Metal vein water jet mining method

A mining method and water jet technology, which are applied in surface mining, earth-moving drilling, underground mining, etc., can solve the problems of increasing ore transportation, beneficiation and other costs, unable to control the size of mined ore, and unfavorable mining continuity. Achieve the effect of improving drilling efficiency, easy control of structure and improving drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, a metal vein water jet mining method, it comprises the following steps:

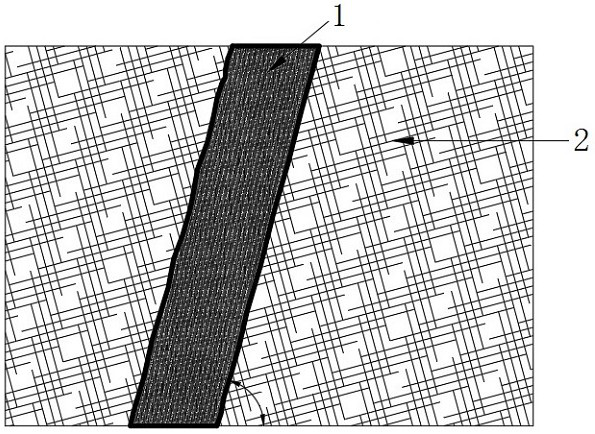

[0026] S1, see figure 1 Firstly, mark the ore body boundary area with a thickness of 40cm at the boundary between ore body 1 and waste rock surrounding rock 2 on the working face of the mine according to the local geological ore body data drawings, and use the water jet cutting component to cut along the marked boundary area , using high-pressure water flow to penetrate the boundary to realize material cutting, so that the ore body is separated from the waste rock surrounding rock.

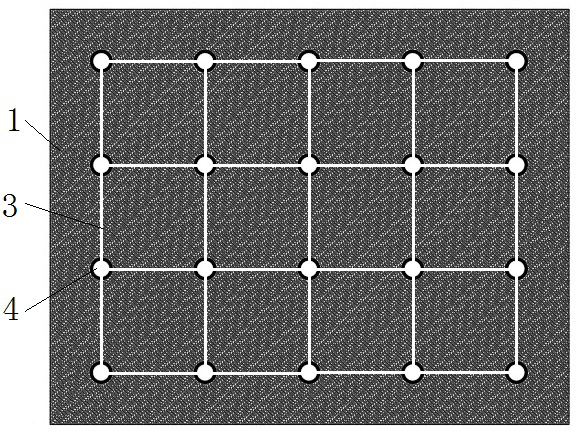

[0027] S2, see figure 2 The axial nozzle of the water jet cutting assembly is used to drill a plurality of positioning holes 3 distributed in an array on the ore body 1. During the water jet cutting operation, it can continuously provide water jets with a pressure of up to 150 MPa and a maximum flow rate of 200 L / min. The seam rate is 50~100mm / min, the depth of the positioning holes 3 is 2.4m, the hol...

Embodiment 2

[0031] Embodiment 2, a metal vein water jet mining method, which includes the following steps:

[0032] S1, first mark the ore body boundary area with a thickness of 40cm at the boundary between the ore body and the waste rock surrounding rock on the mine working face according to the local geological ore body data drawings, and use the water jet cutting component to cut along the marked boundary area, Use high-pressure water flow to penetrate the boundary to realize material cutting, so that the ore body is separated from the waste rock surrounding rock.

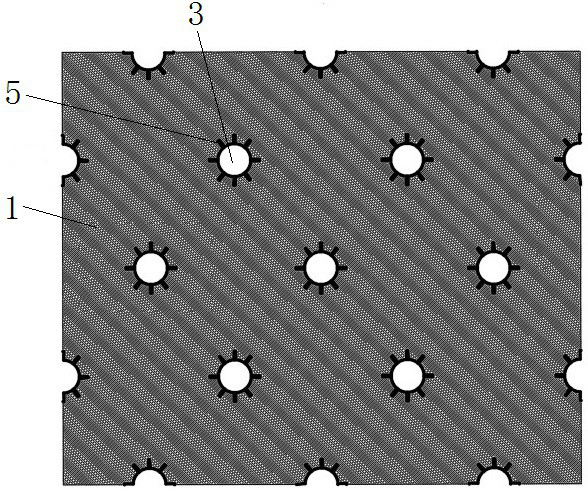

[0033] S2, see image 3 , drilling a plurality of positioning holes 3 distributed in an array on the ore body 1. During the water jet cutting operation, it can continuously provide water jets with a pressure of up to 150MPa, a maximum flow rate of 200L / min, and a slotting rate of 50~100mm / min. The positioning holes 3 have a depth of 3.0 m and a diameter of 38 mm. The row spacing of the positioning holes 3 distributed in an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com