Method for recycling waste alkali liquor in polyformaldehyde device

A technology of waste lye and polyoxymethylene, applied in organic chemistry and other directions, can solve problems such as waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

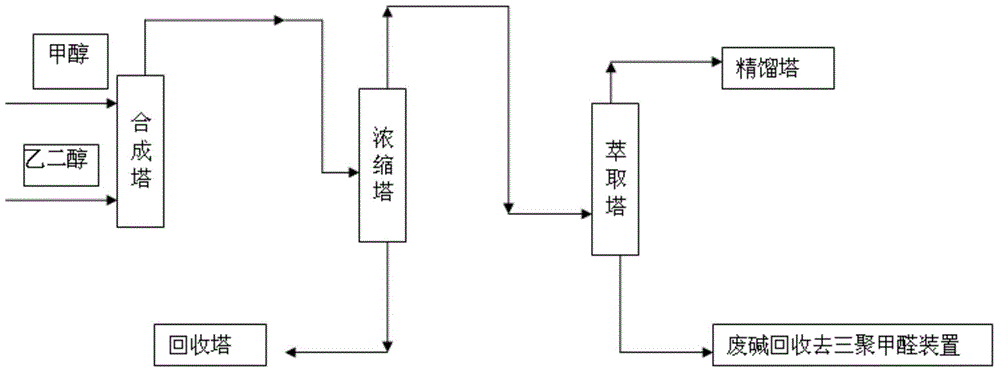

Image

Examples

Embodiment 1

[0015] (1) formaldehyde and ethylene glycol are respectively sent into the dioxane synthesis tower to prepare dioxane, and the reaction mol ratio of described formaldehyde and ethylene glycol is 1.01; (2) the dioxane synthesis tower is The gas phase material at the top of the tower is sent to the dioxane concentration tower to remove ethylene glycol and most of the formaldehyde in the dioxane. The bottom extraction amount is 150kg / h; (3) the gas phase discharge from the top of the dioxane concentration tower is cooled and then sent to the extraction tower for extraction with a sodium oxide solution with a mass percentage content greater than 45%; dioxane In the gas phase discharge at the top of the concentration tower, the mass percentage of dioxane is 91%, the mass percentage of ethylene glycol is zero, the mass percentage of formaldehyde and methanol is not more than 2%, and the remainder is water; (4 ) The dioxane that the mass percentage content obtained at the top of the ...

Embodiment 2

[0018] (1) formaldehyde and ethylene glycol are respectively sent into the dioxane synthesis tower to prepare dioxane, and the reaction mol ratio of described formaldehyde and ethylene glycol is 1.1; (2) the dioxane synthesis tower is The gas phase material at the top of the tower is sent into the dioxane concentration tower to remove ethylene glycol and most of the formaldehyde in the dioxane concentration tower. The bottom output is 120kg / h; (3) the gas phase discharge from the top of the dioxane concentration tower is cooled and then sent to the extraction tower for extraction with a sodium oxide solution with a mass percentage content greater than 45%; dioxane In the gas phase discharge at the top of the concentration tower, the mass percentage of dioxane is 90%, the mass percentage of ethylene glycol is zero, the mass percentage of formaldehyde and methanol is not more than 2%, and the remainder is water; (4 ) The dioxane that the mass percentage content obtained at the t...

Embodiment 3

[0021] (1) formaldehyde and ethylene glycol are respectively sent into the dioxane synthesis tower to prepare dioxane, and the reaction mol ratio of described formaldehyde and ethylene glycol is 1.05; (2) the dioxane synthesis tower is The gas phase material at the top of the tower is sent into the dioxane concentration tower to remove ethylene glycol and most of the formaldehyde in the dioxane concentration tower. The bottom extraction amount is 130kg / h; (3) the gas phase discharge from the top of the dioxane concentration tower is cooled and then sent to the extraction tower for extraction with a sodium oxide solution with a mass percentage content greater than 45%; dioxane In the gas phase discharge at the top of the concentration tower, the mass percentage of dioxane is 92%, the mass percentage of ethylene glycol is zero, the mass percentage of formaldehyde and methanol is not more than 2%, and the remainder is water; (4 ) The dioxane that the mass percentage content obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com