Belt-shape moving body tension differential adjusting and correction method and device therefor

A technology for belt-shaped moving objects and moving objects, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc., and can solve the problems of belt-shaped moving objects width constraints, complex structure, and small application range, and achieve simple structure , low failure rate and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

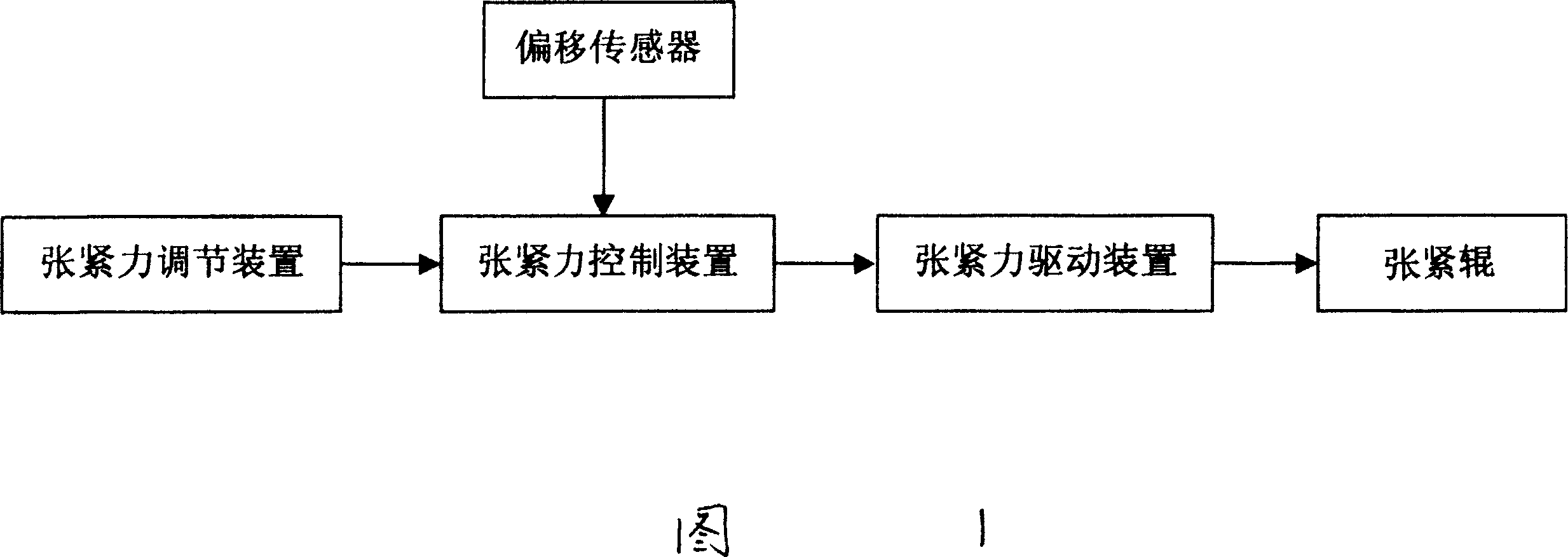

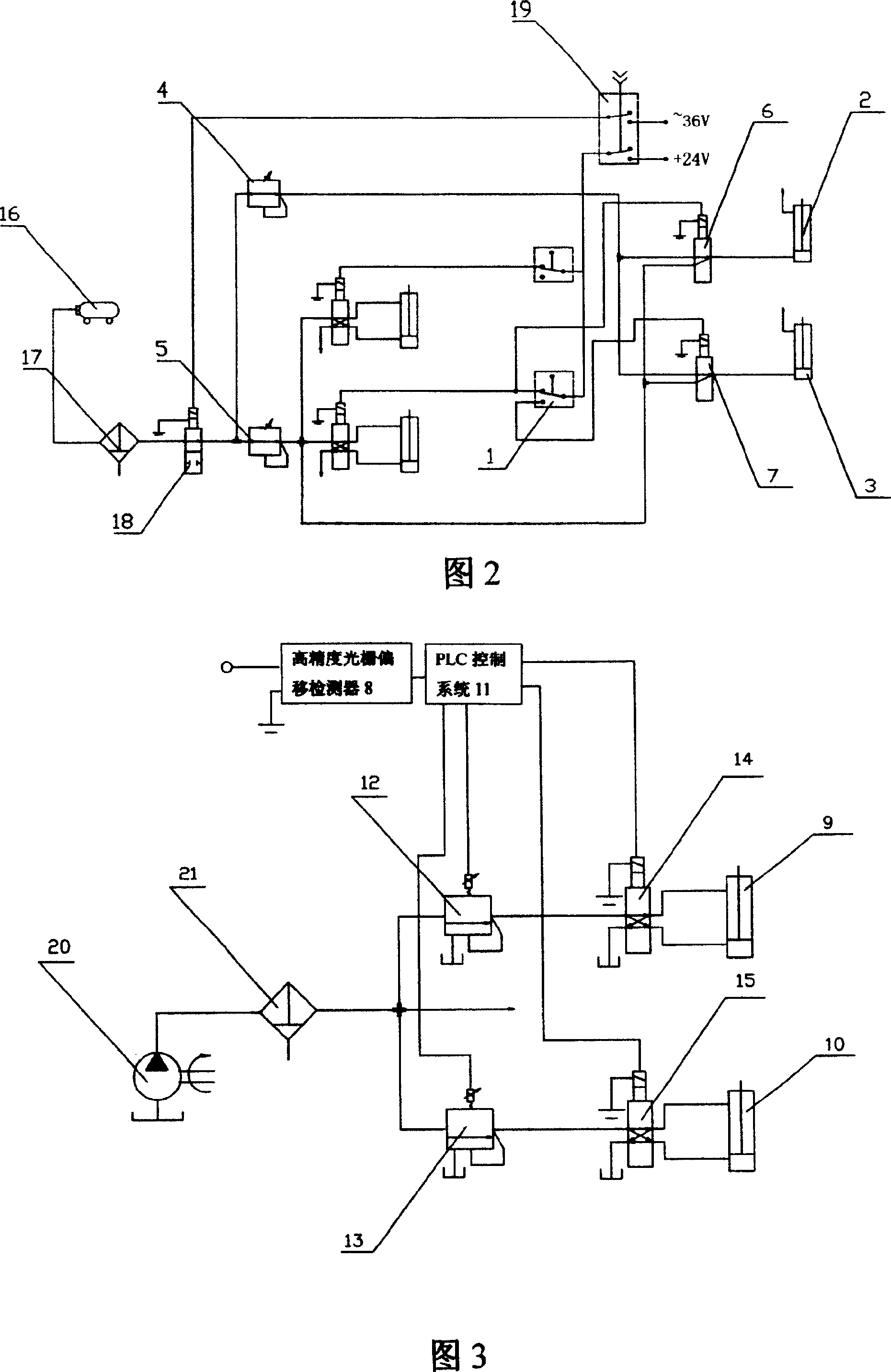

[0033] Embodiment 1 is a fixed-point adjustment device. As shown in Figure 1: belt-shaped moving object tension difference adjustment correction equipment, there are offset sensors, tension rollers and tension drive devices connected to both ends of the tension rollers, and tension control connected to the offset sensors device, the tension adjusting device is connected with the tension driving device through the tension control device. The specific structure can be as shown in Figure 2: the offset sensor is a travel switch 1 arranged on the frame, the tension driving device is a cylinder 2,3, and the tension regulating device is a pressure reducing valve 4,5. The tension control device is electromagnetic valve 6,7.

[0034] The specific connection mode is: the air compressor 16, the filter 17, the switch valve 18 are connected, the output of the switch valve 18 is connected with the pressure reducing valve 4,5 respectively, and the output of the pressure reducing valve 4,5 i...

Embodiment 2

[0038] Embodiment 2 is a continuous adjustment device. As shown in Figure 1: The belt-shaped moving object tension difference adjustment correction device has an offset sensor, and a tension control device is connected to the offset sensor. The tension adjustment device communicates with the tension force through the tension control device. The drives are connected. The specific structure can be as shown in Figure 3: the described offset sensor is a high-precision grating offset detector 8, the tension driving device is a hydraulic cylinder 9,10, and the described tension adjusting device is a PLC control system 11 And the proportional pressure regulating valves 12, 13 connected with the PLC control system 11, the tension control device is the PLC control system 11 and the solenoid valves 14, 15 connected with the PLC control system 11.

[0039] The specific connection method is: after the quantitative pump 20 and the filter 21 are connected, they are respectively connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com