Reconfigurable distribution type wall system and frame type assembly thereof

A distributed, wall technology, applied in building components, walls, building structures, etc., can solve problems such as poor accuracy, prolonged construction period, unfavorable transportation, etc., to meet diverse needs and ensure quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described below in conjunction with the accompanying drawings.

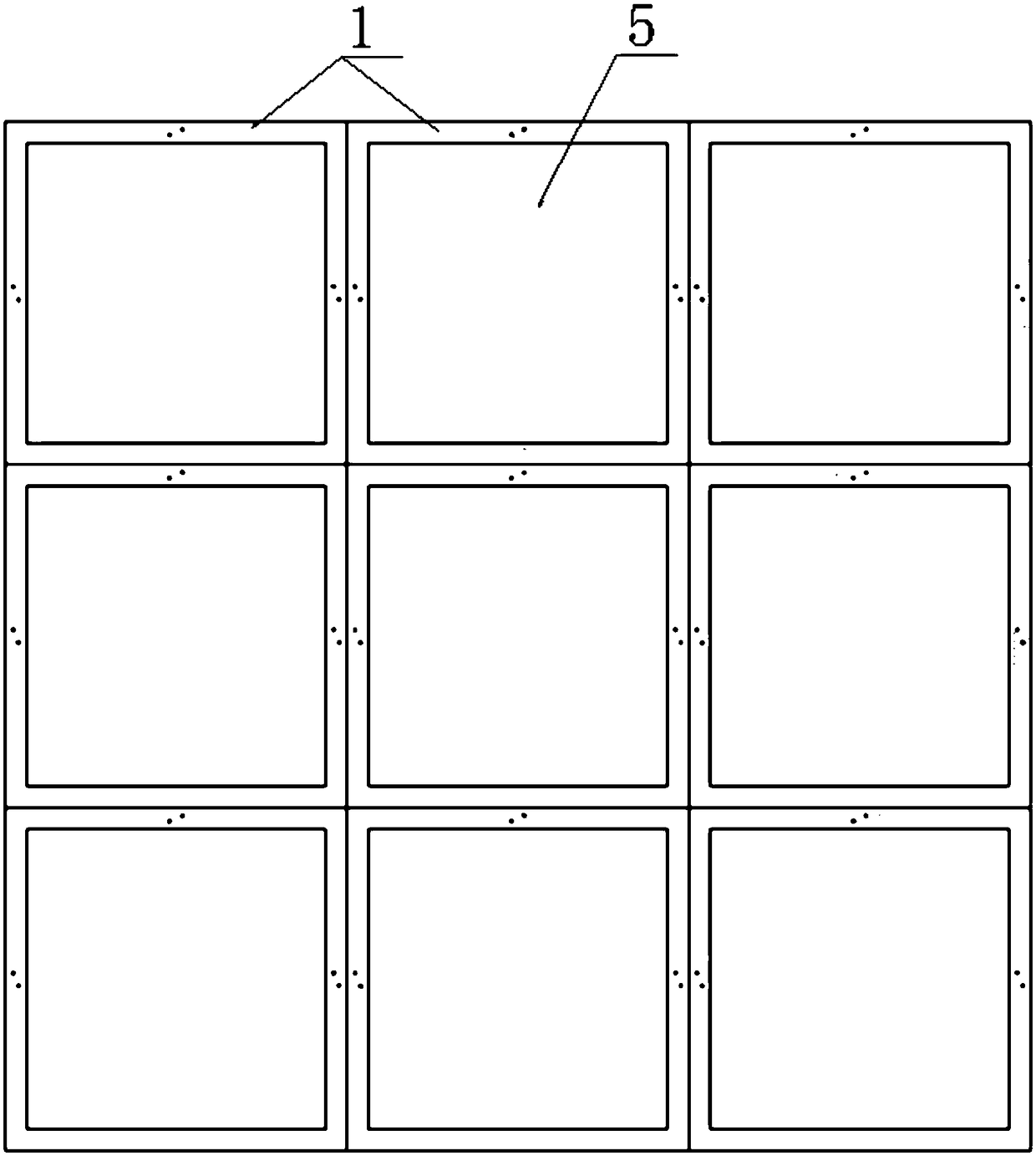

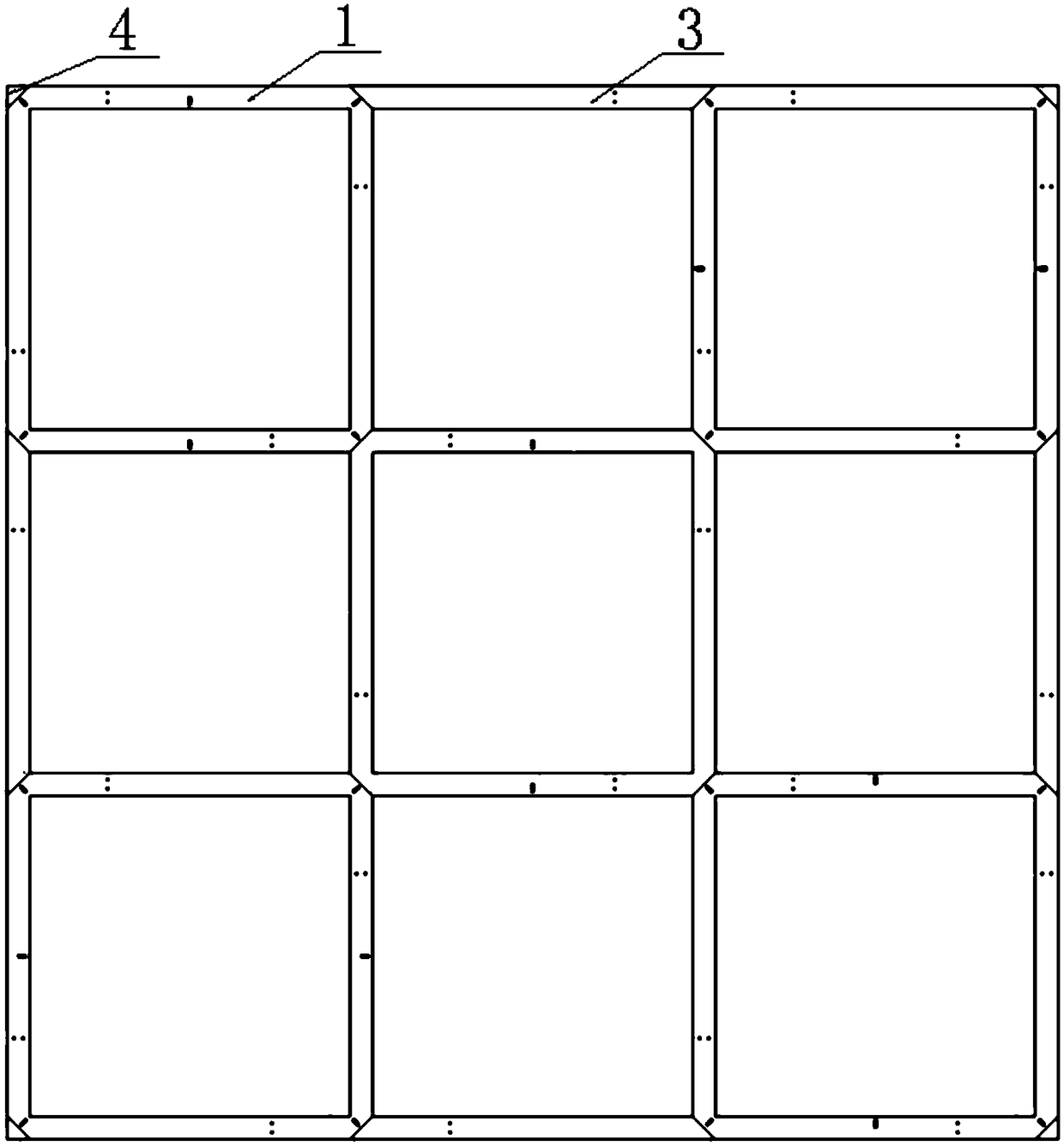

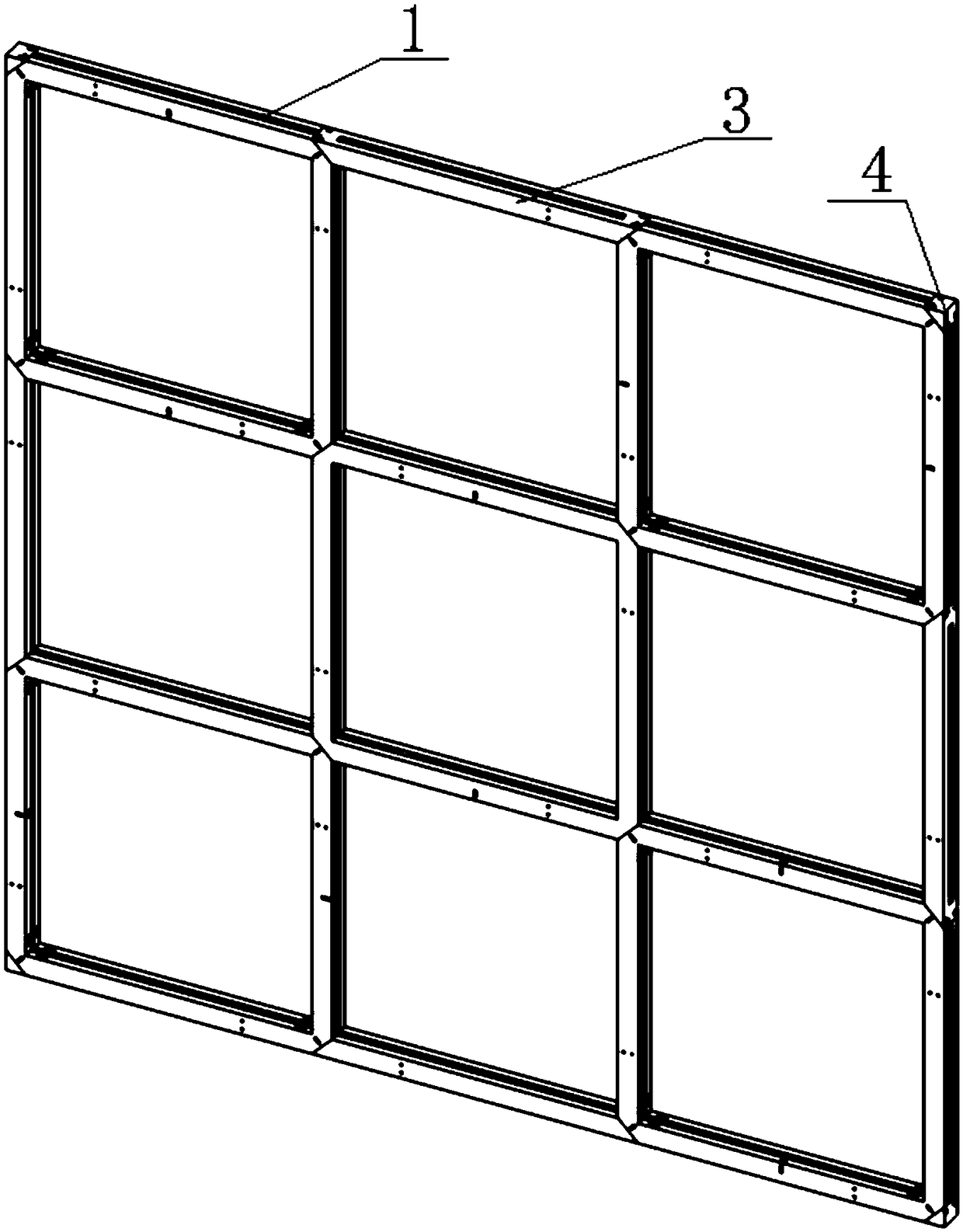

[0076] like figure 2 , image 3 As shown, the reconfigurable distributed wall system of the present invention includes a frame component 1 and a functional module 2, and a structural connection part is provided on the outside of the top corner of the frame component 1, and each frame component 1 passes through the structural connection part Interconnected to form a wall frame, there is a space between adjacent frame components 1, the inner space of the frame component 1 and the space respectively form a module installation space 5, and the functional module 2 is arranged in the module installation space within 5. .

[0077] like figure 2 As shown, the skeleton of the reconfigurable modular wall is a wall frame, and the wall frame is assembled by frame components 1 . The frame component 1 can be rectangular, rhombus, or other polygons, etc. In terms of practicabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com