Reconfigurable wall system and unit assembly thereof

A unit component and component technology, which is applied to building components, walls, building structures, etc., can solve problems such as poor accuracy, adjust wall height, and increase construction volume, so as to meet diverse needs, ensure stability, and ensure quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention is further described below.

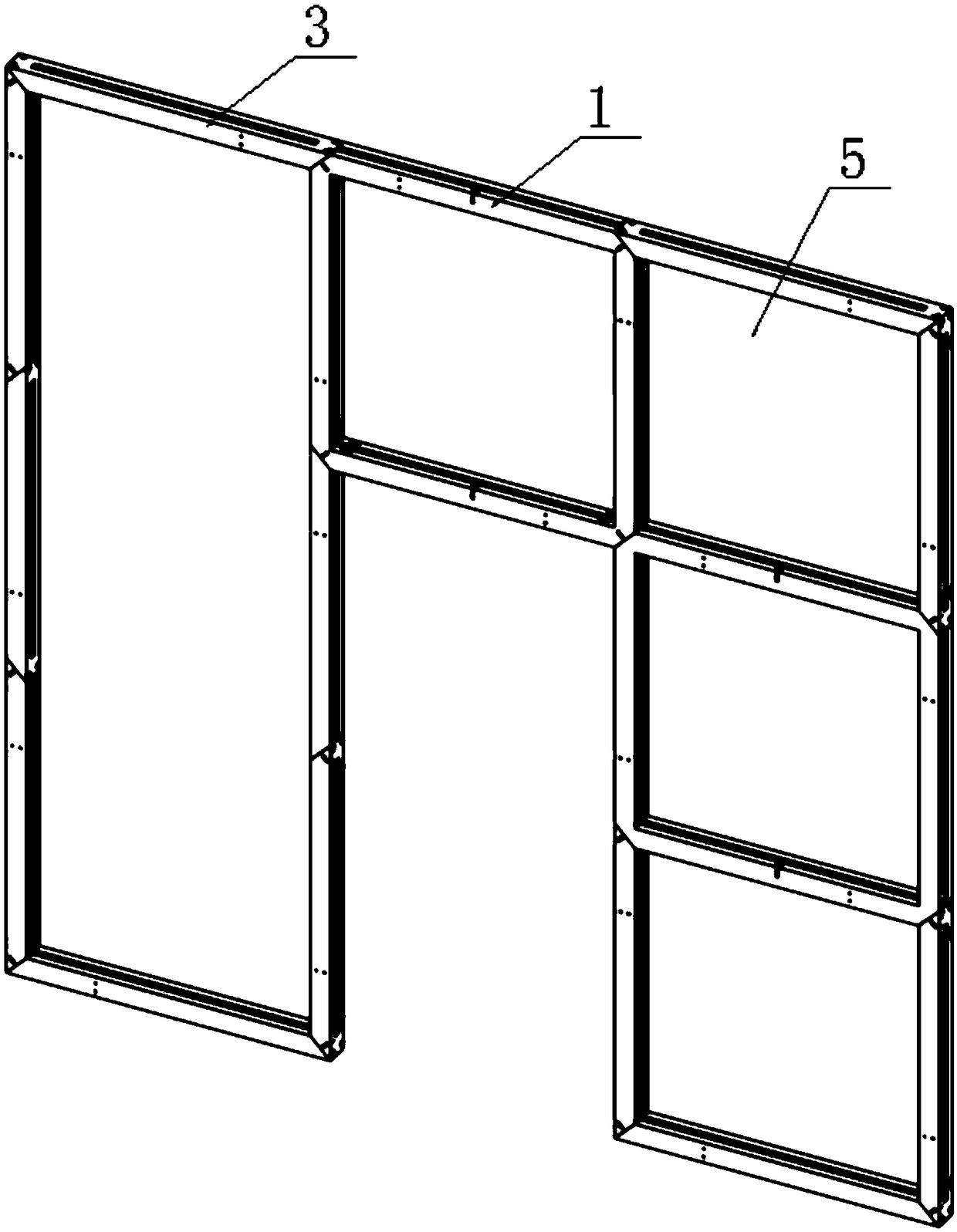

[0067] The reconfigurable wall system disclosed in the present invention is assembled with unit components and functional modules 2, wherein the unit components include a component body and a gate 102, and a gate installation groove 107 is provided on the component body, and the gate 102 is disposed in the gate installation groove 107, and an extending mechanism for extending the gate 102 is provided between the gate 102 and the component body, and the unit component is provided with a structural connection part.

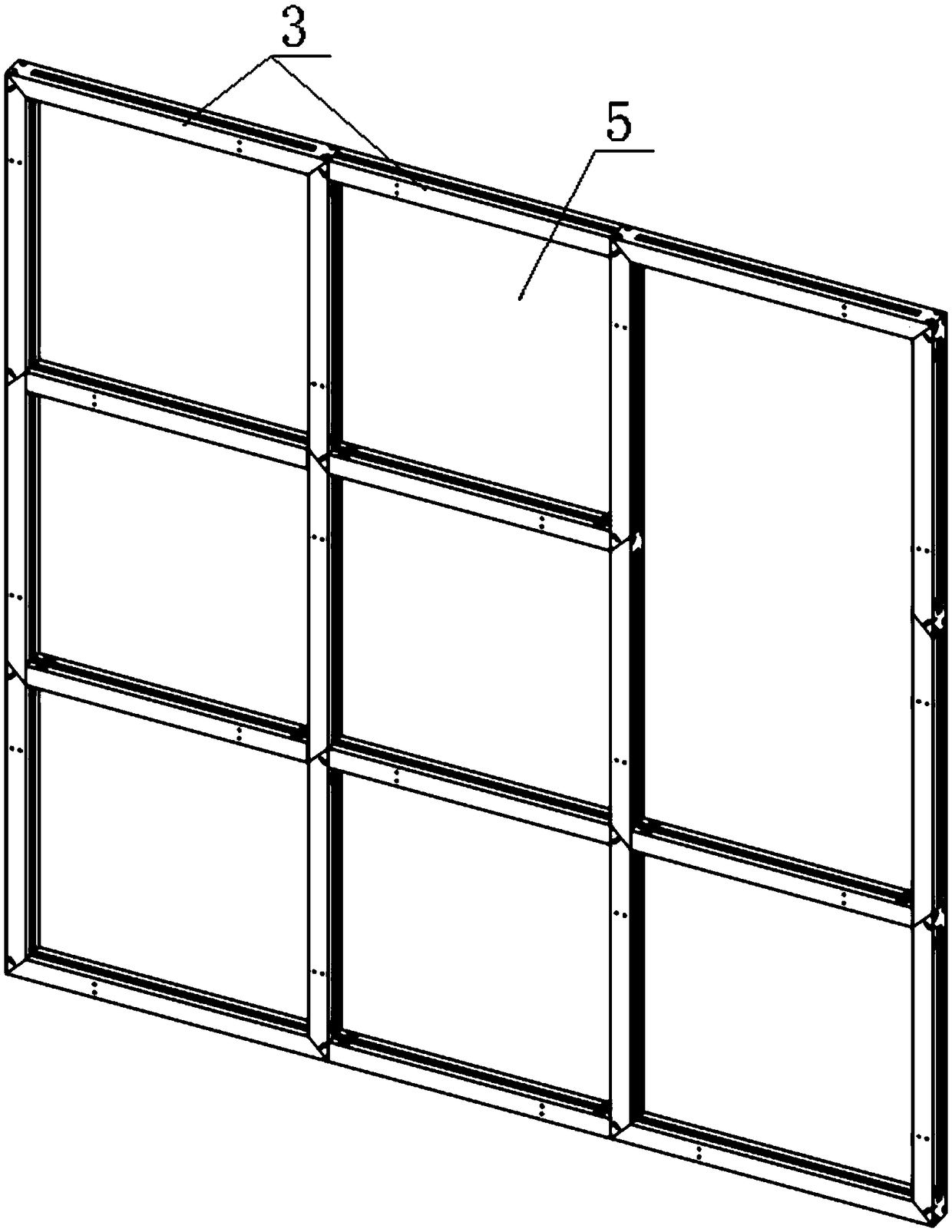

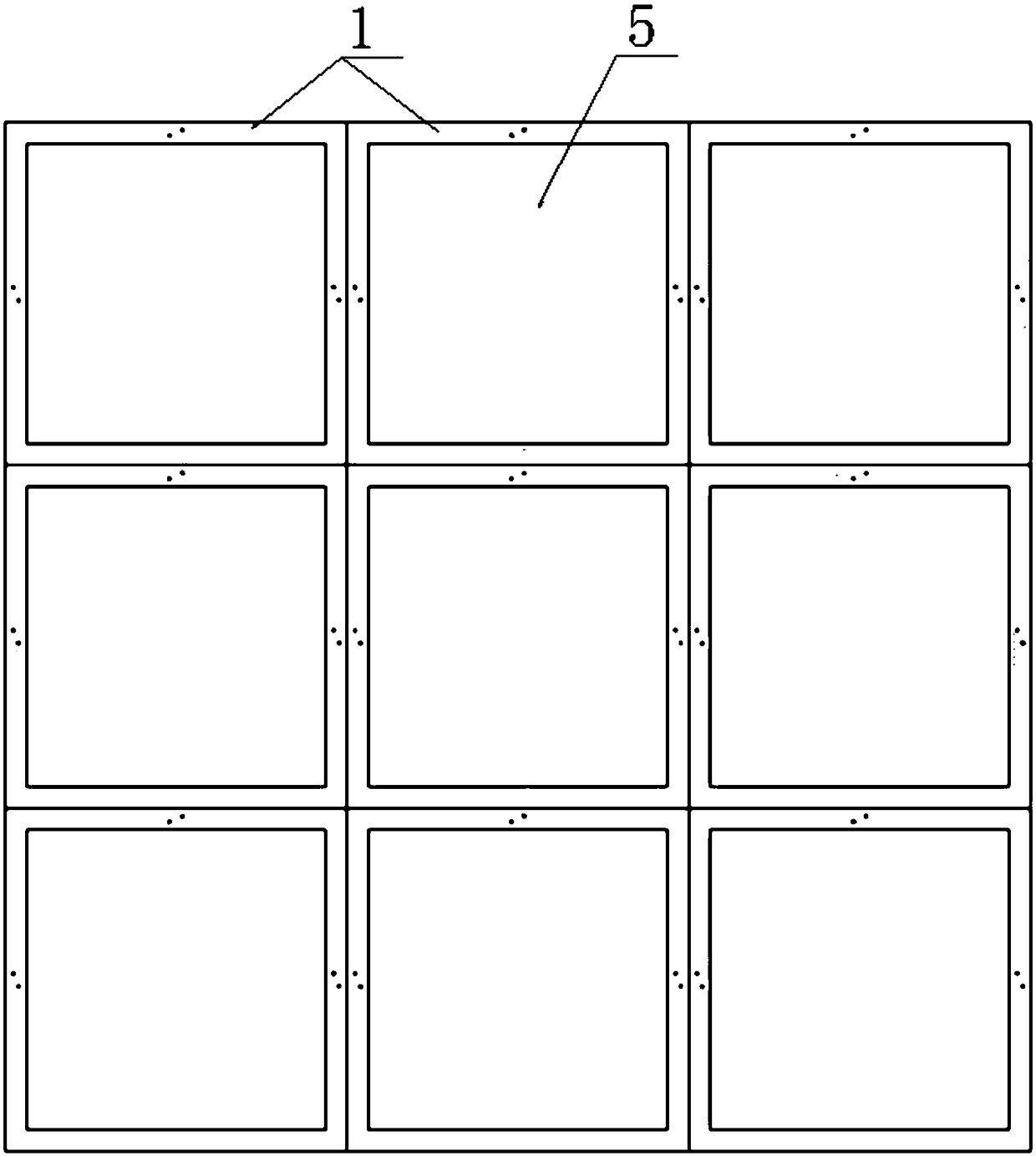

[0068] The reconfigurable wall system using the unit components, each unit component is connected to each other through the structural connection part to form a wall frame, the wall frame has a module installation space 5, and the functional module 2 is installed in the module installation space 5 , at least one side of the module installation space 5 is provided with a gate installation groove 107, the gate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com