Process and device for refining solidified microstructure by consumable shear flow method

A technology of solidification structure and self-consumption, applied in the field of molten metal processing technology and equipment, can solve the problems of electromagnetic stirring attenuation, uneven crystal nucleus distribution, ultrasonic stirring attenuation, etc., to reduce the temperature gradient and concentration gradient, and prolong the crystal nucleus. The effect of increasing formation time, equiaxed crystal ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention are described in detail as follows:

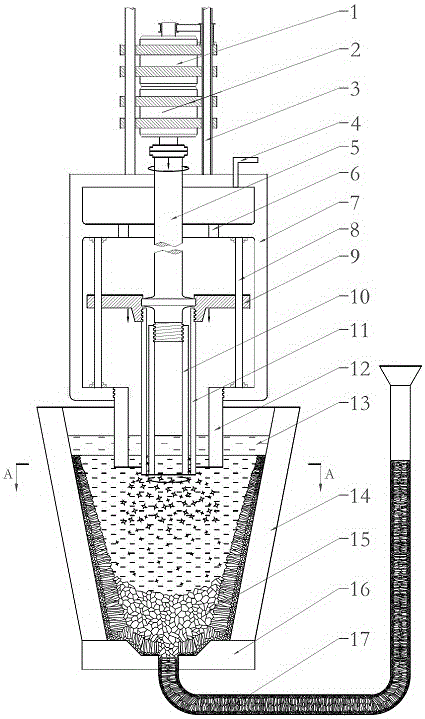

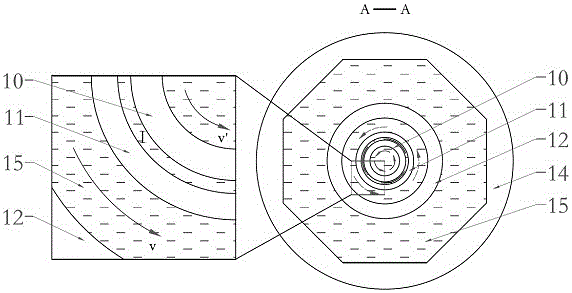

[0029] In this example, see figure 1 and figure 2 , a consumable shear flow metal melt processing device, composed of a shear consumable component fixing device, a shear consumable component driving device and a shear consumable component made of consumable metal, the shear consumable component is composed of a self-consumable component The consumable metal stator assembly 11 and the consumable metal rotor assembly 10 are composed of the consumable metal stator assembly 11 and the consumable metal rotor assembly 10, which are two combined sleeve-shaped assemblies that keep coaxial rotation, and the shearing consumable assembly fixing device consists of the upper The bracket and the lower shell 7 are fixedly connected to each other, the shear self-consumable assembly is sealed and installed in the lower shell 7, the bottom and the top of the lower shell 7 are open, and the bottom openi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com