A three-dimensional acquisition device for the inner wall of a pipeline

A technology for collecting equipment and pipes, applied in mechanical equipment, special pipes, pipe components, etc., can solve problems such as cable entry, blocked pipes, and inability to travel, and achieve stable rotation and collection, prevent inaccurate focus, and reduce equipment weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

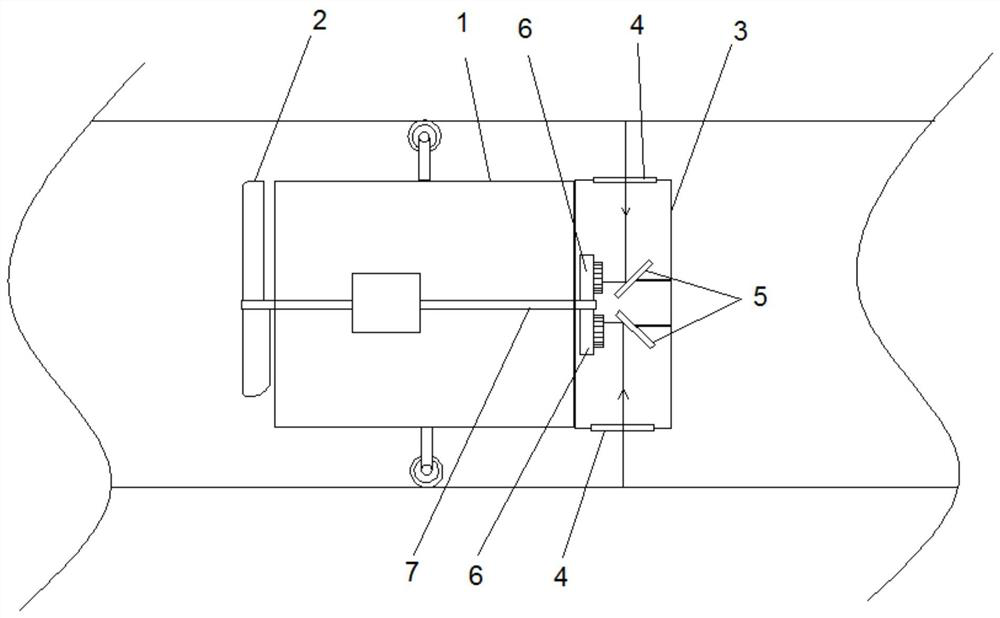

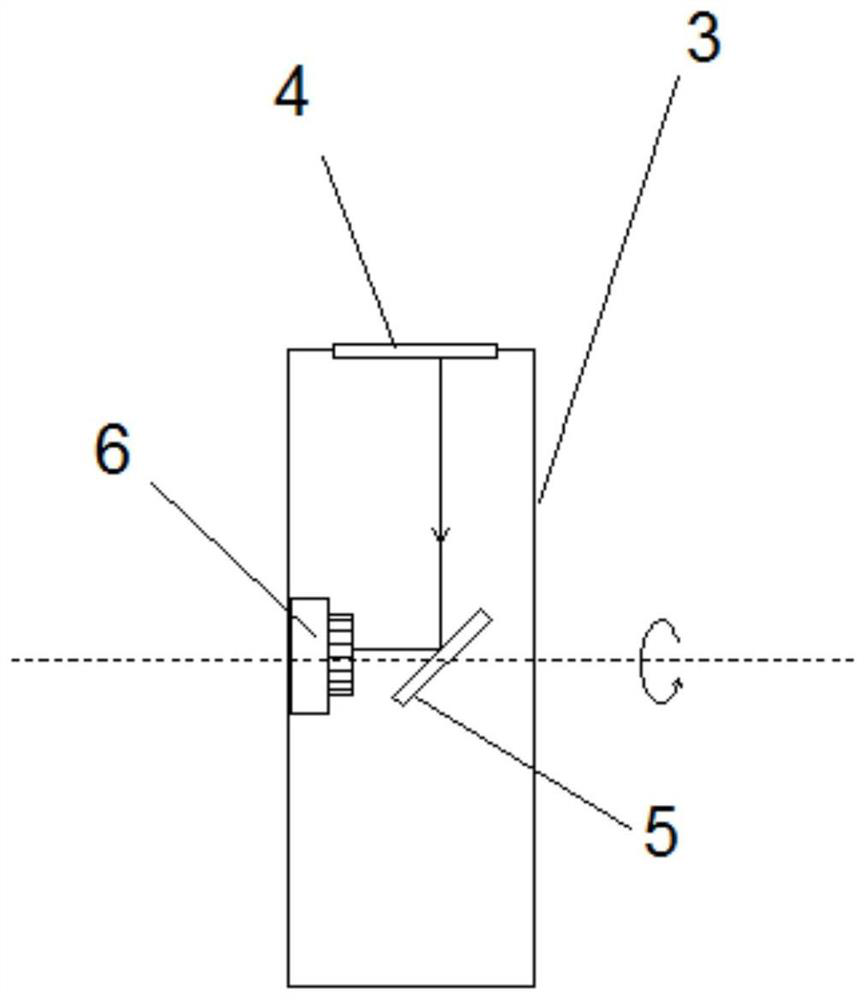

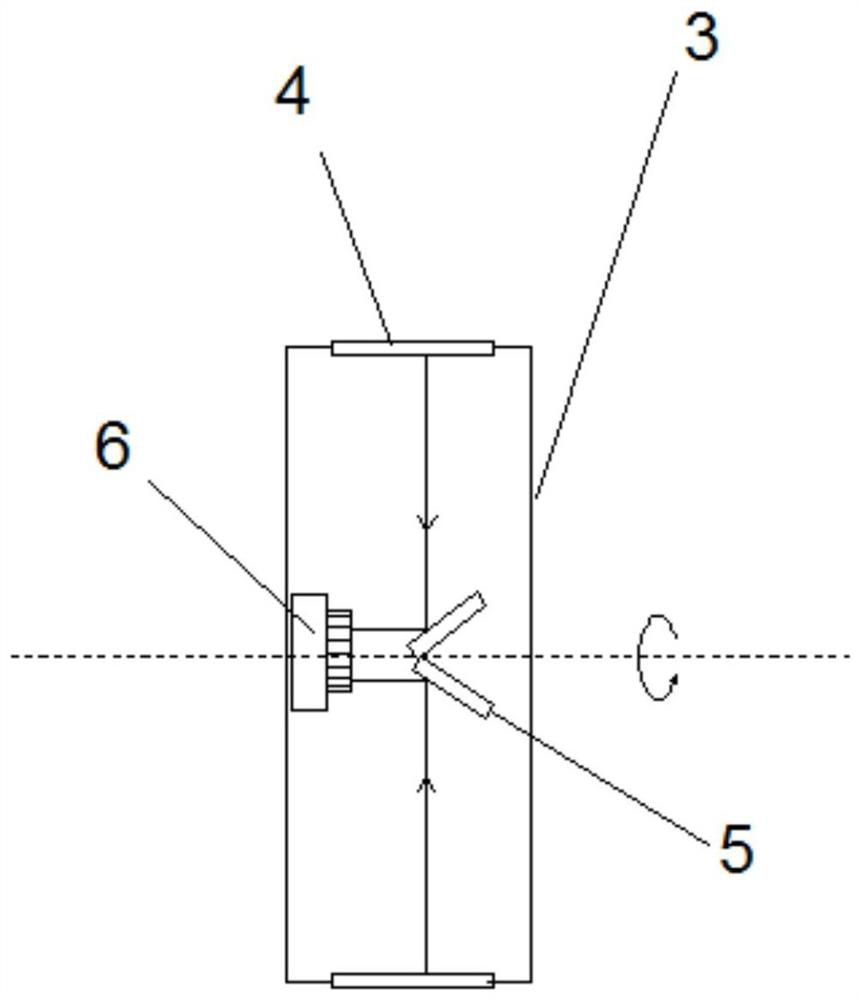

[0038] In order to solve the above technical problems, an embodiment of the present invention provides a three-dimensional acquisition device for the inner wall of a pipeline, also known as a three-dimensional acquisition robot (referred to as a robot in the present invention), including a body 1, an impeller 2, and a traveling unit.

[0039] The body 1 includes a rotating device 3, which may be a hollow rotating disk. The rotating device 3 is provided with one or more image acquisition ports 4 along the circumference, which are used to receive the image light of the inner wall of the target pipeline. The port may be a hole with a transparent material, or may include an optical system capable of shaping a light beam, such as a lens or a lens group, to form a light entrance. A plurality of light sources are arranged around the port. The light source can be an LED lamp bead, but an intelligent light source can also be set, for example, different light source brightness, on and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com