Multi-stage pressure-measuring water-gas alternating oil extraction experimental device and method for CT scanning

A technology of CT scanning and water-gas alternation, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problem of lack of fine basis for water-vapor cross-injection production process design, unclear distribution characteristics of remaining oil, and complex pore structure And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

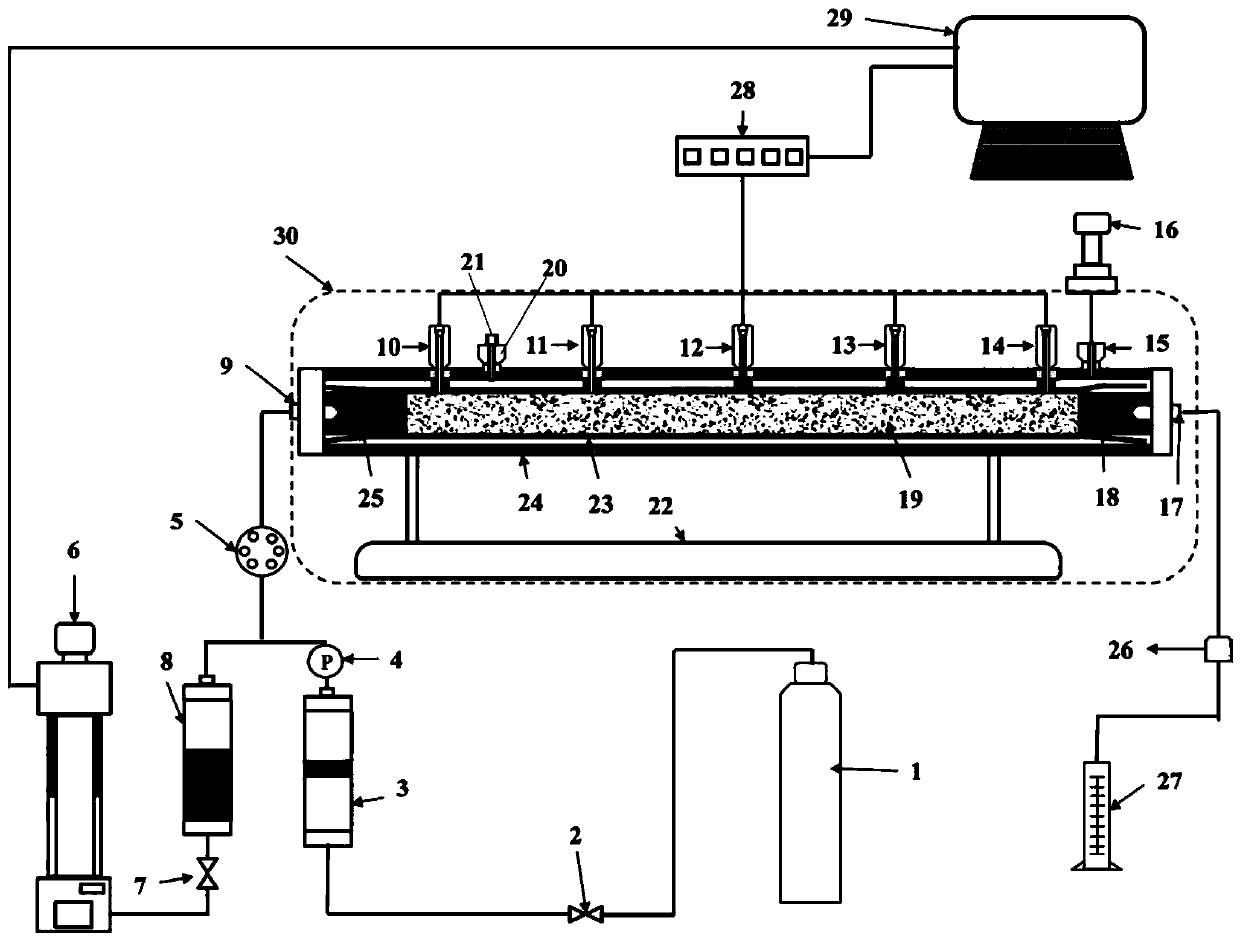

[0055] The multi-stage piezometric water-gas alternate oil recovery experimental device for CT scanning in this embodiment includes an energy supply system, a rock seepage system, a pressure data acquisition system and a metering system.

[0056] The energy supply system includes a water injection system and an air injection system. The water injection system and the air injection system are connected in parallel and controlled by the six-way valve 5 . The gas injection system includes a gas cylinder 1 , a gas control valve 2 , a pressure gauge 4 and a gas intermediate container 3 . The water injection system includes a constant-speed pump 6, a liquid control valve 7, and a liquid intermediate container 8; the rock seepage system includes a seepage cavity 24, a seepage cavity injection port 9, a seepage cavity discharge port 17, a confining pressure port, and a liquid Hand pump, confining pressure drain port 20, confining pressure drain port plug 21, rock rubber holster, seepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com