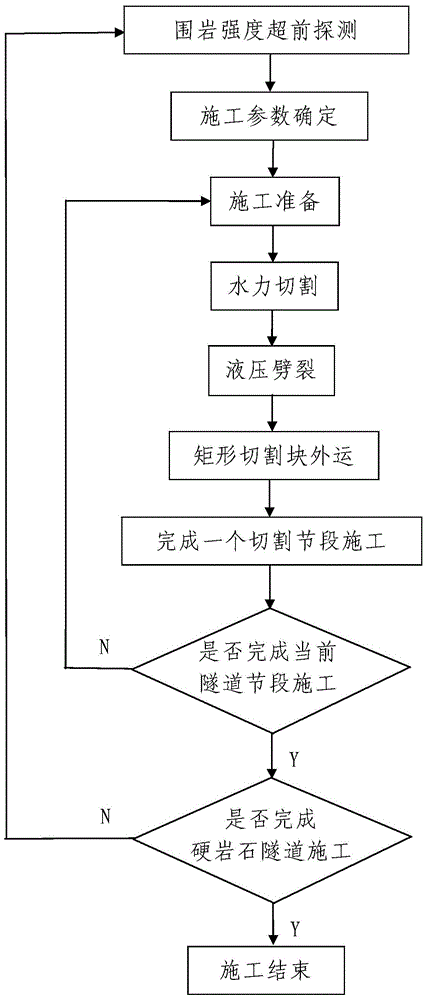

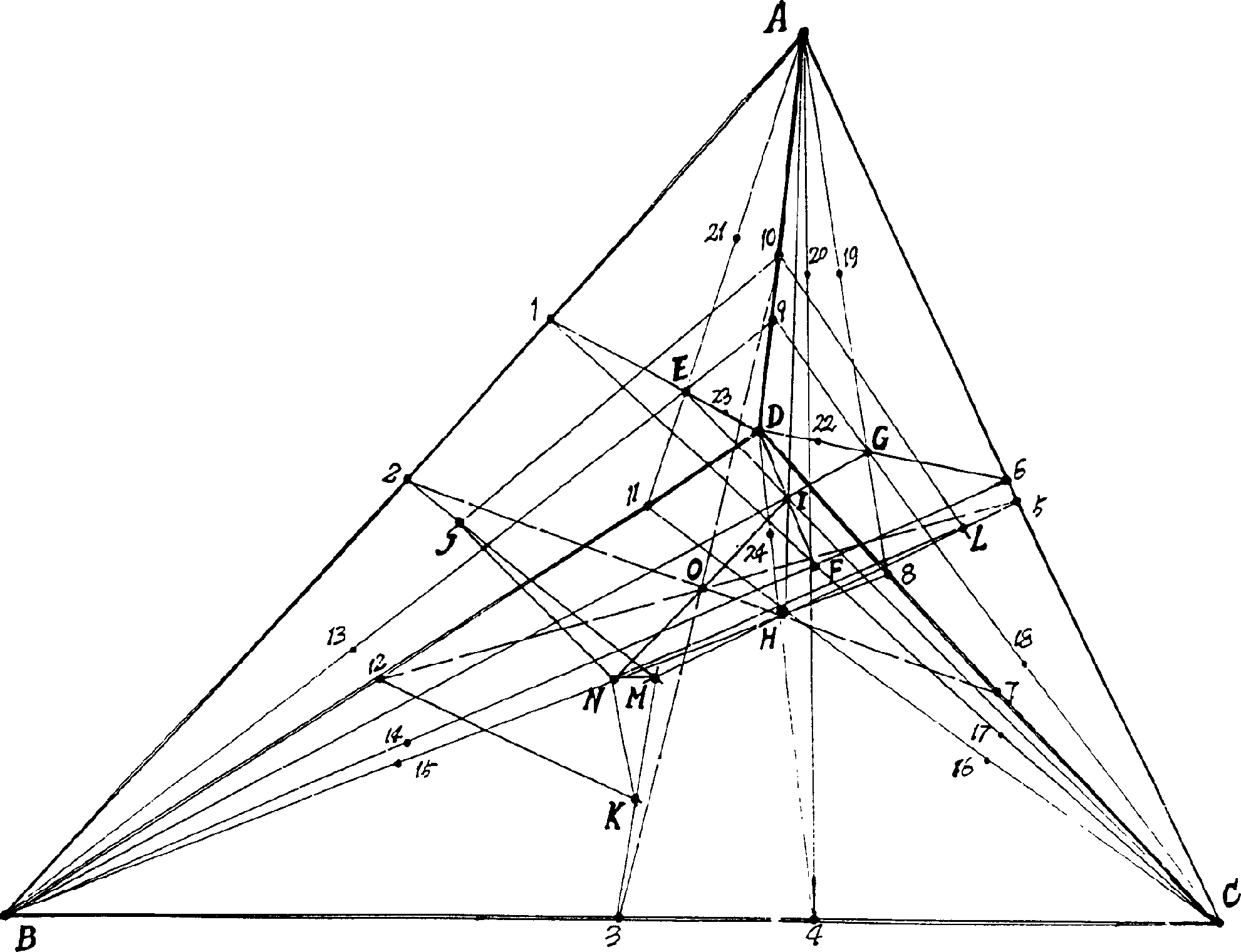

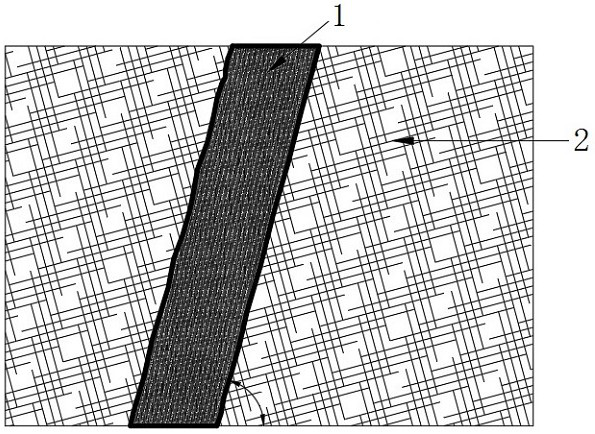

Hard rock tunnel construction method based on water power cutting

The invention discloses a hard rock tunnel construction method based on water power cutting. The hard rock tunnel construction method based on the water power cutting is characterized by constructing multiple tunnel sections from back to front along the longitudinal extending direction of a tunnel. When any one tunnel section is constructed, the process is as follows: 1, surrounding rock classification advanced detection; 2, construction parameter confirmation, wherein the confirmed construction parameters comprise cutting parameters of a water power cutting machine and split force of a hydraulic splitter; 3, current constructed tunnel section construction: constructing multiple cutting sections of the current constructed tunnel sections from back to front along the longitudinal extending direction of the tunnel, wherein when any one cutting section is constructed, the process is as follows: construction preparation, water power cutting, hydraulic splitting and rectangular cutting block outward transporting; 4, repeating steps one, two and three for many times until the construction process of the constructed hard rock tunnel is finished. The method provided by the invention is simple in steps, convenient to implement, lower in input cost, high in construction efficiency, good in construction effect, and can simply, conveniently and quickly finish the construction process of the hard rock tunnel.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

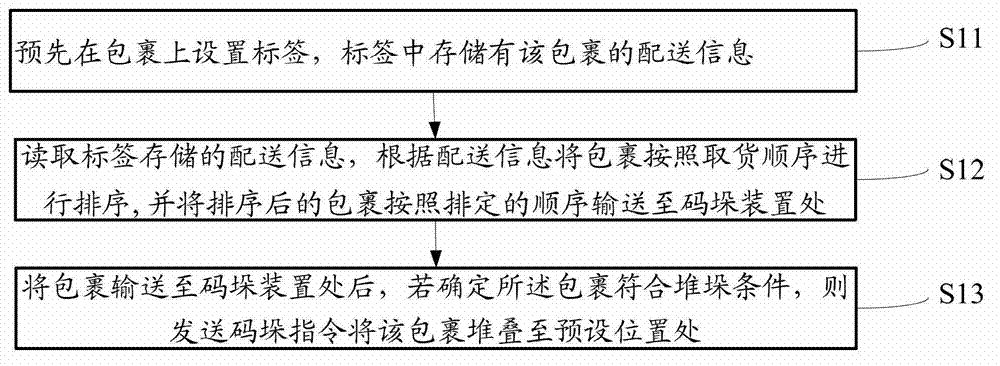

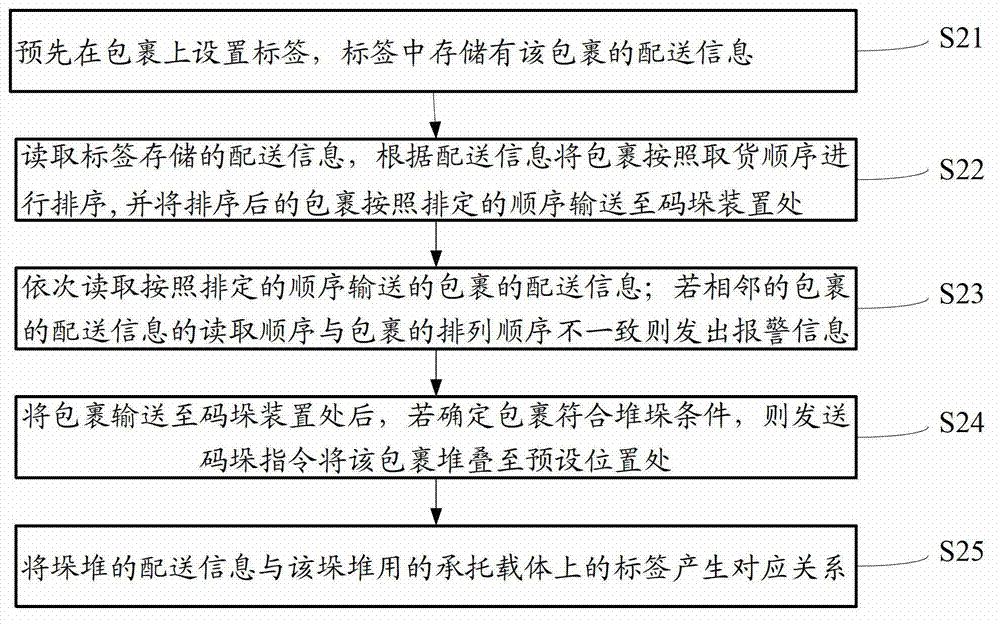

Stacking method and stacking system

InactiveCN103093331AImplement sortingNo confusionStacking articlesLogisticsLogistics managementEmbedded system

The invention relates to the field of logistics, in particular to a stacking method and a stacking system. The stacking method comprises that labels are arranged on packages in advance, distribution information of the packages is stored in the labels; the distribution information stored in the labels is read, the packages are arranged in sequence according to cargo-taking sequence through the distribution information, the sequenced packages are conveyed to a stacking device according to the set sequence; after the packages are conveyed to the stacking device, if the fact that the packages meet stacking requirements is confirmed, a stacking order is sent, and the packages are stacked on a preset position. According to the stacking method and the stacking system, the packages can be stacked according to the cargo-taking sequence.

Owner:ZHONGKE FUCHUANG BEIJING TECH

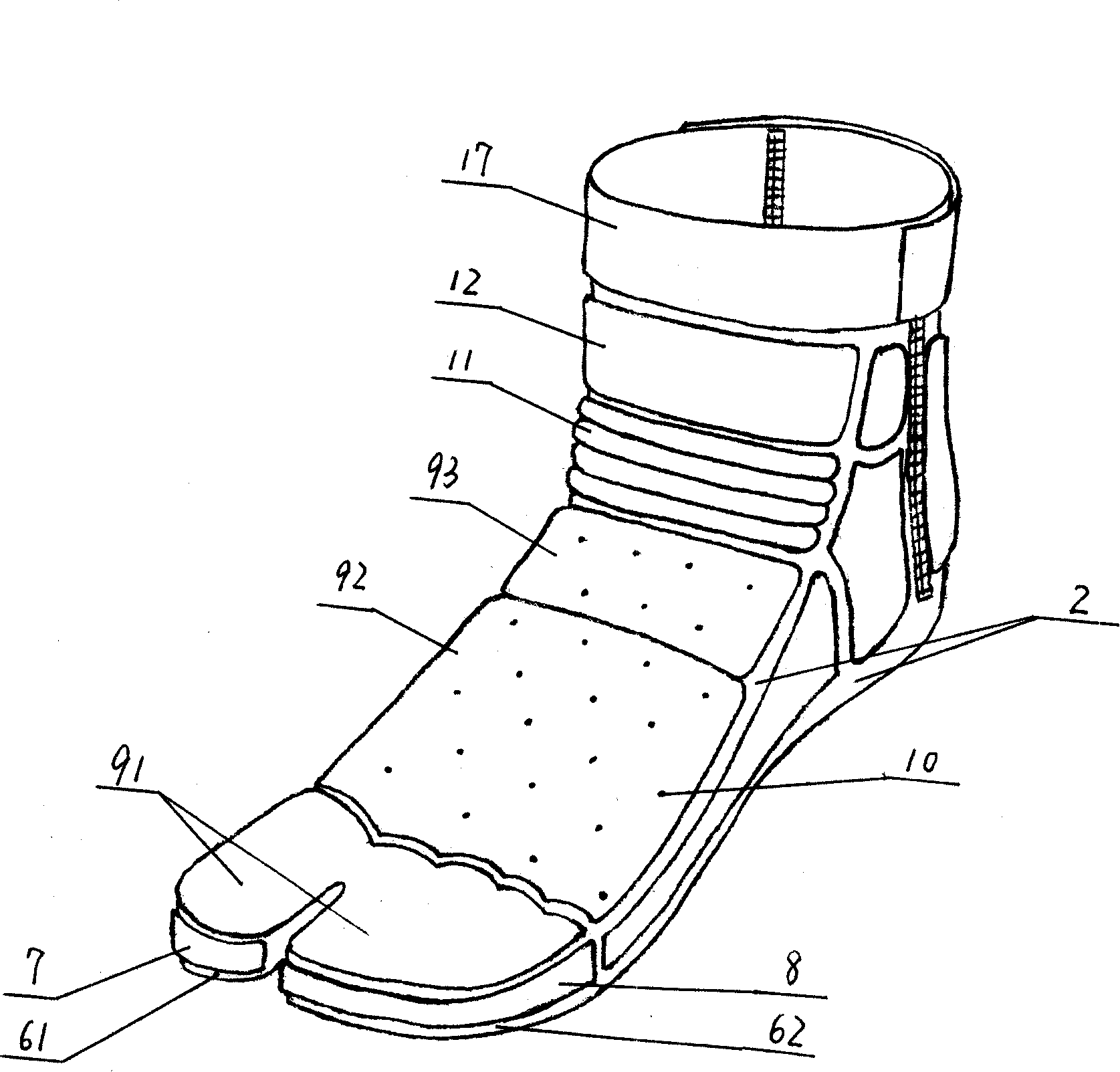

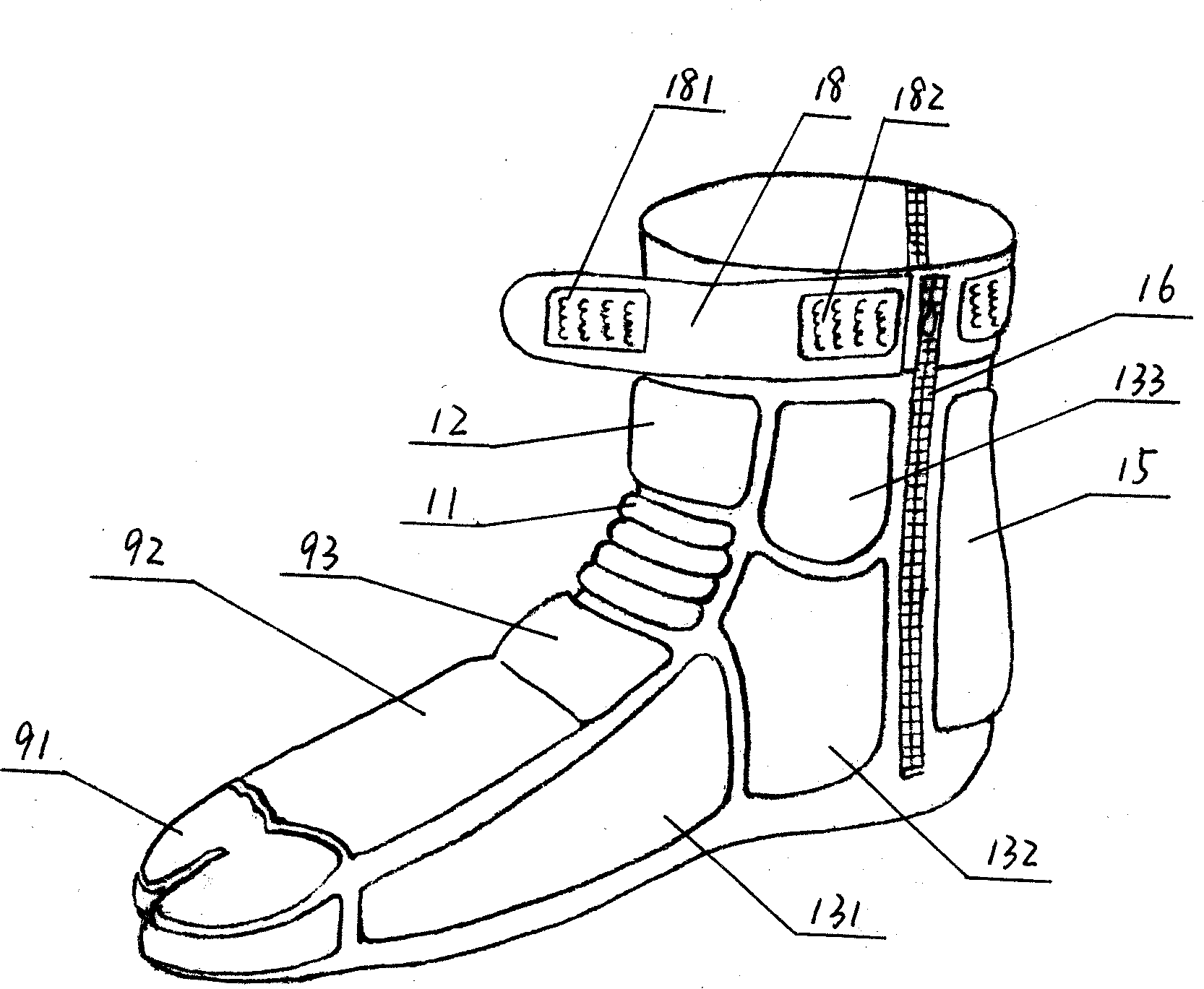

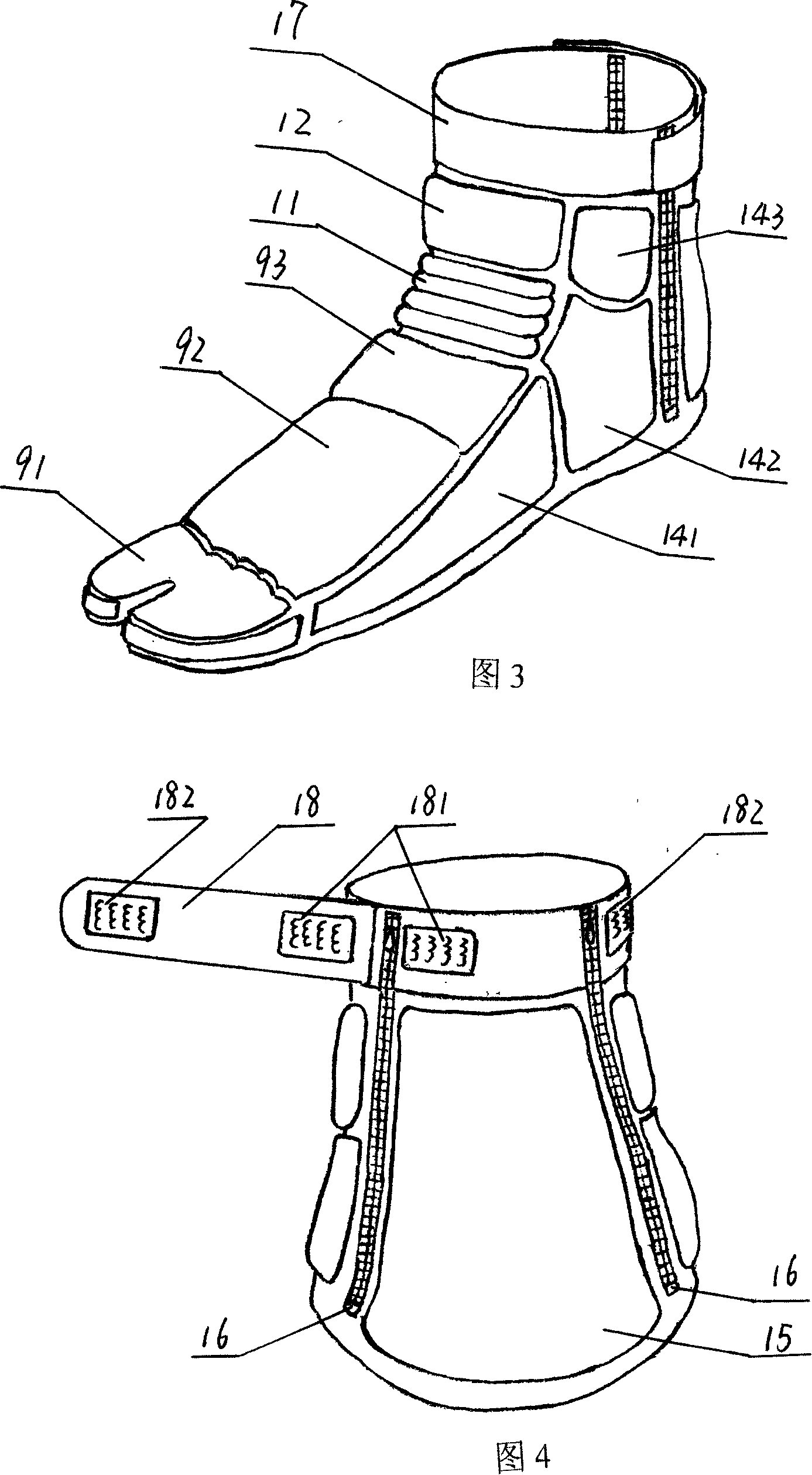

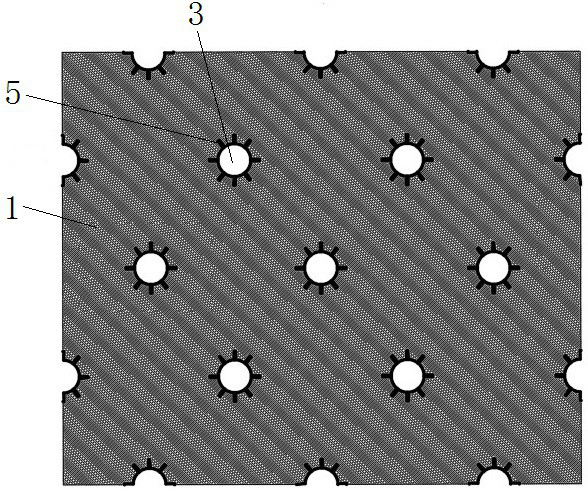

Multifunctional sports shoes

InactiveCN101224052AWill not affect stabilityWith all-round protectionSolesSoft materialsEngineering

The invention relates to a sports protection article, in particular to a pair of multifunctional gym shoes which can protect the feet of athletes from being hurt in an omnidirectional way and synchronously relieve the hurt to the opposite side, comprising a vamp and a sole that is fixedly connected with the vamp; a plurality of protective mats are respectively positioned at the toes, the surface of the feet, the feet wrist, the ankle as well as the inner sides and the outer sides of the feet; the sole is made of soft material, and one side of the sole which is contacted with the feet is provided with convex plastic skidproof granules that are corresponding to the shape of the feet, the other side is provided with a plastic skidproof surface that is corresponding to the shape of the feet; riser vents are arranged around the convex plastic skidproof granules and the plastic skidproof surface. Gap is opened between the great toe and the other four toes at the toe part of the gym shoes and the great toe and the other four toes are connected together by elasticated cloth; the feet wrist part of the vamp is provided with the protective mat used for protecting the feet wrist and an elastic belt arranged above the protective mat; the elastic belt is provided with a drawstring which is fixedly connected with a nylon agraffe. The invention can effectively protect all the parts of the feet and is comfortable, sanitary and skidproof at the same time.

Owner:刘孝臣

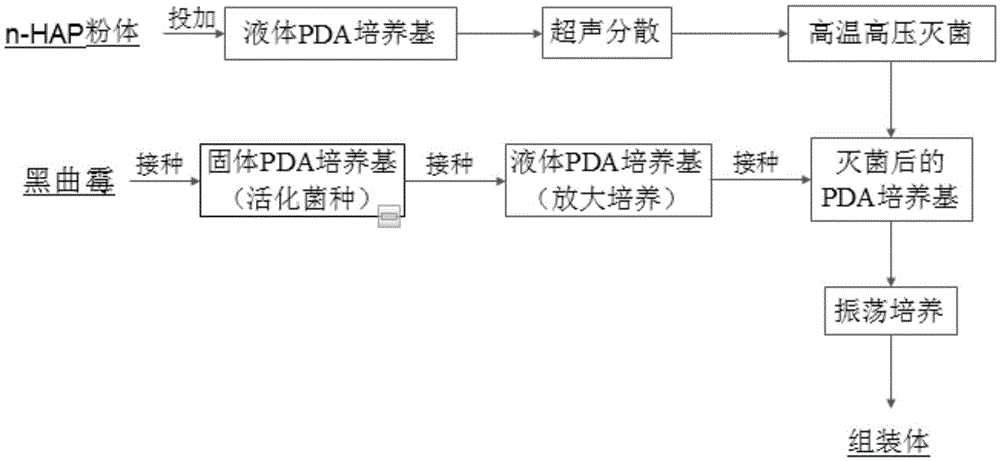

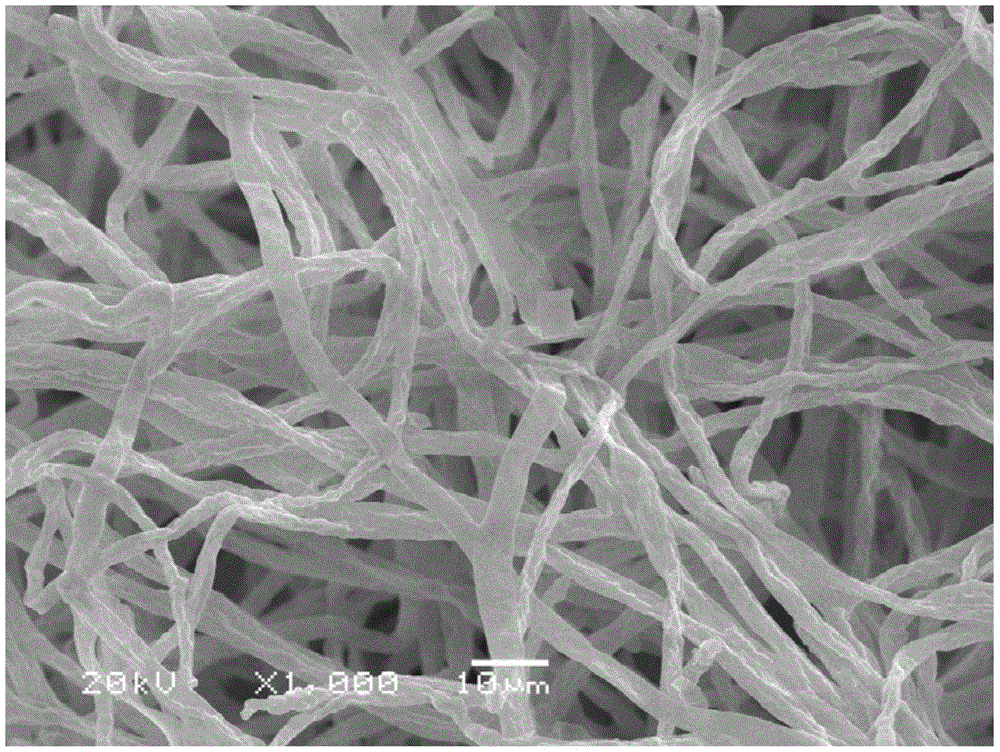

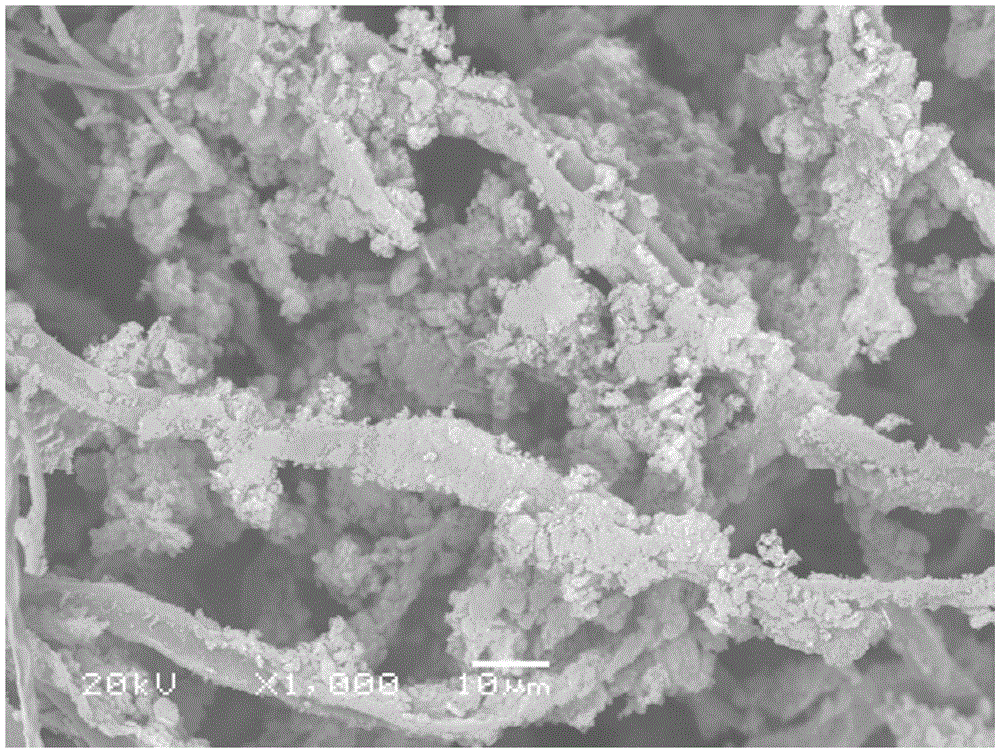

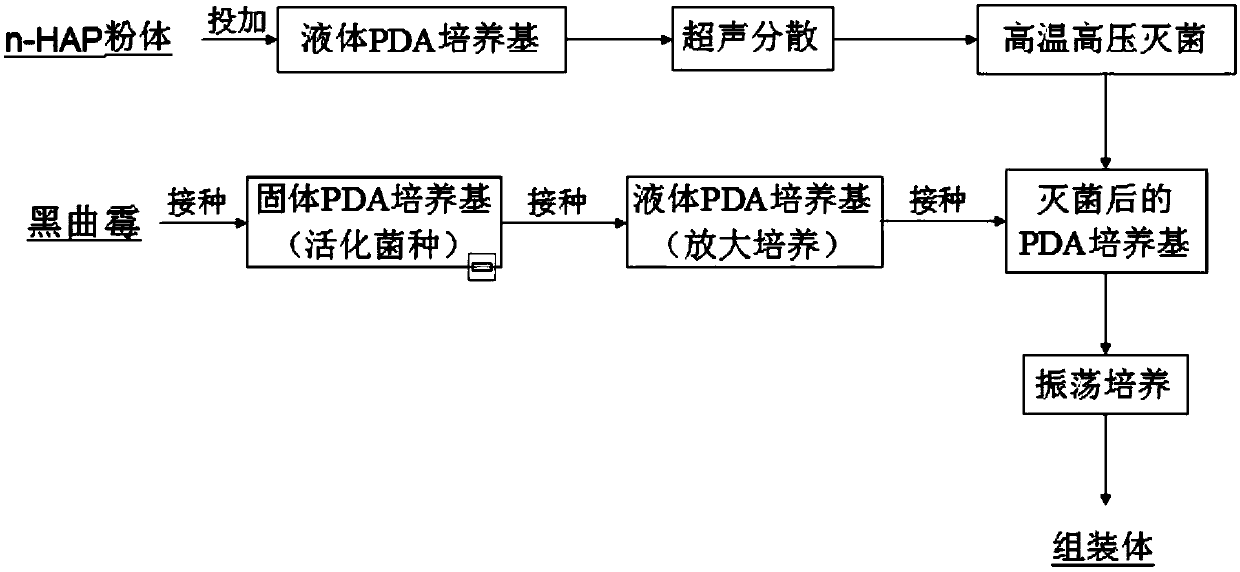

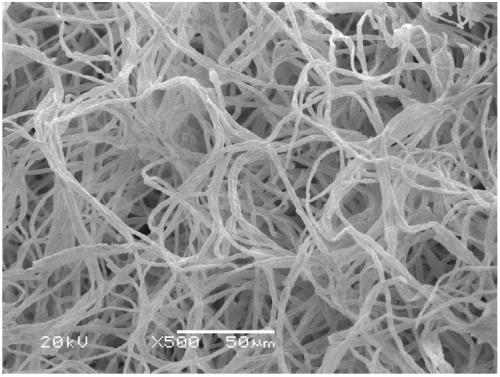

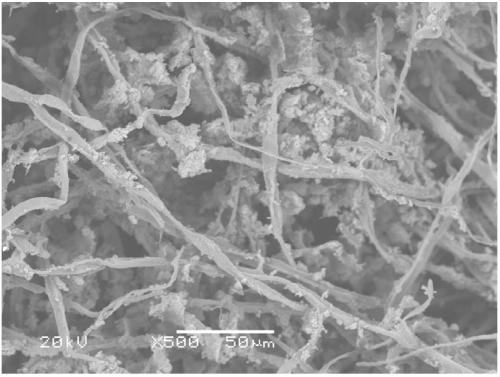

Application of lead-contaminated soil restoring fixing agent synthesized based on microorganism assembly

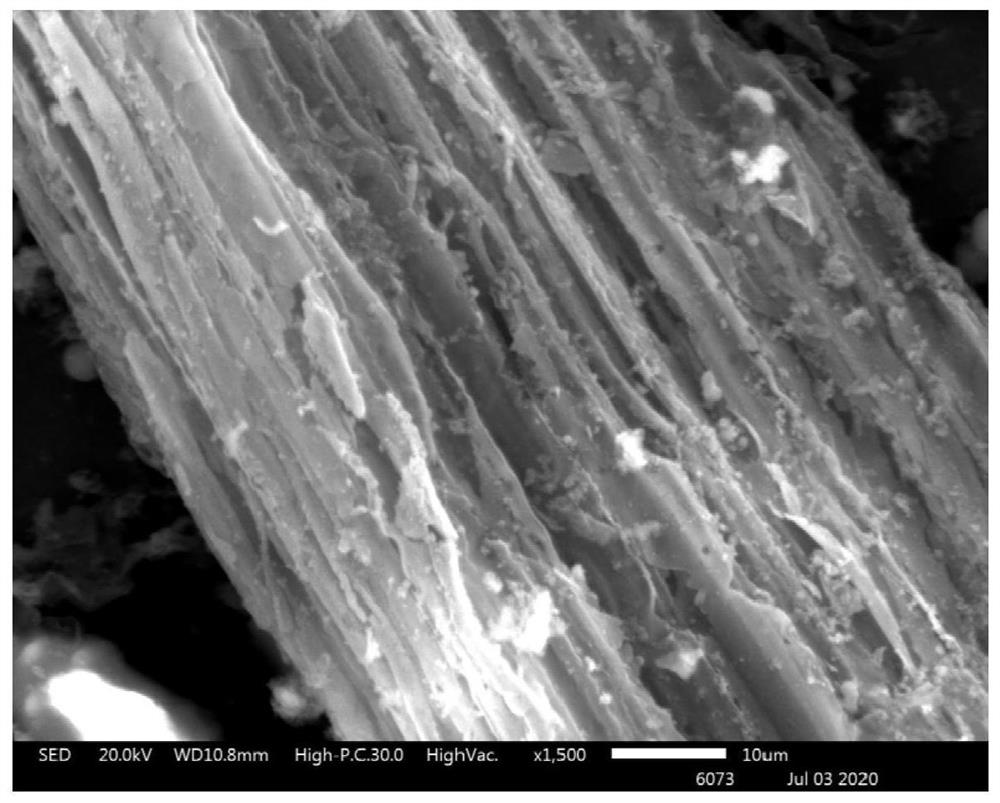

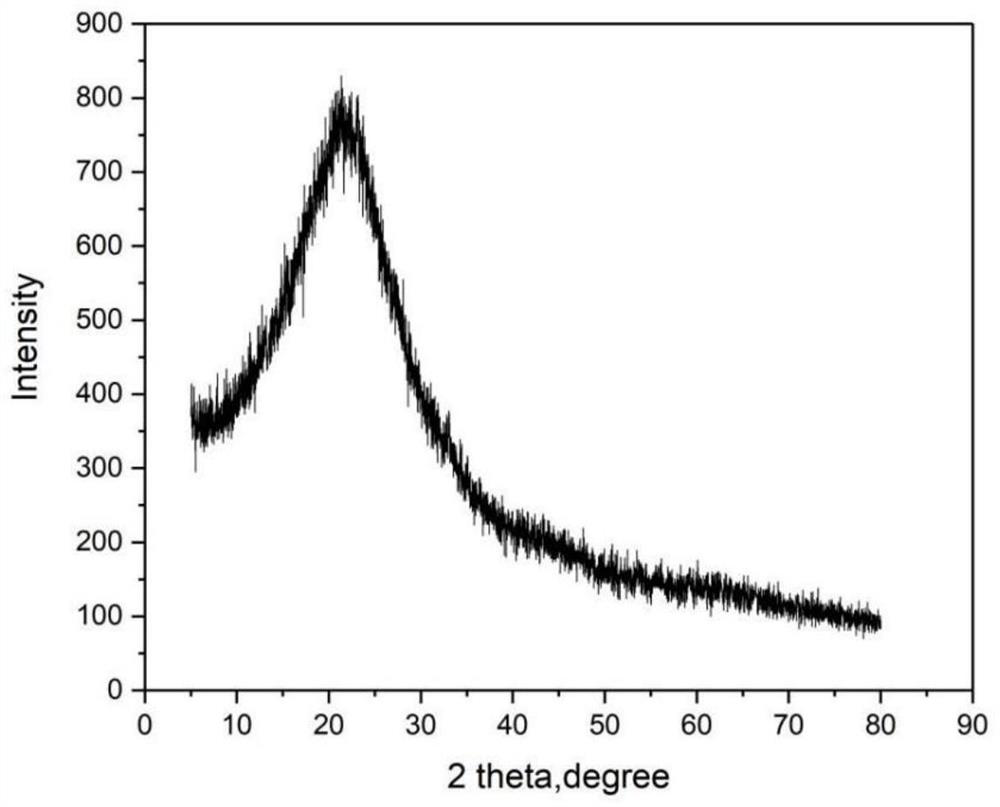

InactiveCN105647539ALarge specific surface areaHigh reactivityAgriculture tools and machinesOrganic fertilisersMicroorganismNano hydroxyapatite

The invention discloses application of a lead-contaminated soil restoring fixing agent synthesized based on microorganism assembly. Nano-hydroxyapatite serves as a central substance and wrapped with aspergillus niger hyphae, and the lead-contaminated soil restoring fixing agent is prepared, so that the problem that a powder material is excessively scattered in practical application is solved. The synthesized product is mixed with soil to be uniform according to a certain proportion, fixing is conducted for 7 days, and the available lead in the soil is reduced by 42.8%-48.6%. The fixing agent is simple in preparation process, low in cost, efficient, free of poisons, biodegradable and free of secondary contamination and is an environment-friendly fixing agent.

Owner:CENT SOUTH UNIV

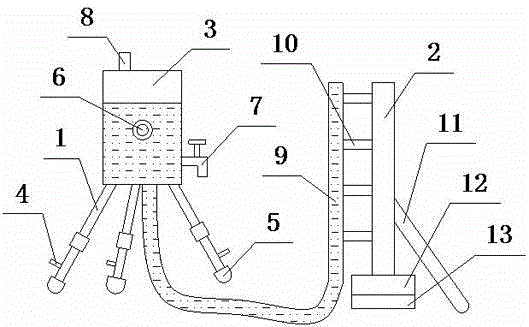

Level gauge for constructional engineering

The invention discloses a level gauge for constructional engineering. The level gauge comprises a scale ruler and a triangular frame, wherein a transparent water tank is arranged on the triangular frame, a supporting rod of the triangular frame is in a stretchable structure, a limiting device is arranged on the lower part of the supporting rod of the triangular frame, a spring shock prevention cover is arranged at the bottom end of the supporting rod of the triangular frame in a sleeving manner, a gradienter is installed on the water tank, a water drain valve is arranged on one side of the water tank, a water inlet is formed in the top of the water tank, a transparent hose is connected to the bottom of the water tank, a snap ring is arranged on one side of the scale ruler while an auxiliary supporting rod is arranged on the lower part of the other side of the scale ruler, the snap ring is clamped with the transparent hose, a base is arranged at the bottom of the scale ruler and a soft cushion is arranged at the bottom of the base. The level gauge for the constructional engineering, disclosed by the invention, is simple in structure and reasonable in design, can be used for guaranteeing the measuring accuracy and is convenient to operate by workers.

Owner:曹年军

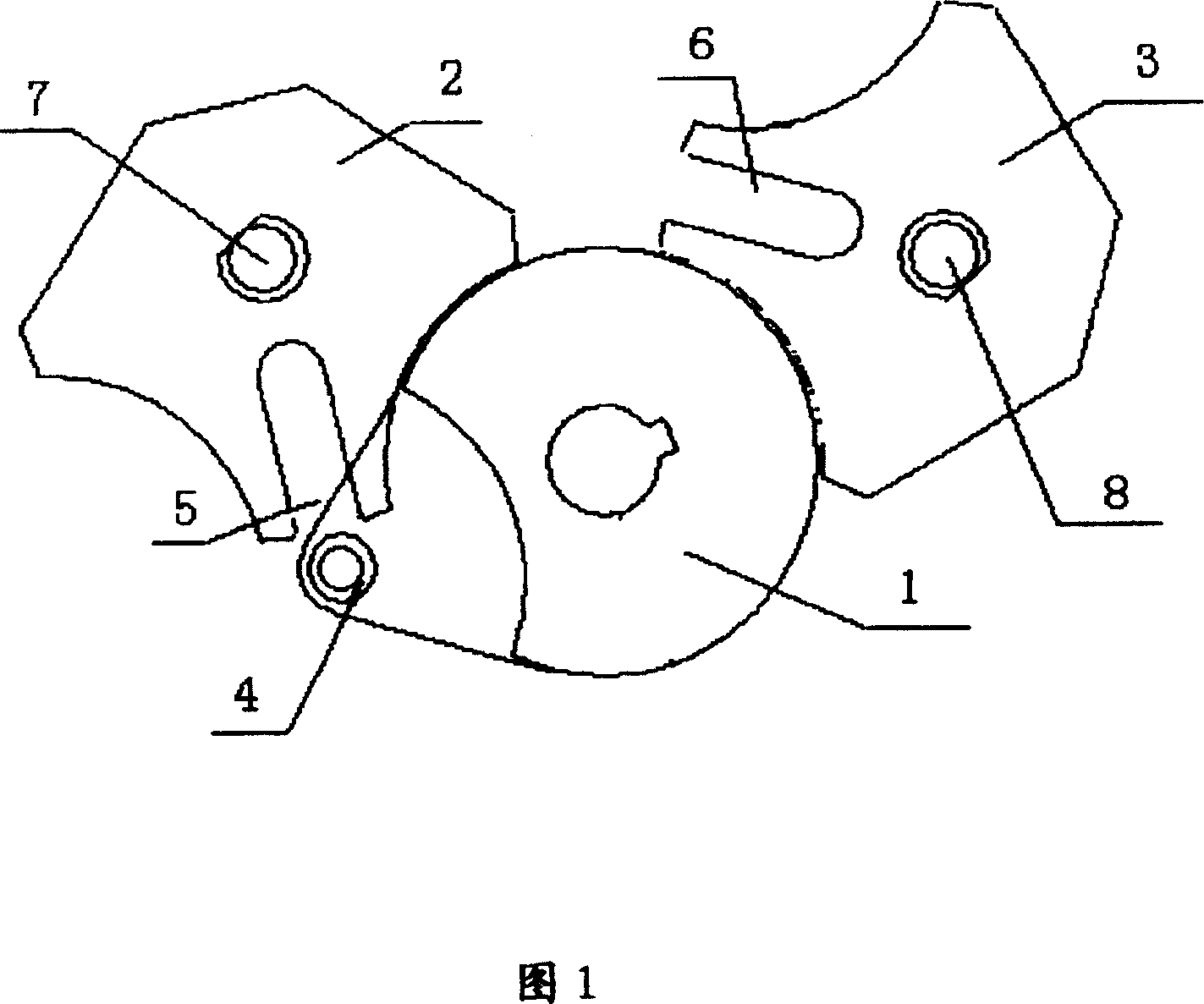

Electric operating equipment for double isolating switch

InactiveCN100345234CWill not affect stabilitySimple and compact structureSwitch power arrangementsHigh-tension/heavy-dress switchesEngineeringControl theory

Owner:武汉合力开关有限公司

Fixing agent for repairing arsenic-antimony compound contaminated soil and preparation method and application thereof

InactiveCN111961473AWide variety of sourcesAchieve recyclingAgriculture tools and machinesOther chemical processesSpecific adsorptionIron salts

The invention discloses a preparation method and application of a fixing agent for repairing arsenic-antimony combined pollution soil. The preparation method of the fixing agent comprises the following steps: 1) by taking an iron salt solution as a modifier, adding straw powder, adjusting the pH value, and filling into a high-pressure reaction kettle, 2) heating the reaction kettle in a muffle furnace, and 3) washing, filtering and drying the reaction product to obtain the chemical fixing agent. After the prepared fixing agent is mixed with soil according to a certain proportion, the effective-state As (III) and As (V) in the contaminated soil are reduced by 42.06% and 50.67% respectively, and the effective-state Sb (III) and Sb (V) are reduced by 21.57% and 59.66% respectively. Non-specific adsorption state arsenic and specific adsorption state arsenic in the soil are respectively reduced by 10% and 11%, the non-specific adsorption-state antimony and the specific adsorption-state antimony are reduced by 8% and 16% respectively, and the fixing agent is simple in preparation process, low in cost and capable of effectively reducing mobility and bioavailability of arsenic and antimonyin soil.

Owner:CENT SOUTH UNIV

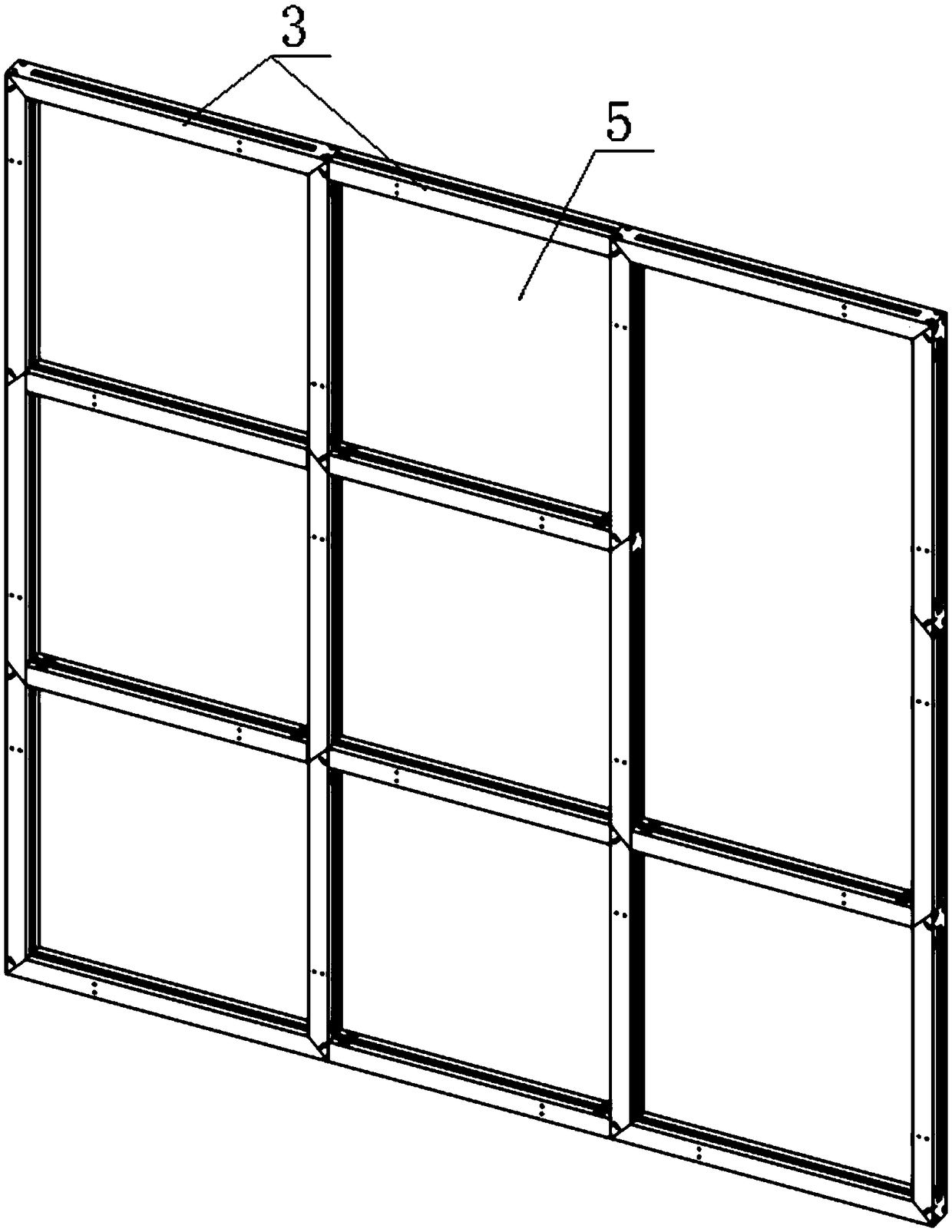

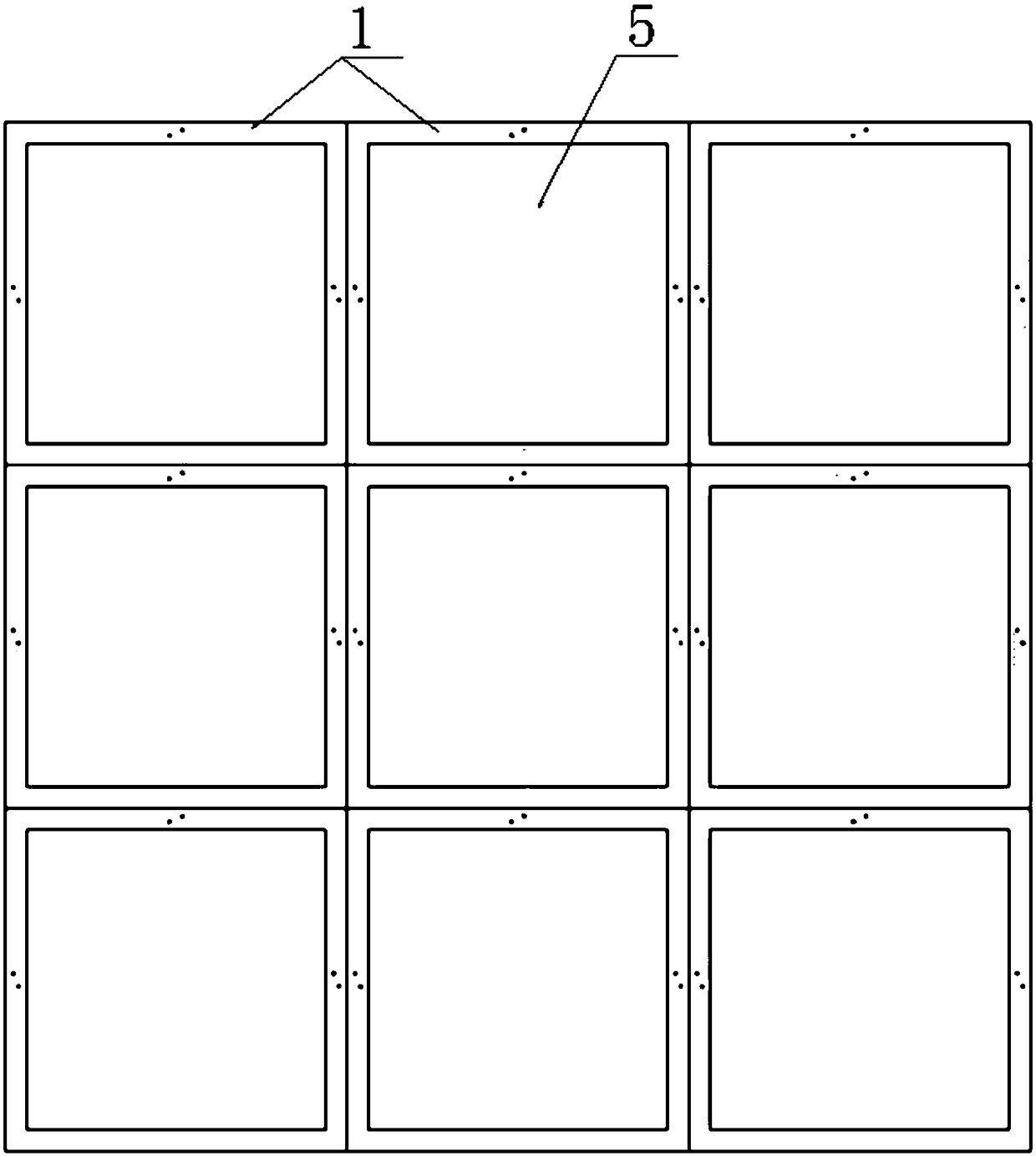

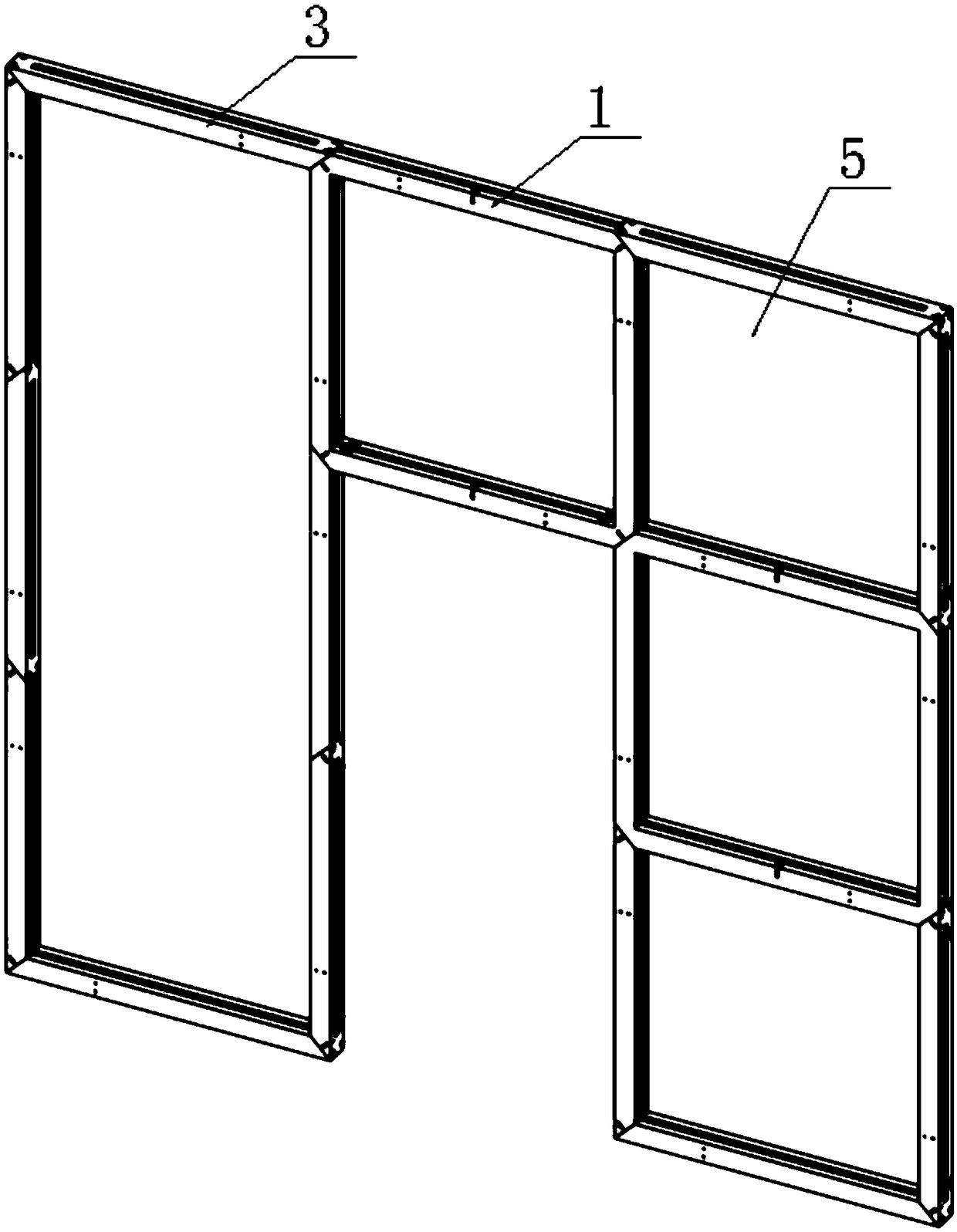

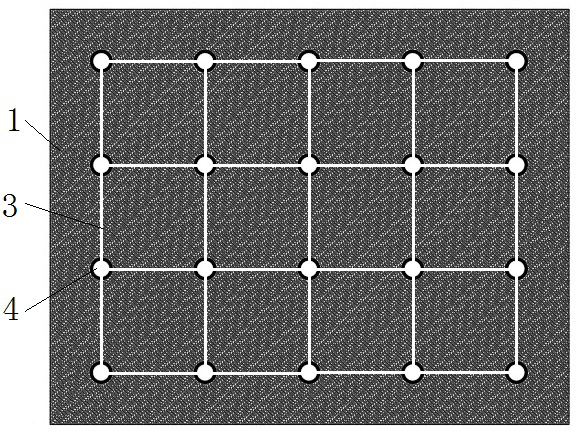

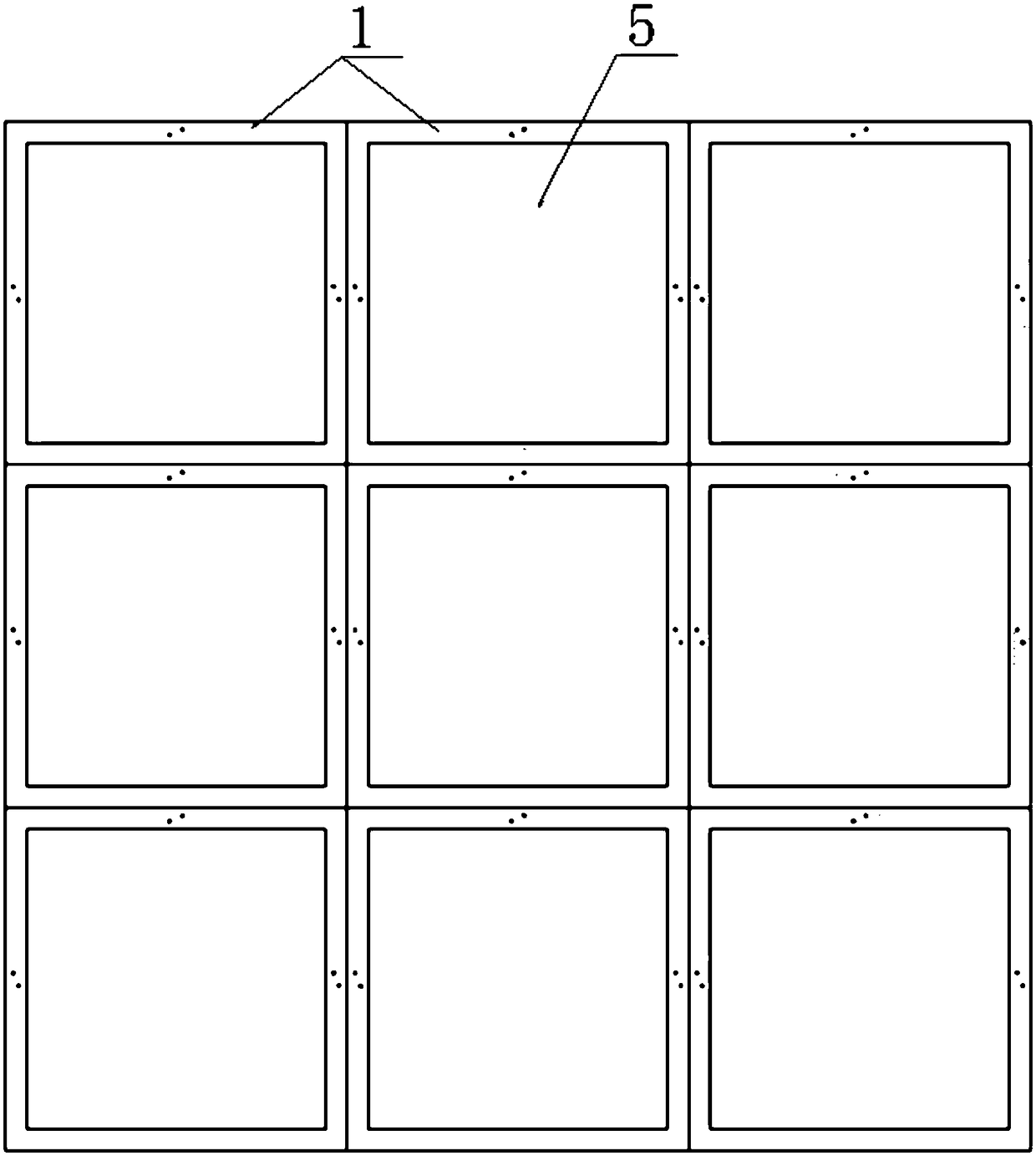

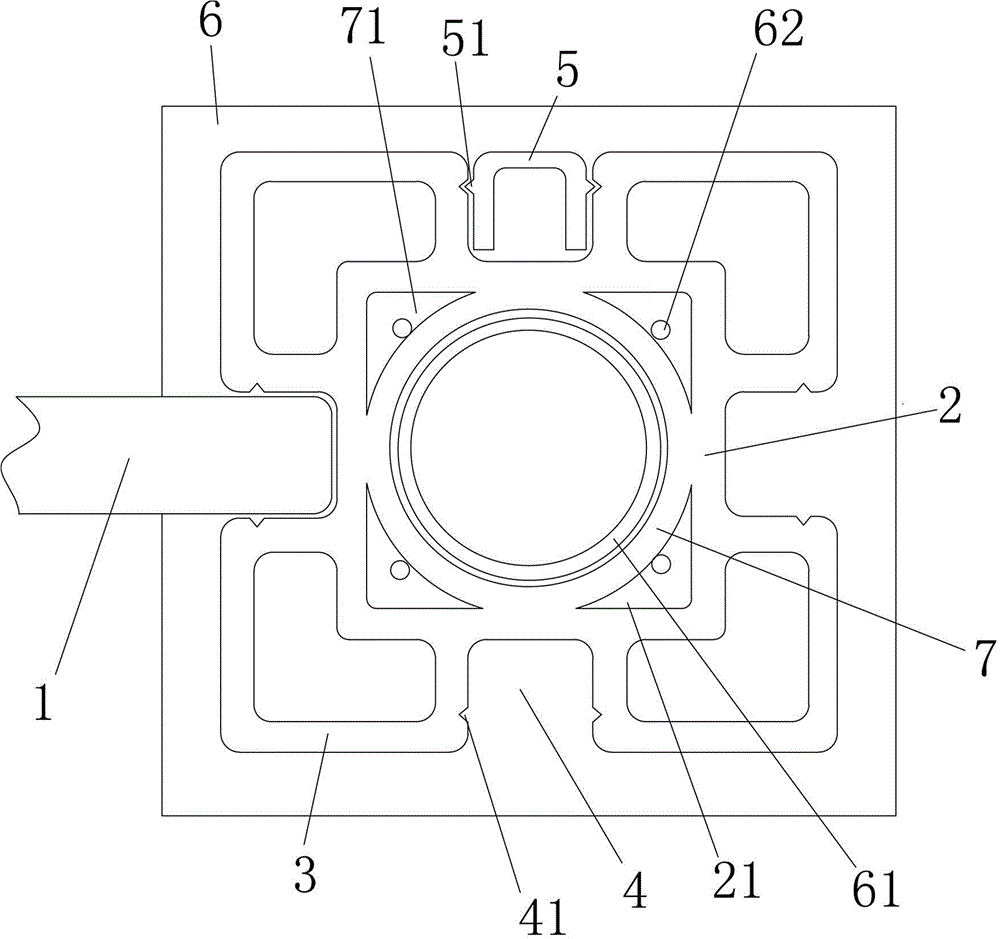

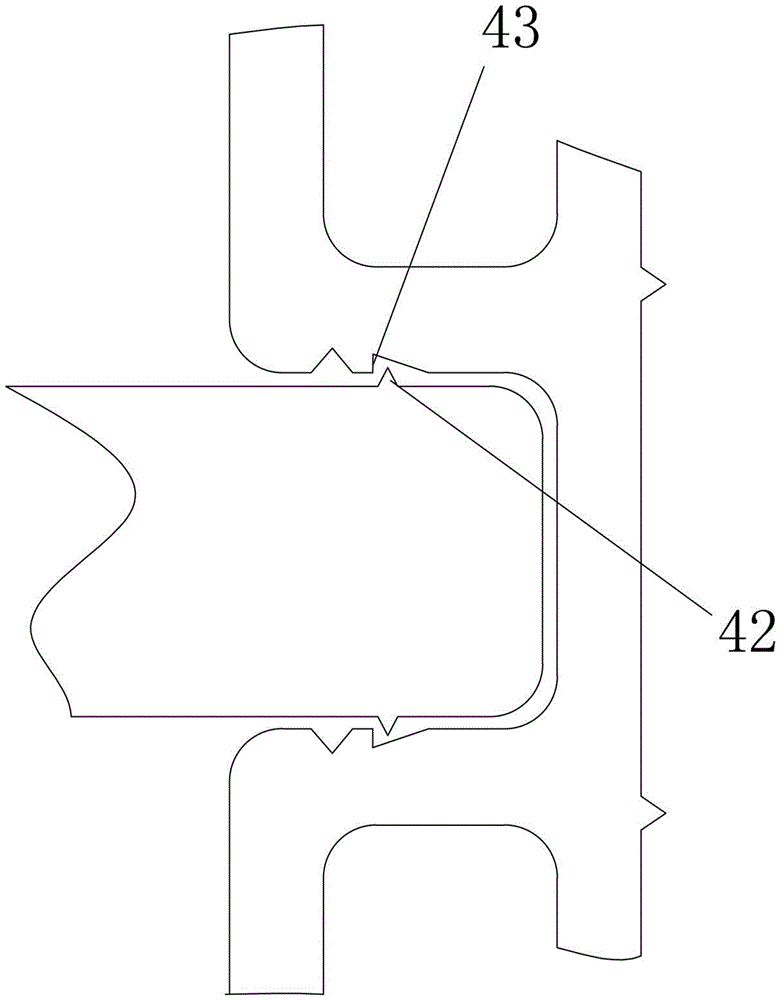

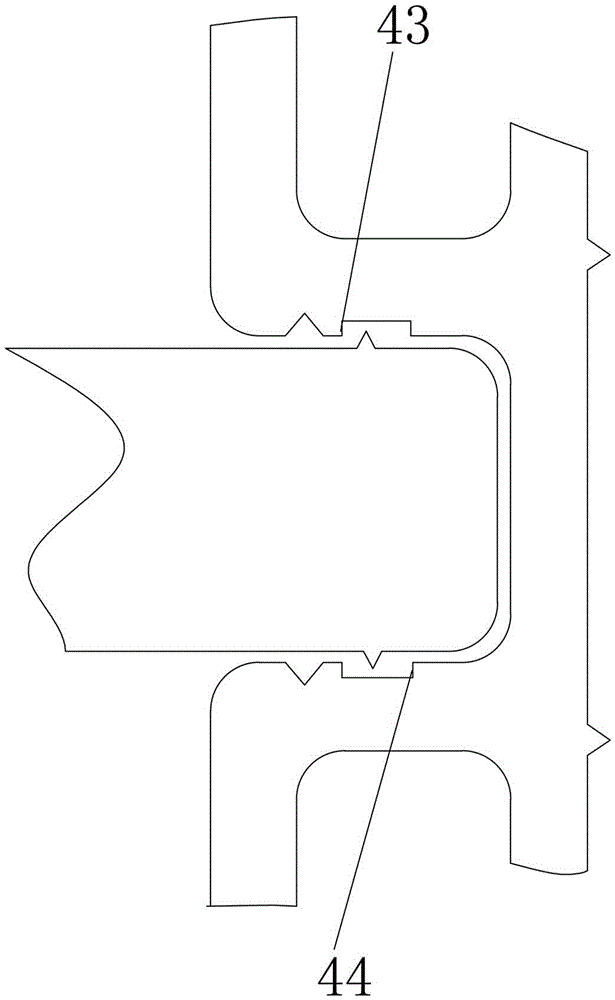

Reconfigurable wall system and unit assembly thereof

The invention relates to the field of assembling walls, in particular to a reconfigurable wall system and a unit assembly thereof. According to the reconfigurable wall system, the unit assemblies areconnected to form a wall frame serving as a main force-bearing body; and function modules are installed at the wall frame and do not bear the wall load basically, so that the effects of the function modules can be realized better without considering the strengths of the function modules; and when the function module needs to be adjusted or replaced, only connection between the function module andthe wall frame needs to be dismounted but the overall stability of the wall is not affected. With slide plates of the unit assemblies, the function modules are fixed well; when the function modules are fixed, one side of each slide plate is clamped into the function module and the other side of the slide plate is arranged in the unit assembly, so that the function module is dismounted convenientlyand the installation stability of the function module is ensured. The wall frame is formed by the unit assemblies and the height and width of the wall are decided by the number of the unit assemblies, so that the wall system has the high universality.

Owner:李劲

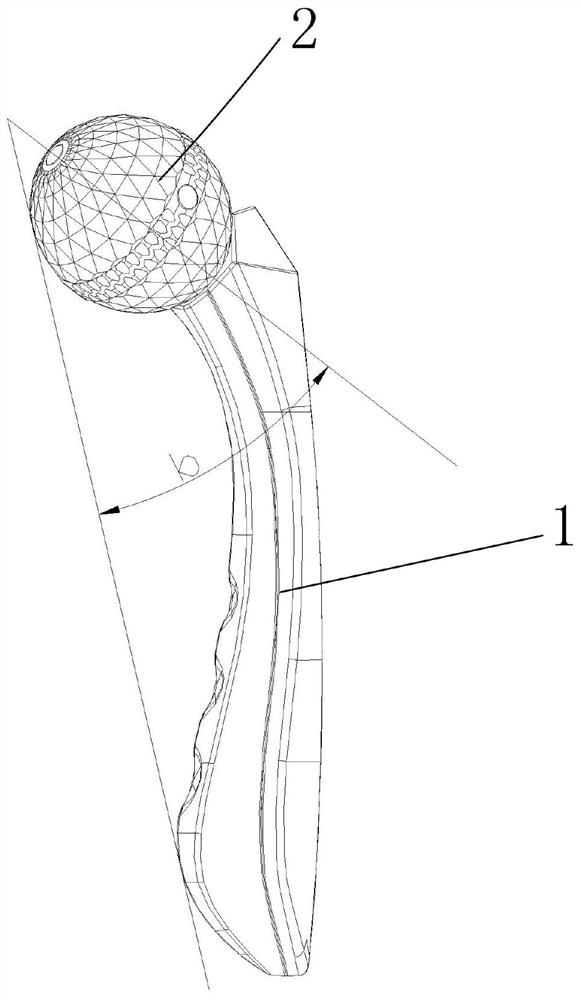

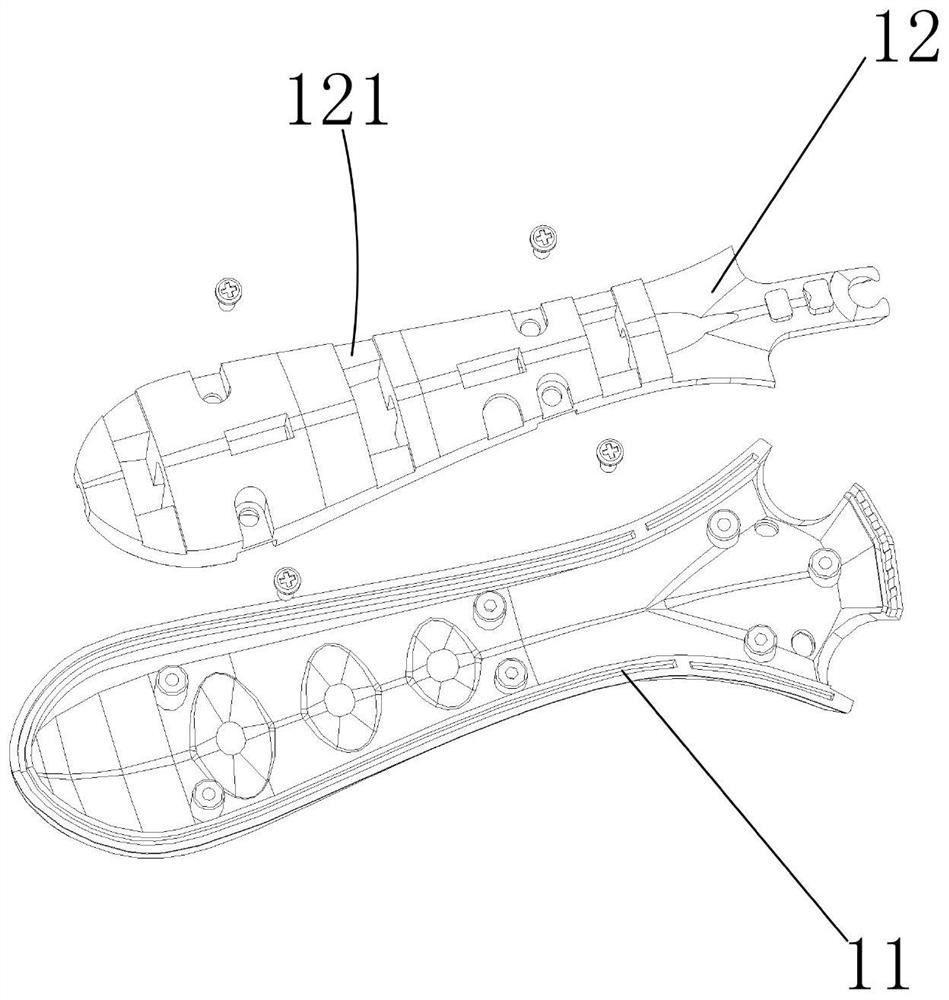

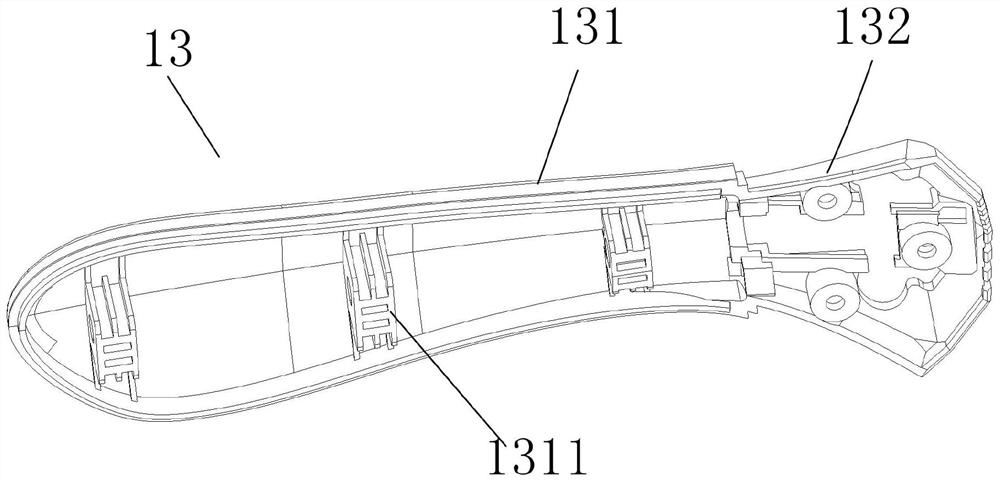

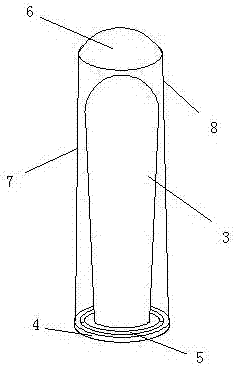

Roller massage instrument

PendingCN111643333AImprove stabilityPromote blood circulationElectrotherapyRoller massageHuman bodyEngineering

The invention discloses a roller massage instrument. A handle comprises a base, a balancing weight and an upper shell, the base is detachably connected with the upper shell, and the balancing weight is detachably connected with the base and the upper shell; rollers are obliquely arranged relative to the handle; a photovoltaic cell panel is arranged in the handle, and a shell, corresponding to thephotovoltaic cell panel, on the handle is made of a light-transmitting material; a positive pole point and a negative pole point of the photovoltaic cell panel are electrically connected with the tworollers respectively, and the two rollers are communicated through human skin to form a loop to generate micro-current; by additionally arranging the balancing weight in the handle, the overall texture and massage strength can be improved, upper and lower shells are connected with the balancing weight in pairs, the stability degree of the handle structure is increased, and the roller massage instrument is easy to disassemble and replace; and in the massage process, micro-current is adopted to stimulate the skin at the same time, skin blood circulation can be promoted, metabolism is improved, fatigue is eliminated, and a better using effect is achieved.

Owner:SHENZHEN REEGIS TECH

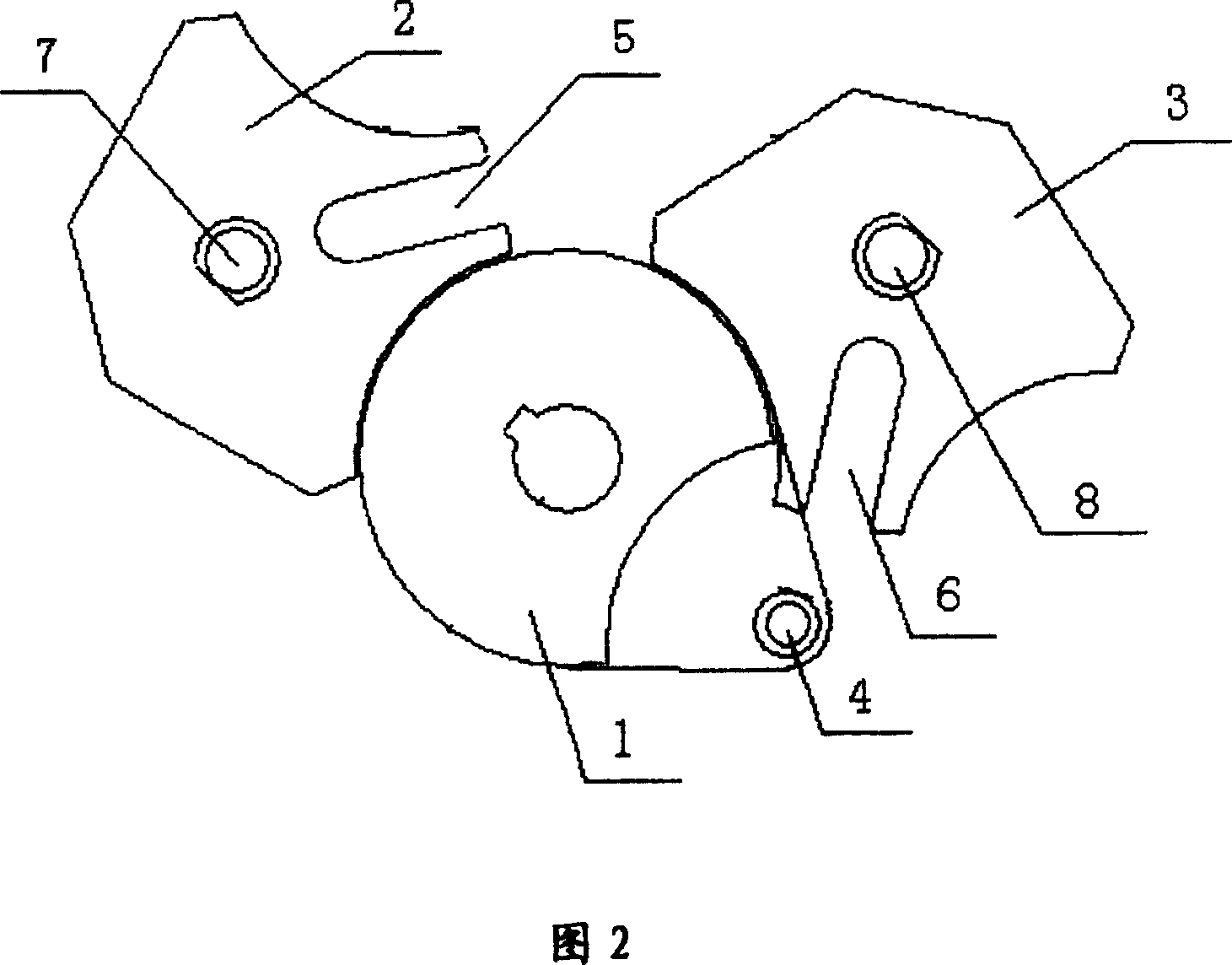

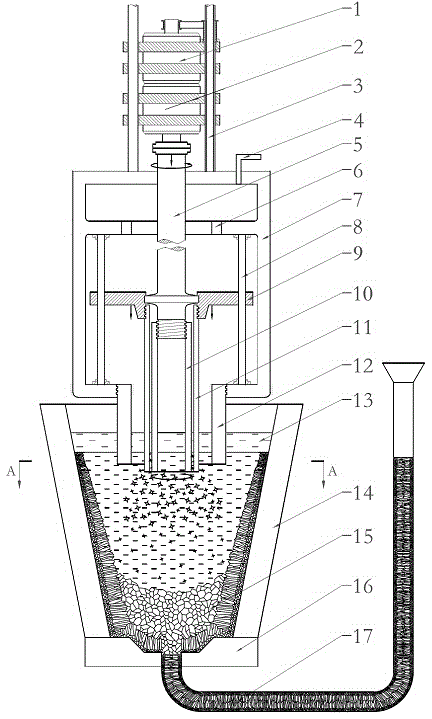

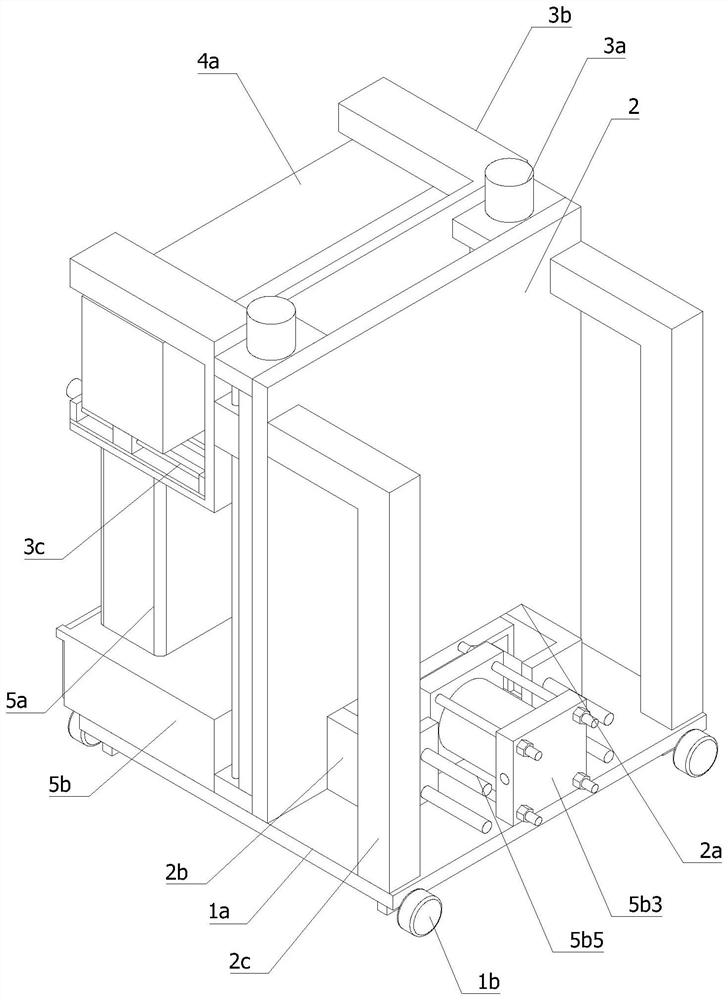

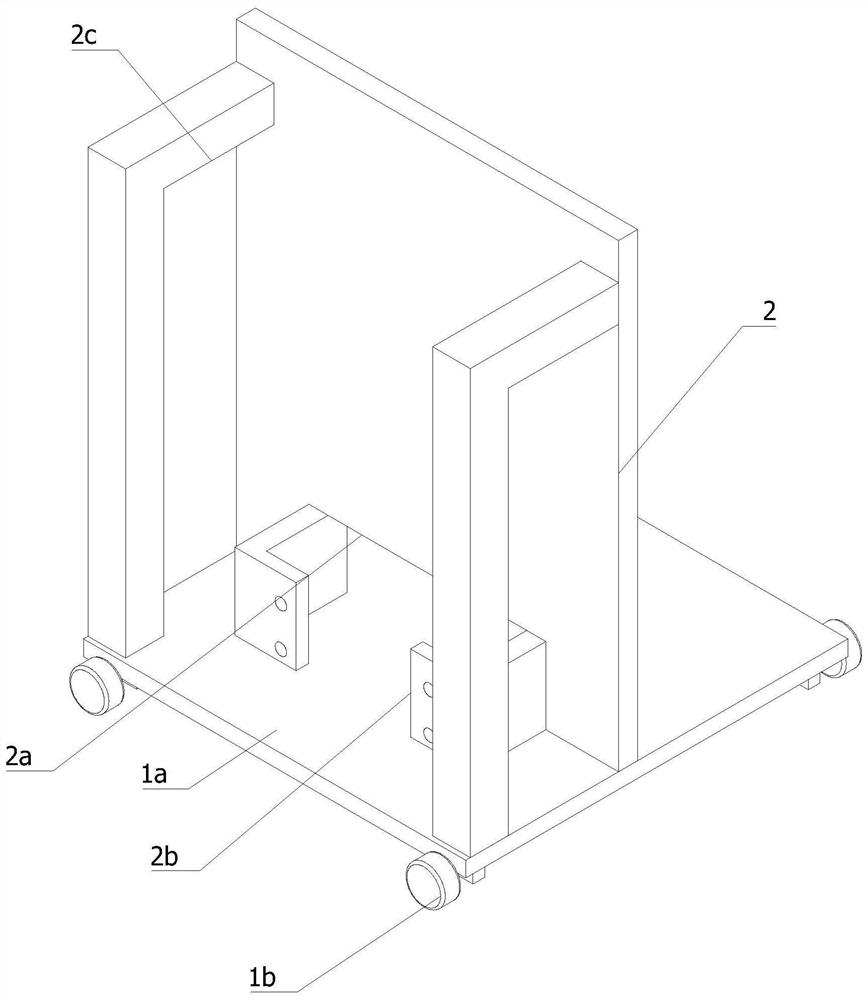

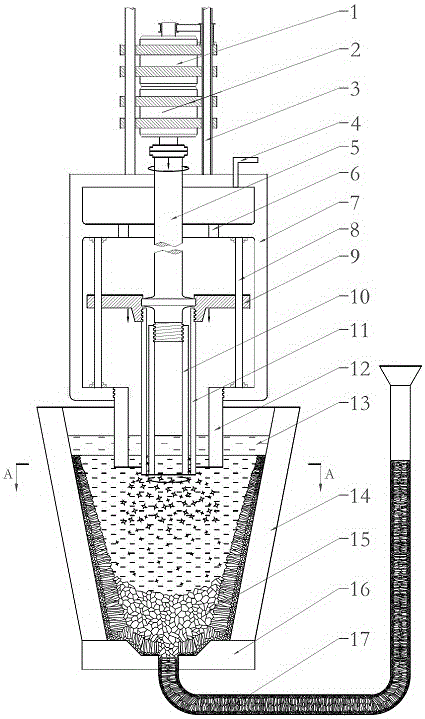

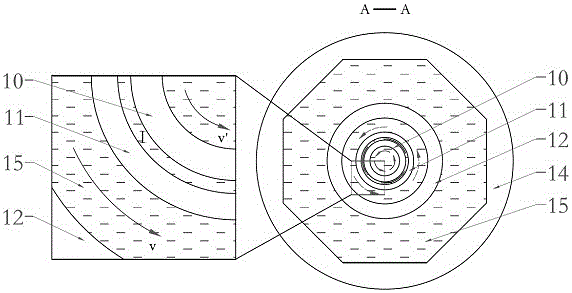

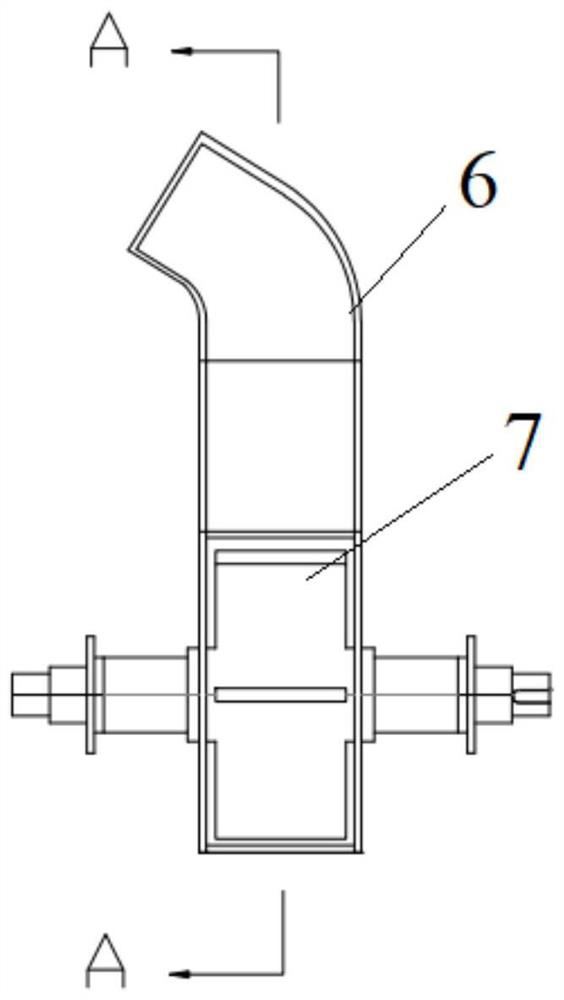

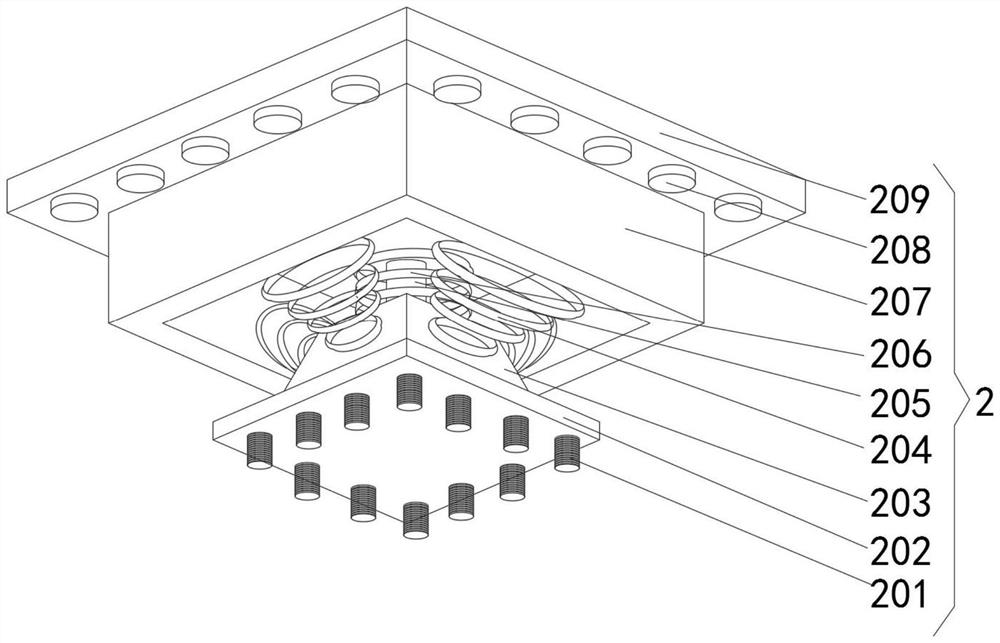

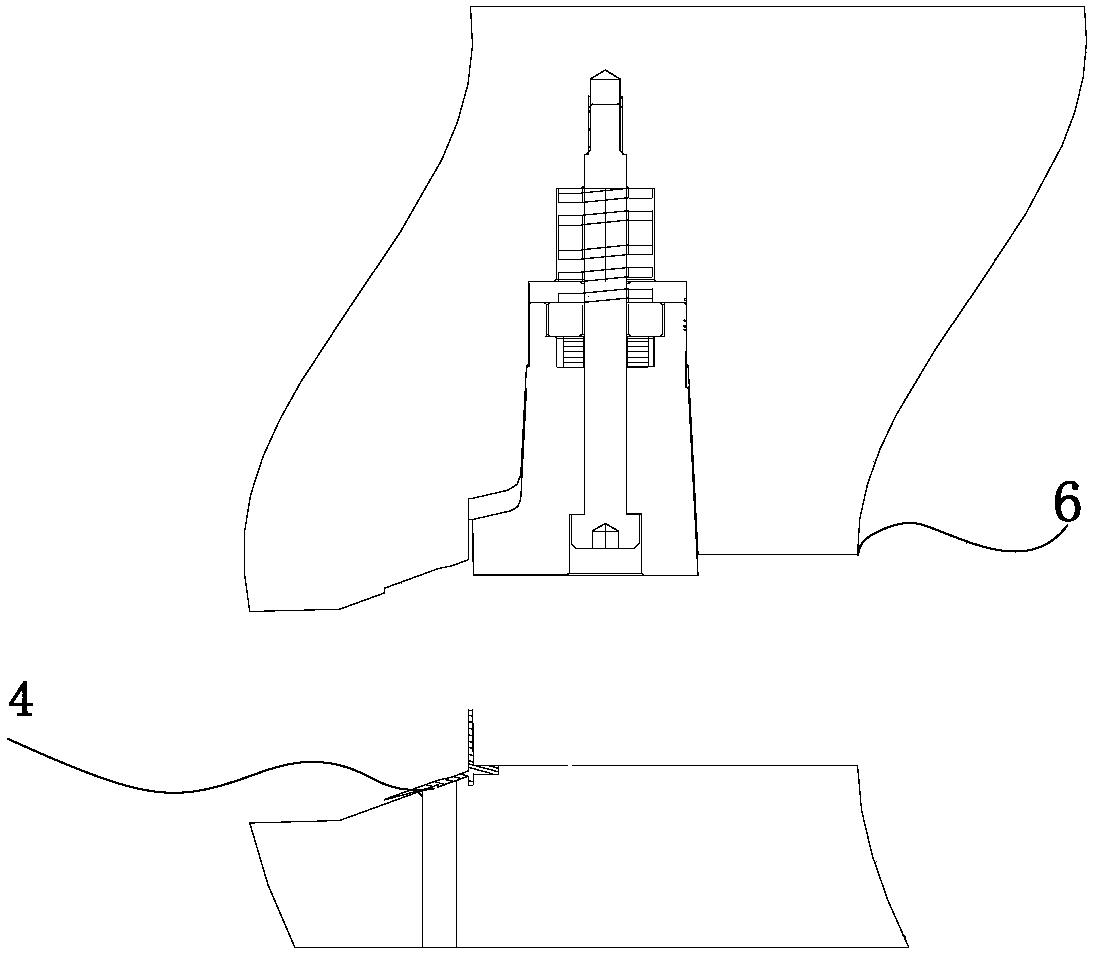

Technology for refining solidification structure through consumable shear flow method and device thereof

The invention discloses a technology for refining a solidification structure through a consumable shear flow method. The technology for refining the solidification structure through the consumable shear flow method is a melt processing method which increases the number of crystal nucleus, refines grains and uniformizes formations through a consumable shear flow, and used for the casting process of large ingot castings and continuous casting billets in large cross section sizes. During the solidification of metal bath, a high-speed motor is used for generating a high rotation speed, a strong shear flow is generated in a tiny gap between a consumable metal rotor component and a consumable metal stator component, the consumable metal rotor component and the consumable metal stator component efficiently generate a plurality of crystal nucleuses under the condition that liquid level stability is not affected in a controllable space, and 'crystal rain' effect is generated. In addition, stator consumable metal and rotor consumable metal move downwards under the drive of a screw, the consumable metal can be supplemented, the purposes of improving solidification speed, refining grains, increasing equiaxial crystal ratio and reducing solute segregation degree are ultimately achieved, and the alloy performance is improved. The invention further provides a consumable shear flow metal melt processing device. The consumable shear flow metal melt processing device comprises a shear consumable component fixing device, a shear consumable component driving device and shear consumable components made of consumable metal.

Owner:SHANGHAI UNIV

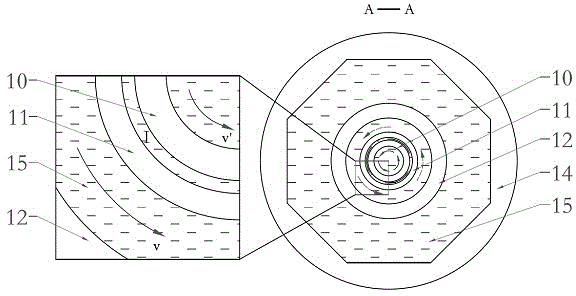

Vertical tetrahedron constructional structure system

InactiveCN1609360AStable structureNot easy to shakeBuilding constructionsSupport pointMulti-function structure

The present invention is one kind of vertical tetrahedron building structure system and features that the perpendicular or the orthocenter of the vertical tetrahedron is the support column or support point of the building structure and the intersection point of the opposite line to the vertical tetrahedron is the stress node of the building structure. The present invention is used in building structure, has reliable versatility, stability and structural mechanical characteristics, and may be used in various kinds of building.

Owner:朱笛

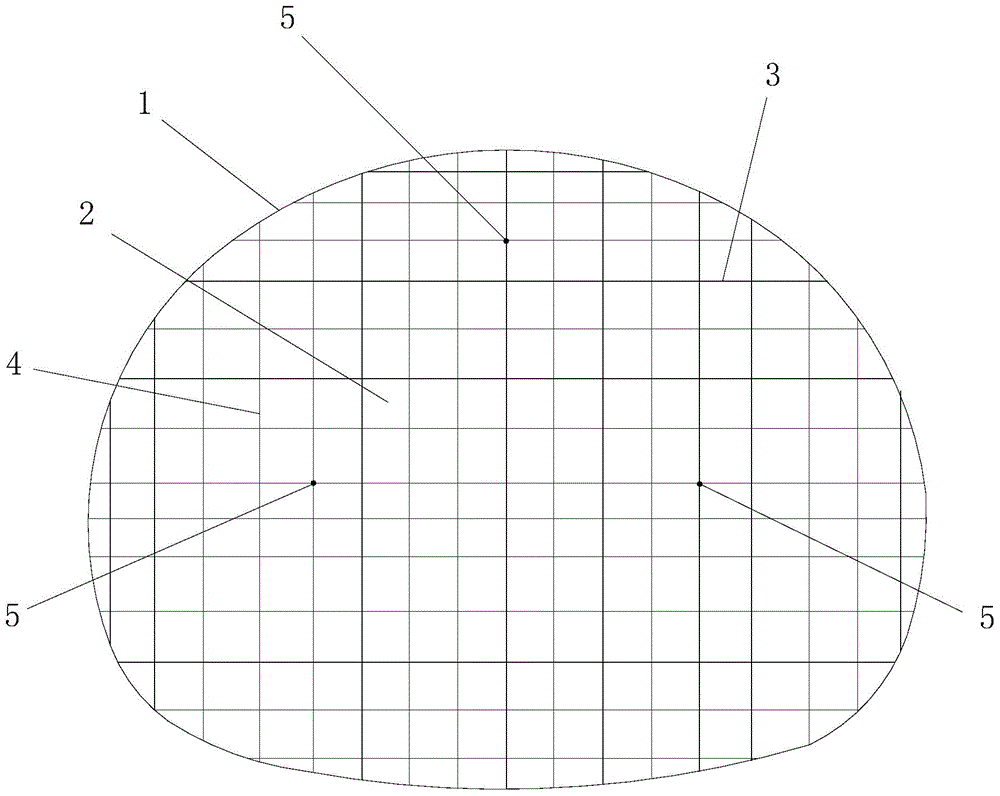

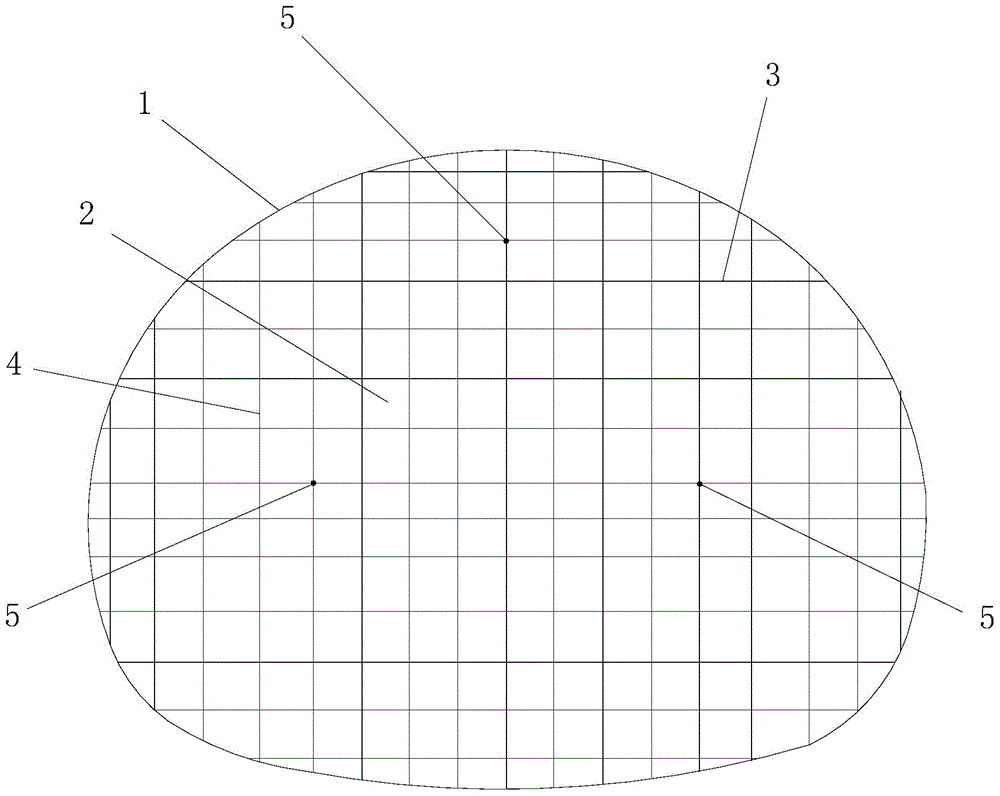

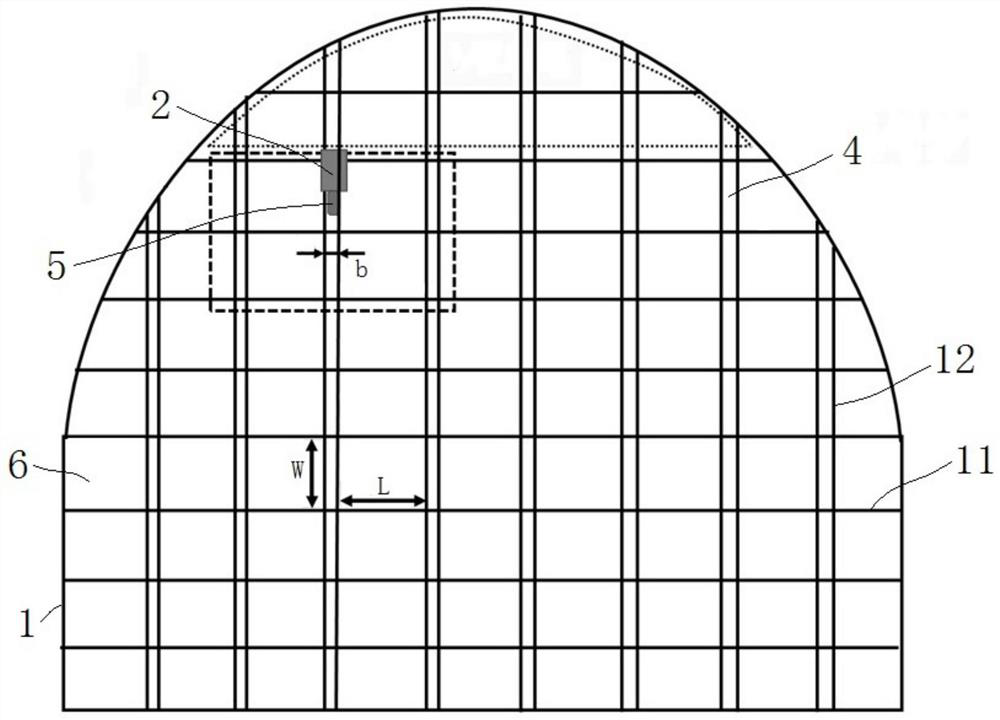

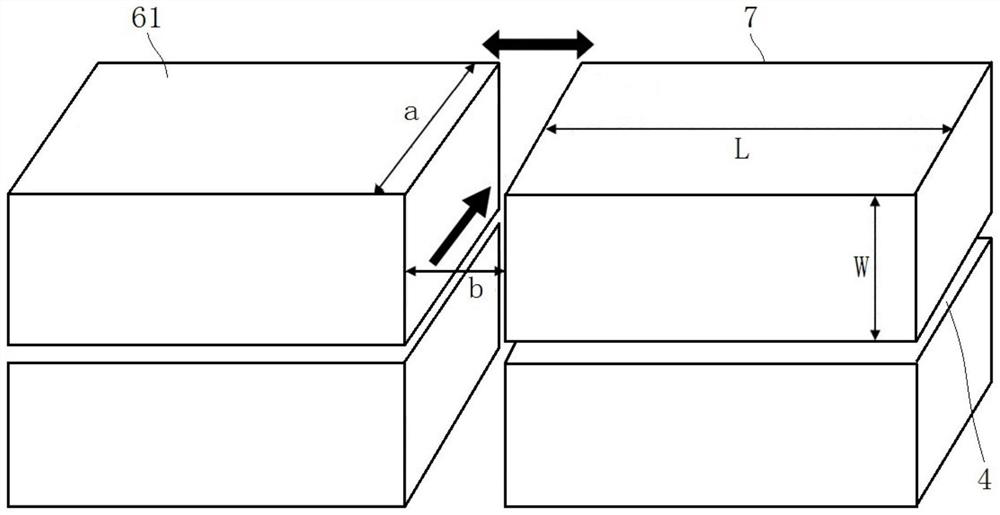

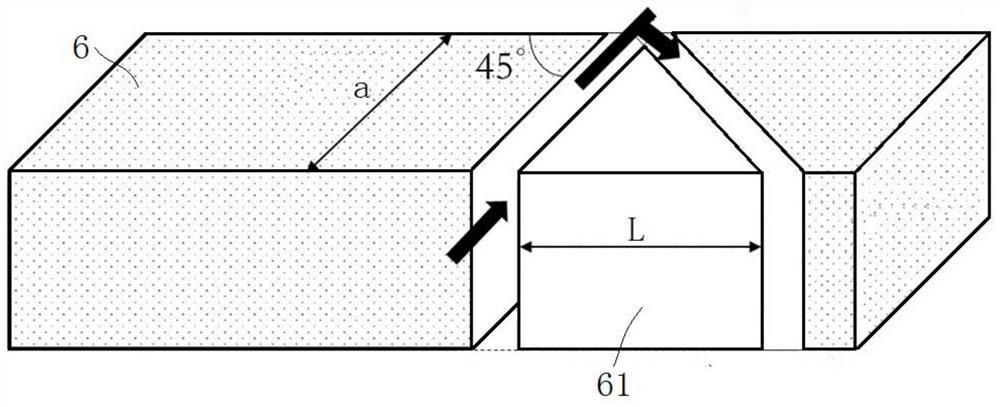

A Construction Method of Hard Rock Tunnel Based on Hydraulic Cutting

The invention discloses a hard rock tunnel construction method based on water power cutting. The hard rock tunnel construction method based on the water power cutting is characterized by constructing multiple tunnel sections from back to front along the longitudinal extending direction of a tunnel. When any one tunnel section is constructed, the process is as follows: 1, surrounding rock classification advanced detection; 2, construction parameter confirmation, wherein the confirmed construction parameters comprise cutting parameters of a water power cutting machine and split force of a hydraulic splitter; 3, current constructed tunnel section construction: constructing multiple cutting sections of the current constructed tunnel sections from back to front along the longitudinal extending direction of the tunnel, wherein when any one cutting section is constructed, the process is as follows: construction preparation, water power cutting, hydraulic splitting and rectangular cutting block outward transporting; 4, repeating steps one, two and three for many times until the construction process of the constructed hard rock tunnel is finished. The method provided by the invention is simple in steps, convenient to implement, lower in input cost, high in construction efficiency, good in construction effect, and can simply, conveniently and quickly finish the construction process of the hard rock tunnel.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

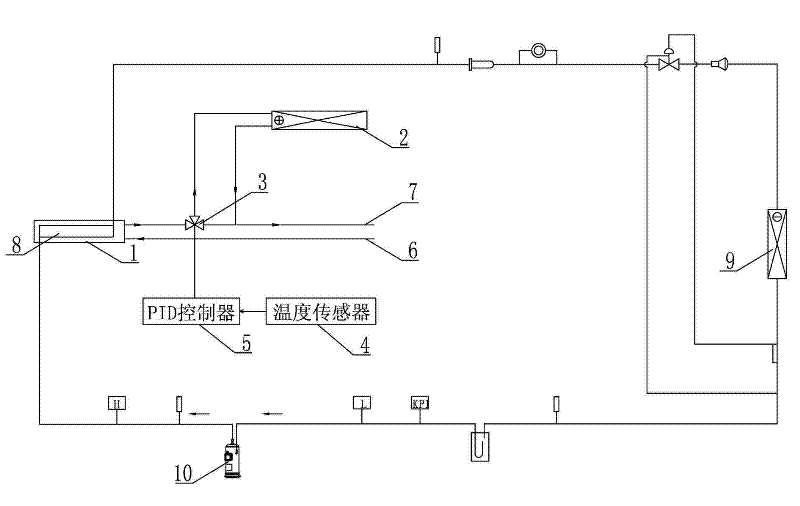

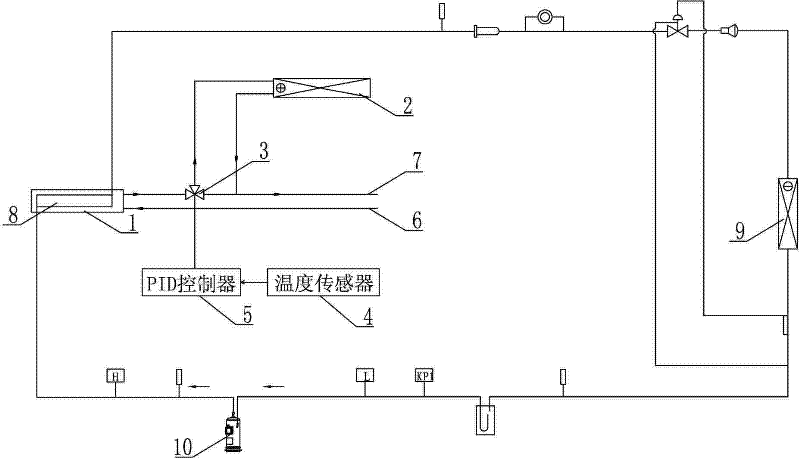

Cooling water type stepless control condensed heat recovery system

ActiveCN102338449AAchieve room temperatureReduce complexityEnergy recovery in ventilation and heatingHeat recovery systemsPipingInductor

The invention discloses a cooling water type stepless control condensed heat recovery system. The heat recovery system comprises a condenser water cold heat exchanger(1), a reheat heat exchanger(2), a proportional three-way valve (3), a temperature inductor(4), and a PID(piping and instruments diagram) controller (5), wherein the condenser water cold heat exchanger(1) is connected with a feed pipe (6) and a return pipe (7) and used for recovering the heat generated by an air condition condenser; the reheat heat exchanger(2) is connected in parallel with the pipeline of the return pipe and used for heating indoor air; the inlet of the proportional three-way valve (3) is connected with the backwater outlet of the condenser water cold heat exchanger, one outlet of the proportional three-way valve (3) is connected with the inlet of the reheat heat exchanger, and the other outlet of the proportional three-way valve (3) is connected with the return pipe; the temperature inductor (4) is usedfor sensing an indoor temperature signal; the PID controller (5) is connected with the proportional three-way valve and the temperature inductor, and used for receiving the temperature signal of the temperature inductor; and the flow opening of the proportional three-way valve is adjusted and controlled according to the temperature signal so as to adjust the reheat flowing to the reheat heat exchanger. The heat recovery system provided by the invention has the advantages of no influence on refrigerating system and self stableness of the refrigerating system, and simultaneously reduces the control complexity.

Owner:广东西屋康达空调有限公司

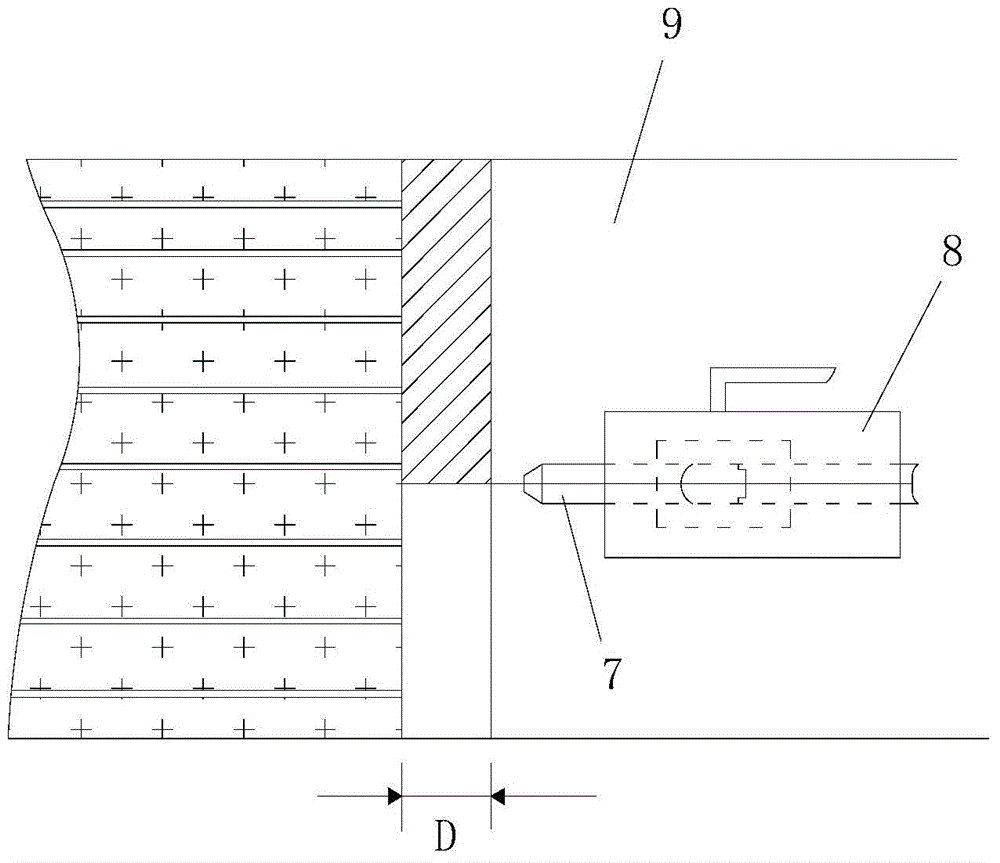

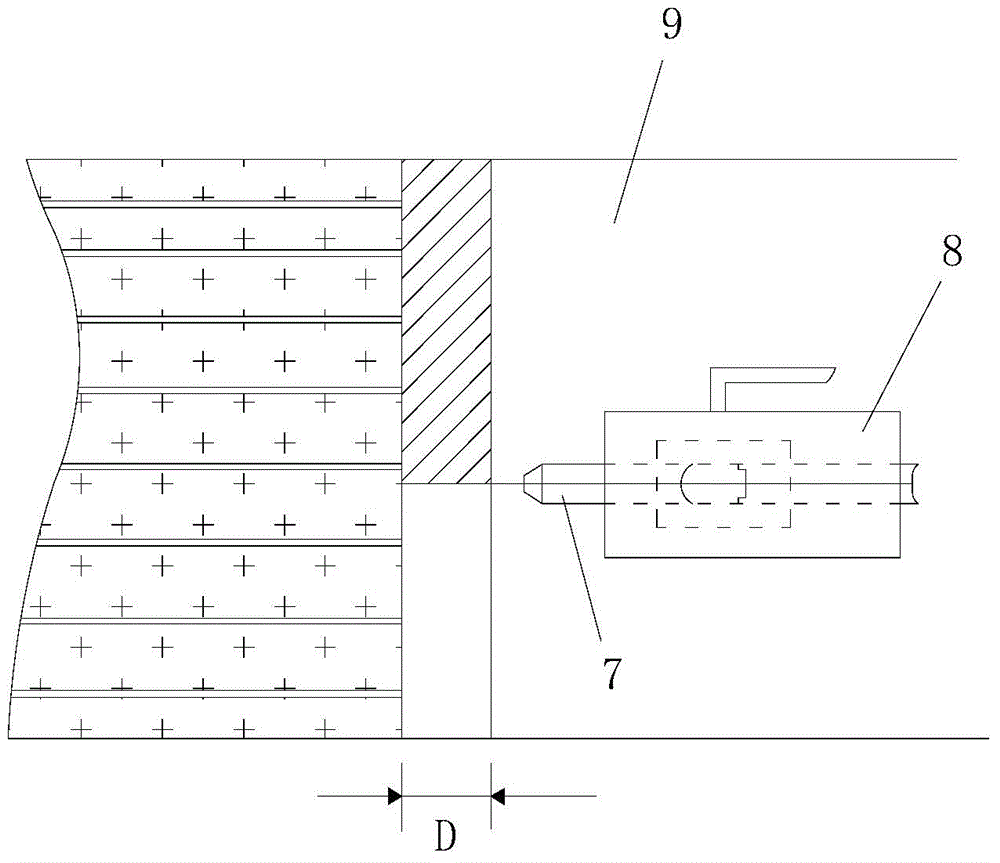

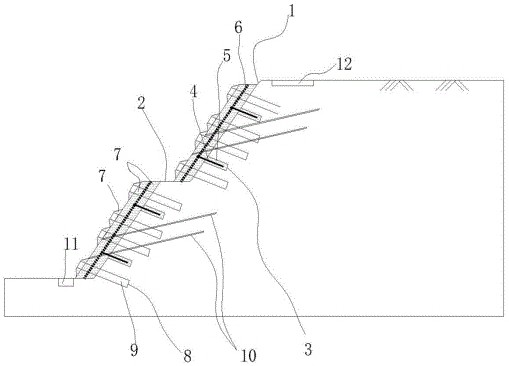

High pressure abrasive water jet tunneling method

ActiveCN113153336BIncrease disturbanceWill not affect stabilityMining devicesTunnelsMining engineeringStructural engineering

The invention discloses a high-pressure abrasive water jet tunnel excavation method, which includes the following steps: S1, confirming the construction parameters, using a high-pressure abrasive water jet device to perform trial cutting on a certain part of the tunnel face, and obtaining slot depths under different processing parameters and the slot width, and then select a set of parameters according to the construction site conditions for construction; S2, divide the tunnel surface grid, and divide the tunnel surface grid according to the construction parameters obtained in S1; S3, cut the slot, and use high-pressure abrasive water jet The abrasive water jet sprayed by the axial nozzle of the device moves along the cutting line of the face grid to form slots, which divide the face into multiple rock blocks; S4, peeling off rock blocks, uses a high-pressure water jet device The abrasive water jet sprayed by the radial nozzle in the slot radially cuts the bottom of the slot, so that the rock blocks are peeled off, and the peeled rock blocks are transported away from the face. It can be applied to rock mass excavation under various complex geological conditions, improve excavation efficiency and accuracy, and reduce environmental pollution.

Owner:CHONGQING UNIV

Metal vein water jet mining method

PendingCN113153293AImprove cutting efficiencyReduce environmental pollutionDisloding machinesUnderground miningMineralogyMining engineering

The invention discloses a metal vein water jet mining method. The metal vein water jet mining method comprises the following steps that S1, cutting is carried out along the boundary of an ore body and waste rock surrounding rock by adopting a water jet cutting assembly, and the ore body is separated from the waste rock surrounding rock; S2, a plurality of positioning holes distributed in an array are formed in the ore body; S3, the positioning holes serve as blast holes, an axial nozzle of the water jet cutting assembly is adopted to cut the periphery of the positioning holes to form at least one detonating seam, openings of the detonating seams communicate with the positioning holes, then the positioning holes are filled with explosive, the holes are sealed, a detonating cord is arranged, and detonating is carried out to enable the ore blocks to be peeled off; or the axial nozzle of the water jet cutting assembly is adopted to cut the slots, and the slots divide the ore body into a plurality of ore blocks; and a radial nozzle in the water jet cutting assembly is used for performing radial cutting on the bottoms of the slots, and stripping of the ore blocks is achieved; and S4, the peeled ore blocks are transported away from the working face. The mechanical degree is high, the ore dilution loss rate can be remarkably reduced, the ore extraction efficiency is improved, and environmental pollution is reduced.

Owner:CHONGQING UNIV

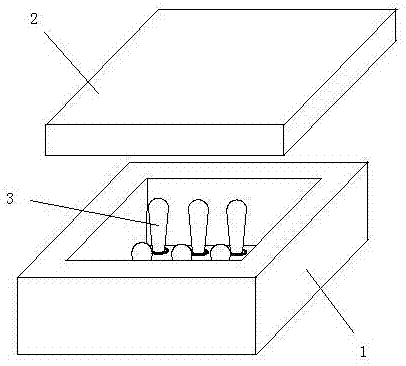

Transport box

InactiveCN107098040AWill not affect stabilityImprove buffering effectCoverings/external coatingsContainers to prevent mechanical damageEngineeringTesting tubes

The invention discloses a transport box. The transport box comprises a box body and a cover body adaptive to the box body, wherein the upper part of the box body is open; an accommodating cavity is formed in the box body; a plurality of support columns distributed at an equal interval are arranged in the accommodating cavity; each support column is an inverted conical body with a large top and a small bottom; a buffer block arranged along the circumferential side of the lower end part of each support column is arranged on the lower end part; a clamping groove formed in the perimeter direction of each buffer block is formed in the buffer lock; an ejection sheet is arranged on the upper end part of each support column; the two ends of each ejection sheet are connected with the upper end of a left hanging rope and the upper end of a right hanging rope separately; the lower end of each left hanging rope is fixed to the buffer block at the left side of the corresponding support column; and the lower end of each right hanging rope is fixed to the buffer block at the right side of the corresponding support column. According to the transport box provided by the invention, test tubes are supported through the support columns, and the open ends of the test tubes are limited through the clamping grooves of the buffer blocks; and meanwhile, the bottoms of the test tubes are wrapped with the ejection sheets, the hanging ropes are tensioned, and the components are mutually cooperated in a matching manner. The transport box is high in stability, good in application prospect and worthy of popularization.

Owner:JURONG DINGSHENG CARTON PACKING

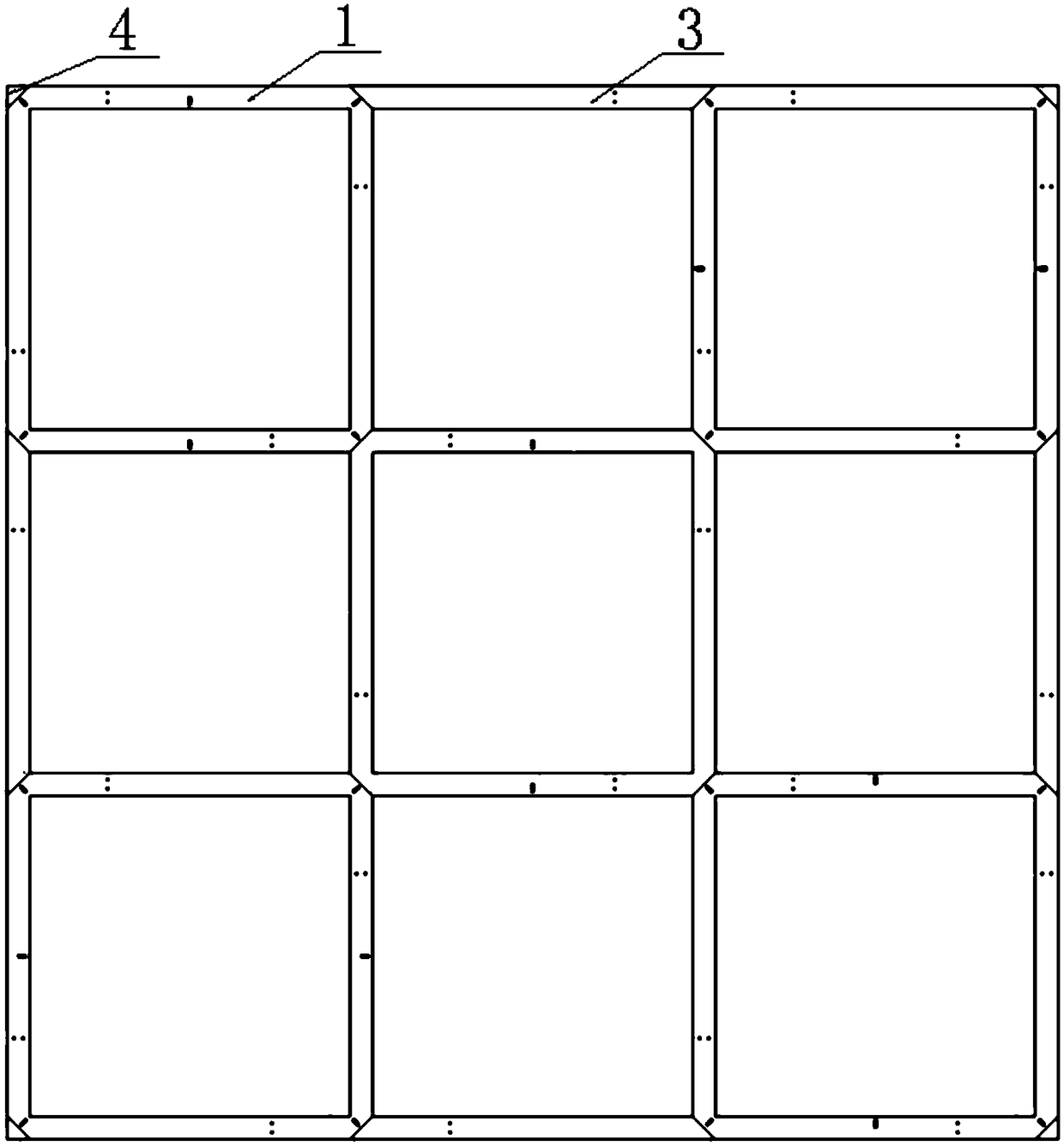

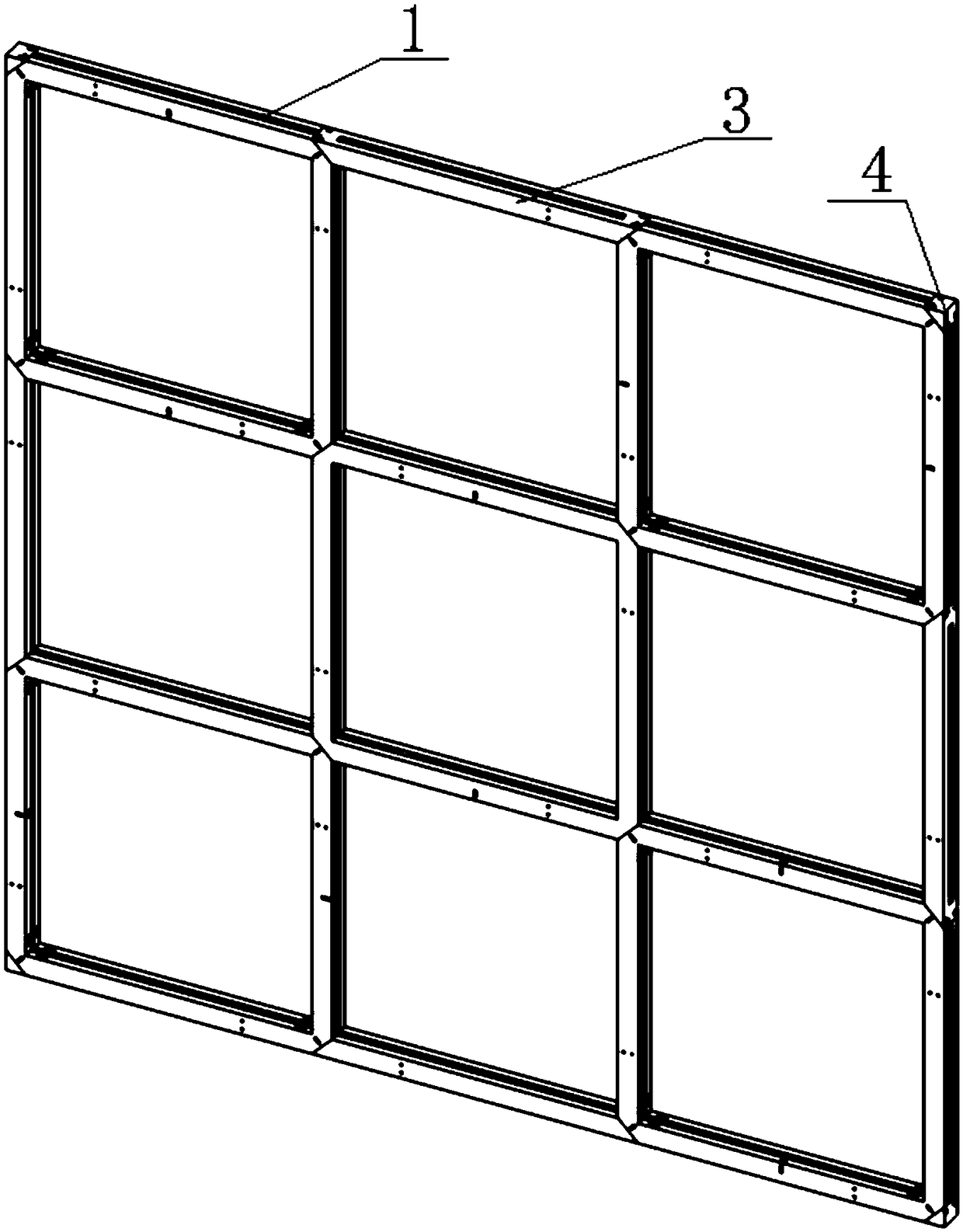

Reconfigurable distribution type wall system and frame type assembly thereof

The invention, which relates to the field of assembling walls, discloses a reconfigurable distribution type wall system and a frame type assembly thereof. The reconfigurable distribution type wall system comprises frame type assemblies and functional modules. Structural connecting portions are arranged at the outer sides of the corner angles of the frame type assemblies; all frame type assembliesare connected mutually by the structural connecting portions to form a wall frame; interval space is formed between every two adjacent frame type assemblies; inner-side space of the frame assemblies and the interval space form module installation space; and the function modules are arranged in the module installation space. According to the reconfigurable modular wall, the effects of the functionmodules can be realized better without considering the strengths of the function modules; when the function module needs to be adjusted or replaced, only connection between the function module and thewall frame needs to be dismounted but the overall stability of the wall is not affected; and under the condition of having the same wall area, the number of the frame type assemblies is reduced effectively, so that the stress performance of the overall wall frame is enhanced.

Owner:李劲

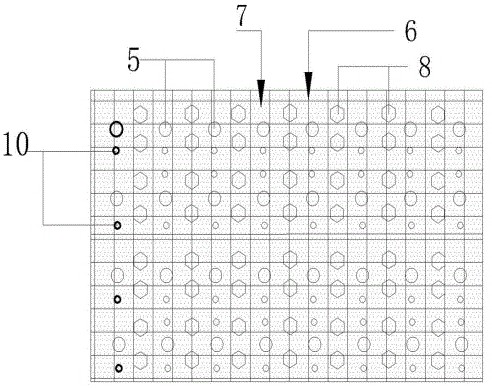

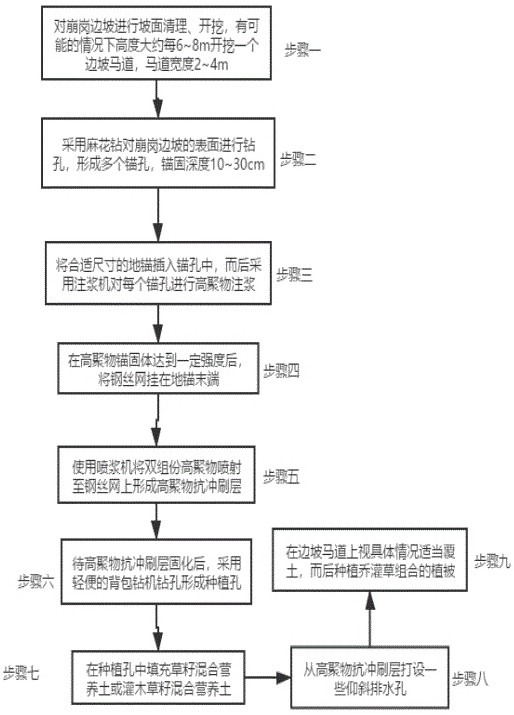

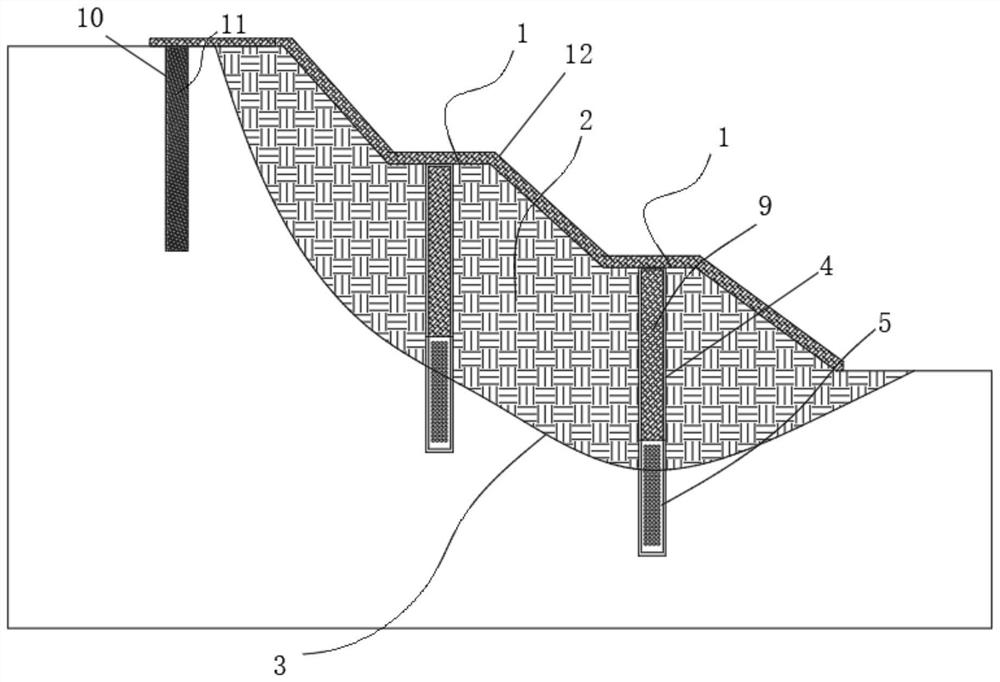

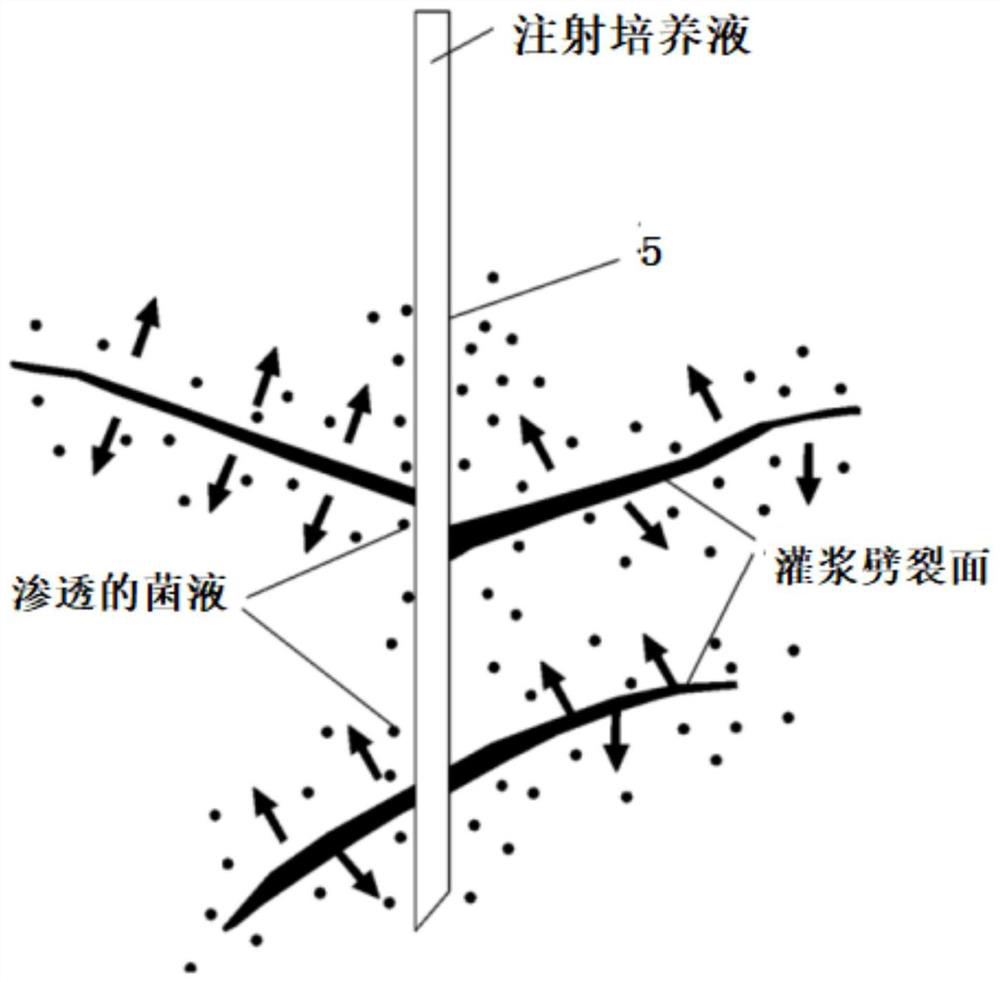

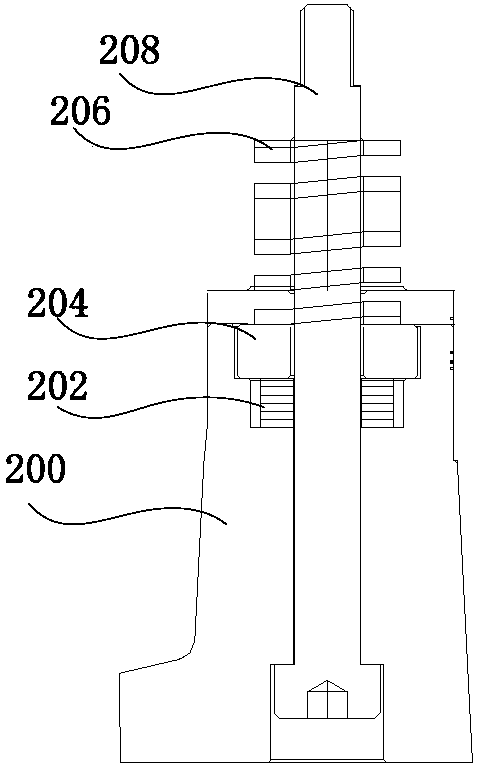

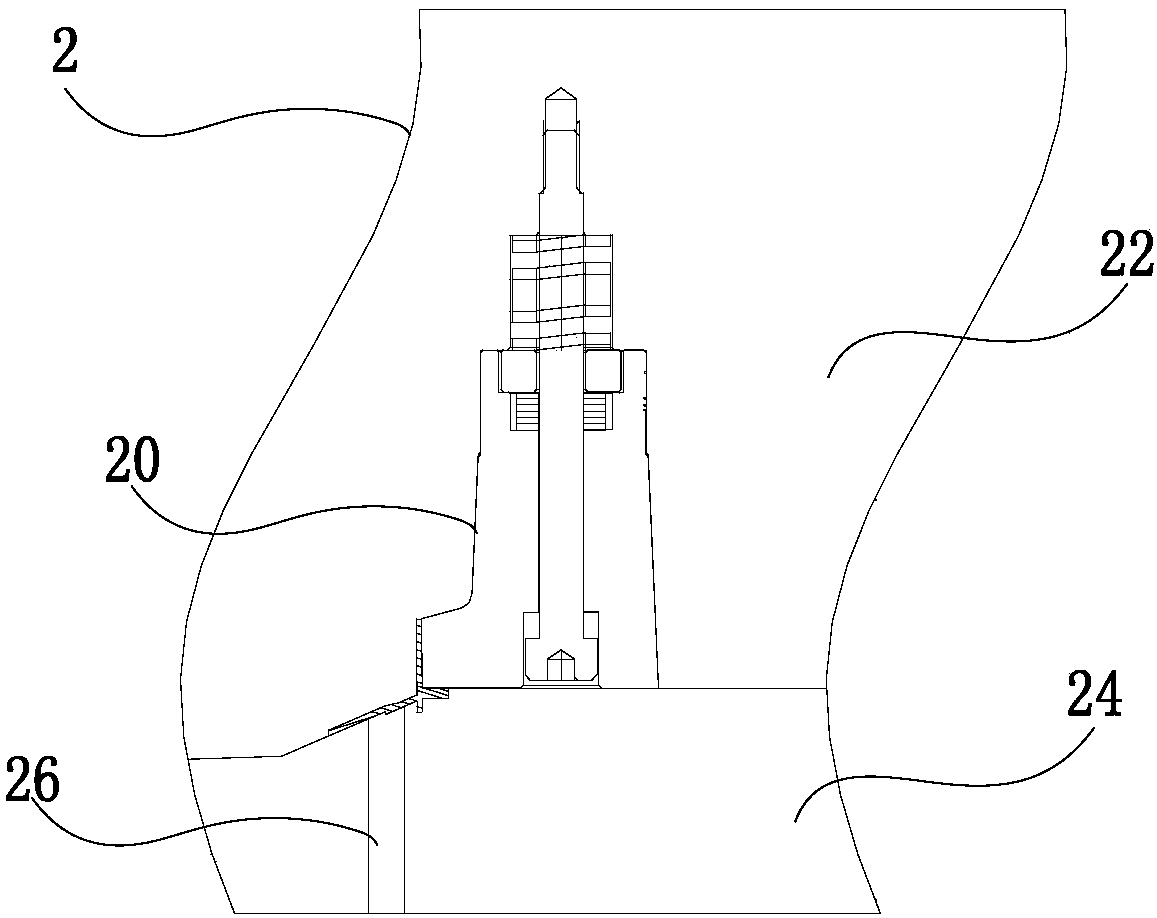

Construction method of fast-setting polymer grouting for rapid control of collapsed hills

ActiveCN113529753BEffective squeezeIncrease anchoring forceHops/wine cultivationTurf growingEnvironmental resource managementEcological environment

The invention relates to a construction method for fast-setting polymer grouting to quickly control collapsed hillocks. The scheme includes the following construction steps: excavating at least one side slope horse track on the collapsed hillside slope; drilling a plurality of anchor holes on the collapsed hillside slope ; Insert the ground anchor into each anchor hole and perform polymer grouting to form a polymer anchor; Lay the steel mesh on the surface of the collapsed hillside slope and connect and fix it with the end of each ground anchor, and the steel mesh is connected to the There are several spacers between the surface of the collapsed hillside slope; two-component intumescent polymer grouting material is sprayed on the steel wire mesh to form a high polymer anti-scour layer; drills are drilled on the collapsed hillside slope through the mesh of the steel mesh. Take a plurality of planting holes; fill each planting hole with mixed nutrient soil of grass seeds; set a plurality of inclined drainage holes inwardly and upwardly from the high polymer anti-scour layer, this method has the advantages of short construction period, ecological environment protection and convenient construction And the advantages of high strength and strong erosion resistance.

Owner:FUJIAN GEOLOGICAL ENG SURVEY INST

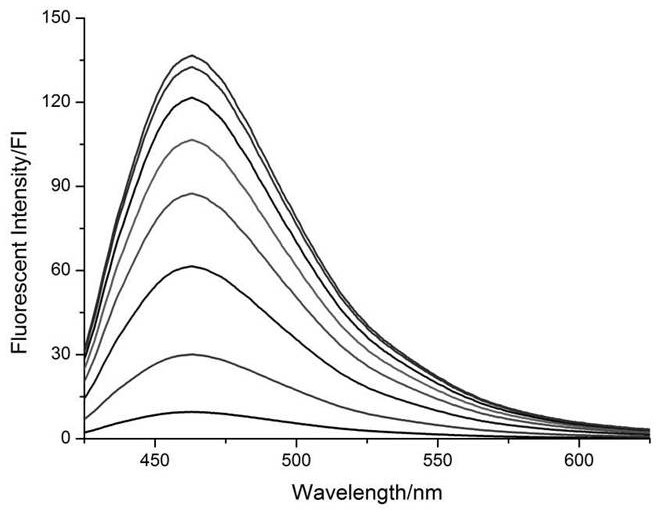

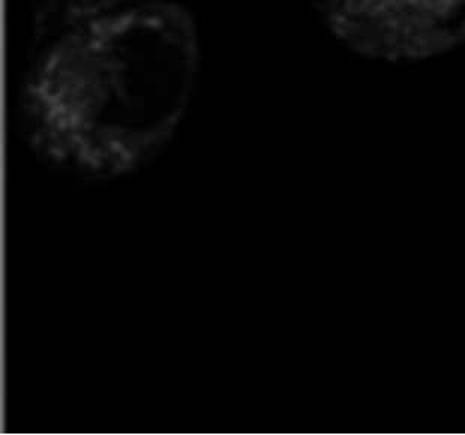

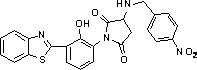

Preparation and application of novel fluorescent probe having ICT-PET effect and capable of being used for formaldehyde detection

ActiveCN112795377AGood for bioimagingWill not affect stabilityOrganic chemistryFluorescence/phosphorescenceFluoProbesChemical structure

The invention relates to preparation and application of a novel fluorescent probe having an ICT-PET effect and capable of being used for formaldehyde detection, which belong to the technical field of analytical chemistry. The chemical structure of the novel fluorescent probe is shown as a formula (I). The invention also discloses a preparation method of the fluorescent probe and application of the fluorescent probe in detection of environment and biological samples. The fluorescence intensity of the probe is obviously improved along with the increase of the formaldehyde content, and the probe can be used for formaldehyde detection and fluorescence imaging in different systems such as environment and living cells, and has a good application prospect. The formula (I) is as shown in the specification.

Owner:HUNAN TARGETING DETECTION TECH CO LTD

A fence with convenient adjustment and wide versatility

The invention belongs to the field of wood and plastic rails and particularly relates to a rail convenient to adjust and high in universality. The rail convenient to adjust and high in universality comprises a base, a stand column and a rail plate, wherein the stand column comprises an inner casing pipe and an outer wall pipe which is provided with one or more mounting grooves, and locating grooves are formed in the groove walls of the mounting grooves. The rail further comprises a sealing strip which is provided with matching ribs, wherein the locating grooves are formed in the sides, close to groove openings, of the groove walls of the mounting grooves, and the outer wall pipe is fixedly connected with the inner casing pipe through the groove walls of the mounting grooves. The inner casing pipe is a square pipe, a circular pipe is arranged on the inner pipe wall of the inner casing pipe in an internally tangent mode, locating cavities are formed in the parts, located at the four corners of the inner casing pipe, between the circular pipe and the inner casing pipe, and the base comprises a bottom plate and a locating pipe and is further provided with locating bars. The rail convenient to adjust and high in universality is simple in structure, good in mounting stability, not prone to shaking, high in universality of all parts, convenient to process, low in cost and small in mounting waste, and the mounted wood and plastic rail is high in integrality, high in universality of parts and convenient to adjust.

Owner:浙江中吴建设有限公司

A cadmium-contaminated soil remediation fixative based on microbial assembly synthesis and its preparation and application method

ActiveCN105733599BLarge specific surface areaHigh reactivityOrganic fertilisersSoil conditioning compositionsEutrophicationPhosphate

The invention discloses a cadmium-contaminated soil remediation fixing agent based on microorganism assembly synthesis as well as preparation and an application method thereof. At present, multiple nano phosphate fixing agents for cadmium-contaminated soil remediation are easily dispersed and lost, underground water eutrophication is caused, and further secondary pollution is caused. Aiming at solving the problems, nano-hydroxyapatite is taken as a central substance, aspergillus niger hyphae are adopted for wrapping the nano-hydroxyapatite, and a cadmium-contaminated soil remediation fixing agent specific to high contamination and high acidity is prepared, so that the problem of excessive dispersion in practical application is solved. A synthesized product is uniformly mixed with cadmium-contaminated soil in a certain rate, and effective state cadmium content is reduced by 67-86%. The cadmium-contaminated soil remediation fixing agent disclosed by the invention is simple in preparation process, low in cost, efficient, non-toxic and biodegradable and has no secondary pollution, thereby being an environment-friendly fixing agent.

Owner:JIANGXI GAIA ENVIRONMENTAL SCI & TECH CO LTD

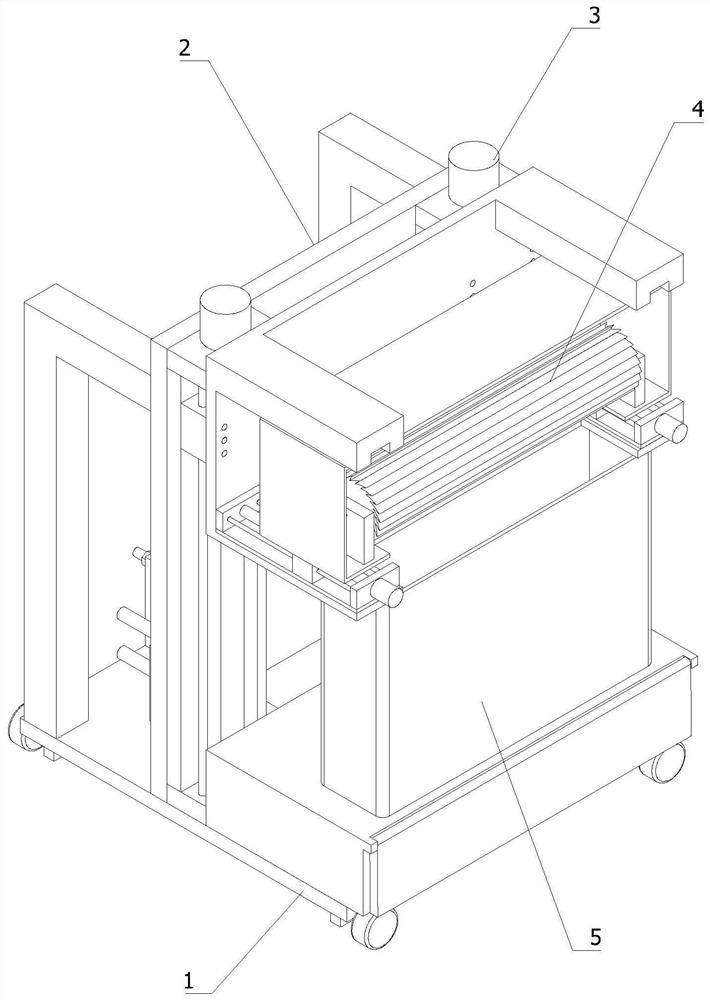

Wall surface refurbishment machine for building construction

The invention relates to the field of building construction, in particular to a wall surface refurbishment machine for building construction. The wall surface refurbishment machine for building construction comprises a moving seat, the moving seat is a rectangular flat plate, a fixed plate is vertically and fixedly mounted on the upper surface of the moving seat, the fixed plate is a rectangular flat plate, a driving assembly is fixedly mounted on the fixed plate, the driving assembly is used for achieving movement in the vertical direction and the horizontal direction, a refurbishment device is fixedly installed at the driving end of the driving assembly, a working shaft of the refurbishment device is arranged to be a horizontal defense line, the refurbishment device is used for shoveling old coatings on the surface of a wall, a waste material collecting device is fixedly installed on the moving seat, the waste material collecting device is connected with the lower end of the refurbishment device, and the waste material collecting device is used for collecting the old coatings shoveled by the refurbishment device. According to the wall surface refurbishment machine for building construction, the purpose that automatically shoveling is carried out on the old coatings on the surface of the wall is achieved, and the technical problem that the working efficiency is low when a shovel blade is manually used is solved.

Owner:司敏

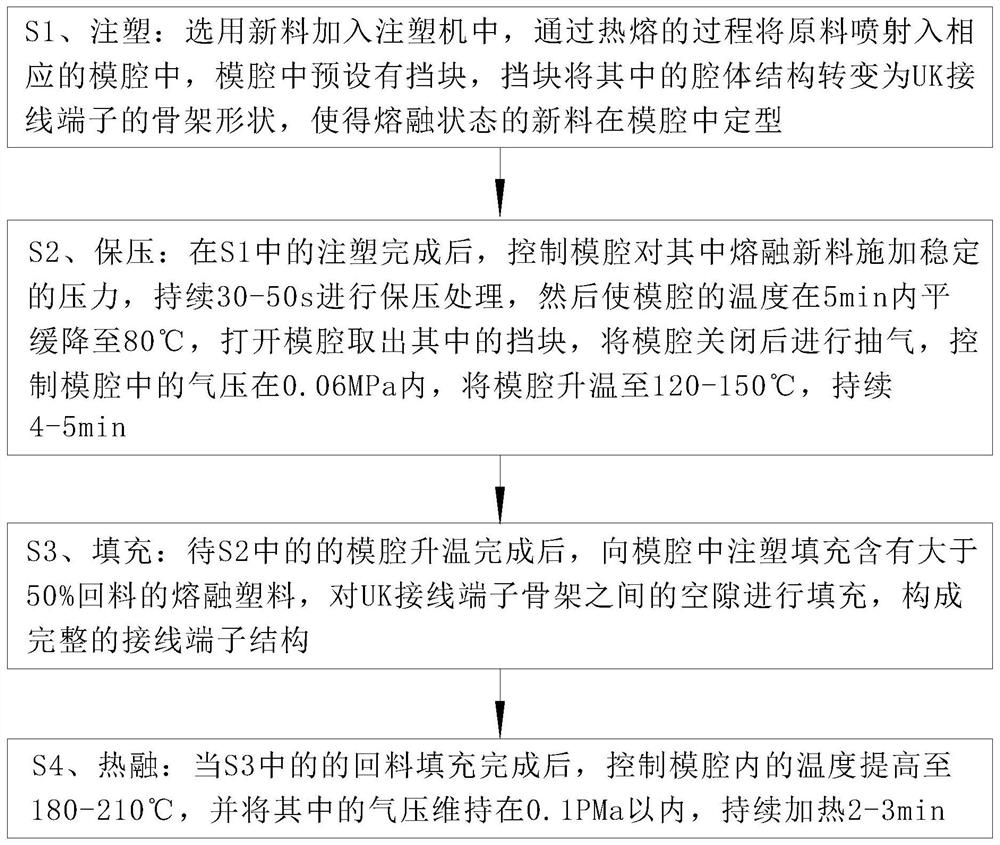

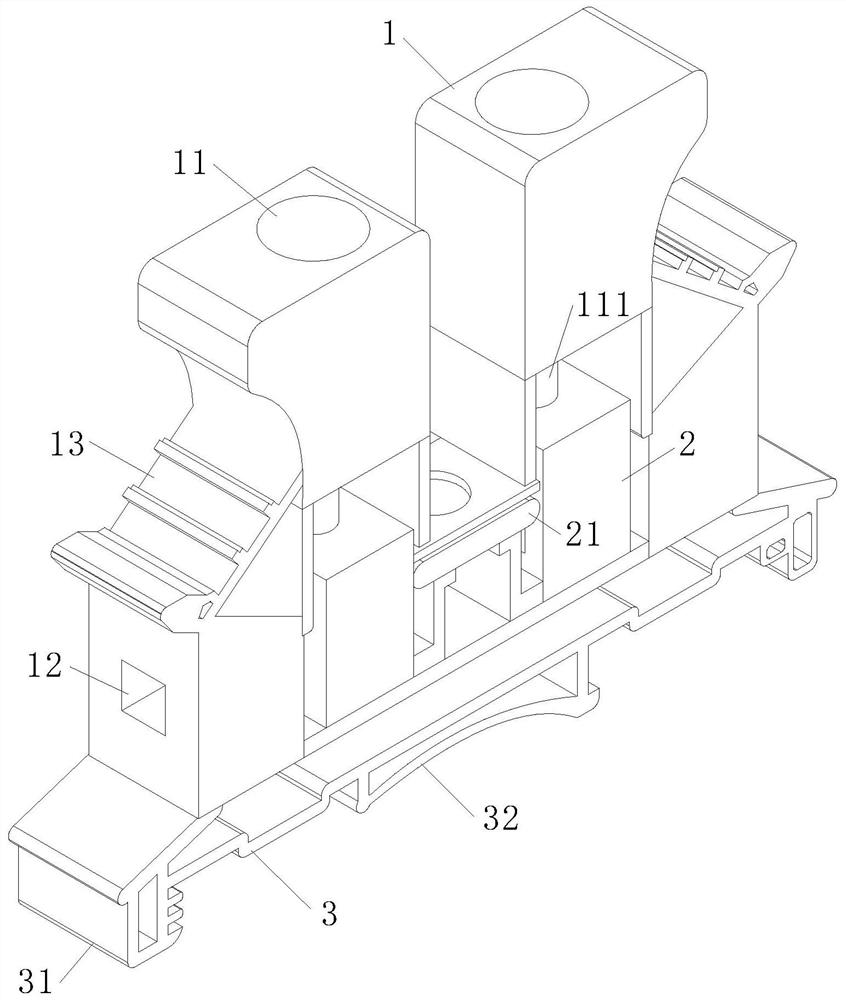

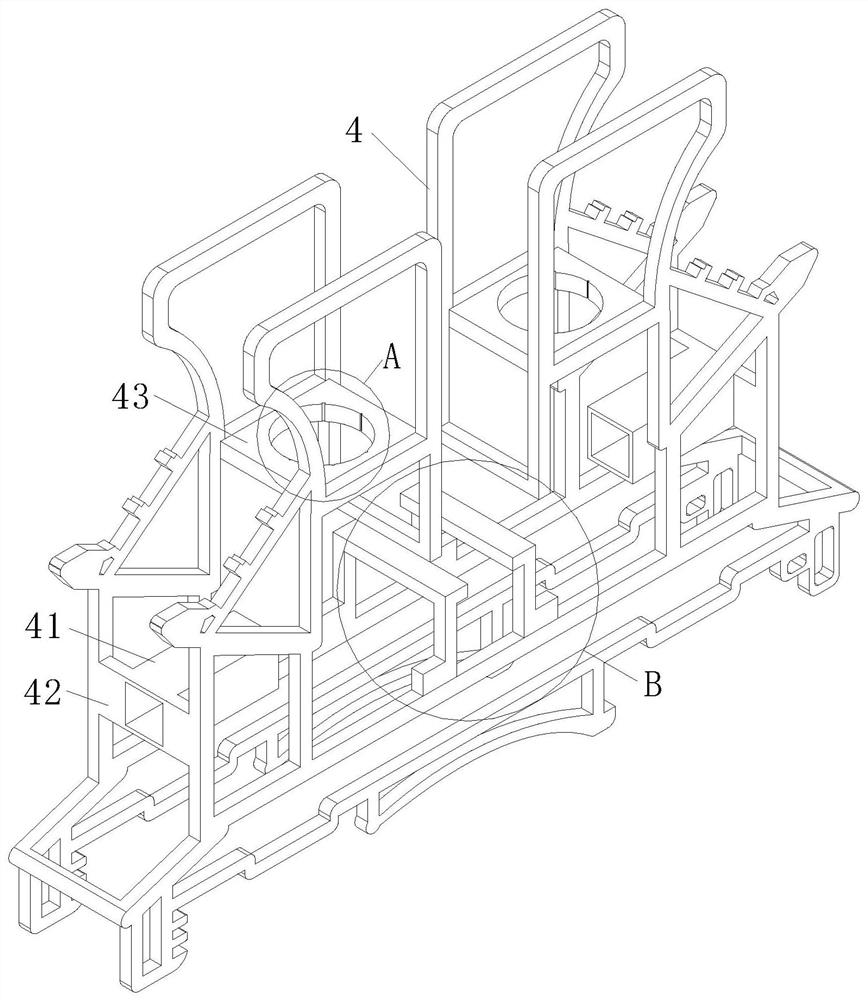

UK wiring terminal and manufacturing method thereof

InactiveCN111653881AGuaranteed performance parametersGuaranteed stabilityElectrically conductive connectionsContact member cases/bases manufactureElectrical connectionInjection moulding

The invention relates to the technical field of electrical connection, in particular to a UK wiring terminal and a manufacturing method thereof. The UK wiring terminal comprises a shell and an electricity receiving block, and the shell comprises a framework body and a filling body; and the framework body is of a frame type structure. The filling body is arranged between the frameworks of the framework body, and the framework body and the filling body are prepared through the steps of injection molding, pressure maintaining, filling and hot melting. As the UK wiring terminals are fixed on the guide rail in use, the application environment of the UK wiring terminals has corresponding requirements on aging and insulating properties of the UK wiring terminals, and the UK wiring terminals are widely applied to a circuit system, so that the cost is reduced and the reliable service life of the UK wiring terminals can be damaged by using a certain proportion of returned materials for manufacturing; therefore, the framework body formed by new material injection molding is arranged to form the shell frame, and the returned material is supplemented, injected and filled between the frames of the shell, so that the effective service life of performance parameters in use is maintained, the cost of raw material expenditure is reduced, and the competitiveness of UK wiring terminal products isimproved.

Owner:潘笑

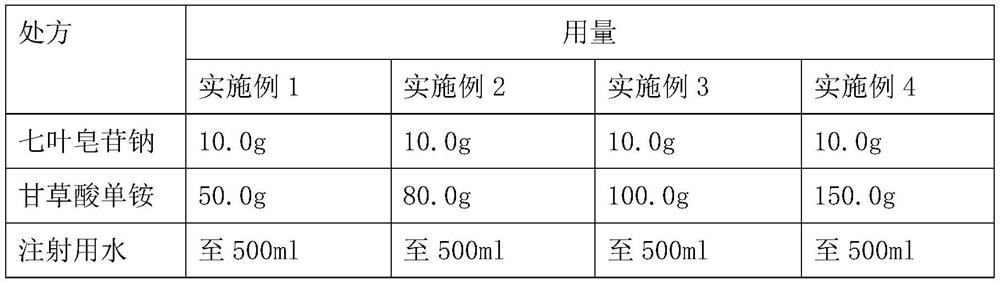

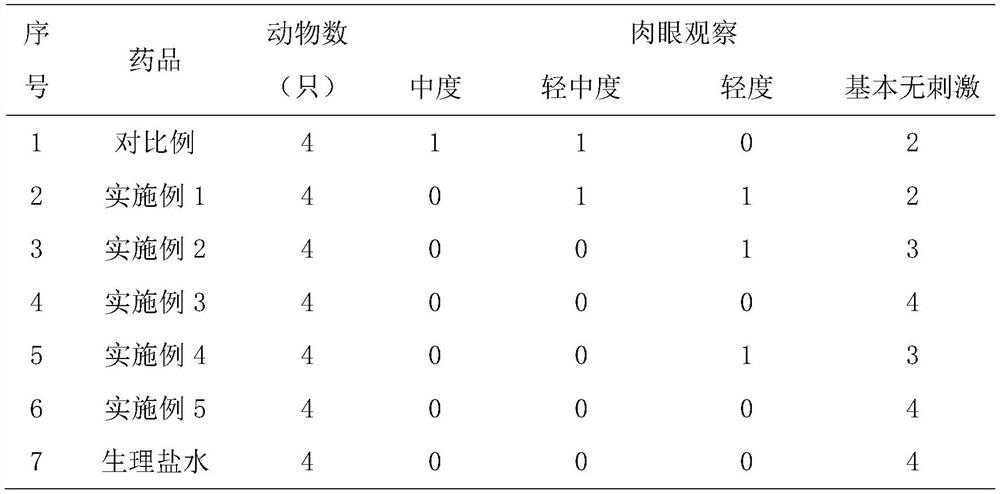

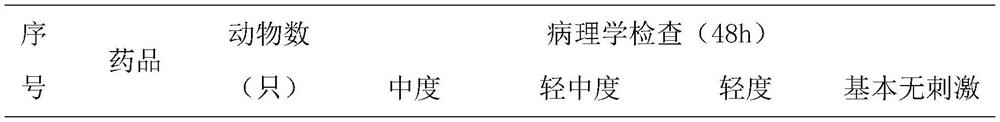

Sodium aescinate compound preparation for injection

ActiveCN114588118ALess irritatingLow incidence of adverse reactionsPowder deliveryOrganic active ingredientsIrritationCurative effect

The invention discloses a sodium aescinate compound preparation for injection, which contains sodium aescinate and glycyrrhizinate, and belongs to the field of medicines. According to the sodium aescinate injection, the problem that the occurrence rate of untoward effects is high generally existing in clinical use of an existing sodium aescinate product for injection is solved, irritation of blood vessels and injection parts caused by injection of the sodium aescinate is reduced, and meanwhile the anti-swelling curative effect of the sodium aescinate is improved.

Owner:WUHAN AIMIN PHARMA

Process and device for refining solidified microstructure by consumable shear flow method

The invention discloses a technology for refining a solidification structure through a consumable shear flow method. The technology for refining the solidification structure through the consumable shear flow method is a melt processing method which increases the number of crystal nucleus, refines grains and uniformizes formations through a consumable shear flow, and used for the casting process of large ingot castings and continuous casting billets in large cross section sizes. During the solidification of metal bath, a high-speed motor is used for generating a high rotation speed, a strong shear flow is generated in a tiny gap between a consumable metal rotor component and a consumable metal stator component, the consumable metal rotor component and the consumable metal stator component efficiently generate a plurality of crystal nucleuses under the condition that liquid level stability is not affected in a controllable space, and 'crystal rain' effect is generated. In addition, stator consumable metal and rotor consumable metal move downwards under the drive of a screw, the consumable metal can be supplemented, the purposes of improving solidification speed, refining grains, increasing equiaxial crystal ratio and reducing solute segregation degree are ultimately achieved, and the alloy performance is improved. The invention further provides a consumable shear flow metal melt processing device. The consumable shear flow metal melt processing device comprises a shear consumable component fixing device, a shear consumable component driving device and shear consumable components made of consumable metal.

Owner:SHANGHAI UNIV

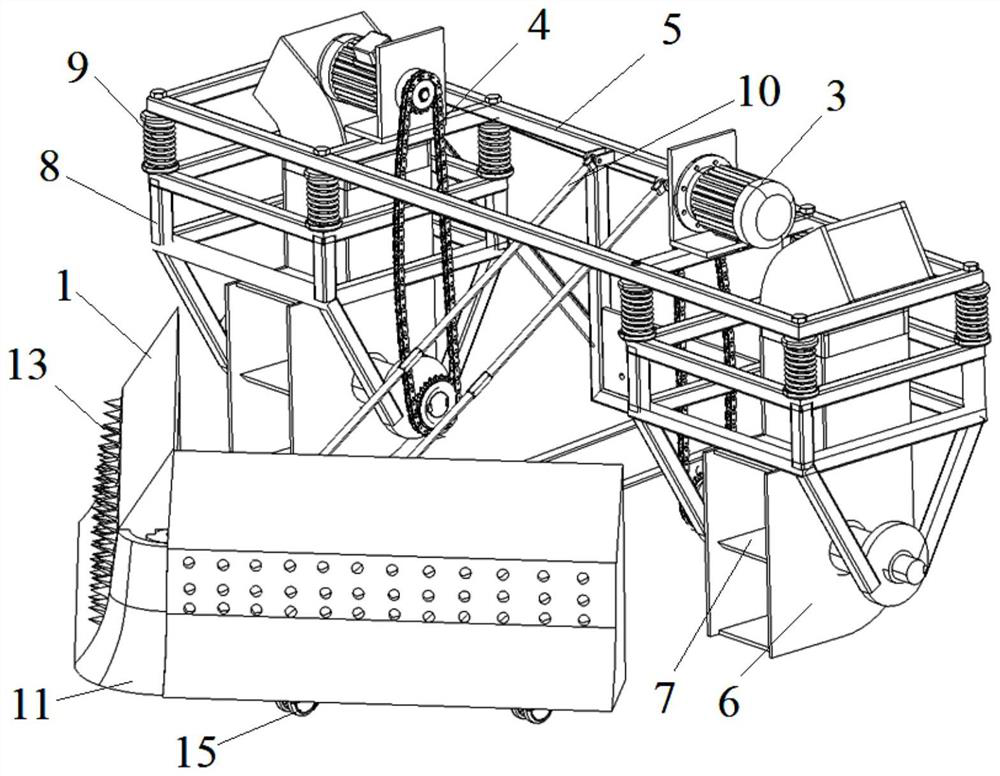

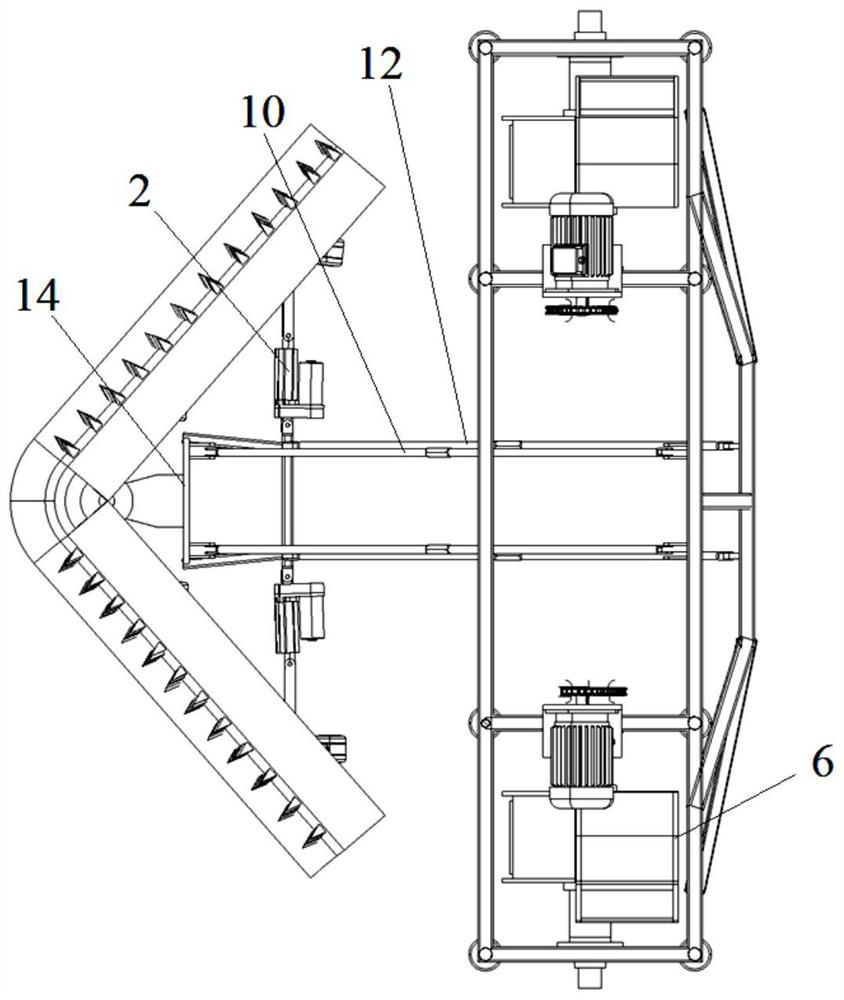

Vehicle-mounted snow sweeping device

ActiveCN114457740ARealize intelligent snow removalImprove the efficiency of snow separationSnow cleaningSnowpackIn vehicle

The invention discloses a vehicle-mounted snow sweeping device which comprises a rack used for being connected with a vehicle, a snow shoveling mechanism connected with the rack through a connecting mechanism and used for pushing accumulated snow on a front road surface, a snow throwing device arranged on the rack and used for conveying the accumulated snow on the road surface to the two sides in the advancing direction, and a driving mechanism connected with the snow throwing device. The snow shoveling mechanism is located in front of the snow thrower.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

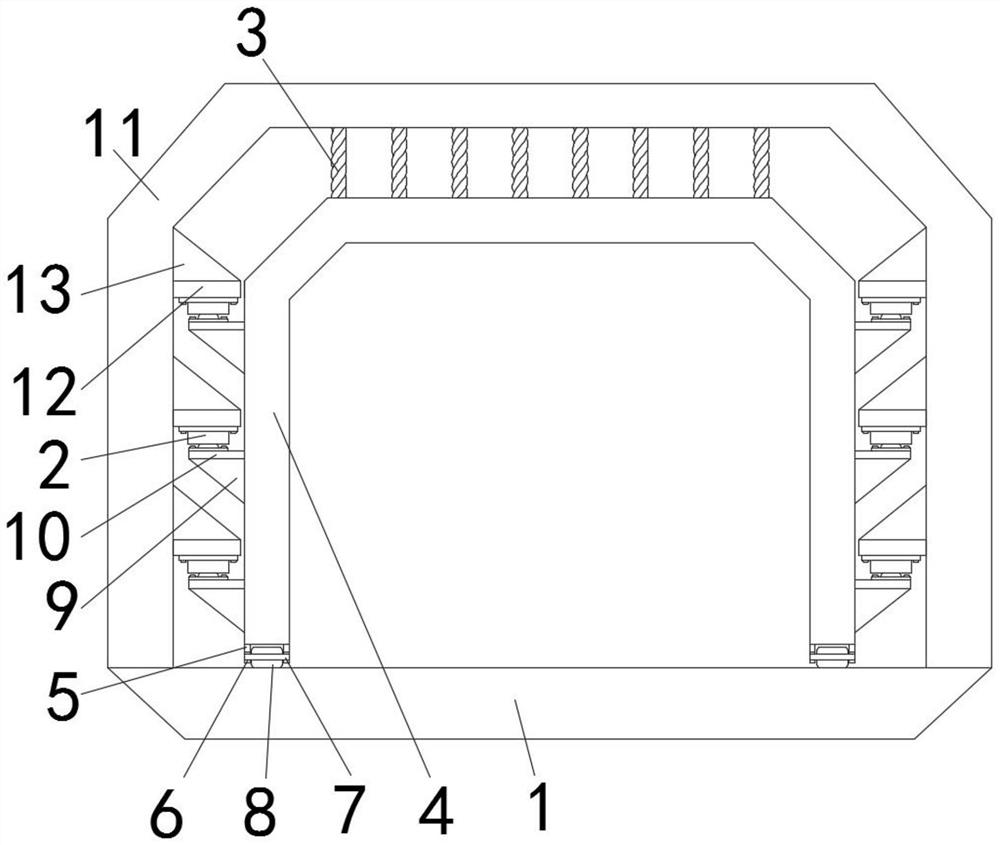

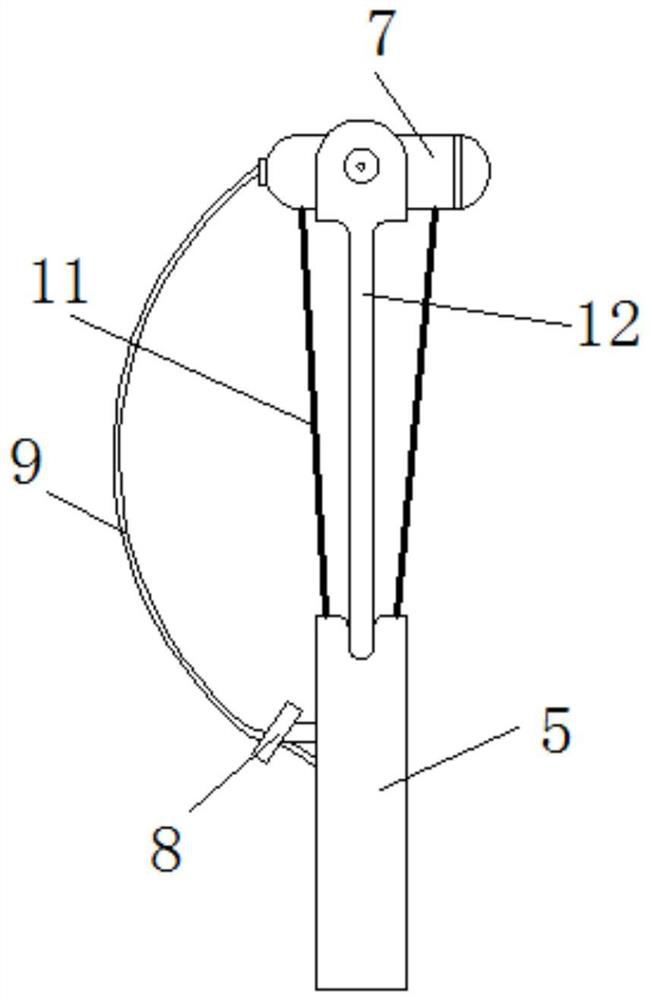

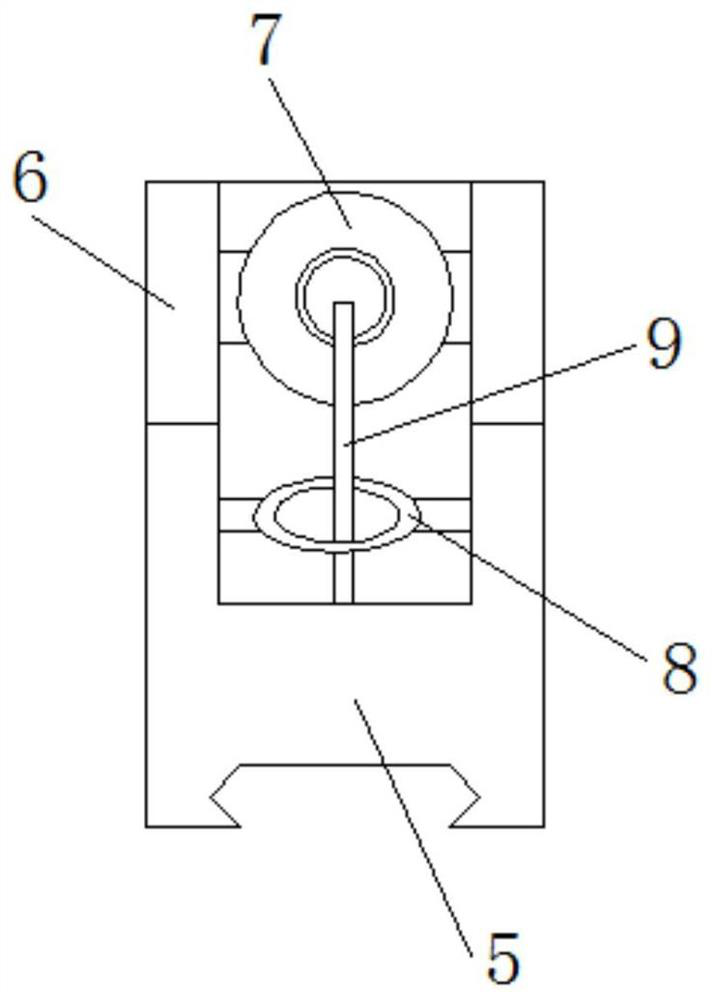

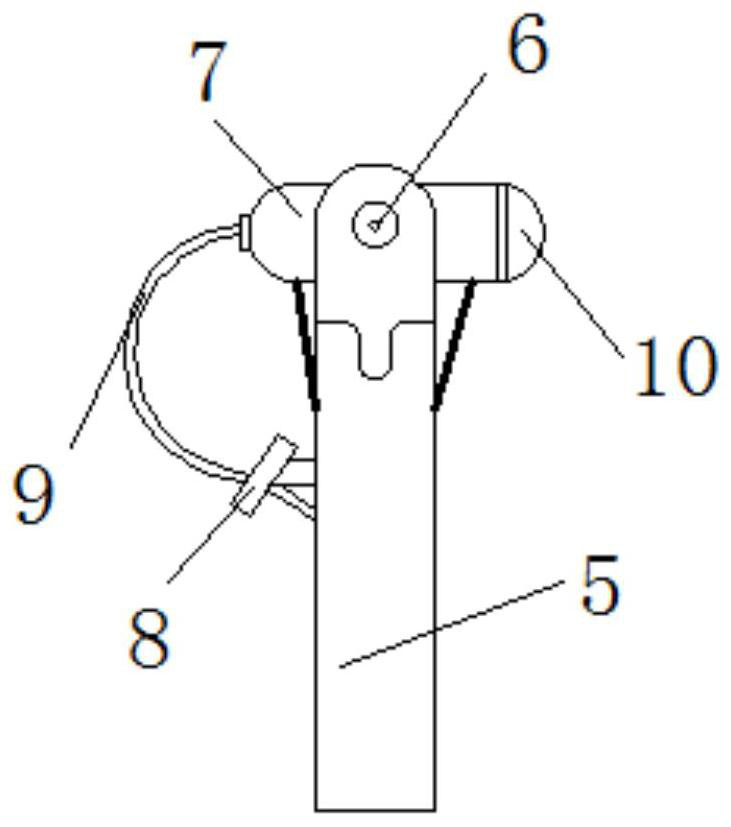

Vibration isolation reinforcing device for tunnel wall construction

InactiveCN112431608AWill not affect stabilityReduce vibration effectsMining devicesUnderground chambersArchitectural engineeringTunnel wall

The invention relates to a vibration isolation reinforcing device for tunnel wall construction. The vibration isolation reinforcing device for tunnel wall construction comprises a support fixed on theupper part of a foundation; an inner partition wall is arranged in the support; the support and the inner partition wall are connected through a first steel wire rope; a connecting base is arranged at the bottom of the inner partition wall; a rotating shaft is arranged at the bottom of the connecting base; two ends of the rotating shaft are connected with the connecting seats through bearings; rollers are arranged outside the bearings; first supporting seats are arranged on two sides of the exterior of the inner partition wall; the bottoms of the first supporting seats are connected with theinner partition wall through first triangular supporting plates; second supporting seats are arranged on two sides of the interior of the support; the tops of the second supporting seats are connectedwith the support through second triangular supporting plates; and connecting pieces are arranged between the first supporting seats and the second supporting seats. The device is high in practicability, the influence on a tunnel wall caused by vibration generated when a train passes through a tunnel can be rapidly and effectively reduced, then the situation that the tunnel wall is damaged or loosened due to long-term vibration is avoided, and potential safety hazards are reduced.

Owner:FUJIAN JIANGXIA UNIV

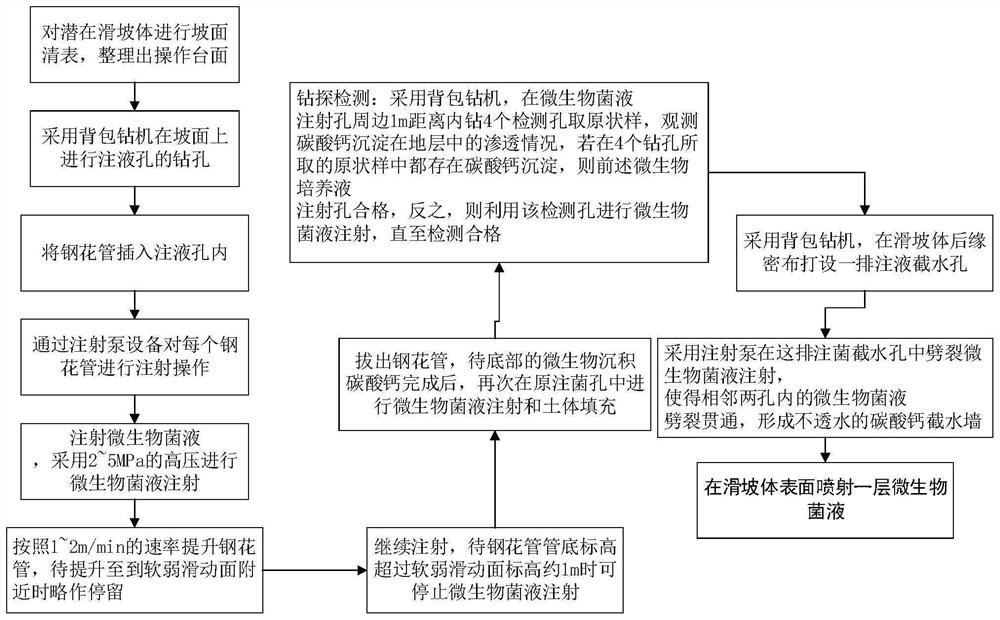

Construction method of high pressure spraying microbial bacteria liquid to deposit calcium carbonate to control landslide

Owner:FUJIAN GEOLOGICAL ENG SURVEY INST

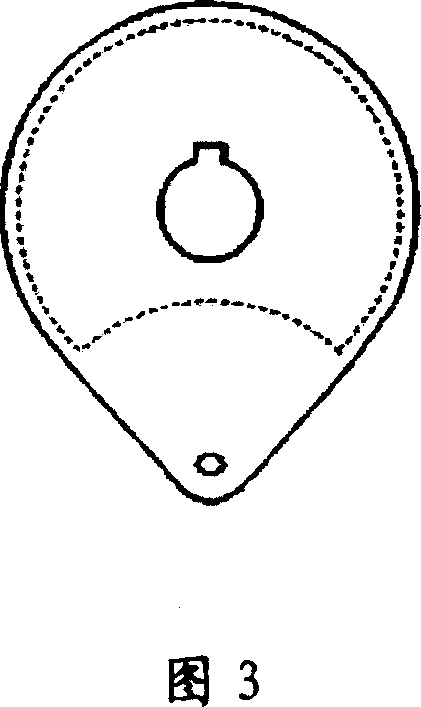

Spring block components and molds

The invention provides an elastic block component and a mold. The elastic block component comprises an elastic block, a route screw, at least one first spring, a support component and at least one second spring, wherein a through hole is formed in the elastic block; counter bores are respectively formed at the two ends of the through hole; the route screw is arranged in the through hole of the elastic block and passes through the through hole; the head part of the route screw is located in the counter bore at one end of the through hole; the first spring sleeves the route screw and is resisted against the interior of the counter bore at the other end of the through hole; the support component is located above at least two belleville springs and sleeves the route screw; the second spring is located above the support component and sleeves the route screw. The elastic block component provided by the invention combines the characteristics of large elastic force and small route of the belleville spring and small elastic force and large route of the rectangular spring, so that the elastic block can smoothly pop up without influence on the stability of the elastic block, no safety problem is caused and the requirements for normal production and convenience in maintenance of the mold can be met.

Owner:FOSHAN CITY SHUNDE DISTRICT BAINIAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com