Patents

Literature

37results about How to "Unlimited width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

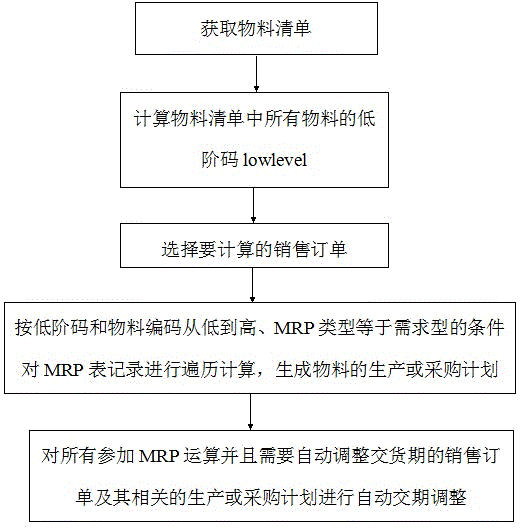

Adaptive material requirement plan (MRP) calculation method

InactiveCN105389653AIncrease flexibilityAvoid restrictionsResourcesLogisticsBill of materialsOrder form

The invention discloses an adaptive material requirement plan (MRP) calculation method. The method comprises steps: a material list is acquired; lowlevel codes of all materials in the material list are calculated; sales orders in need of calculation are selected; according to conditions that the lowlevel codes and the material codes are ranked from low to high and the MRP type is equal to a requirement type, traverse calculation is carried out on MRP table records, and a production or procurement plan on the materials is generated; and automatic delivery date adjustment is carried out on all orders which participate in MRP calculation and need to automatically adjust the delivery dates. Delivery date adjustment can be automatically carried out on orders, whose delivery dates can not be met, and the generated plans, the process comprises steps in which the delivery dates of the sales orders are properly adjusted automatically, and the plan starting dates and the plan ending dates for a production order and a procurement order related to the sales order can be automatically adjusted, system flexibility is improved, and management by a manager is facilitated.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

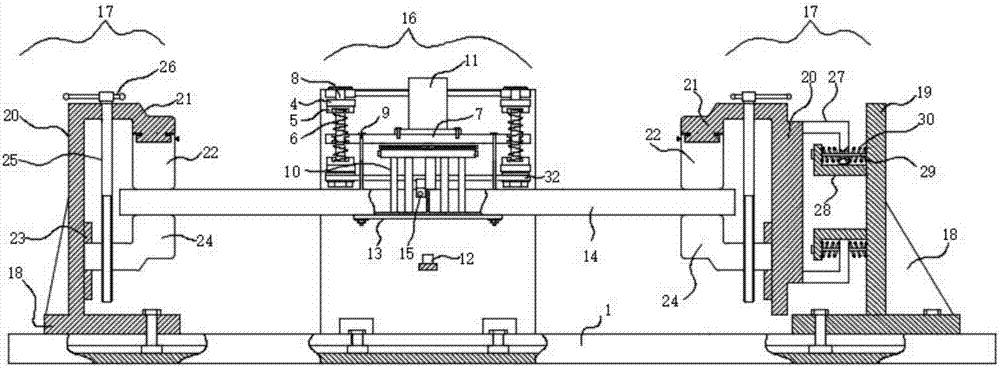

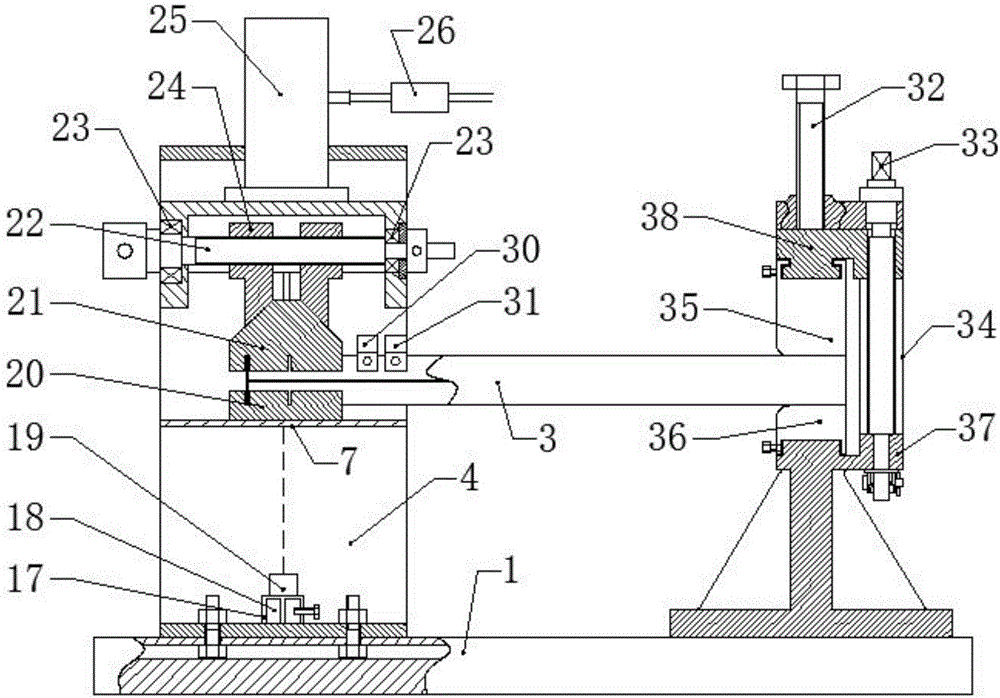

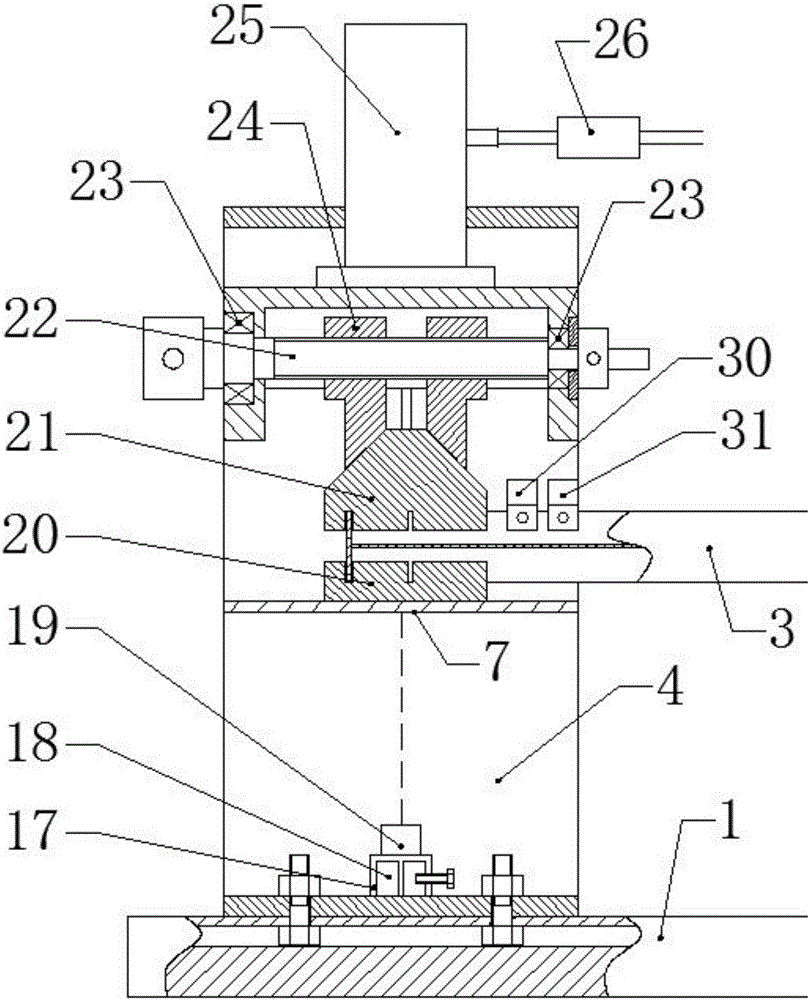

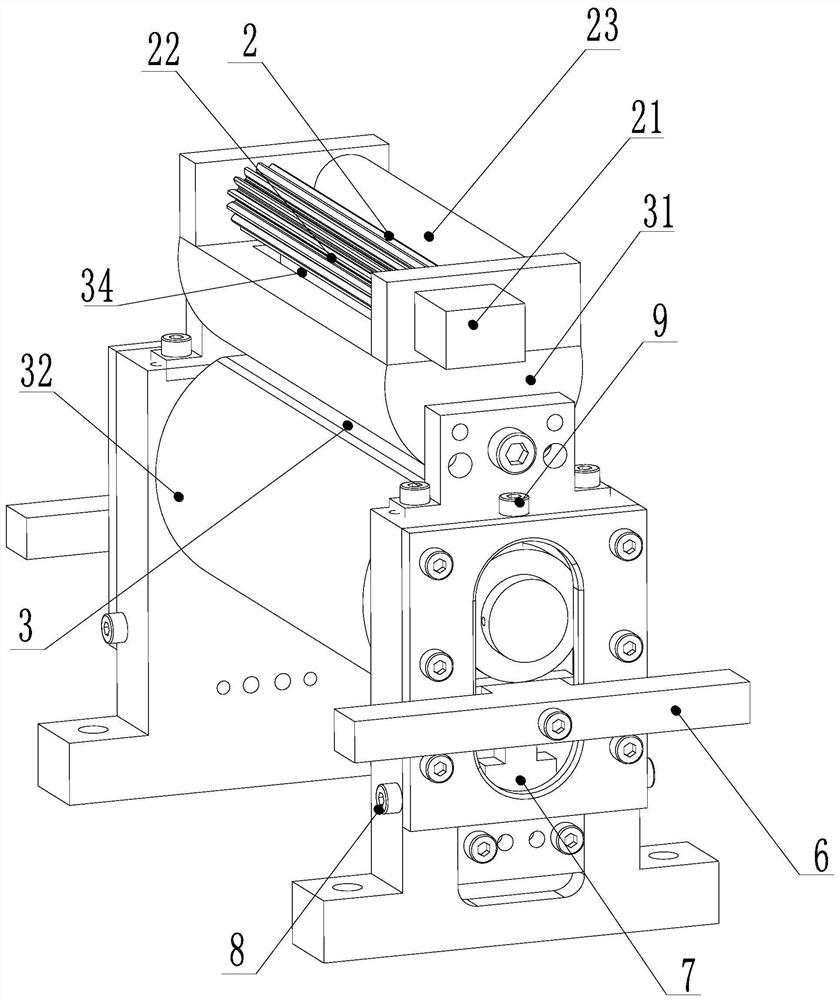

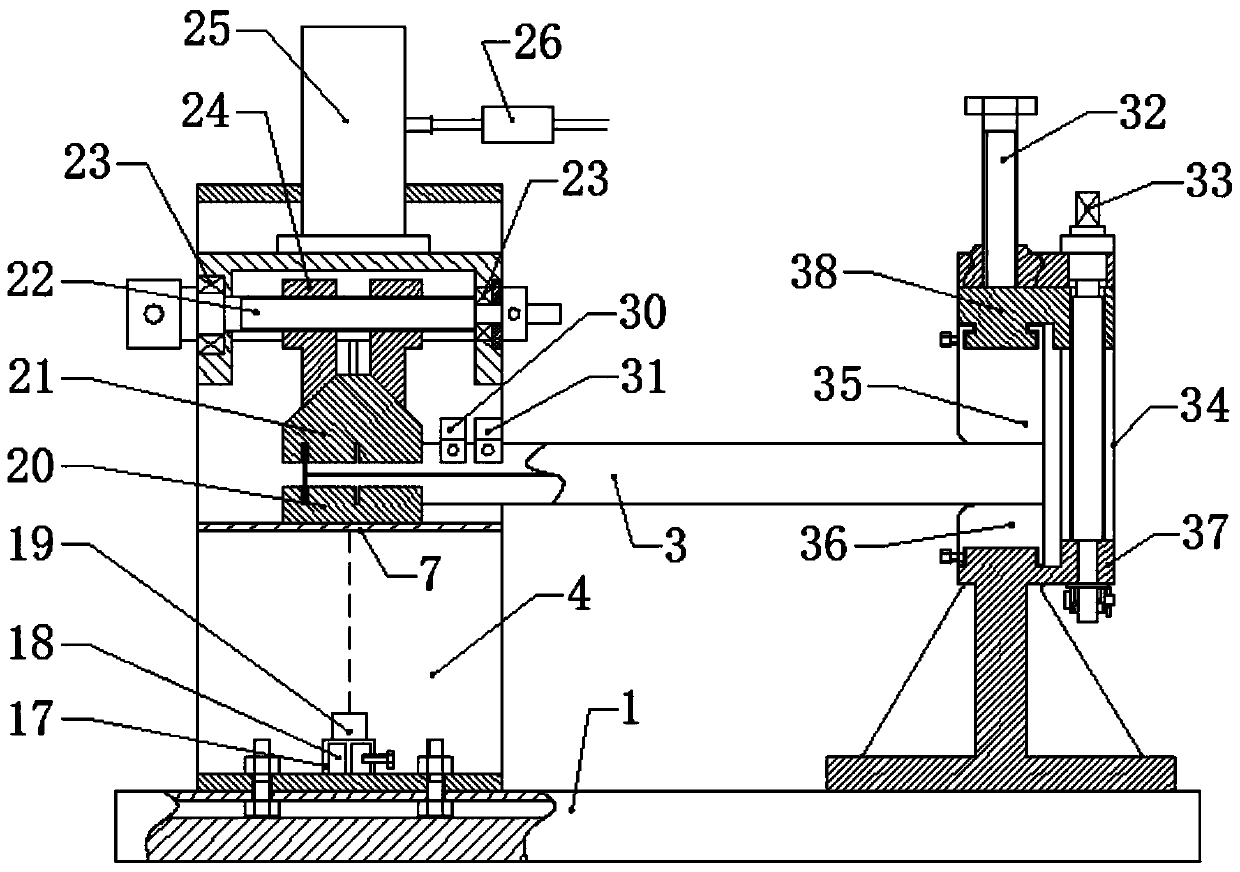

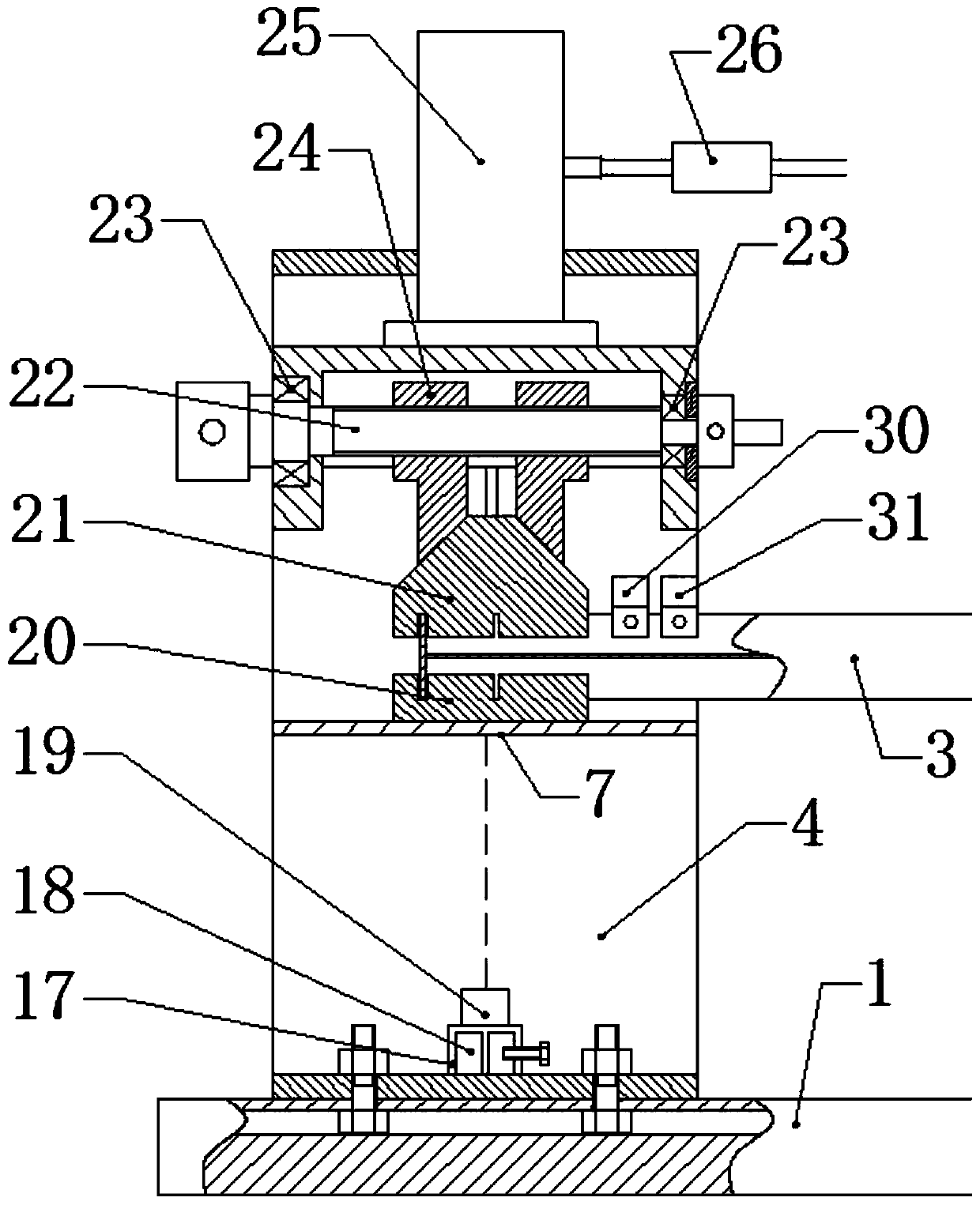

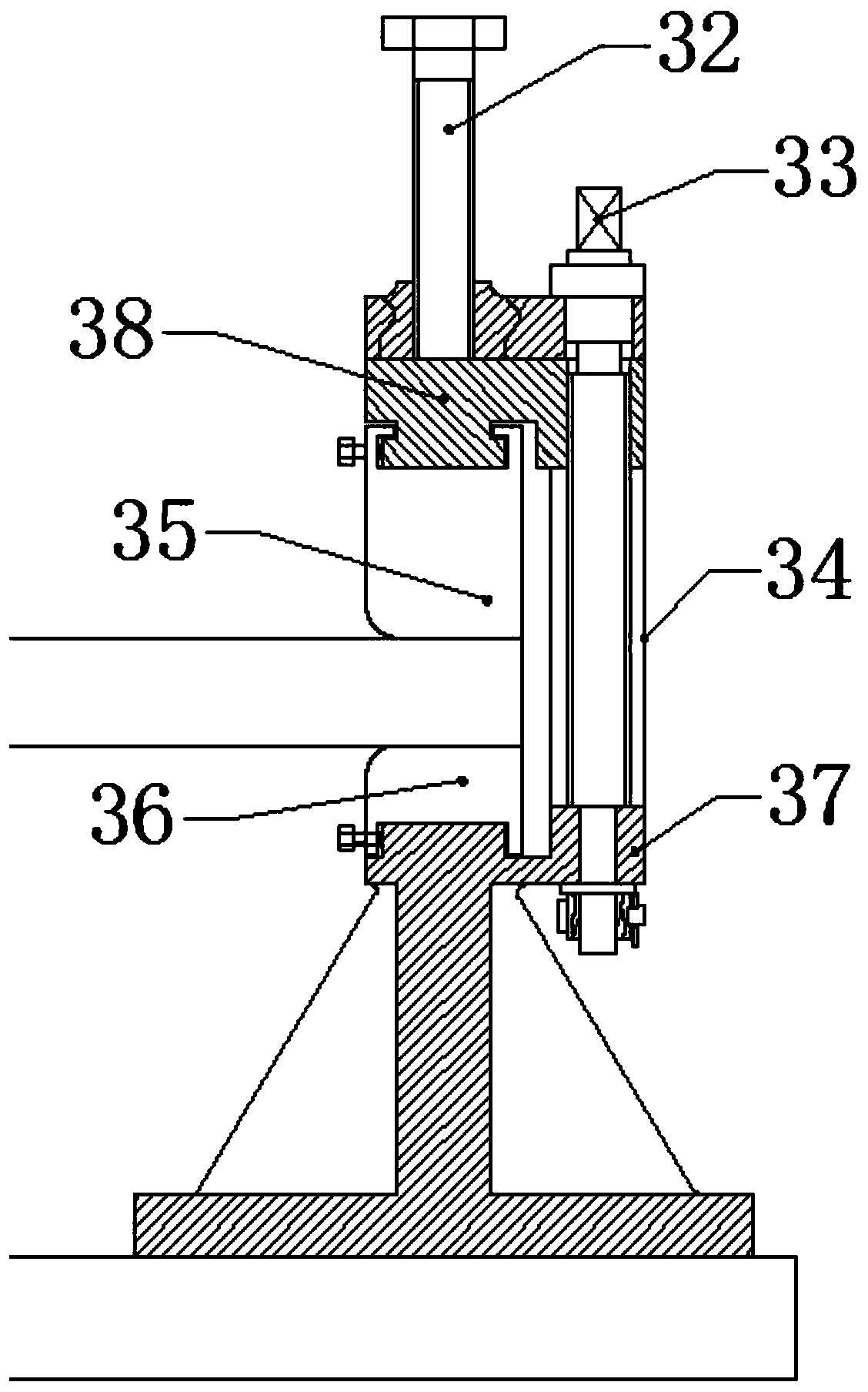

Simply supported type vibrating aging platform for beam component

ActiveCN107460303AWith universal adjustabilityGuaranteed stabilityProcess efficiency improvementFatigue damageVibration exciter

The invention discloses a simply supported type vibrating aging platform for a beam component. The two ends of a base of the platform are provided with end head clamping tools. The middle of the base of the platform is provided with an exciting vibration source testing device. The exciting vibration source testing device comprises a U-shaped bracket. The upper end of the U-shaped bracket is provided with a hanging plate. The upper end of the hanging plate is provided with an electric vibration exciter. The lower end of the hanging plate is connected with a horizontal supporting plate. A pressing clamping tool is arranged between the hanging plate and the supporting plate. The beam component is provided with an acceleration sensor. The bottom of the U-shaped bracket is provided with a laser displacement sensor. The pressing clamping tool comprises a rotating disc. A sliding groove is formed in the bottom surface of the rotating disc. An adjusting screw rod is arranged in the sliding groove. The adjusting screw rod is provided with a pressing plate. An end head of the adjusting screw rod is coaxially provided with an adjusting gear and an adjusting rotary knob. The upper end of the rotating disc is provided with a center shaft. The center shaft is provided with a gear disc and a nut ring. The edge of the bottom surface of the gear disc is provided with a gear ring meshing with the adjusting gear. By means of the simply supported type vibrating aging platform for the beam component, vibration exciting can be achieved under first order inherent frequency of the component, aging processing is conducted on the component, residual stress is eliminated, and the fatigue damage and crack development of the component are reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

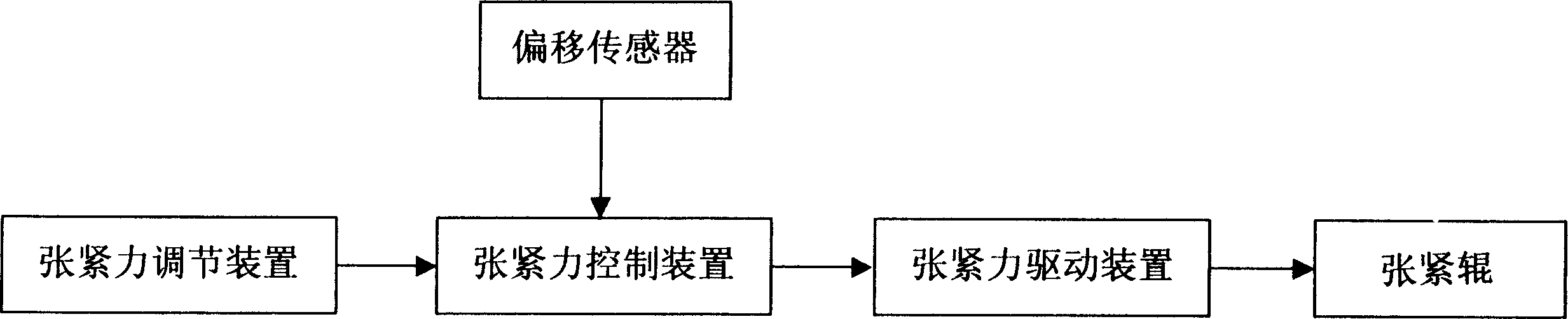

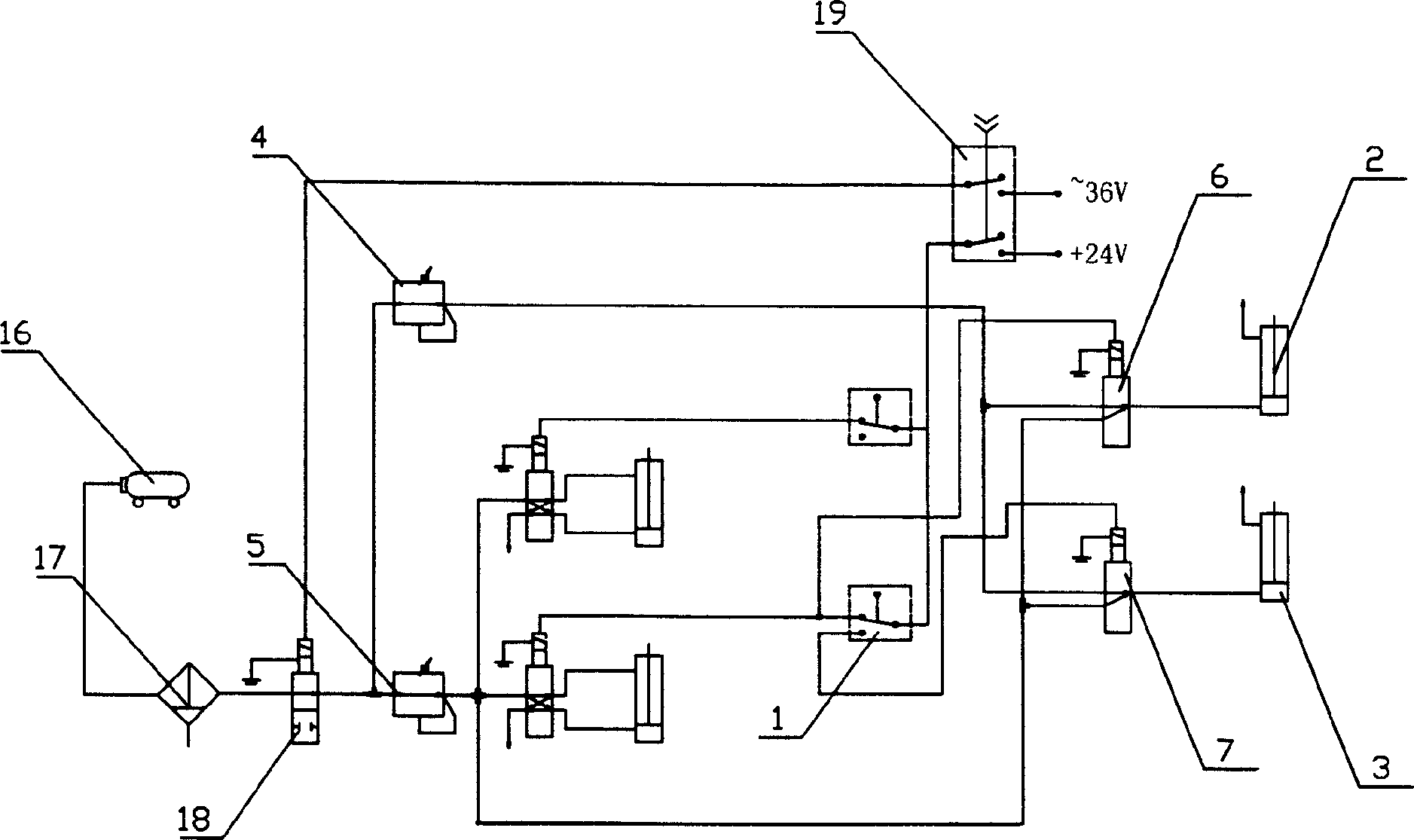

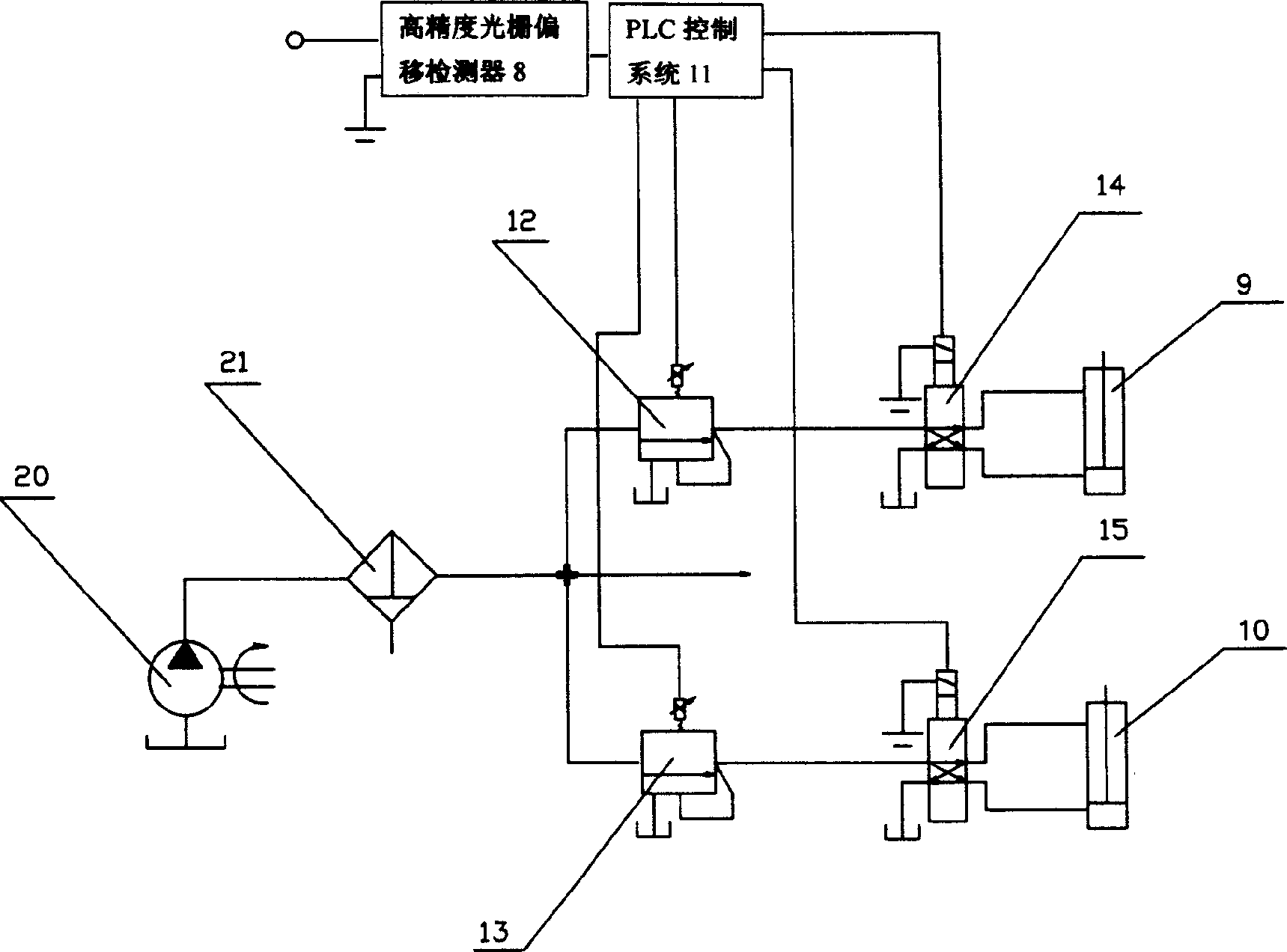

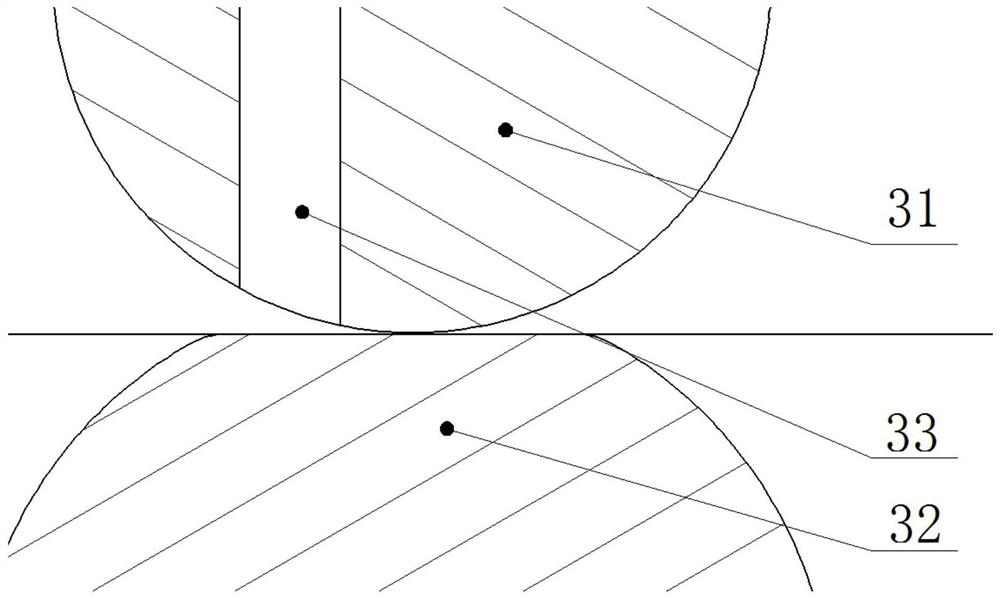

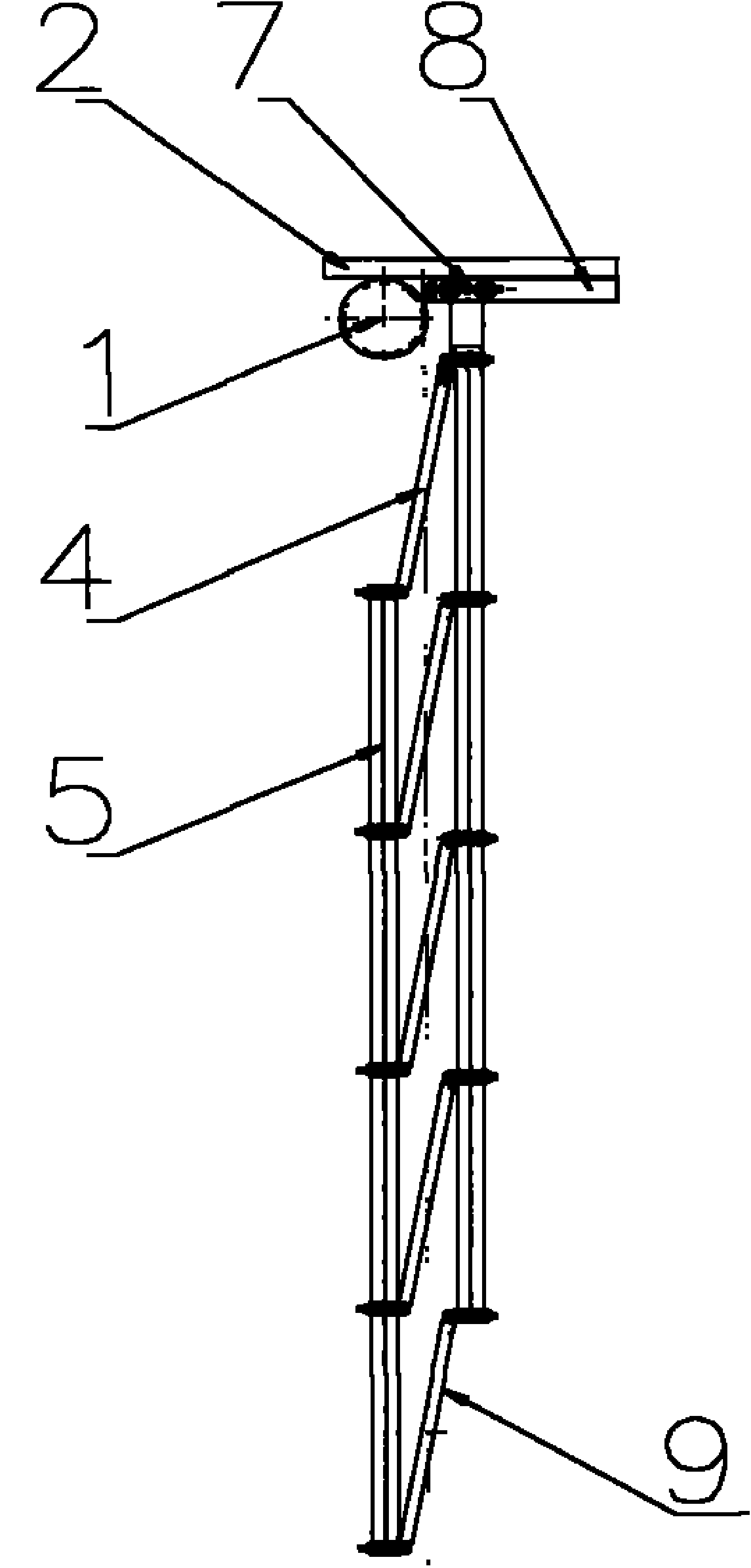

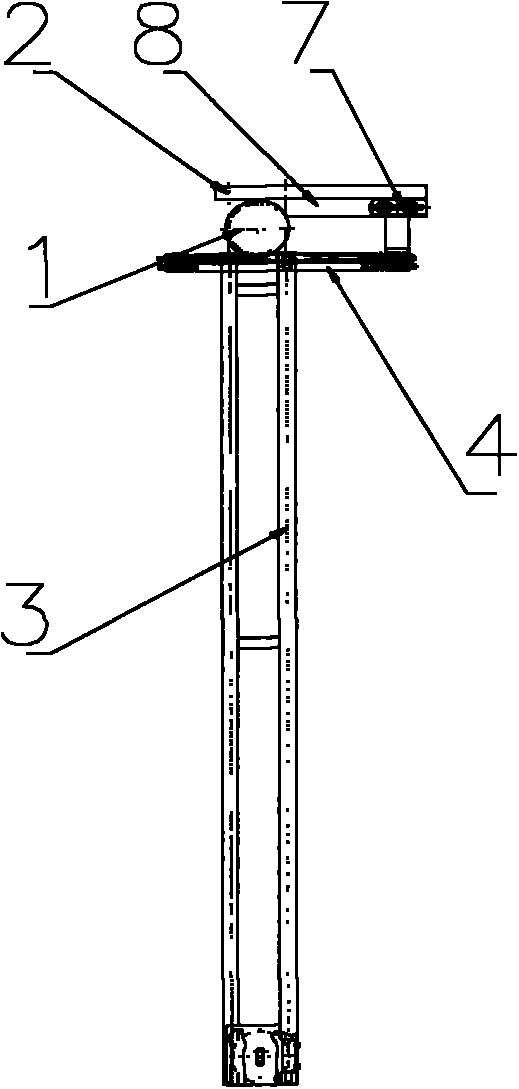

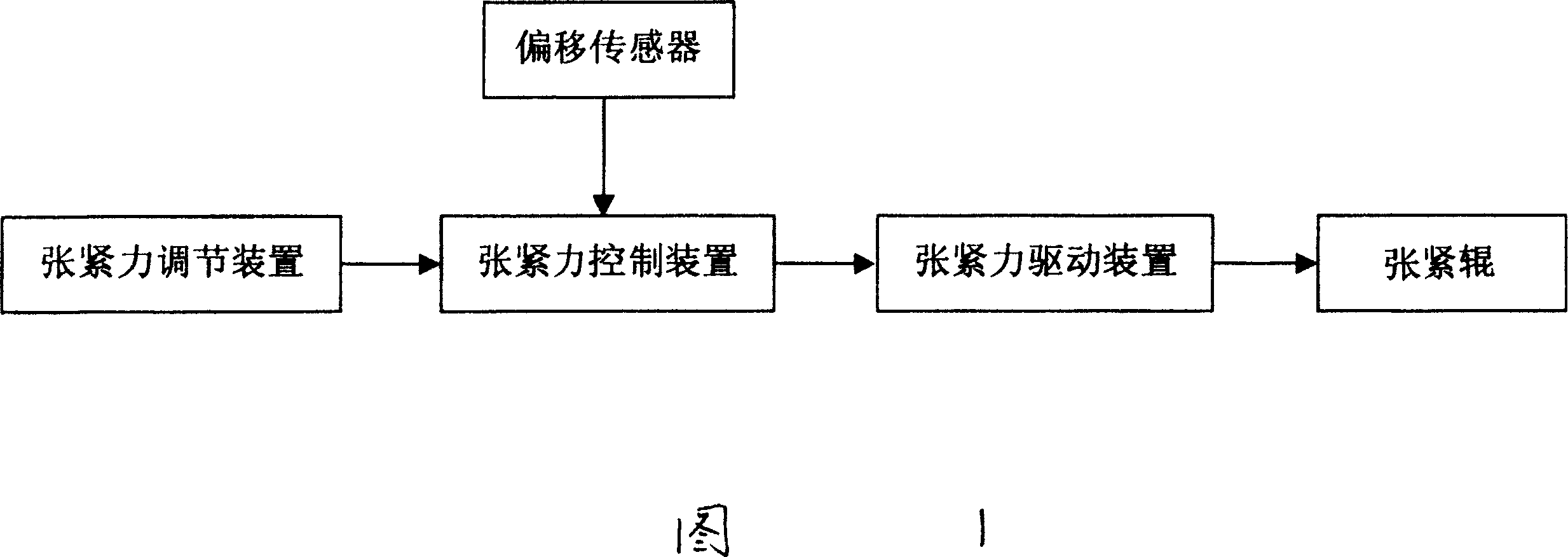

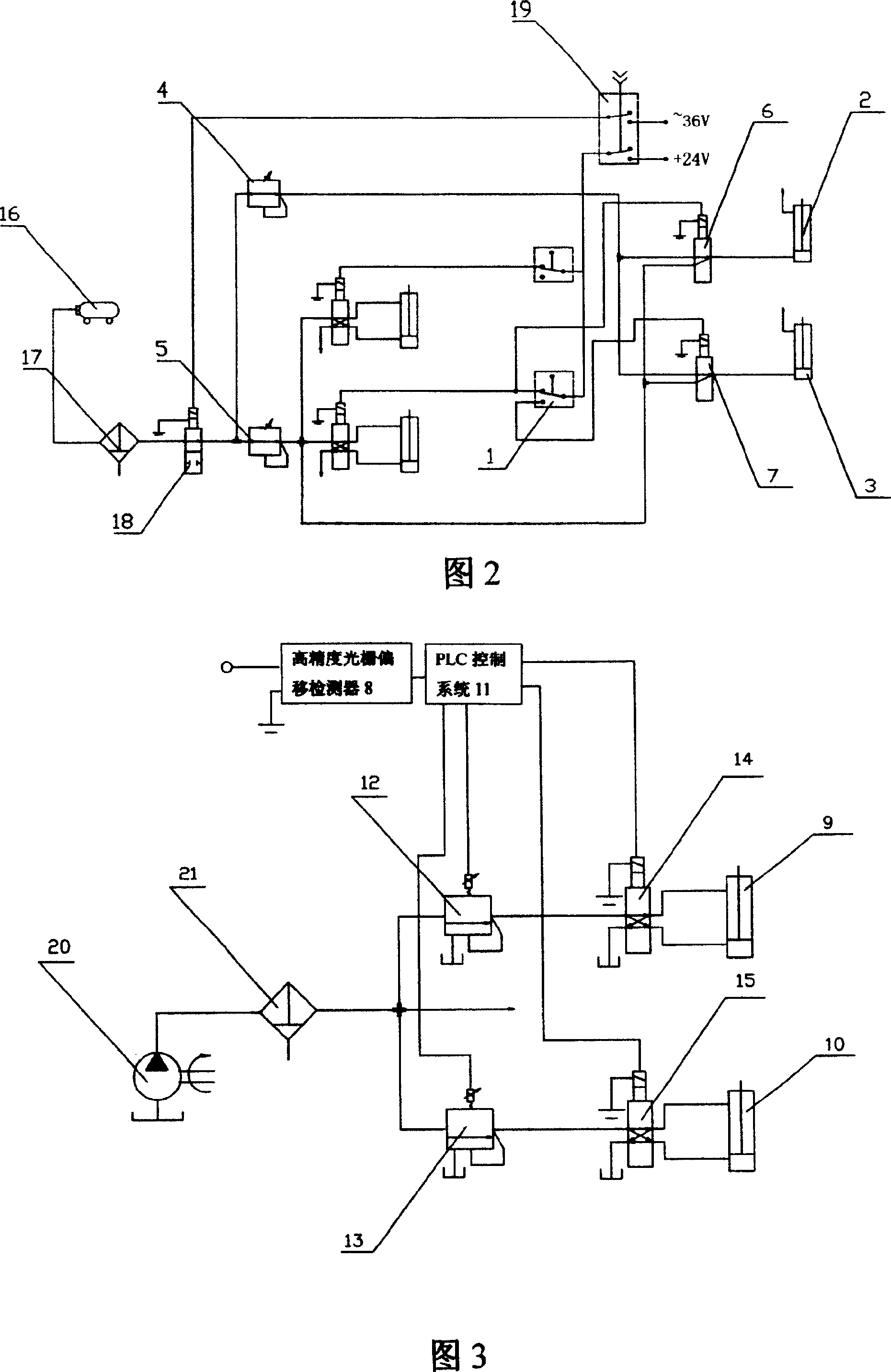

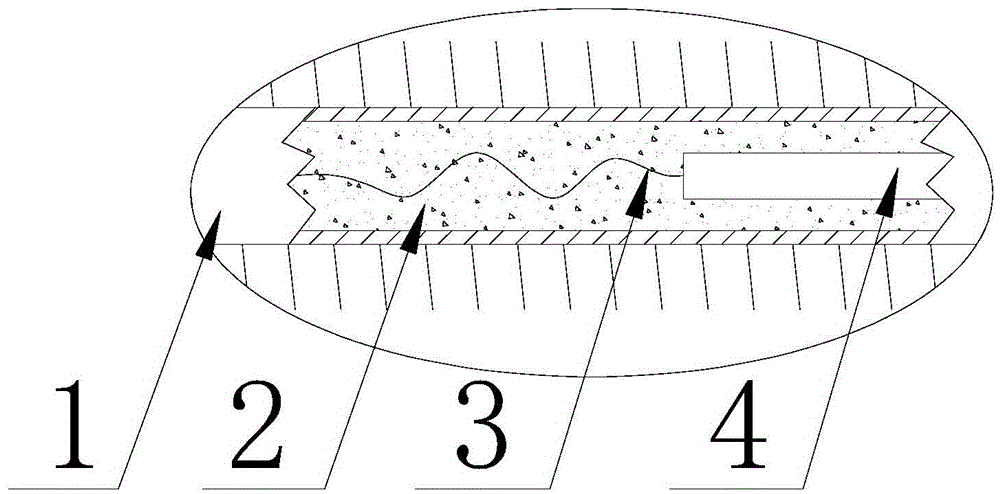

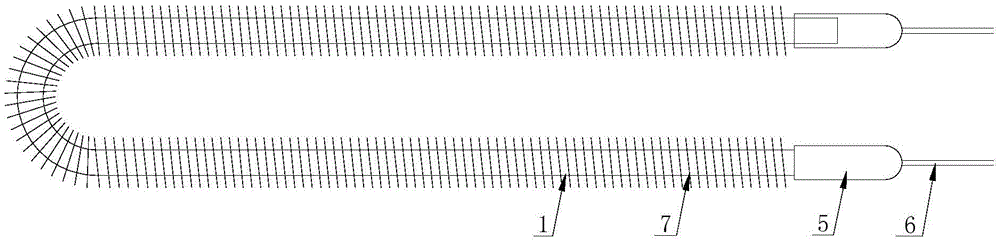

Belt-shape moving body tension differential adjusting and correction method and device therefor

Owner:大连经济技术开发区排水管理有限公司

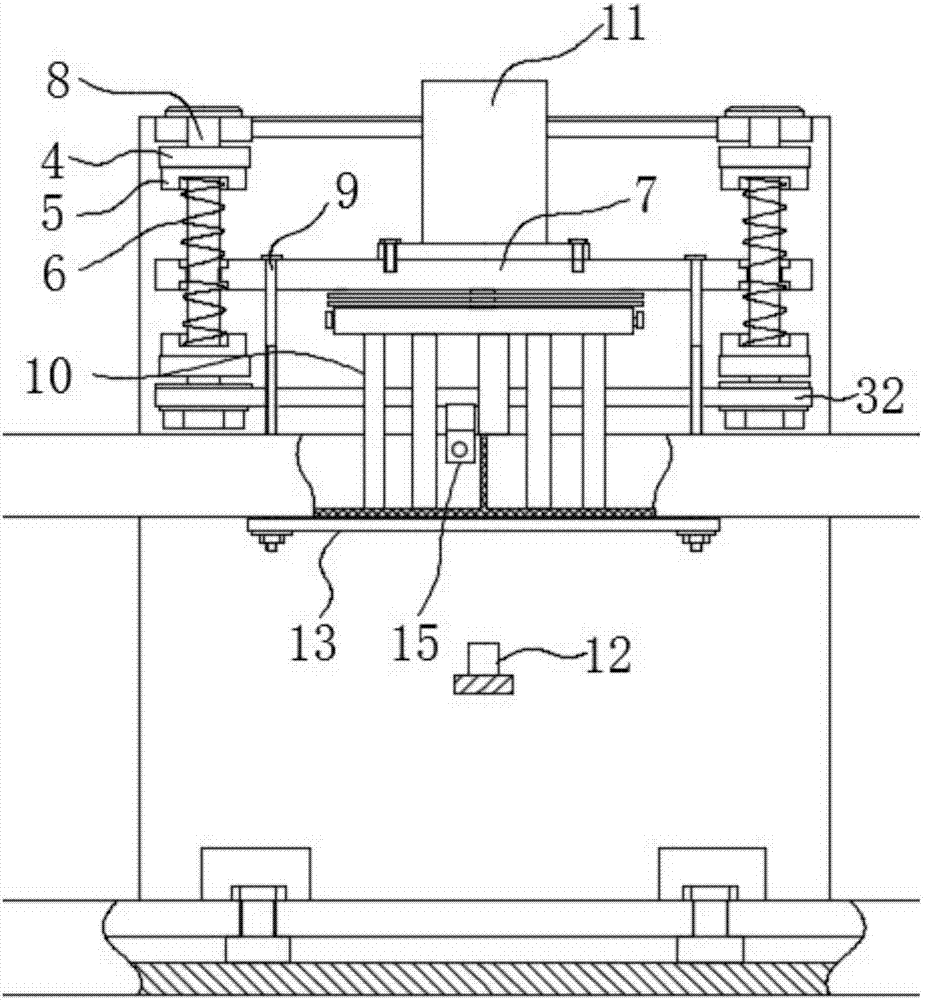

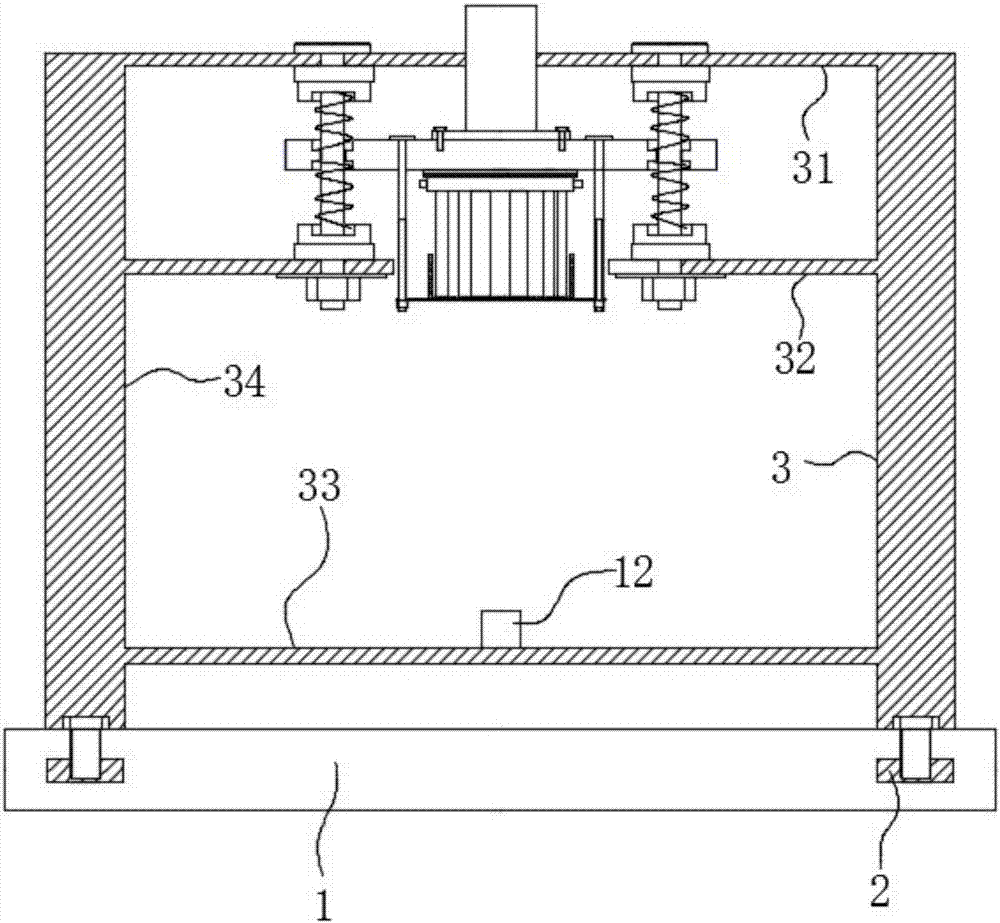

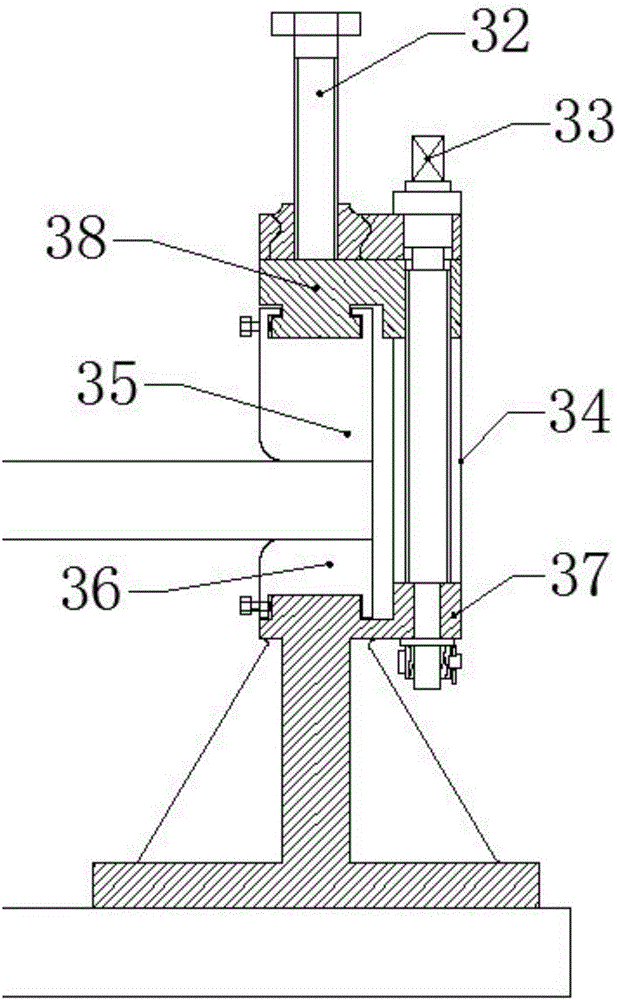

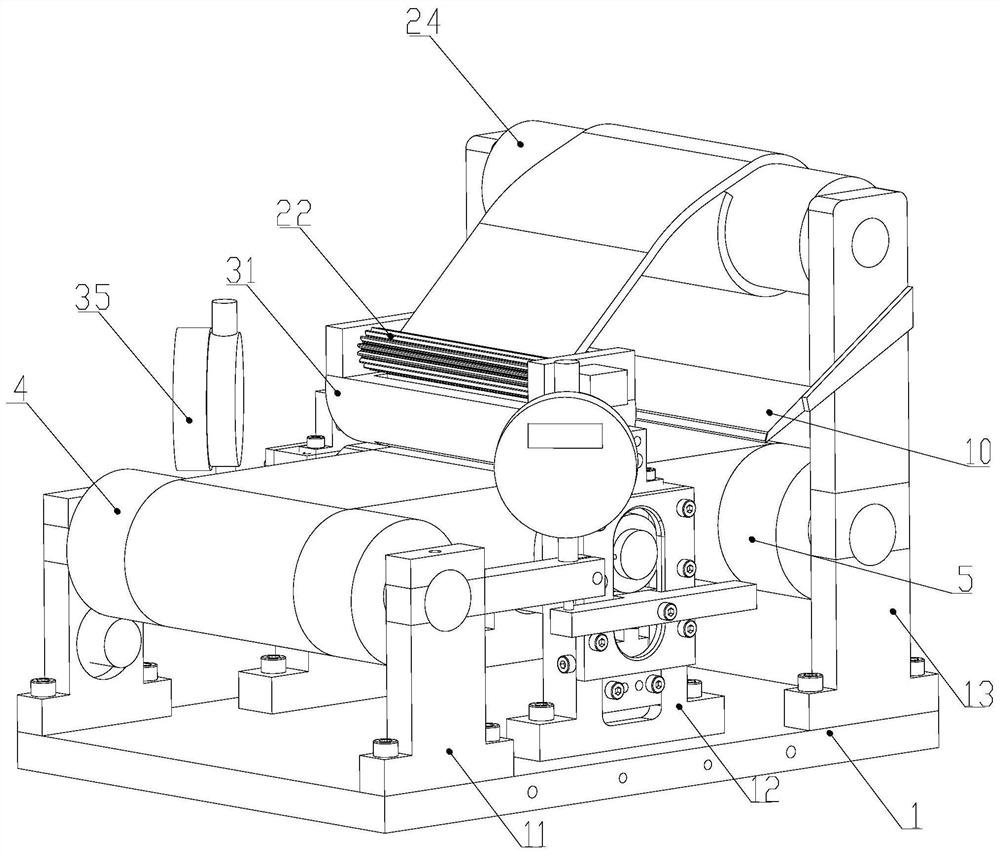

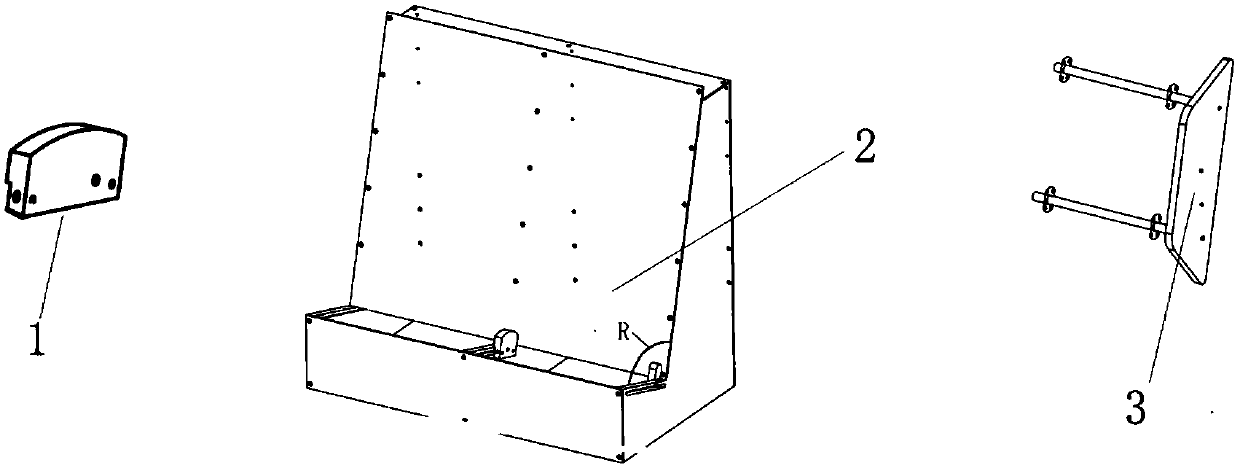

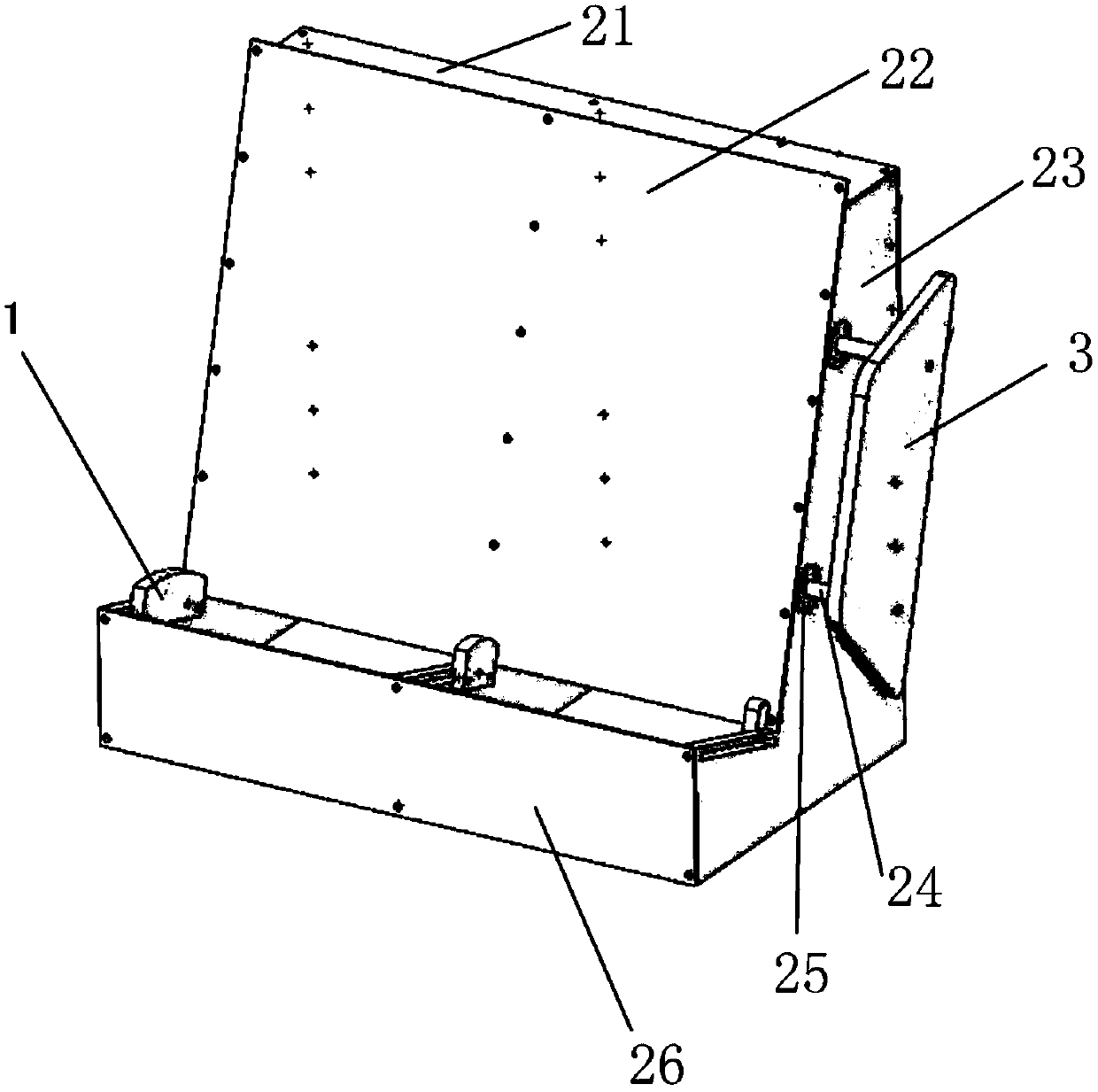

Vibration experimental platform for thin-walled member fatigue test

The invention discloses a vibration experimental platform for a thin-walled member fatigue test. The vibration experimental platform comprises an excitation source test device and an end clamp on a platform base; the excitation source test device comprises a U-shaped bracket; a laser displacement sensor is disposed on the bottom of the U-shaped bracket; first hinge pins are disposed on both sides of the upper end of the U-shaped bracket; the first hinge pins are sleeved by boxes; damping springs are arranged between each box and both ends of the corresponding box; piston vibration exciters are disposed on the tops of the boxes; first screws are disposed in the boxes; each first screw is provided with two symmetrical wedges; the lower ends of the wedges are in contact with a upper splint; the bottom cover of each box is provided with a lower splint; the upper and lower splint are cooperating with each other to form a clamp for sandwiching the thin-walled member; and a speed sensor and an acceleration sensor are arranged on one end of the excitation source test device on the thin-walled member. The vibration experimental platform can equivalently regenerate the fatigue process of an aviation aluminum alloy thin-walled component in a relatively short period, and calculates and evaluates the service life of the component.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

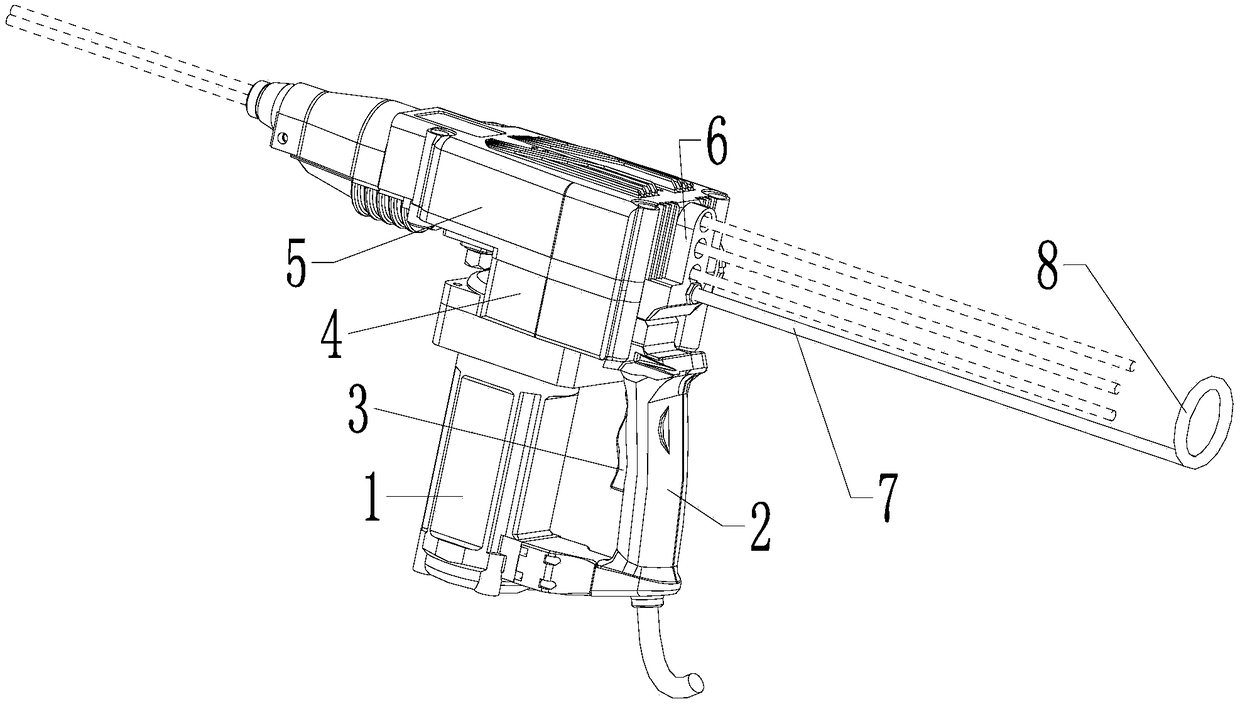

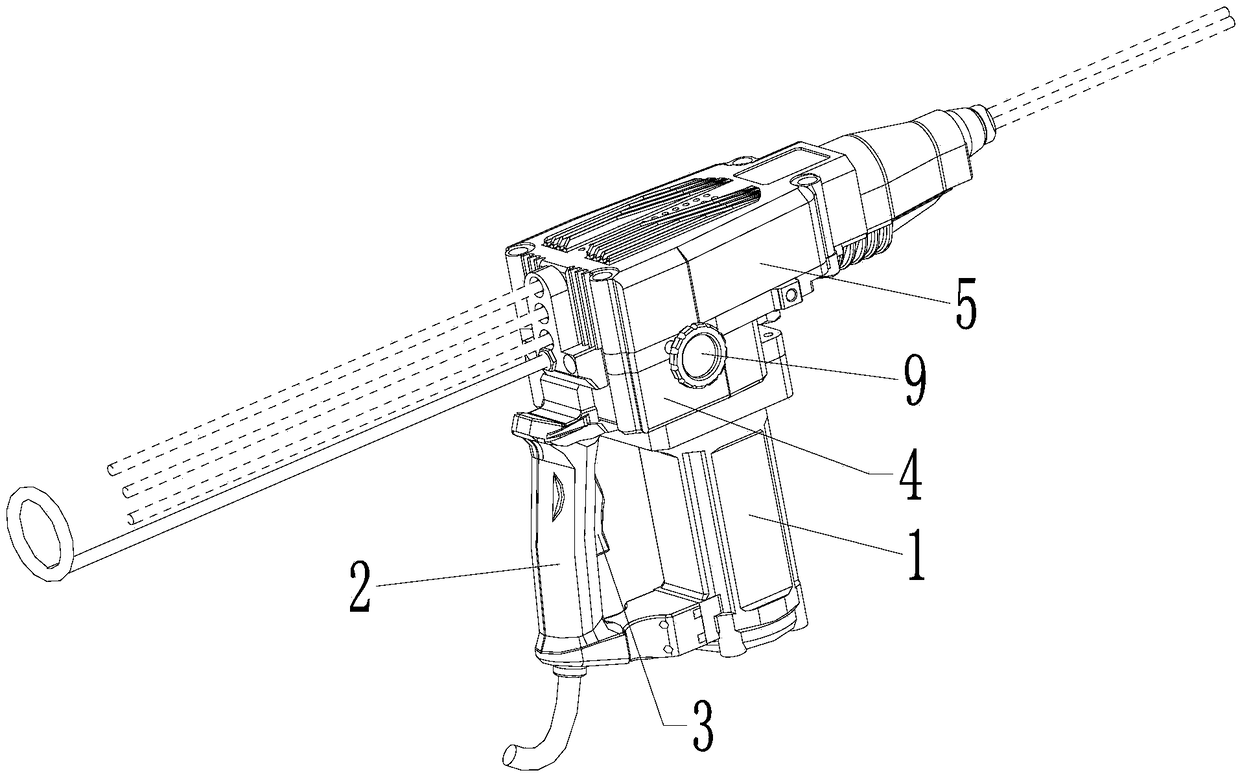

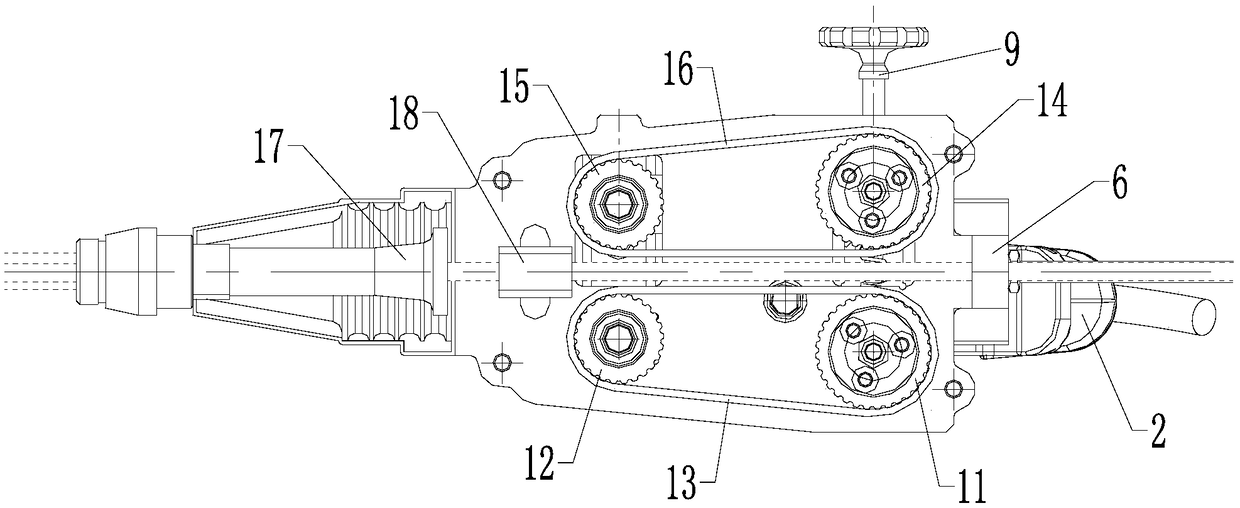

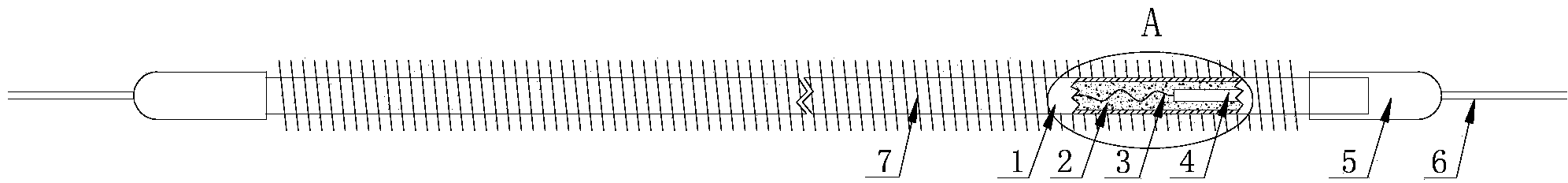

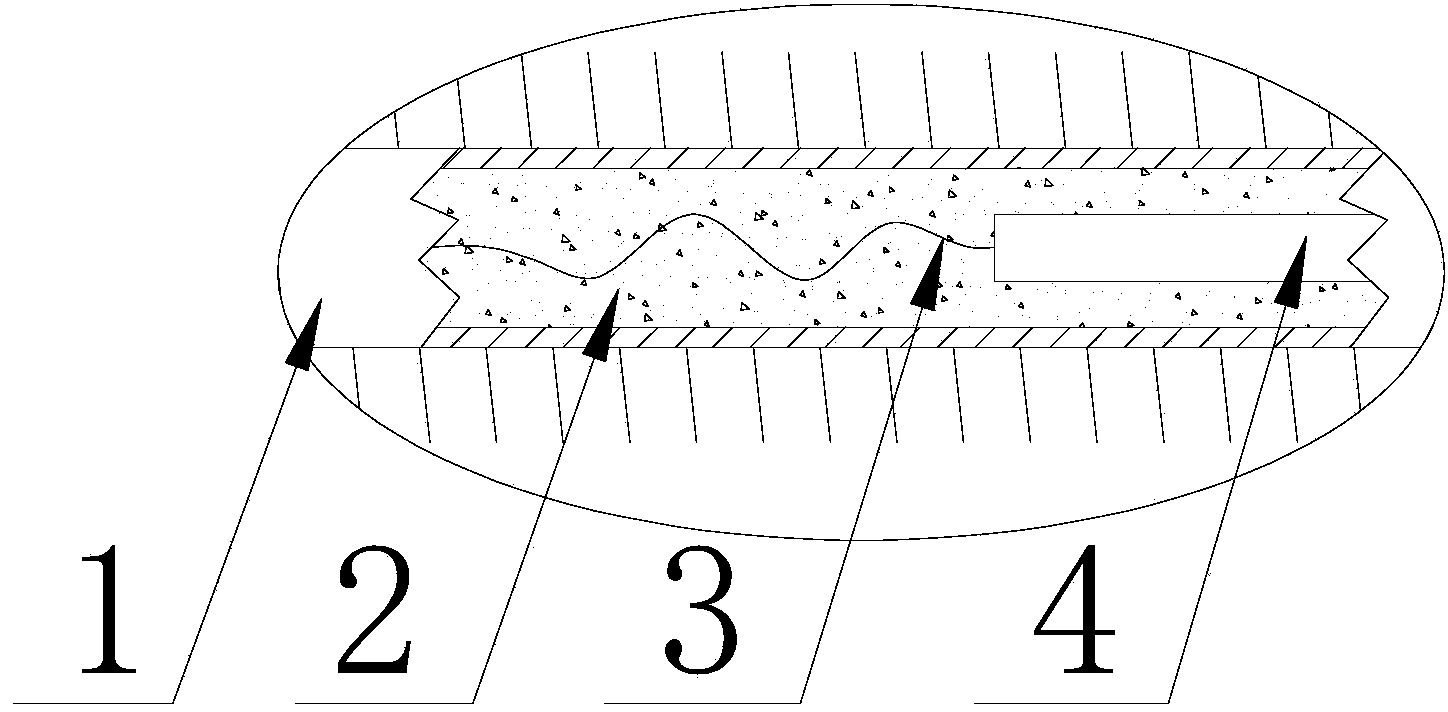

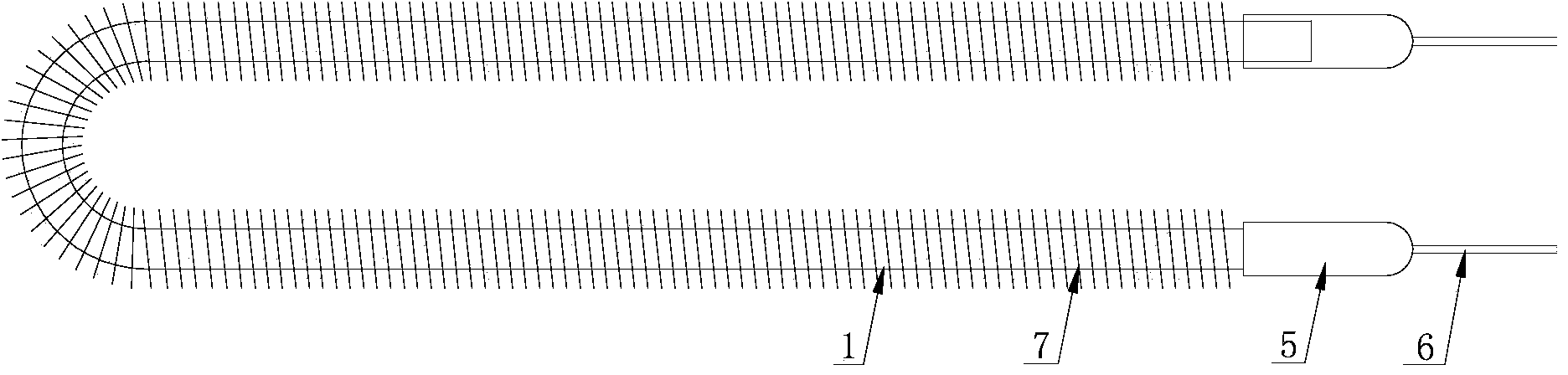

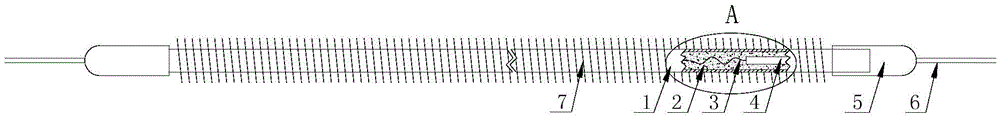

Pre-buried pipe threader

PendingCN109038377AAccelerated injectionAvoid damageApparatus for laying cablesEngineeringSynchronizing

The invention discloses a pre-buried pipe threader, which includes symmetrically mounted first synchronizing belt and second synchronizing belt, at least one annular groove is for on that first synchronization belt, a groove corresponding to the surface of the first synchronizing belt is formed on the second synchronizing belt, the corresponding grooves on the first synchronization belt and the second synchronization belt form an over-line channel, the first synchronous belt and the second synchronous belt rotate in the opposite direction synchronously, and a conductor plate is mounted on theinlet side of the conductor passage, a small via hole corresponding to the conductor passage is formed on the conductor plate, a conductor sleeve is mounted on the outlet side of the conductor passage, and a large via hole is formed on the conductor sleeve. Such that the cable is clamped and accelerated using the over-wire channel formed between the first and second synchronization belts, the cable penetrates through the pre-buried pipe, not only time and labor are saved, but also the threading efficiency is remarkably improved, the labor cost is saved, control of the construction cost is facilitated, and the threader has the characteristics of ingenious conception, simple structure, wide application range, convenient use and the like.

Owner:李洪

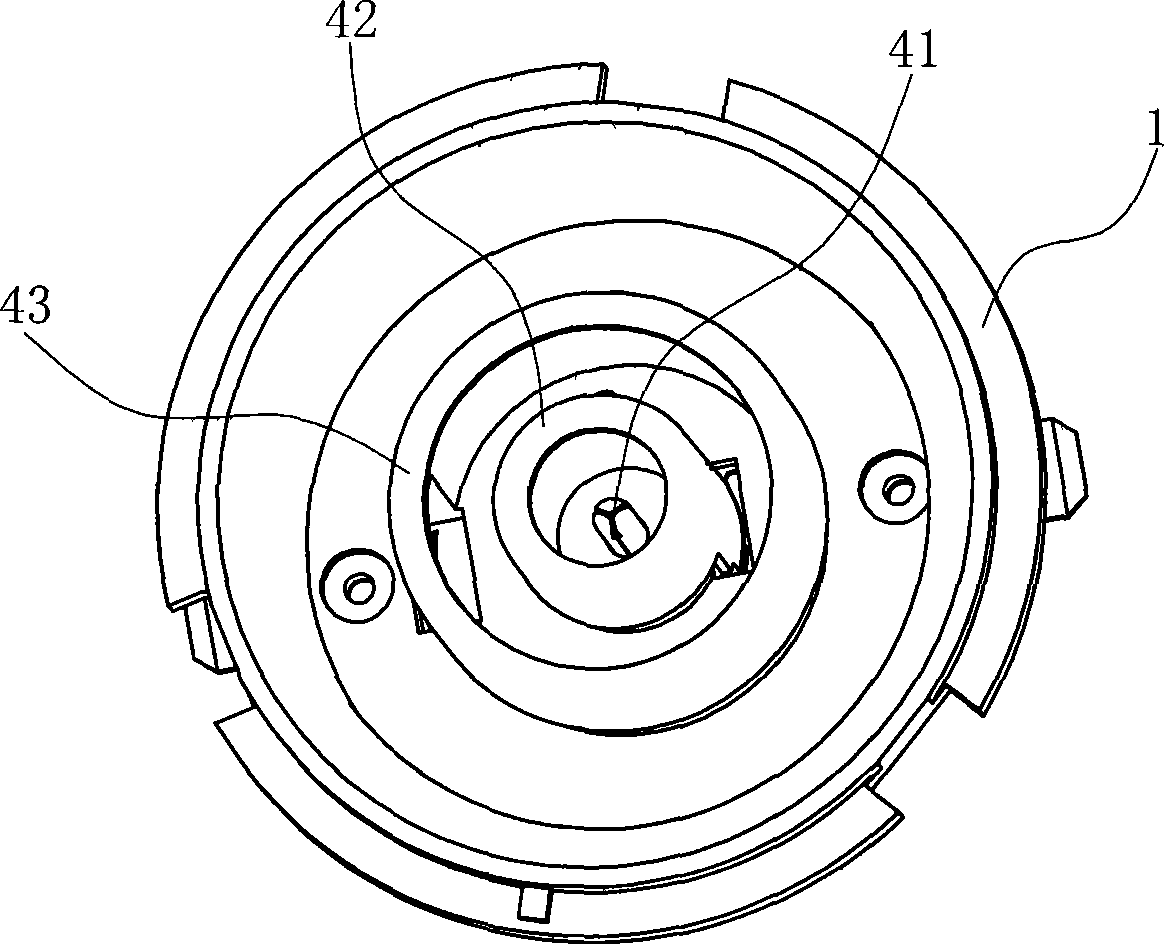

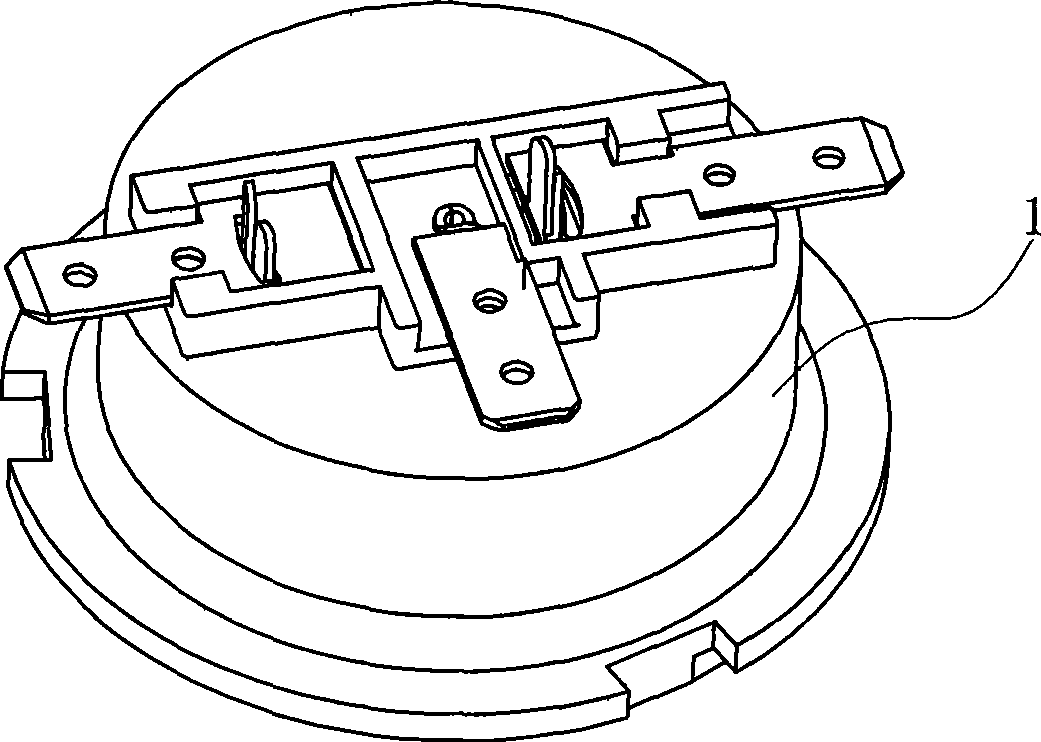

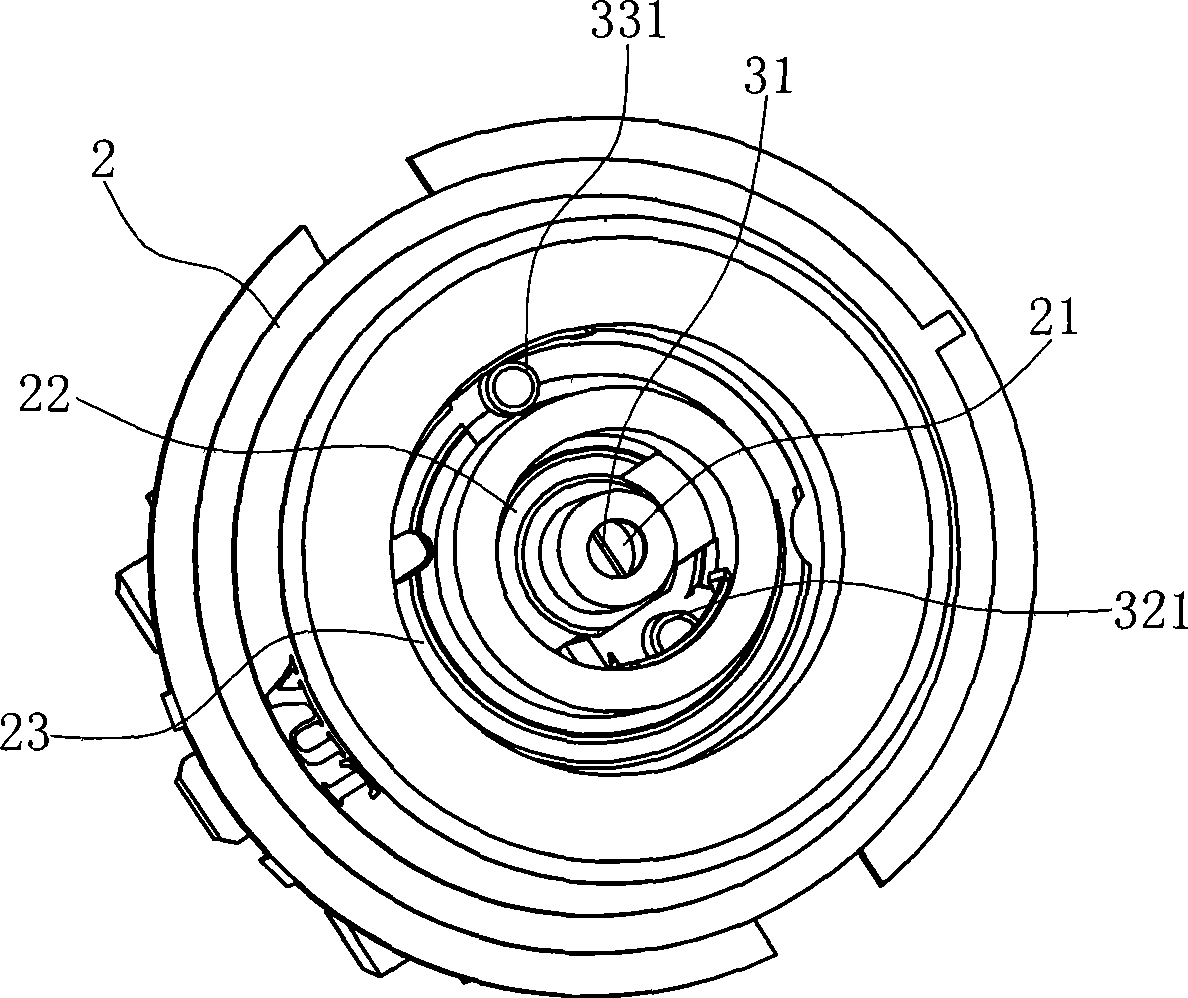

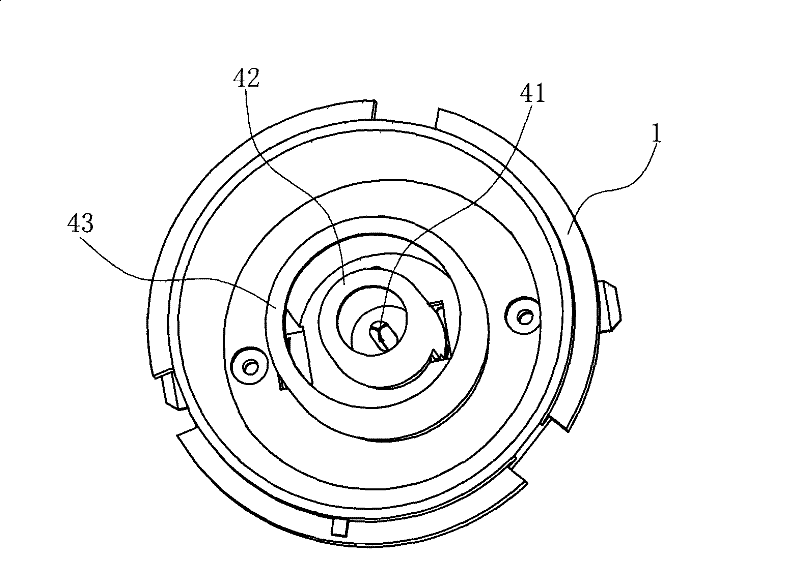

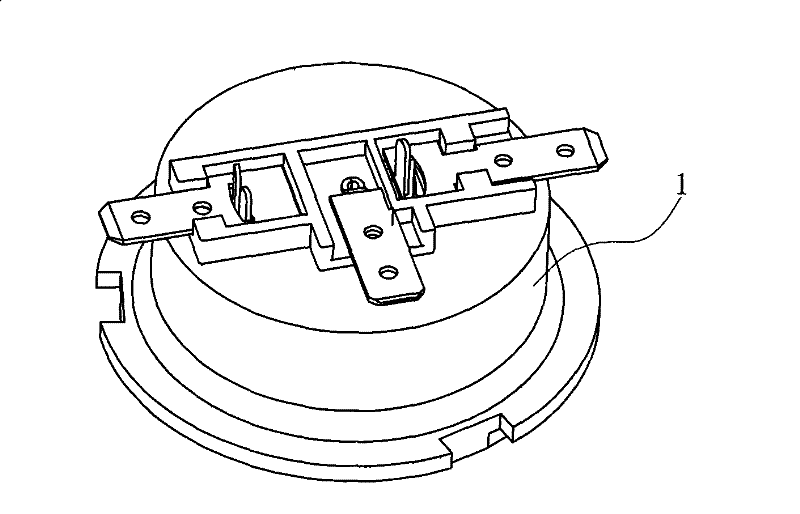

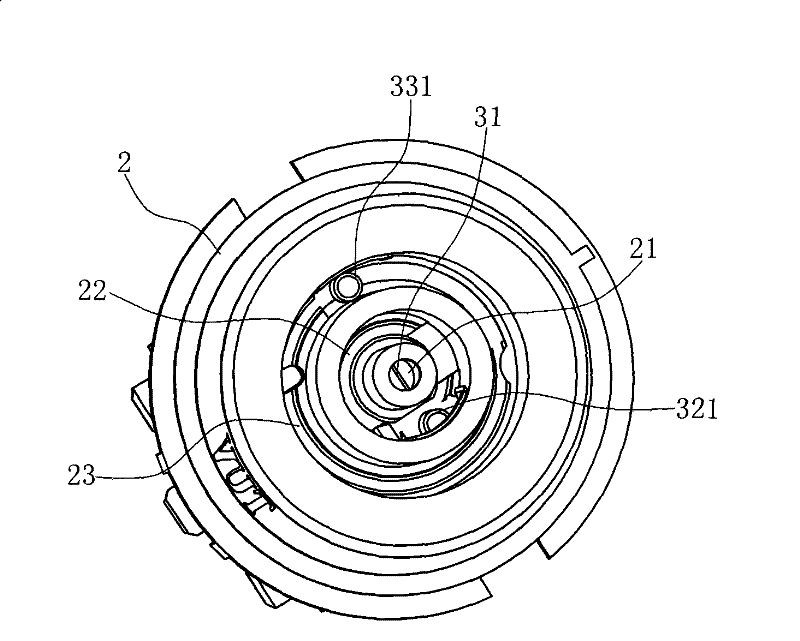

Safety coupler of cordless electric appliance

InactiveCN101521346AUnlimited widthUnlimited depthCoupling device detailsFlexible/turnable line connectorsElectricityEngineering

The invention relates to a safety coupler of a cordless electric appliance, which comprises an appliance input socket and an electric connector, wherein the inside of the electric connected is provided with a power-receiving connecting terminal and at least one power supply contact piece, and the input socket is provided with a cylindrical power-receiving connecting terminal and an annular power-receiving connecting terminal. The safety coupler is characterized in that: the power-receiving connecting terminal corresponding to the power supply contact piece is an elastic piece; the power-receiving connecting terminal is provided with a pushing part which is made of conductive material and is matched with the corresponding power-receiving connecting terminal; when the electric connector is not plugged in the appliance input socket, the power supply contact piece and the corresponding power-receiving connecting terminal are kept in a contact normal open state; when the electric connector is plugged in the appliance input socket, the annular power-receiving connecting terminal directly participates in the contact with the pushing part to push the power-receiving terminal and the corresponding power supply contact piece close to turn on power. Due to the direct cooperation between the annular power-receiving connecting terminal and the pushing part made of the conductive material, a specially arranged contact closing and opening structure is saved, the structure of the safety coupler is simplified, and the production and manufacturing cost of the coupler is reduced.

Owner:柯赐龙

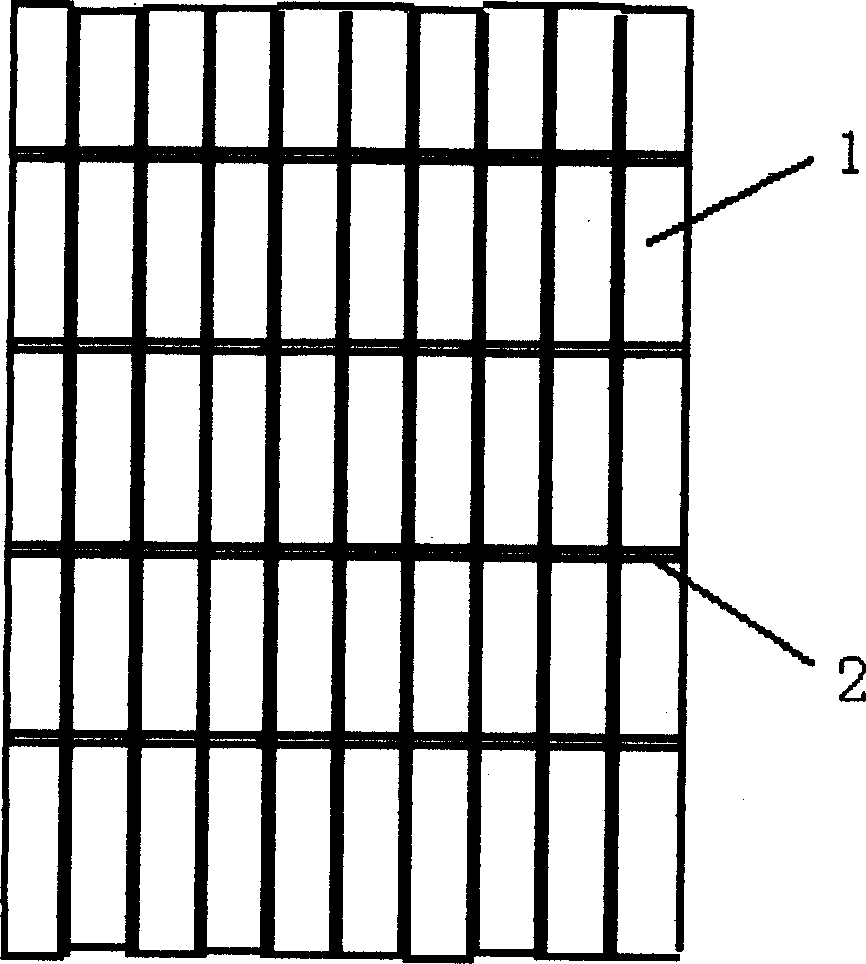

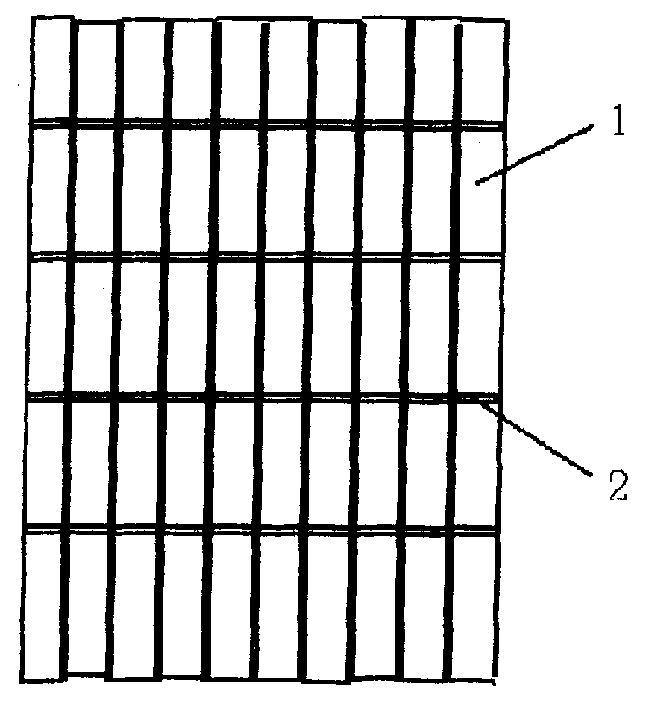

Bamboo plywood and process for making same

The present invention features that the glued bamboo board made of assembled and glued bamboo strips has ribs to string adjacent bamboo strips. The making process of the glued bamboo board includes cutting bamboo strip, moth-proof treatment, stringing, gluing and stoving. The present invention eliminates the limitation of glued bamboo board in width, raises the quality and use effect of glued bamboo board and makes glued bamboo board firm, pressure resistant, no crack, light, easy to install and suitable for various fields.

Owner:张运根

Novel energy-efficient fin type electric heating pipe

The invention relates to a novel energy-efficient fin type electric heating pipe which comprises a shell, a heating wire and heat-conducting insulating padding. A strip-shaped cooling fin is spirally wound on the outer surface of the shell and provided with continuously-distributed fan-shaped concave-convex structures, the shrinkage end of each structure is close to the surface of the shell, the unfolded end of each structure is close to the outer edge of the fin, and a smooth arc transition face is arranged between each unfolded end and the outer edge of the cooling fin. Mounting seats are connected with the shell in a sealed mode, power lines are arranged on the end portions of the mounting seats, and the power lines are connected with the heating wire in the shell through the mounting seats. The continuous concave-convex structures which are arranged at intervals are adopted by the cooling fin, the fin can be conveniently wound on the shell, and internal stress of the cooling fin is effectively eliminated. Welding machining is facilitated, the width of the fin is not limited, the cooling area is enlarged, the cooling effect is better, and the service life of the electric heating pipe is longer. Cooling efficiency of the fin is enhanced, the power of the electric heating pipe can be properly lowered, and the purposes of efficiency raising and energy saving are achieved.

Owner:江苏大唐电器制造有限公司

Preparation method of liquid crystal polymer film material with low dielectric constant and low dielectric loss

ActiveCN112172210AEvenly dispersedImprove dispersion uniformityFlat articlesCoatingsDielectric lossMixed materials

The invention discloses a preparation method of a liquid crystal polymer film material with a low dielectric constant and a low dielectric loss. The preparation method comprises the following steps of: S1, dissolving a liquid crystal polymer into a solvent to obtain a liquid crystal polymer solution; S2, adding fluororesin powder into the liquid crystal polymer solution, and dispersing the mixed material; S3, coating the surface of a release base material with the mixed material obtained in the step S2, and carrying out drying and melting treatment on a coating layer to form a film; and S4, separating a film layer from the release base material to prepare the liquid crystal polymer film material. The preparation method of the liquid crystal polymer film material with the low dielectric constant and the low dielectric loss sequentially comprises the four steps of dissolving the liquid crystal polymer, dispersing the fluororesin powder, coating and drying the mixed material and forming the film to separate from the release base material, and more fluororesin is conveniently added into the liquid crystal polymer film material by adopting a liquid mixing mode; and the fluororesin powder in the liquid crystal polymer film material is dispersed more uniformly. The invention also discloses the liquid crystal polymer film material and a mobile phone antenna based on the liquid crystalpolymer film material.

Owner:江苏中际信通讯材料有限公司

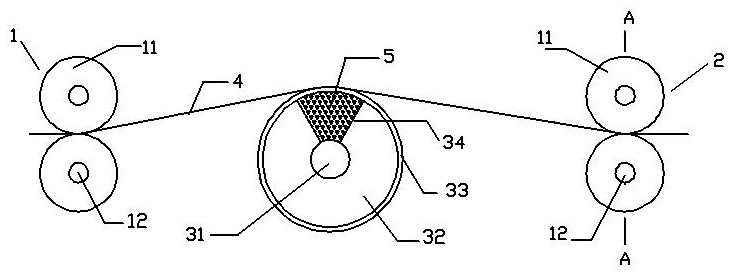

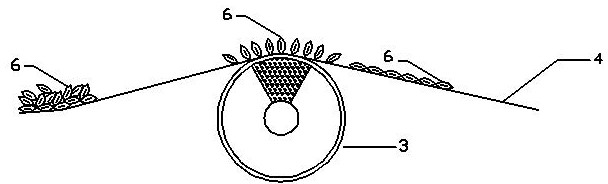

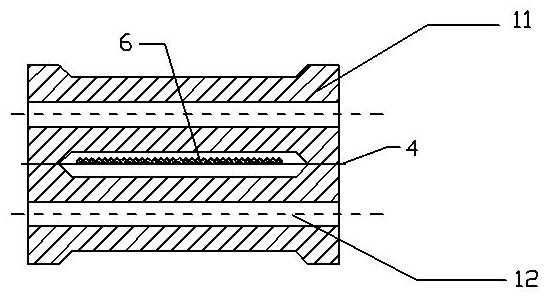

Magnetic field orientation method and device for tape casting of magnetic materials and product

ActiveCN112635154AUnlimited widthReduce volumeMagnetic bodiesInductances/transformers/magnets manufactureMagnetic tension forceMagnetization

The invention discloses a magnetic field orientation device for tape casting of magnetic materials. The magnetic field orientation device comprises a support, a first limiting pair roller, a magnetic field orientation roller, a second limiting pair roller and a tape casting base band which sequentially passes through the first limiting pair roller, the magnetic field orientation roller and the second limiting pair roller; tape casting slurry to be subjected to tape casting is carried on the tape casting base band, and the slurry comprises magnetic fillers to be oriented; the casting base band is in contact with the top arc section of the magnetic field orientation roller; the magnetic field orientation roller consists of a fixed shaft, a magnet mounting layer and a rubber sleeve layer; and the magnet mounting layer is provided with a magnetic hard magnet for performing magnetic field orientation arrangement and magnetization on each magnetic filler in the tape casting slurry. The invention further discloses a magnetic field orientation method adopting the device and a product. The magnetic materials are rearranged and oriented under the combined action of magnetic force and gravity, and the magnet is small in size, uniform in strength at all positions, higher in orientation efficiency and better in effect; and a prepared magnetic film material is large in thickness, and the width of the magnetic film material can be expanded as required.

Owner:广东高鑫信息股份有限公司 +1

Device and method for producing large-width ultrathin metal lithium strip

PendingCN112410784AUnlimited widthAvoid fireCell electrodesMetallic material coating processesMetallic lithiumThin metal

The invention discloses a device and method for producing a large-width ultrathin metal lithium strip, and belongs to the technical field of lithium metal. The device comprises a rack, a lithium material feeding device, a lithium material melting and blade coating device, a base material unwinding roller and a composite belt winding roller; the lithium material melting and blade coating device comprises a lithium material box and a blade coating lower roller, the blade coating lower roller is arranged on the rack, the lithium material box is arranged above the blade coating lower roller, a working gap allowing a base material to penetrate through is formed between the lithium material box and the blade coating lower roller, and a discharging gap allowing molten lithium liquid to flow out is formed at the bottom of the lithium material box; and the base material unwinding roller and the composite belt winding roller are arranged at the two sides of the lithium material melting and bladecoating device correspondingly. The base material on the base material unwinding roller penetrates through the working gap and then is wound around the composite belt winding roller. The lithium material feeding device is arranged above the composite belt winding roller and the lithium material box. The device is simple in structure and easy to debug, an ultrathin metal lithium strip with the thickness of 5-100 microns can be automatically produced, and the working efficiency and the product quality are greatly improved.

Owner:天齐卫蓝固锂新材料(深圳)有限公司

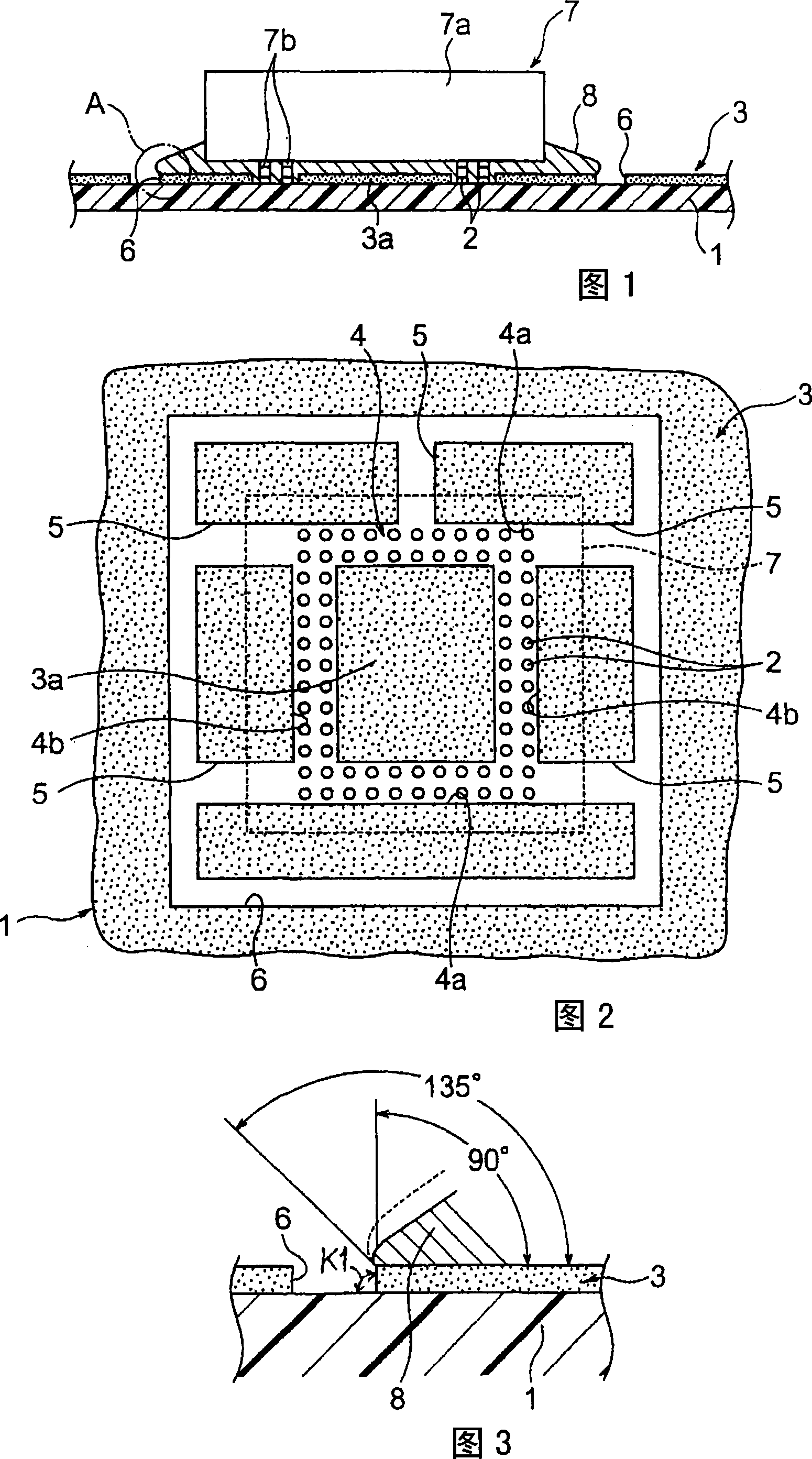

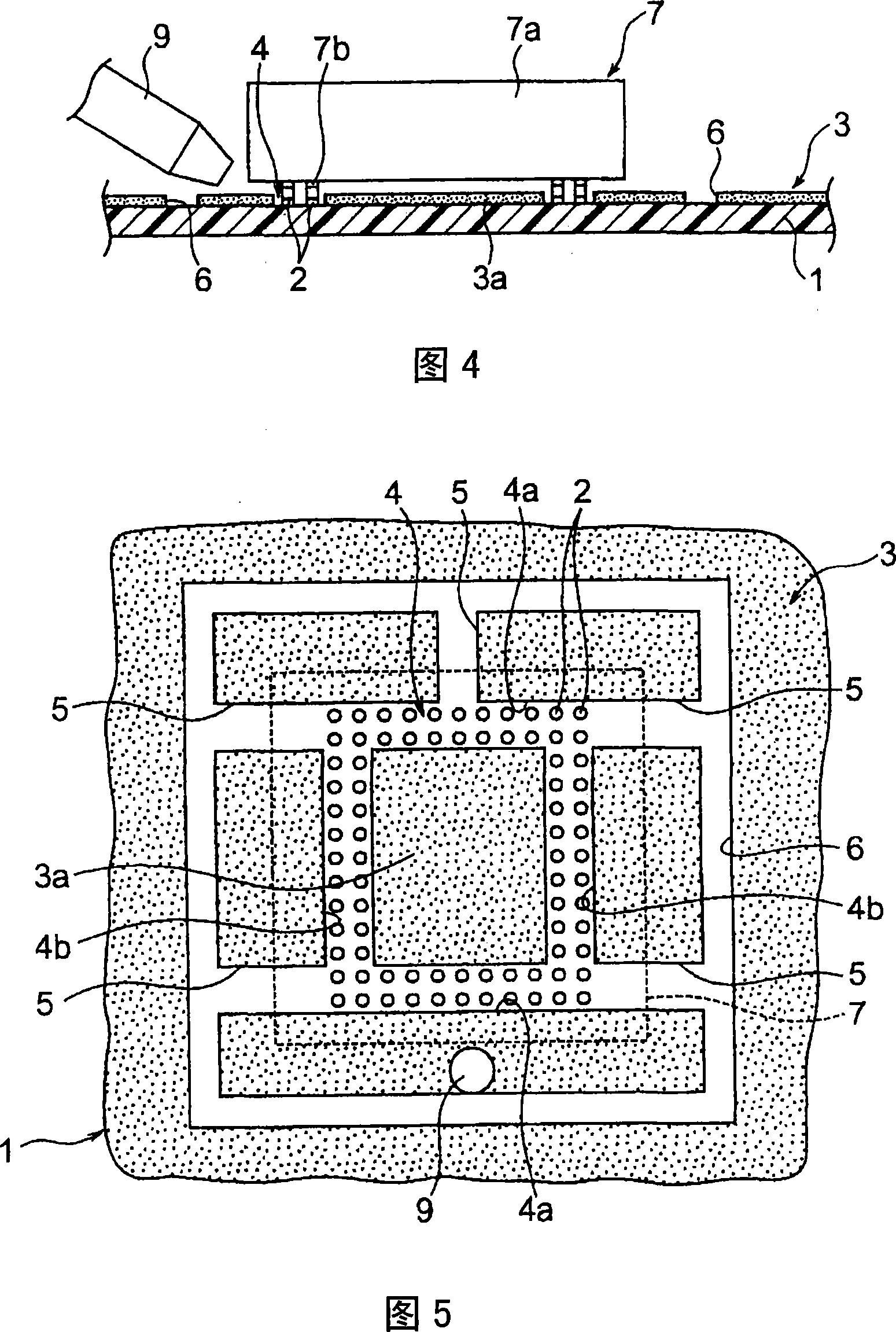

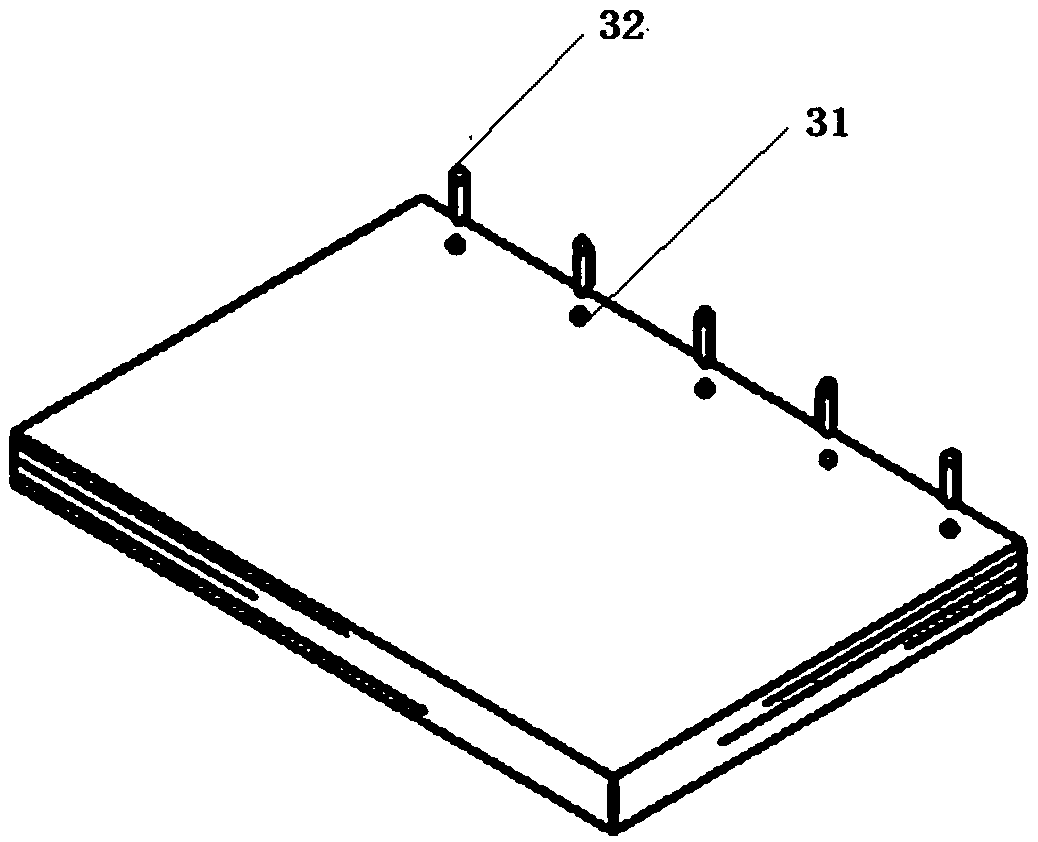

Mounting structure of electronic component

InactiveCN101093821AUnlimited thicknessUnlimited depthPrinted circuit assemblingSemiconductor/solid-state device detailsMiniaturizationEngineering

To provide a low-cost mounting structure of electronic component with a small size where the spreading of underfill on an insulating coat is suppressed by a film removing portion. In the mounting structure of the electronic components, spreading of the underfill 8, prepared on the insulating coat 3, is controlled by the coat exception portion 6, and the spreading of the underfill 8 beyond it does not exist. Since the suppression effects of the spreading of the underfill 8 is not relevant to the thickness, the depth and the width of the film removing portion 6, the film removing portion 6 can be made thin, shallow and narrow, and low cost, and thus miniaturization and thinning of an insulating substrate 1 can be facilitated.

Owner:ALPS ALPINE CO LTD

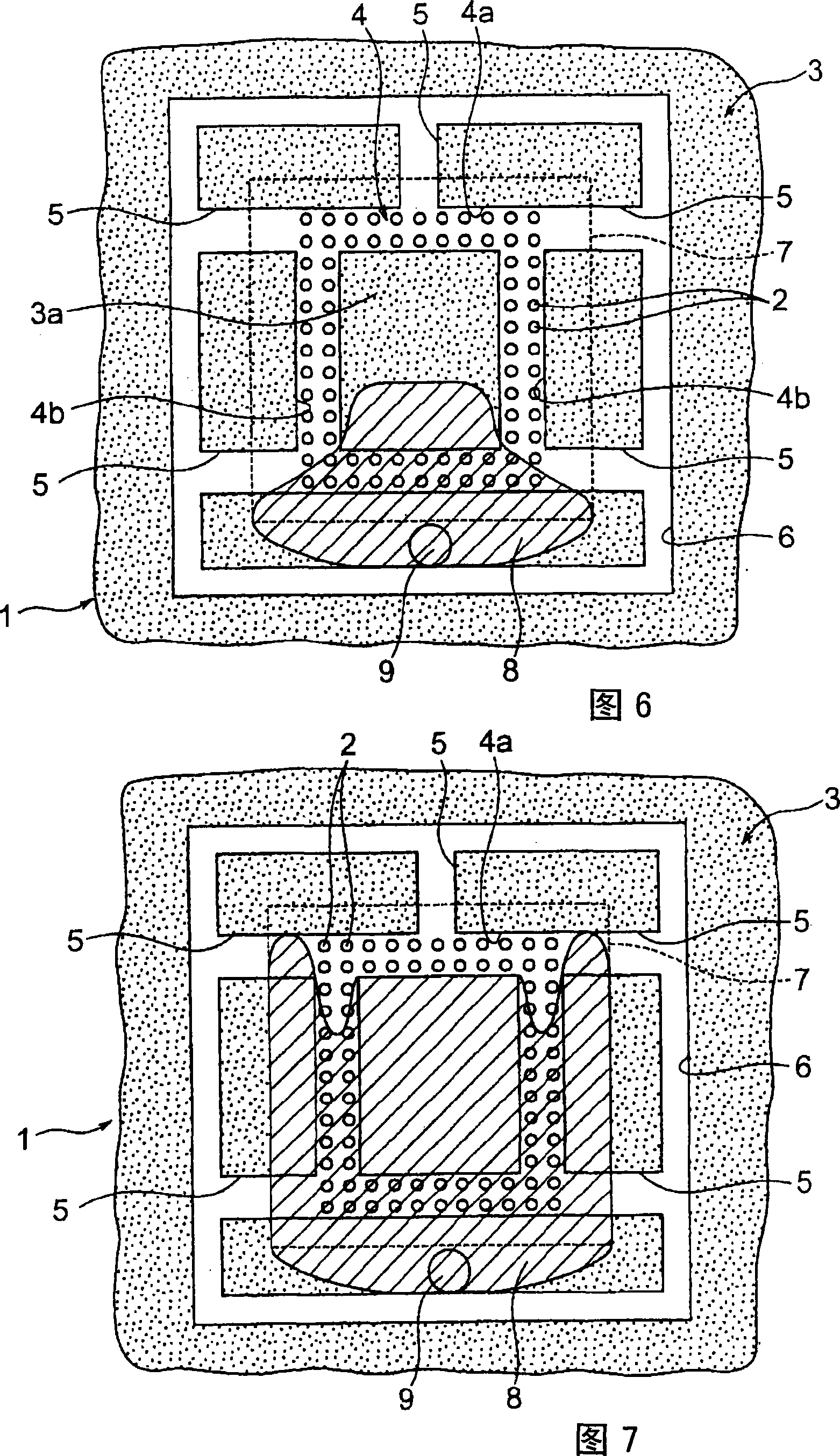

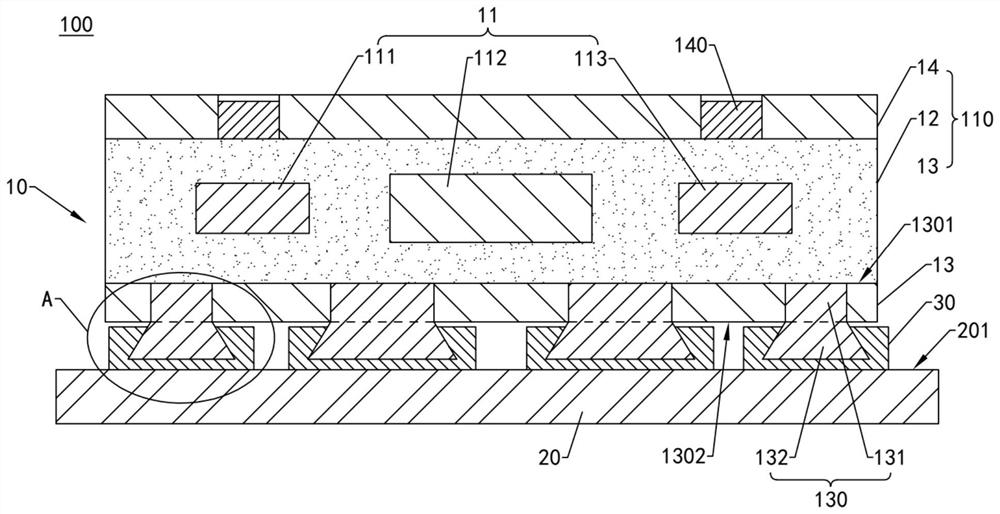

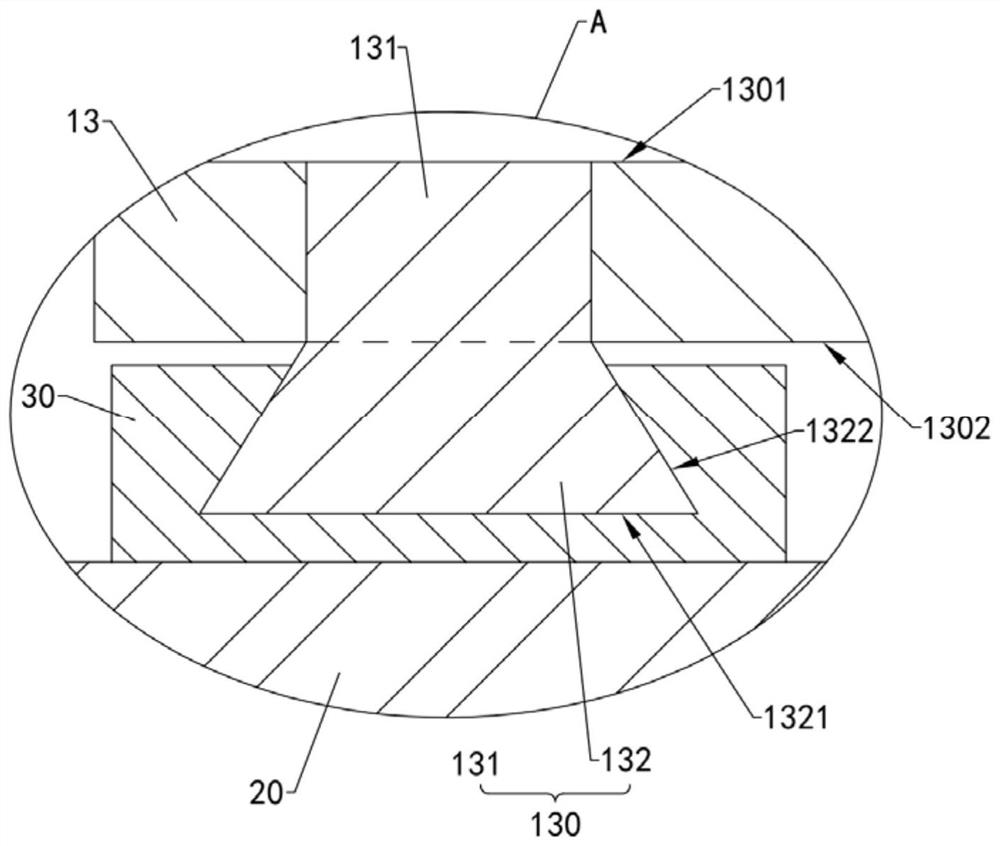

Electronic component packaging body, electronic component assembling structure and electronic equipment

ActiveCN113056098AImprove welding strengthImprove reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringElectronic component

An embodiment of the invention discloses an electronic component packaging body, an electronic component assembling structure and electronic equipment. The electronic component assembling structure comprises the electronic component packaging body, a circuit board and welding spots, wherein the electronic component packaging body comprises a substrate, an electronic component and a pin, the electronic component is packaged in the substrate, the pin is electrically connected with the electronic component, the pin comprises a first part and a second part connected with the first part, the first part is embedded in the substrate, the second part protrudes relative to the substrate, the second part comprises a bottom surface and a side surface, the bottom surface is an outer surface, far away from the substrate, of the pin, and the side surface is connected between the bottom surface and the substrate; the electronic component packaging body is mounted on the circuit board, and the circuit board is electrically connected with the electronic component; and the welding spots are connected between the pins and the circuit board and surround the bottom surface and the side surfaces of the second part. According to the electronic component assembling structure provided by the invention, the welding reliability of the electronic component packaging body and the circuit board is relatively high.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

Printing technology of printing color paste

The invention discloses a printing technology of printing color paste. The technology comprises the steps of printing color paste preparing, film making, platemaking, sample making, drying and shaping. The printing technology solves the problems that pattern and color in screen printing is not bright, and the pattern definition is poor and overcomes the detects that in digital printing, the yield is low, and the breadth is limited. The printing breadth is increased, and the printing speed is high.

Owner:WUXI SINTEX PRINTING & DYEING CO LTD

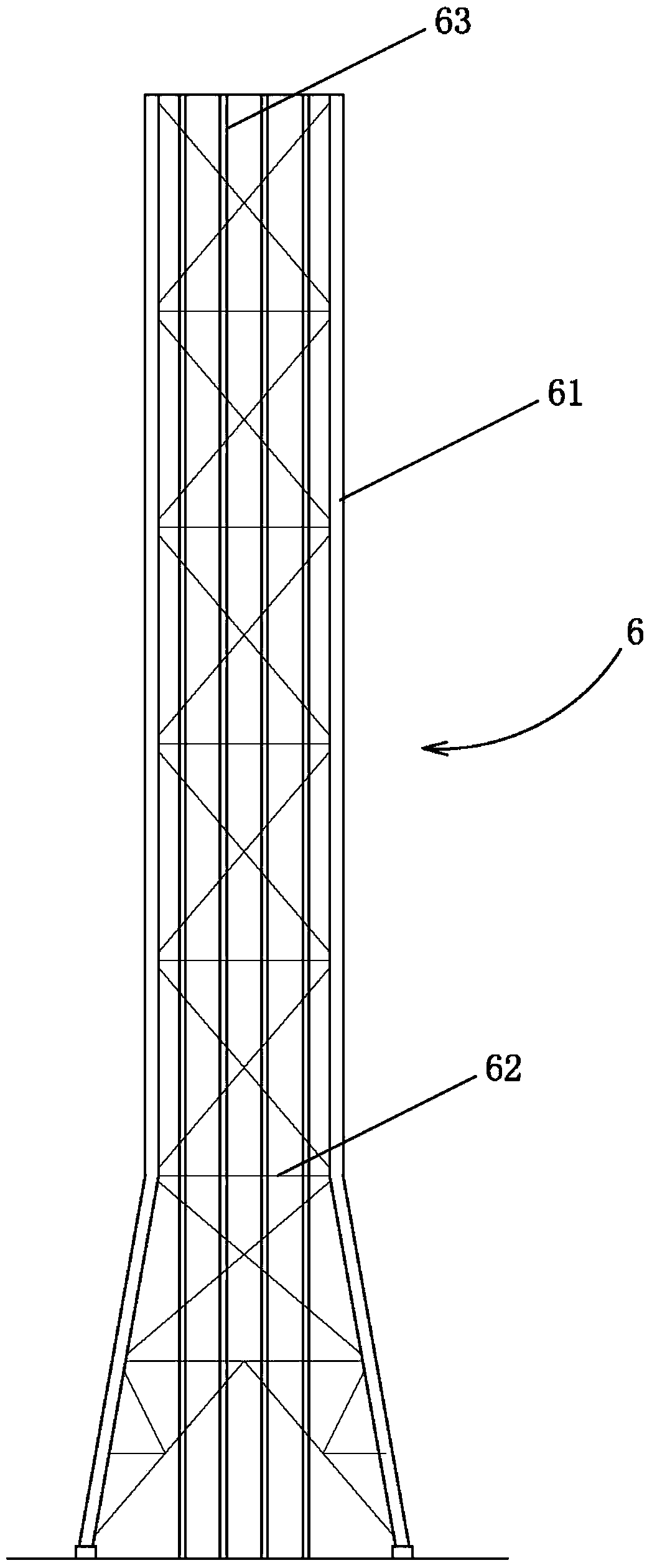

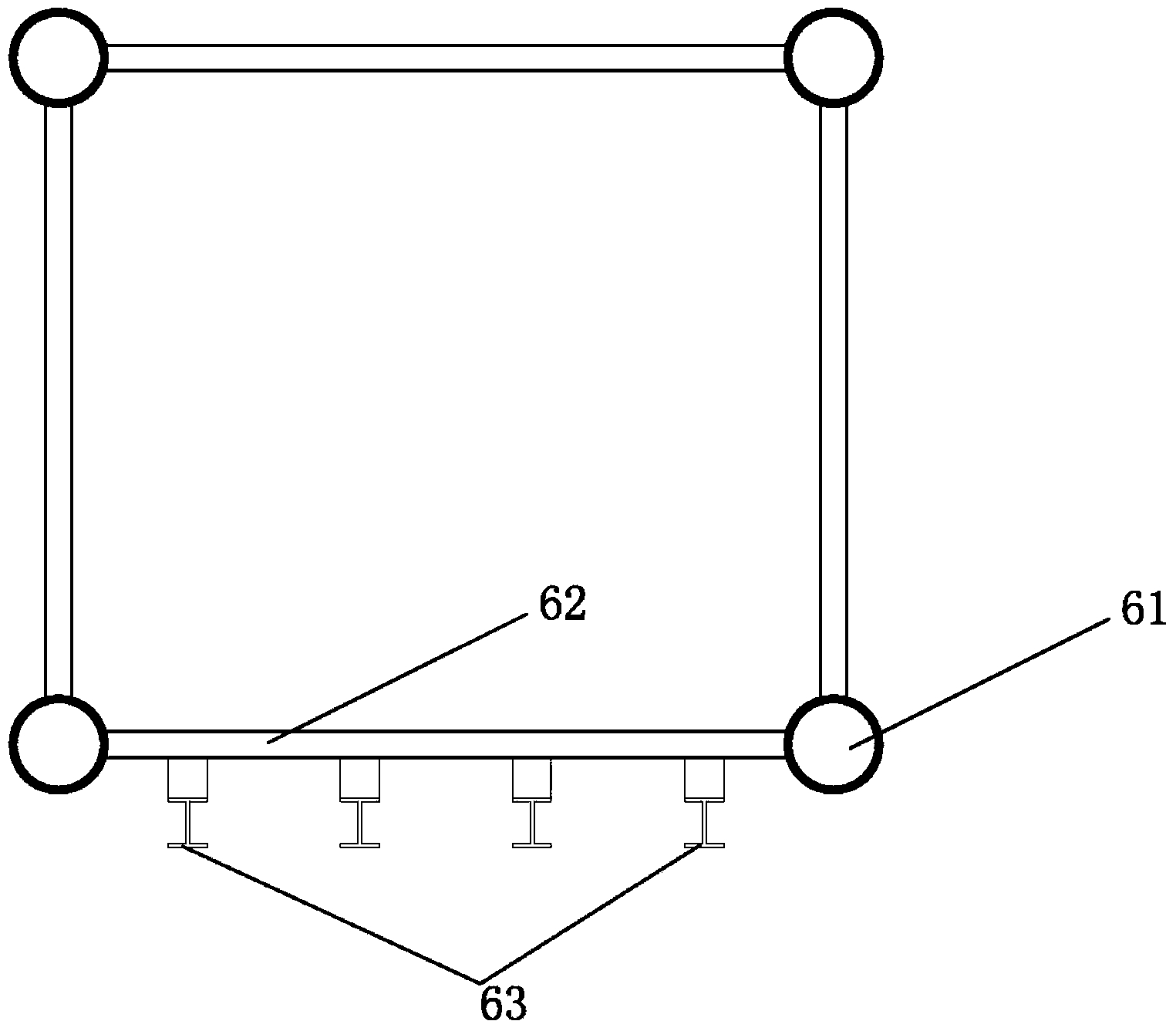

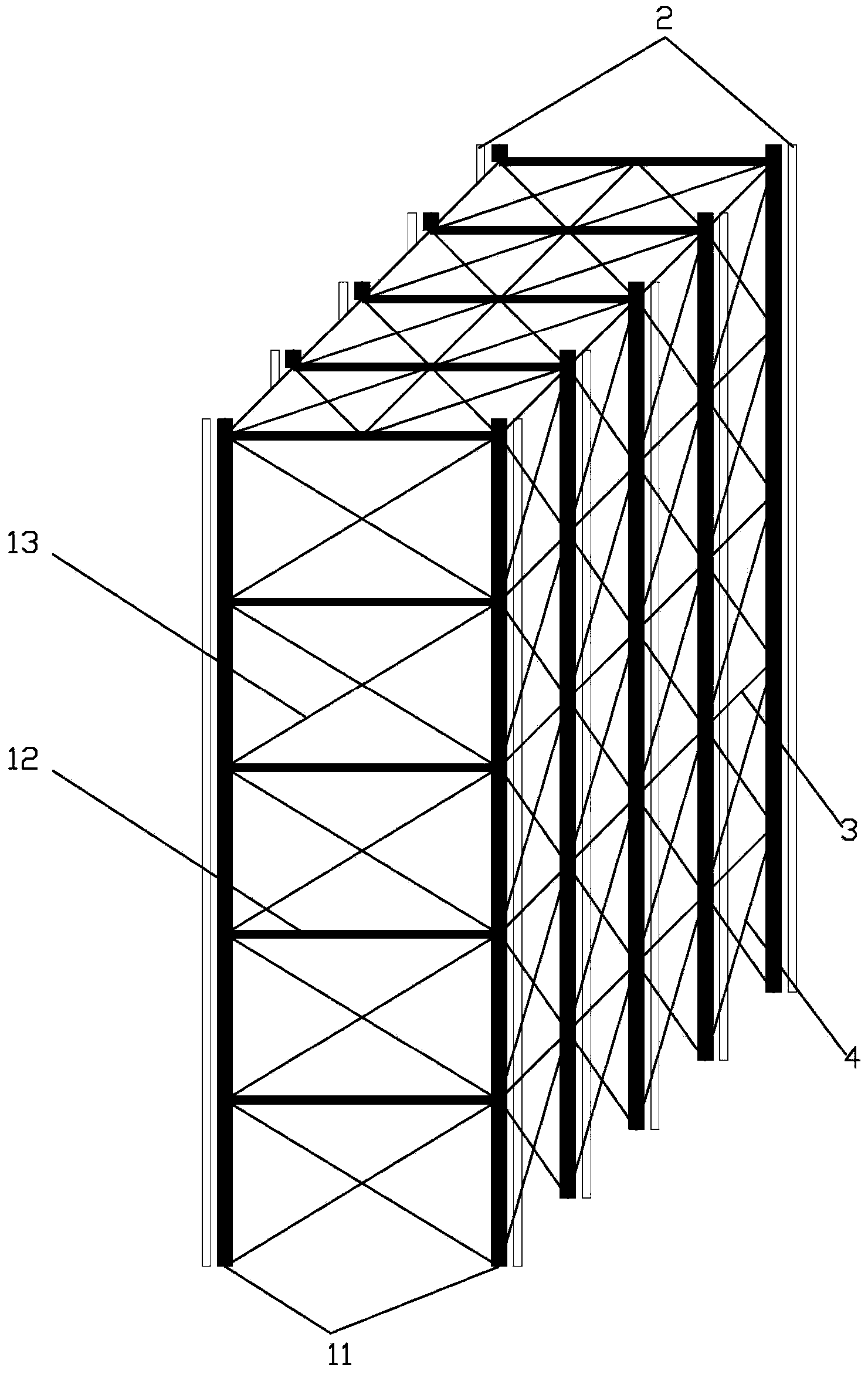

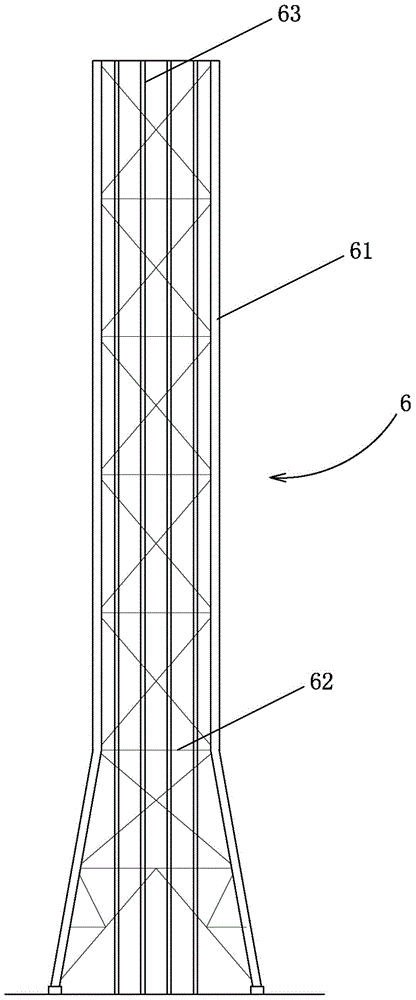

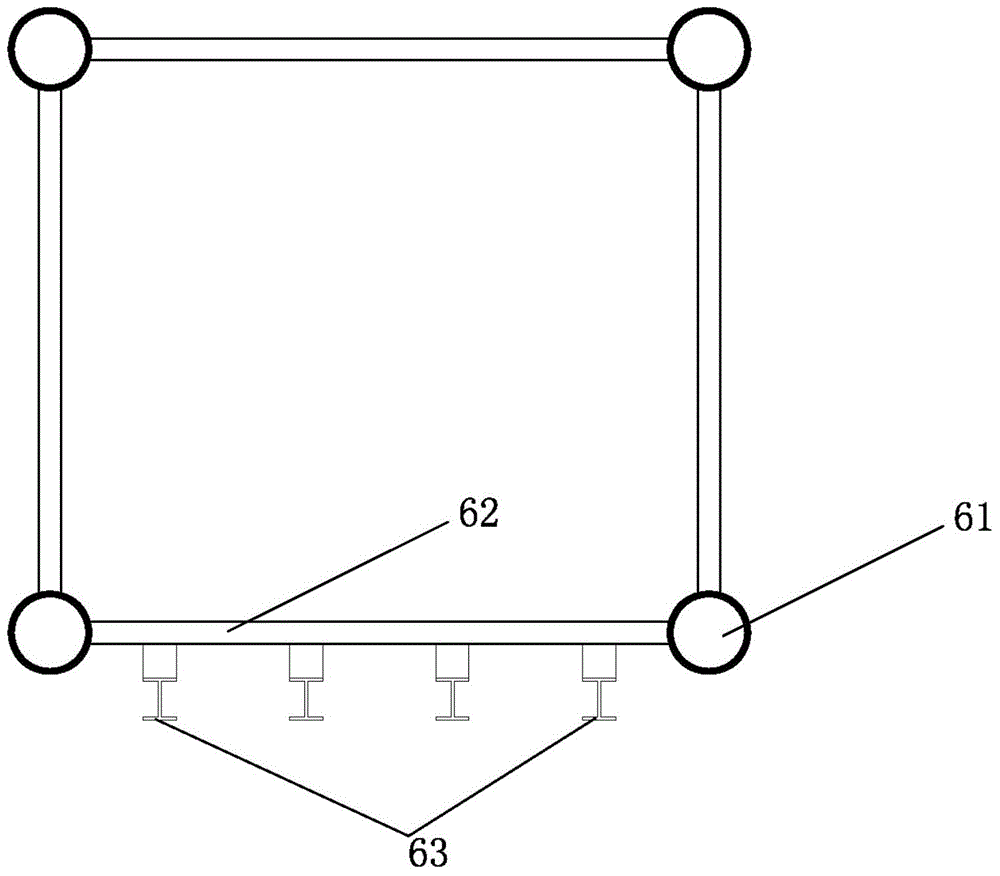

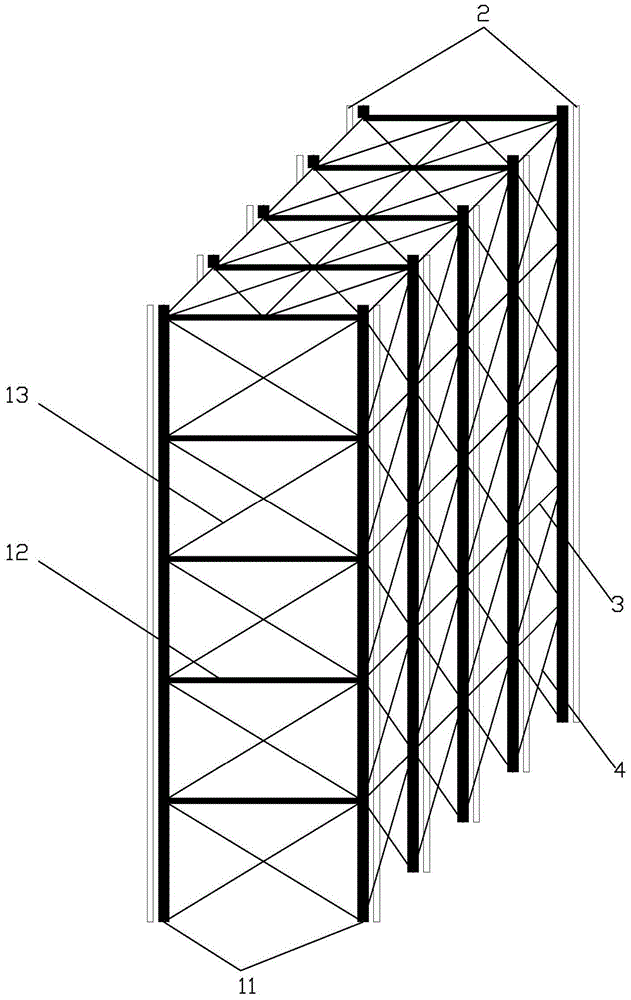

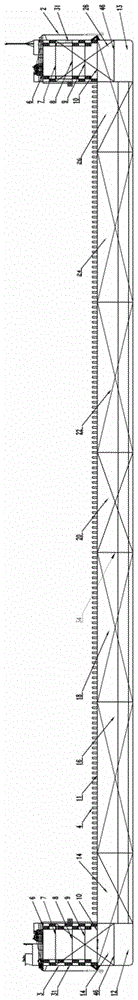

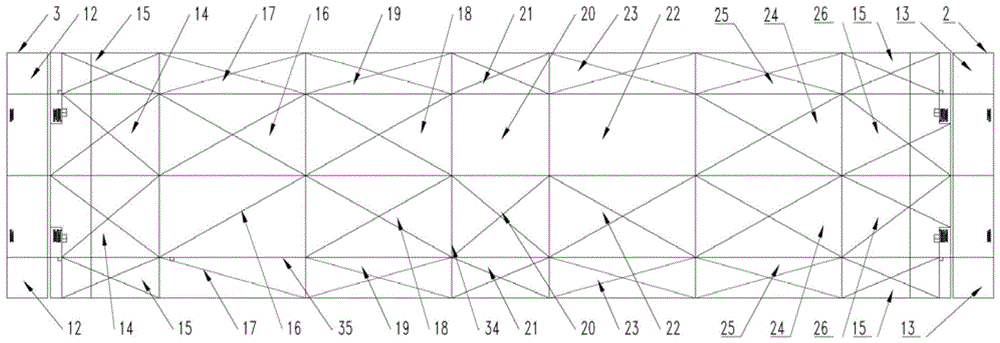

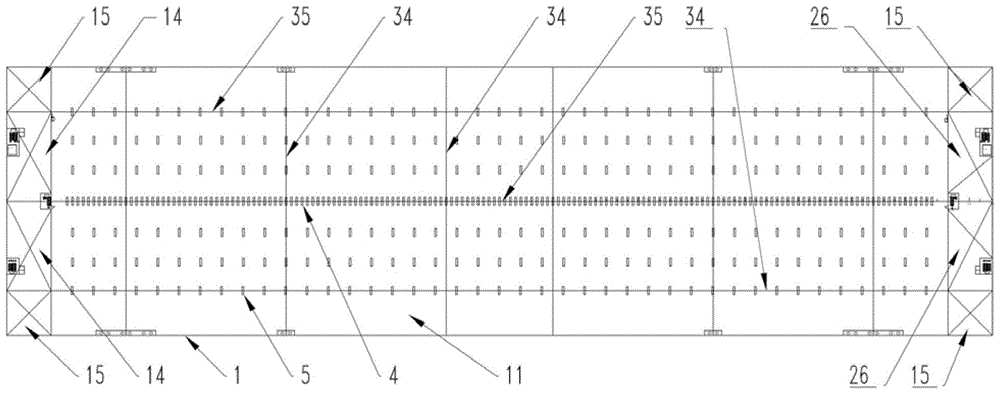

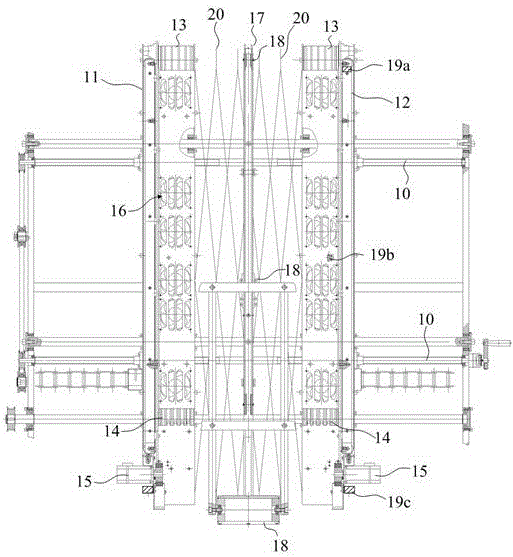

Side-by-side type torch supporting tower

The invention relates to a side-by-side type torch supporting tower which comprises torch supporting units, unit connecting cross rods and unit connecting oblique rods. The torch supporting units are arranged in parallel and perpendicular to the ground, the unit connecting cross rods and the unit connecting oblique rods are arranged between adjacent torch supporting units, and the torch supporting units are connected to be a spatial overall structure. According to the side-by-side type torch supporting tower, all torch lifting tracks are fixed on tower columns, rigidity of the torch lifting tracks is greatly improved, deformation of the torch lifting tracks is reduced, and torches can be assembled and disassembled more smoothly. Torch loads directly act on the main stress structure, the structure is more reasonable, the torch supporting tower is convenient to manufacture, convey and mount, and steel using amount can be lowered.

Owner:铖熤科技(山西)有限责任公司

Parallel torch support tower

The invention relates to a side-by-side type torch supporting tower which comprises torch supporting units, unit connecting cross rods and unit connecting oblique rods. The torch supporting units are arranged in parallel and perpendicular to the ground, the unit connecting cross rods and the unit connecting oblique rods are arranged between adjacent torch supporting units, and the torch supporting units are connected to be a spatial overall structure. According to the side-by-side type torch supporting tower, all torch lifting tracks are fixed on tower columns, rigidity of the torch lifting tracks is greatly improved, deformation of the torch lifting tracks is reduced, and torches can be assembled and disassembled more smoothly. Torch loads directly act on the main stress structure, the structure is more reasonable, the torch supporting tower is convenient to manufacture, convey and mount, and steel using amount can be lowered.

Owner:铖熤科技(山西)有限责任公司

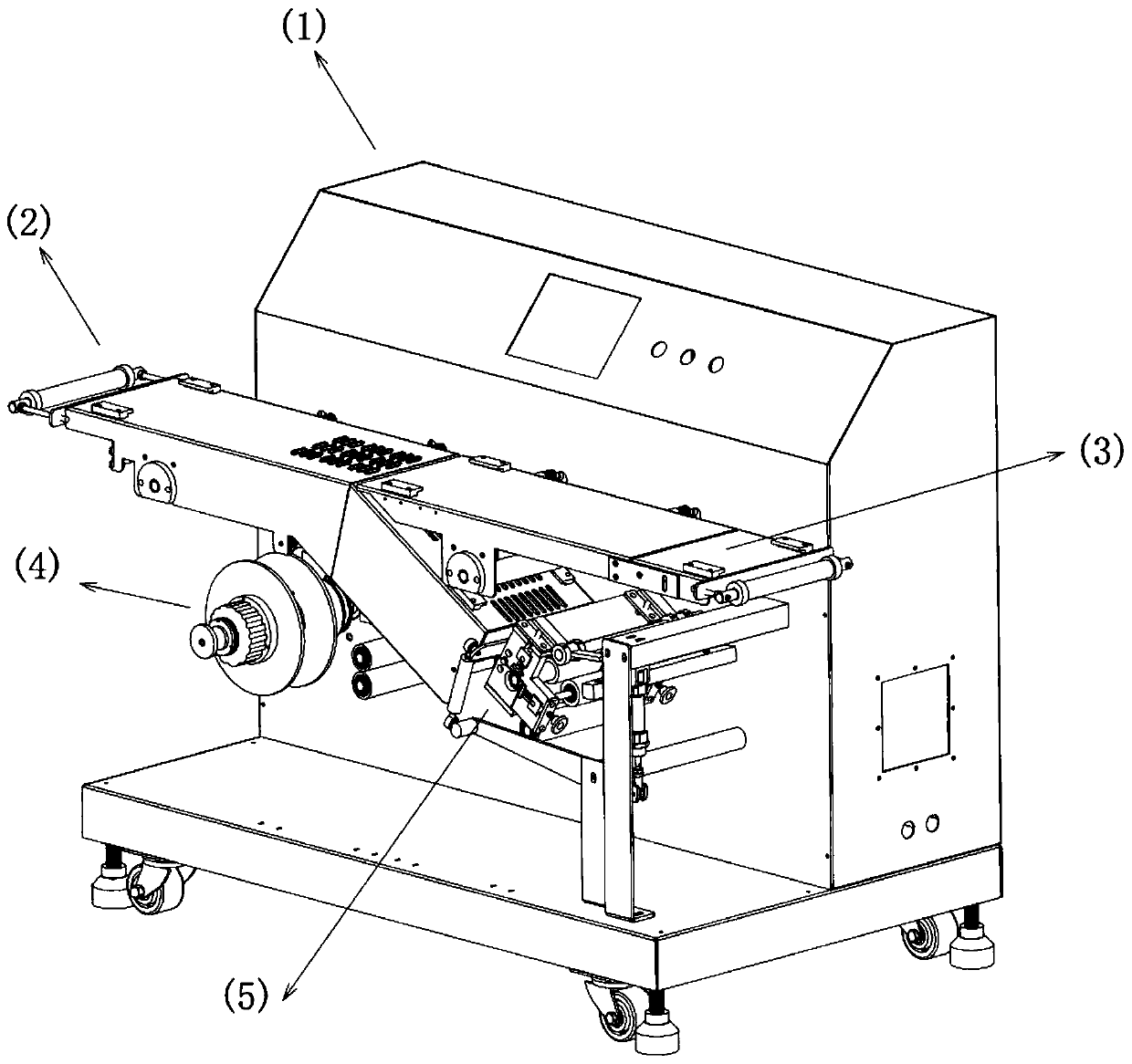

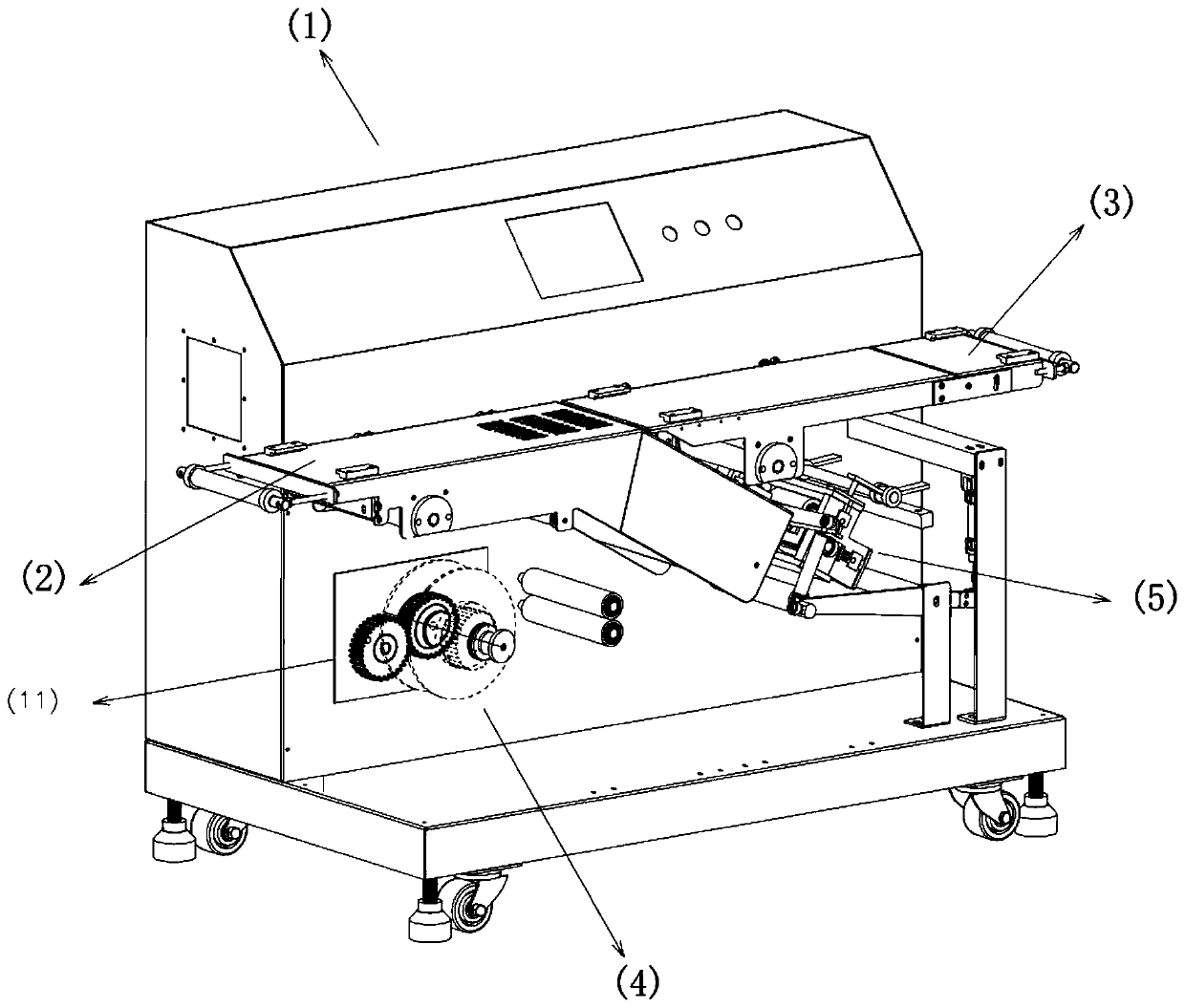

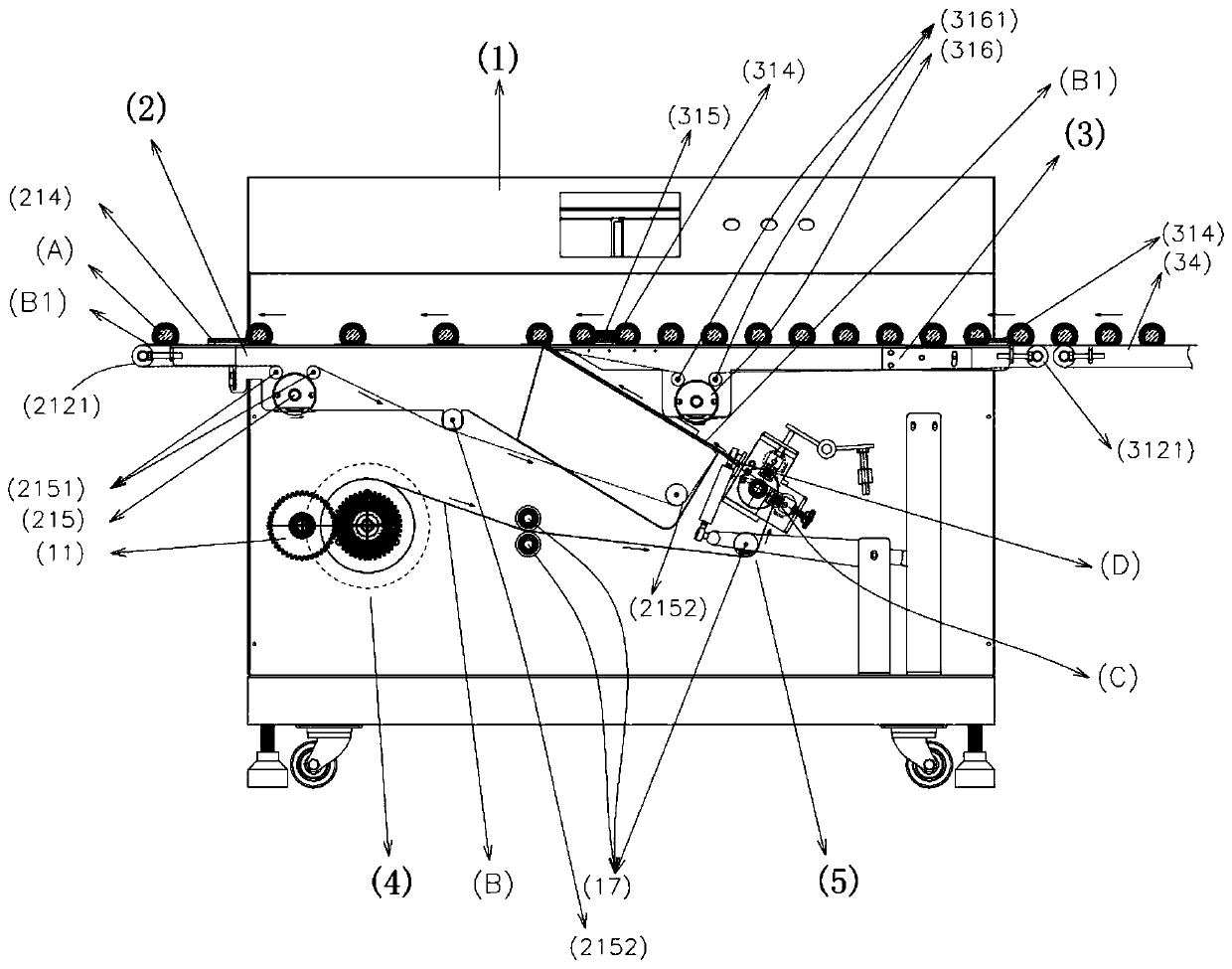

Multi-function high-speed packing paper equipment and high-speed packing paper method

PendingCN111204605AAdsorption is stable and effectiveAvoid Scattered Suck HolesArticle deliveryWebs handlingControl engineeringProcess engineering

The invention relates to a multi-function high-speed packing paper equipment and a high-speed packing paper method. The equipment comprises a whole-machine platform; and a back conveying device, a front conveying device provided with an adsorbing device, a braking and fine adjustment device, a packing paper cutting and clamping device and multiple packing paper transition pulleys are mounted on the whole-machine platform. The front conveying device provided with the adsorbing device is adopted, an air suction hole part is designed into a longitudinal long air suction hole, thus packing paper can be adsorbed stably and effectively, and dispersed air suction leaks are avoided. The packing paper braking and fine adjustment device is arranged, the braking and center correction functions for the whole-roll of packing paper can be realized, and the packing paper can be prevented from deviating from a track during clamping. A packing paper conveying device of the packing paper cutting and clamping device adopts multiple reclining driven rollers and a packing paper clamping driving roller, placing and stop actions of the packing paper are realized through opening and closing of the packingpaper clamping driving roller, and the packing paper is effectively ensured to move on the conveying track and is prevented from deviating from the center of the track.

Owner:YANG JENQ MACHINERY

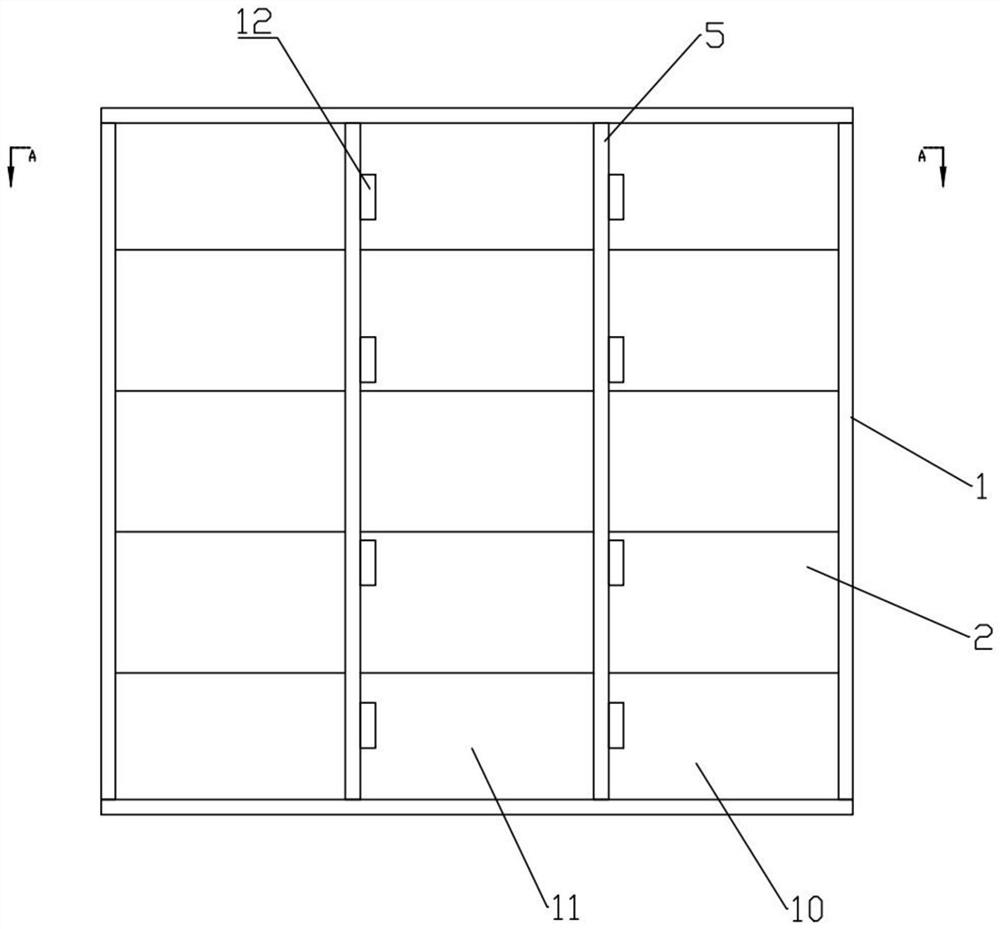

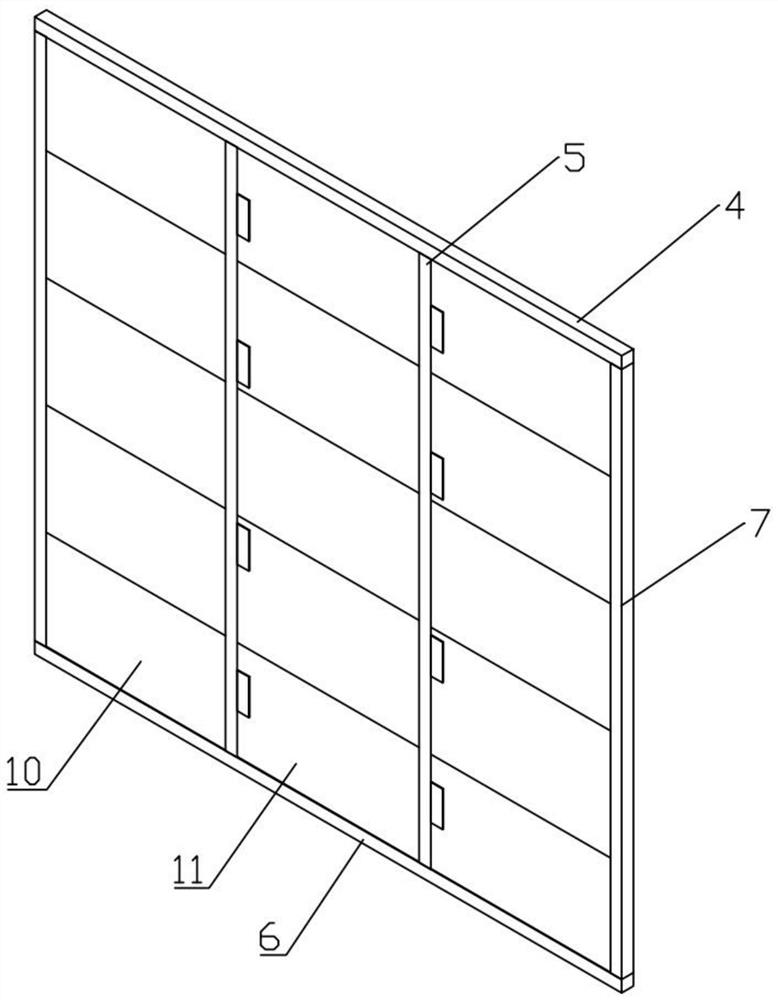

Novel assembled light steel wall

InactiveCN112796437AExpand applicable scenariosSimple and efficient operationWallsFilling materialsEarthquake resistant

The invention discloses a novel assembled light steel wall. The novel assembled light steel wall comprises a supporting frame, prefabricated wall plates and a filling material, wherein the supporting frame comprises a rectangular frame and a supporting keel; first fixing grooves are formed in the inner side of the rectangular frame; the two ends of the supporting keel are matched with the first fixing grooves; second fixing grooves are symmetrically formed in the two sides of the supporting keel; the prefabricated wall plates are arranged on the inner side of the rectangular frame; and the filling material is arranged between the two layers of prefabricated wall plates. Compared with the prior art, the novel assembled light steel wall has the advantages that (1) the height, width and thickness of wall manufacturing are not limited; (2) the surface of the wall is smooth and flat, painting is not needed, only joint positions of different materials need to be subjected to batch painting treatment through fiber cloth, and wall grooves are not needed during water and electricity pipeline laying; (3) operation is easy and convenient, the construction speed is high, and the construction period is shortened; and (4) the strength is high, the novel assembled light steel wall is resistant to shock, fire, sound and impact, and the performance is better than that of an existing product.

Owner:浙江众承建材科技发展有限公司

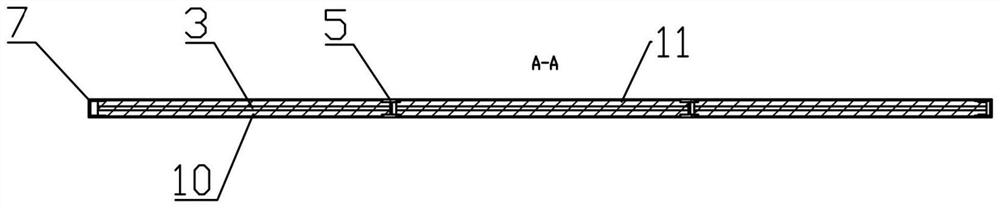

Variable-feed cutting method for circular groove machining

ActiveCN111299610AIncrease Margin ControlArbitrary control of chip cutting lengthMachine toolMachining

The invention provides a variable-speed cutting method for circular groove machining, and belongs to the field of machining. By the adoption of the variable-speed cutting method for circular groove machining, the problem of poor chip breaking effect during grooving in the prior art is solved. According to the variable-speed cutting method for circular groove machining, an automatic machine tool executes multiple variable-speed cycles within one cutting circumference to conduct grooving on a workpiece, and each variable-feed cycle includes a normal feed F1 and a variable feed F2; before machining, the cutting depth ap is set, and F1 and F2 are set, wherein F2<F1<ap, and F1+F2<ap; and then the following steps are conducted: Step 1, the workpiece is cut according to the feed F1, wherein the number of rotating turns of a spindle is F1 / ap; Step 2, the workpiece is cut according to the feed F2, wherein the number of rotating turns of the spindle is F2 / ap; and after one variable-feed machining cycle formed by Step 1 and Step 2 is completed, actions in the variable-feed cycle are repeated cyclically until grooving within one cutting circumference is completed. In this way, a good chip tailcurling effect can be realized.

Owner:浙江海德曼智能装备股份有限公司

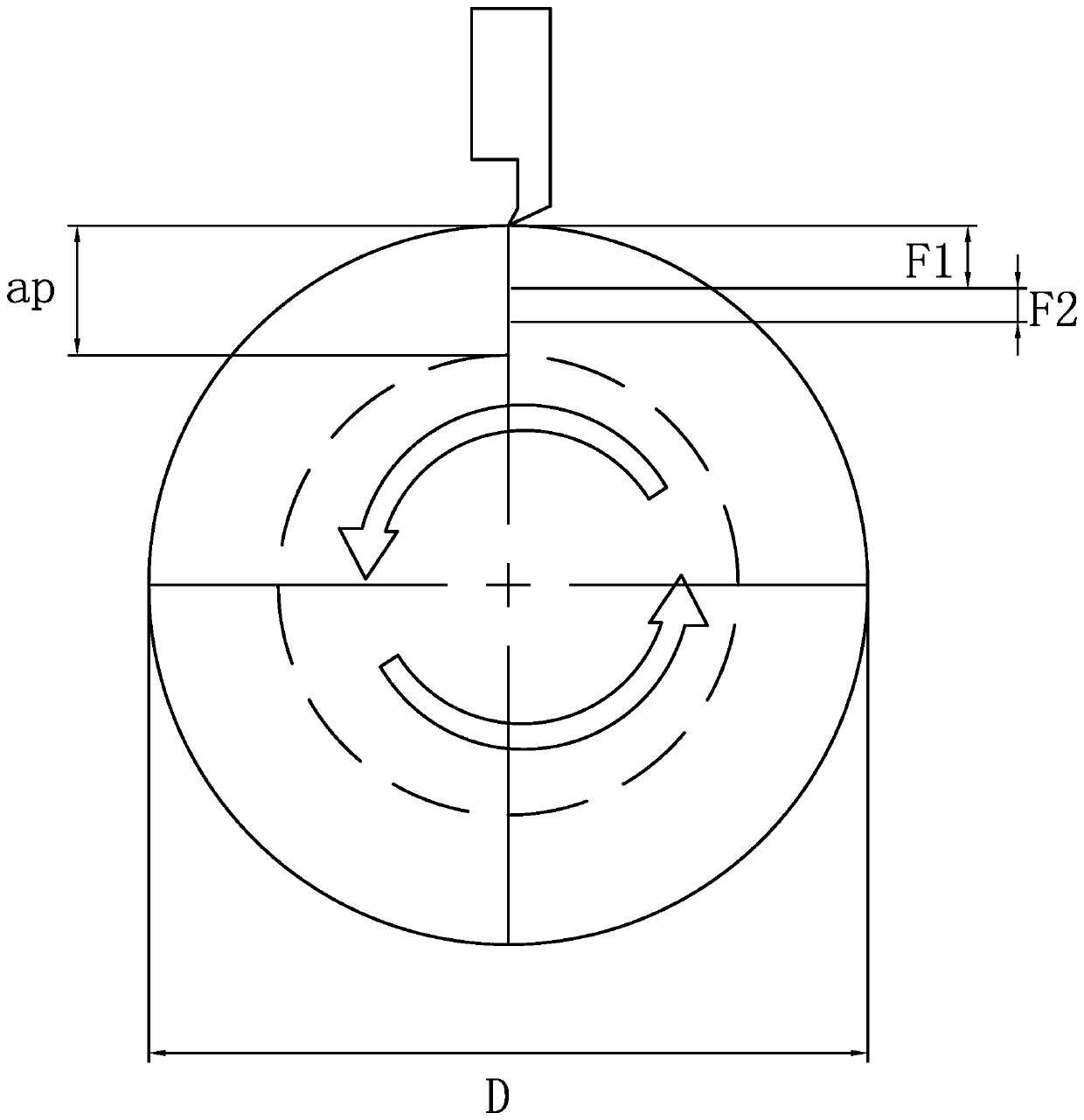

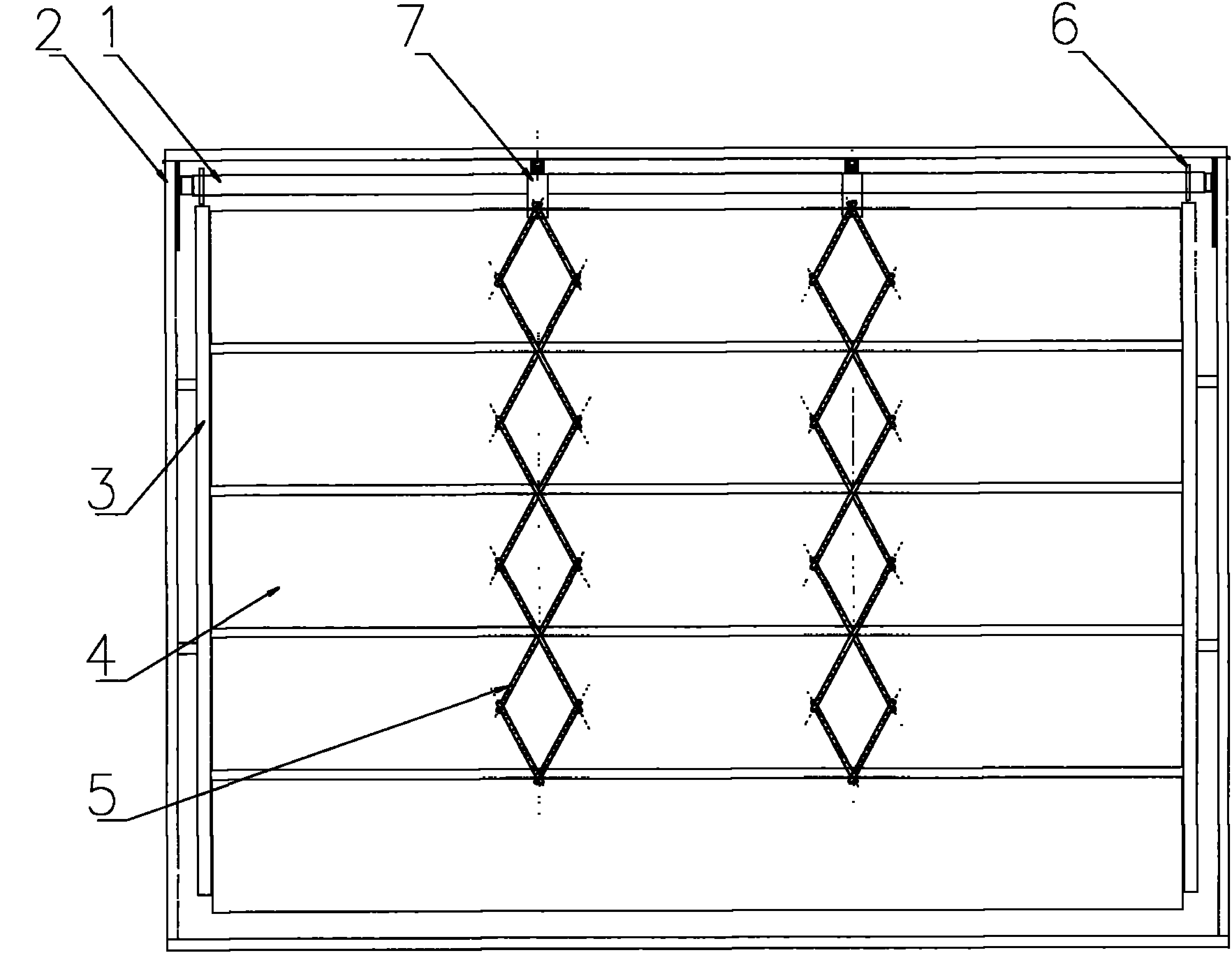

Outdoor sunshade curtain

The invention discloses an outdoor sunshade curtain, belongs to a sunshade appliance, and aims at providing an outdoor curtain which is convenient to operate, has the functions of sun-shading, ventilating, lighting and protecting, and meets the modern building requirements in height and width. The outdoor sunshade curtain comprises a mounting frame, a track system, a drive system, a sunshade part and a structure frame used for bearing a wind load of the sunshade part, wherein the structure frame comprises a series of frame rod members and a lifting frame comprising a plurality of parallelograms; the lifting frame is used for controlling the frame rod members; the frame rod members are used for supporting the sunshade part and sliding along tracks; a drive shaft at the top of the curtain is used for driving the bottommost frame rod member through chains in the tracks on the two sides; the bottom frame rod member is used for driving the lifting frame to be folded or unfolded, so that the frame rod members can be folded or unfolded and meanwhile the sunshade part can be also folded or unfolded.

Owner:赵培显

Belt-shape moving body tension differential adjusting and correction method and device therefor

InactiveCN100366517CAdjust the tensioning pressure in timeTo achieve the purpose of correctingWebs handlingState of artBand shape

Owner:大连经济技术开发区排水管理有限公司

Printing paste preparation and printing process thereof

The invention discloses a printing paste preparation and printing process thereof and belongs to the technical field of textile printing or printing. The method for preparing the printing paste comprises the following steps: performing finish machining on each raw material, and mixing with printing paste, wherein the pigment accounts for 1-10 mass percent, and the printing paste accounts for 90-99 mass percent. The printing paste prepared by the method is dyed, dried and set. By the adoption of the technical scheme, the problems that the design and color are not bright and the pattern definition is low during screen printing are solved, the defects of low yield and limited breadth during digital printing are overcome, the printing breadth is improved, the printing speed is high, and the speed is generally 3,000m / h; and moreover, the adopted pigment and base material are pollution-free green dyes, and the dye is environment-friendly, has the effects of energy conservation and emission reduction and can be widely applied to the textile printing or printing process.

Owner:绍兴市天基印刷材料厂

A bow and stern pontoon type shipbuilding platform

The invention relates to a bow and stern pontoon type shipbuilding platform, which comprises: a main hull of a cuboid box-shaped structure, a number of keel piers are set up on the deck along the direction of the ship's length, and a number of ballast tanks bounded by bulkheads are formed in the main hull The first pontoon and the stern pontoon are correspondingly set up at the fore and stern positions of the main hull to ensure the stability of the main hull. At least one of them is provided with ship repairing equipment; a ballast system for ballasting or draining the ballast tank, the fore pontoon and the stern pontoon. Its advantages are: only the pontoons are set at the bow and stern of the hull, there is no restriction on the side, the width is not limited when the platform is entered and exited in sections by ship repairing or construction, and the stroke of entering and exiting the platform is short, which is convenient for operation. It effectively meets the requirements of the ship repairing / building operation site, enables the existing facilities of the wharf to be fully utilized, facilitates the hoisting and moving work of the ship repairing / building, and can significantly improve the efficiency of ship repairing and building construction operations.

Owner:SHANGHAI SHIP & SHIPPING RES INST

New high-efficiency energy-saving finned electric heating tube

The invention relates to a novel energy-efficient fin type electric heating pipe which comprises a shell, a heating wire and heat-conducting insulating padding. A strip-shaped cooling fin is spirally wound on the outer surface of the shell and provided with continuously-distributed fan-shaped concave-convex structures, the shrinkage end of each structure is close to the surface of the shell, the unfolded end of each structure is close to the outer edge of the fin, and a smooth arc transition face is arranged between each unfolded end and the outer edge of the cooling fin. Mounting seats are connected with the shell in a sealed mode, power lines are arranged on the end portions of the mounting seats, and the power lines are connected with the heating wire in the shell through the mounting seats. The continuous concave-convex structures which are arranged at intervals are adopted by the cooling fin, the fin can be conveniently wound on the shell, and internal stress of the cooling fin is effectively eliminated. Welding machining is facilitated, the width of the fin is not limited, the cooling area is enlarged, the cooling effect is better, and the service life of the electric heating pipe is longer. Cooling efficiency of the fin is enhanced, the power of the electric heating pipe can be properly lowered, and the purposes of efficiency raising and energy saving are achieved.

Owner:江苏大唐电器制造有限公司

Book binding method

ActiveCN107554122BSolve many technical problems in the way of bindingUnlimited thicknessToysBooksFixed frameBiomedical engineering

The invention provides a book binding method. The method mainly comprises the following steps: after a book core of a book is molded, multiple through holes are drilled in the side edge of a book spine of the book core; and nails are inserted in the through holes for fixing the book core through the through holes. A book nailing device consists of a book spine clamping piece, a nail gun fixing frame and a nail gun guide rail; a hole position is arranged on the book spine clamping piece; the book spine position of the book core is clamped by using the book spine clamping piece; a nail gun is fixedly mounted by using the nail gun fixing frame; the nail gun guide rail is connected with the nail gun fixing frame; the nail gun fixing frame moves in the horizontal position; a nail outlet of thenail gun is aligned to the hole position in the book spine clamping piece; and the nail is driven into the hole position. The book is produced by the method; the problems in a traditional circular spine or square spine book binding mode are thoroughly solved; and the thickness, the width and the length of the book cannot be limited, and can be infinitely amplified.

Owner:BEIJING ARTRON GRAPHIC ART CO LTD +2

Safety coupler of cordless electric appliance

InactiveCN101521346BUnlimited widthUnlimited depthCoupling device detailsFlexible/turnable line connectorsElectricityEngineering

The invention relates to a safety coupler of a cordless electric appliance, which comprises an appliance input socket and an electric connector, wherein the inside of the electric connected is provided with a power-receiving connecting terminal and at least one power supply contact piece, and the input socket is provided with a cylindrical power-receiving connecting terminal and an annular power-receiving connecting terminal. The safety coupler is characterized in that: the power-receiving connecting terminal corresponding to the power supply contact piece is an elastic piece; the power-receiving connecting terminal is provided with a pushing part which is made of conductive material and is matched with the corresponding power-receiving connecting terminal; when the electric connector is not plugged in the appliance input socket, the power supply contact piece and the corresponding power-receiving connecting terminal are kept in a contact normal open state; when the electric connector is plugged in the appliance input socket, the annular power-receiving connecting terminal directly participates in the contact with the pushing part to push the power-receiving terminal and the corresponding power supply contact piece close to turn on power. Due to the direct cooperation between the annular power-receiving connecting terminal and the pushing part made of the conductive material, a specially arranged contact closing and opening structure is saved, the structure of the safety coupler is simplified, and the production and manufacturing cost of the coupler is reduced.

Owner:柯赐龙

A vibration experiment platform for fatigue testing of thin-walled components

The invention discloses a vibration experimental platform for a thin-walled member fatigue test. The vibration experimental platform comprises an excitation source test device and an end clamp on a platform base; the excitation source test device comprises a U-shaped bracket; a laser displacement sensor is disposed on the bottom of the U-shaped bracket; first hinge pins are disposed on both sides of the upper end of the U-shaped bracket; the first hinge pins are sleeved by boxes; damping springs are arranged between each box and both ends of the corresponding box; piston vibration exciters are disposed on the tops of the boxes; first screws are disposed in the boxes; each first screw is provided with two symmetrical wedges; the lower ends of the wedges are in contact with a upper splint; the bottom cover of each box is provided with a lower splint; the upper and lower splint are cooperating with each other to form a clamp for sandwiching the thin-walled member; and a speed sensor and an acceleration sensor are arranged on one end of the excitation source test device on the thin-walled member. The vibration experimental platform can equivalently regenerate the fatigue process of an aviation aluminum alloy thin-walled component in a relatively short period, and calculates and evaluates the service life of the component.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

High-speed broad paper discharging device

ActiveCN106219274AUnlimited widthControl delivery accuracyFunction indicatorsArticle feedersPulp and paper industryAutomation

The embodiment of the invention discloses a high-speed broad paper discharging device. The high-speed broad paper discharging device comprises a pair of paper conveying groove edges arranged above a bothway screw. The pair of paper conveying groove edges are connected through a plurality of reeds. The bothway screw drives the pair of paper conveying groove edges, and the width is changed through compressional deformation of the reeds. By the adoption of the high-speed broad paper discharging device, the bothway screw is used for driving the pair of paper conveying groove edges so that the width can be changed, and the reeds are arranged between the paper conveying groove edges. Moreover, the paper conveying groove edges are independently provided with conveying wheels and conveying ribs, conveying capacity is guaranteed when the width is changed, and the width of output paper is not limited. Moreover, the conveying precision of the surface paper can be accurately controlled through paper sensors, the discharging device can be used in various places where paper conveying is required, and the purposes of automation and high-speed production are achieved.

Owner:广东山河实业有限公司

A high-speed large-scale paper output device

ActiveCN106219274BUnlimited widthControl delivery accuracyFunction indicatorsArticle feedersPulp and paper industryAutomation

The embodiment of the invention discloses a high-speed broad paper discharging device. The high-speed broad paper discharging device comprises a pair of paper conveying groove edges arranged above a bothway screw. The pair of paper conveying groove edges are connected through a plurality of reeds. The bothway screw drives the pair of paper conveying groove edges, and the width is changed through compressional deformation of the reeds. By the adoption of the high-speed broad paper discharging device, the bothway screw is used for driving the pair of paper conveying groove edges so that the width can be changed, and the reeds are arranged between the paper conveying groove edges. Moreover, the paper conveying groove edges are independently provided with conveying wheels and conveying ribs, conveying capacity is guaranteed when the width is changed, and the width of output paper is not limited. Moreover, the conveying precision of the surface paper can be accurately controlled through paper sensors, the discharging device can be used in various places where paper conveying is required, and the purposes of automation and high-speed production are achieved.

Owner:广东山河实业有限公司

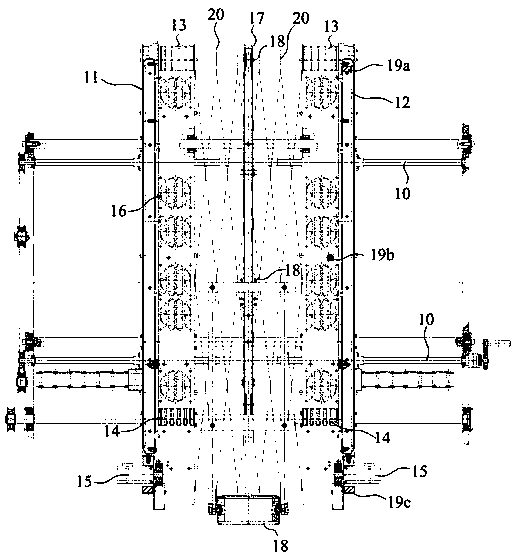

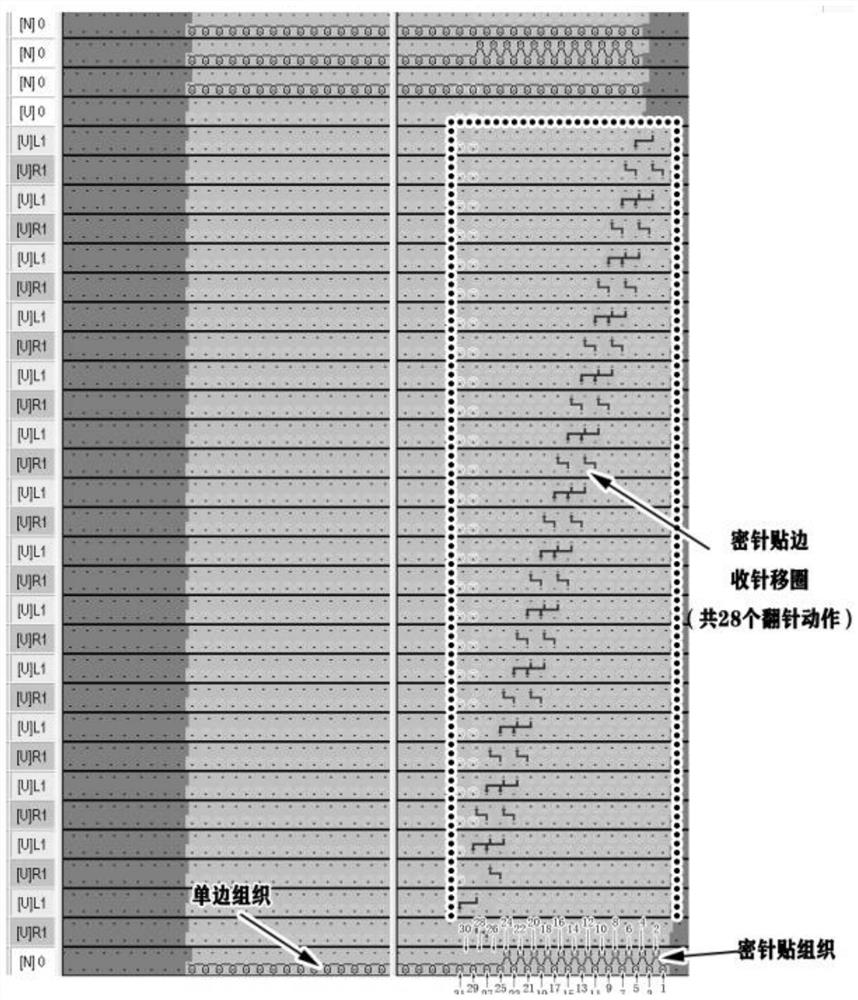

Method for knitting single-sided fabric with dense needle sticker

PendingCN113355793AAvoid the problem of dirty or even broken yarnUnlimited typesWeft knittingYarnBatch manufacturing

The invention relates to a method for knitting a single-sided fabric with a dense needle sticker, and the method is successfully applied to knitting of a double-needle-bed computerized flat knitting machine. According to the method, a loop transfer procedure of a conventional dense needle sticker is transferred to a single-sided weave, so that a needle turning action during knitting of the flat knitting machine is simplified, and the dense needle sticker is always kept vertical; and needle moving actions of needle adding and narrowing are arranged at the single-sided position of a body, and the dense needle sticker does not perform needle moving, so that in the process of knitting the single-sided fabric with the dense needle sticker, knitting can be completed at one time without making repeated needle moving actions, the knitting efficiency is greatly improved, and the knitting time can be greatly saved during batch production. The single-sided fabric with the dense needle sticker, which is woven by the method disclosed by the invention, can realize the required inclination and effect of the original dense needle sticker, and meanwhile, the problem that a dense needle sticker loop is dirty and even yarn is broken due to repeated loop transfer friction of a knitting needle is avoided.

Owner:ZHUHAI JIAN XUAN CLOTHING LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com