High pressure abrasive water jet tunneling method

An abrasive water jet and tunneling technology, which is used in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems that the vertical height of the driving face cannot be too large, the rock blocks cannot be cut off, and the cutting capacity is limited, etc. Construction efficiency, improved driving accuracy, and less disturbance of surrounding rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

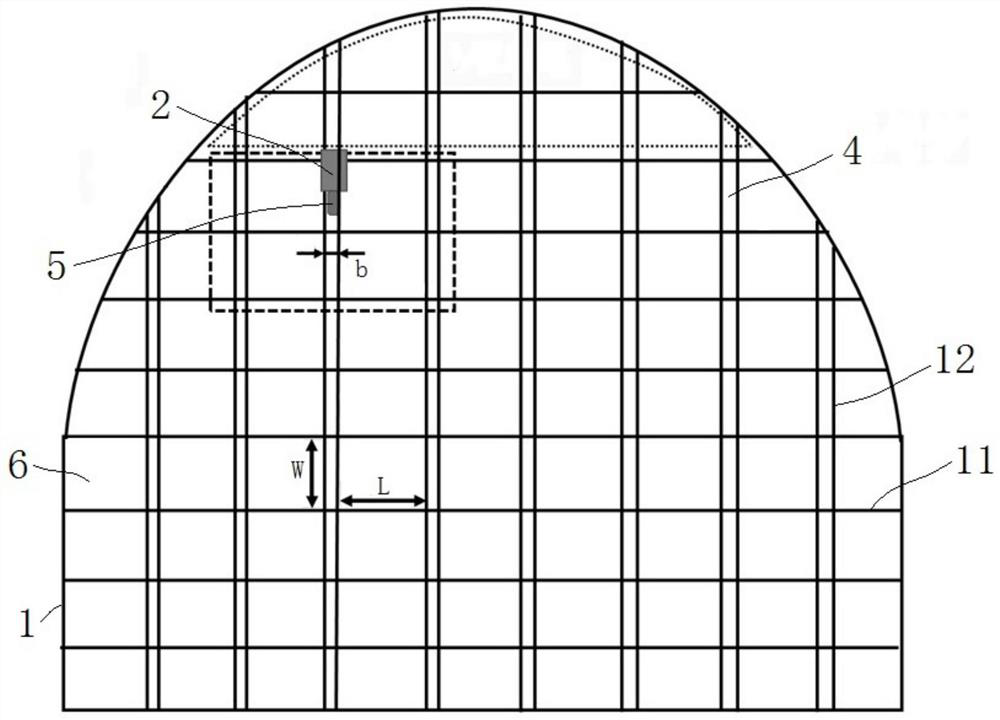

[0035] Embodiment 1, a high-pressure abrasive water jet tunneling method, which includes the following steps:

[0036] S1, confirm the construction parameters, use the high-pressure abrasive water jet device to carry out trial cutting on a certain part of the face, and conduct continuous trial cutting for 3 to 5 times to obtain the cutting depth, width and abrasive jet moving speed, target distance, jet pressure, flow rate, abrasive The dynamic relationship between parameters such as concentration. For the specific tunnel face, the specific parameters of the trial cutting are: the pump pressure of the high-pressure abrasive water jet device is set to 60-120 MPa; the selected abrasive is 60-120 mesh quartz sand or other, and the volume of the abrasive in the jet mixture accounts for 8 ~20%; the selected nozzle diameter d is 2 ~ 6mm, the nozzle diameter d 1 is 20d, radial nozzle length L 1 is 10d, and the axial nozzle swing amplitude is slightly larger than 40d. Select a set ...

Embodiment 2

[0041] Embodiment 2, high-pressure abrasive water jet tunnel excavation method, its S1 confirms the construction parameters and S2 divides the tunnel face grid is the same as the embodiment 1, adopts the vertical cutting method to cut and form the horizontal section slots, and adopts the oblique cutting method Cut to create vertical faceted slots.

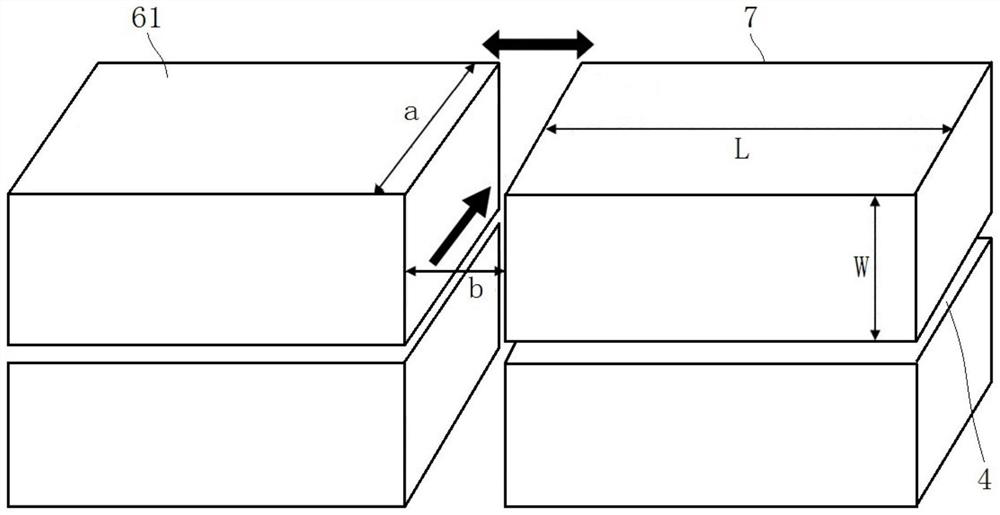

[0042] S3, cutting slots, first move the abrasive water jet 5 sprayed by the axial nozzle 2 of the high-pressure abrasive water jet device along the contour cutting line on the periphery of the face grid 1, and the axial direction of the injected abrasive water jet 5 is aligned with the face Vertically, the rock mass 6 is cut to form the peripheral contour slot 4 of the driving face. Then move the axial nozzle 2 along the transverse cutting line 11 of the face grid 1, the amplitude A of the axial nozzle 2 is 0, forming the slot 4 of the transverse section, and cutting the rock mass sequentially from bottom to top by vertical cuttin...

Embodiment 3

[0045] Embodiment 3, high-pressure abrasive water jet tunnel excavation method, in which S1 confirms the construction parameters, S2 divides the tunnel face grid, and cuts the slots in the transverse section are the same as in Example 2, and adopts oblique cutting to form the vertical section slot.

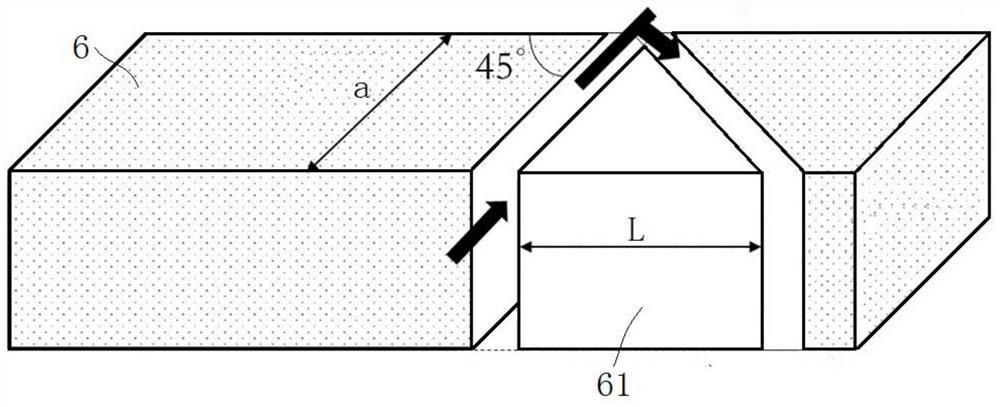

[0046] see Figure 5 , move the axial nozzle along the vertical cutting line 12 of the palm face grid 1, the amplitude of the axial nozzle is A, adopt the oblique cutting method to form the slot 4 of the vertical section, the slot width b is the same as that of the axial nozzle The amplitude A is equal, and the cutting depth c is smaller than the slot depth a when cutting obliquely. When oblique cutting is performed on adjacent vertical cutting lines, the incident angles β and γ of the abrasive water jet sprayed by the axial nozzle of the two oblique cuttings and the face of the face are complementary angles, β=45°, γ=135 °, the bottoms of the slots 4 and 4 in the vertical secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com