Multi-function high-speed packing paper equipment and high-speed packing paper method

A multi-functional, paper-laying technology, which is applied in the direction of winding strips, sending objects, thin material processing, etc., which can solve the problems of expensive procurement, limited width of paper-laying, and inability to keep up with paper rolls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Specific embodiments of the present invention will be described below.

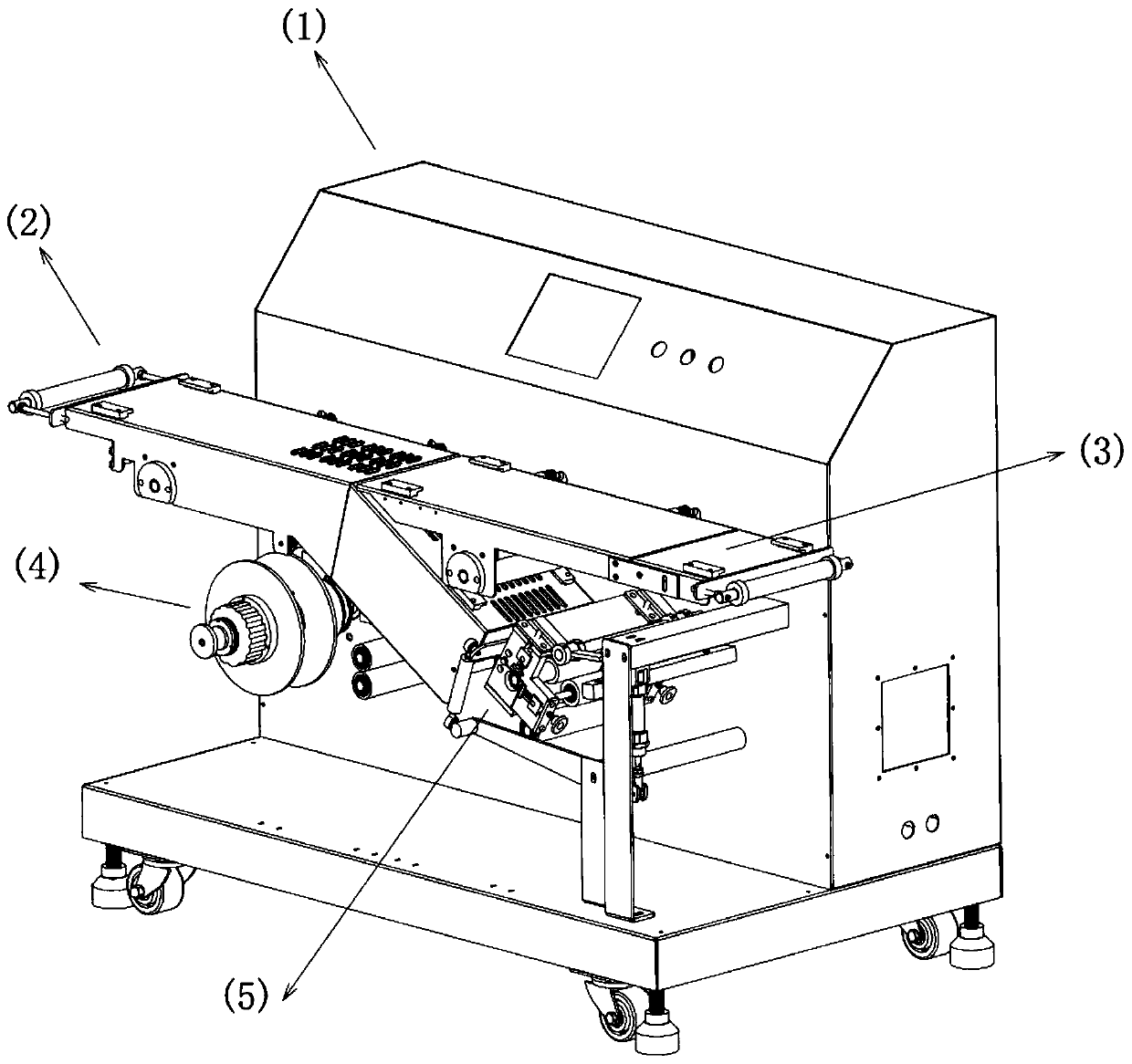

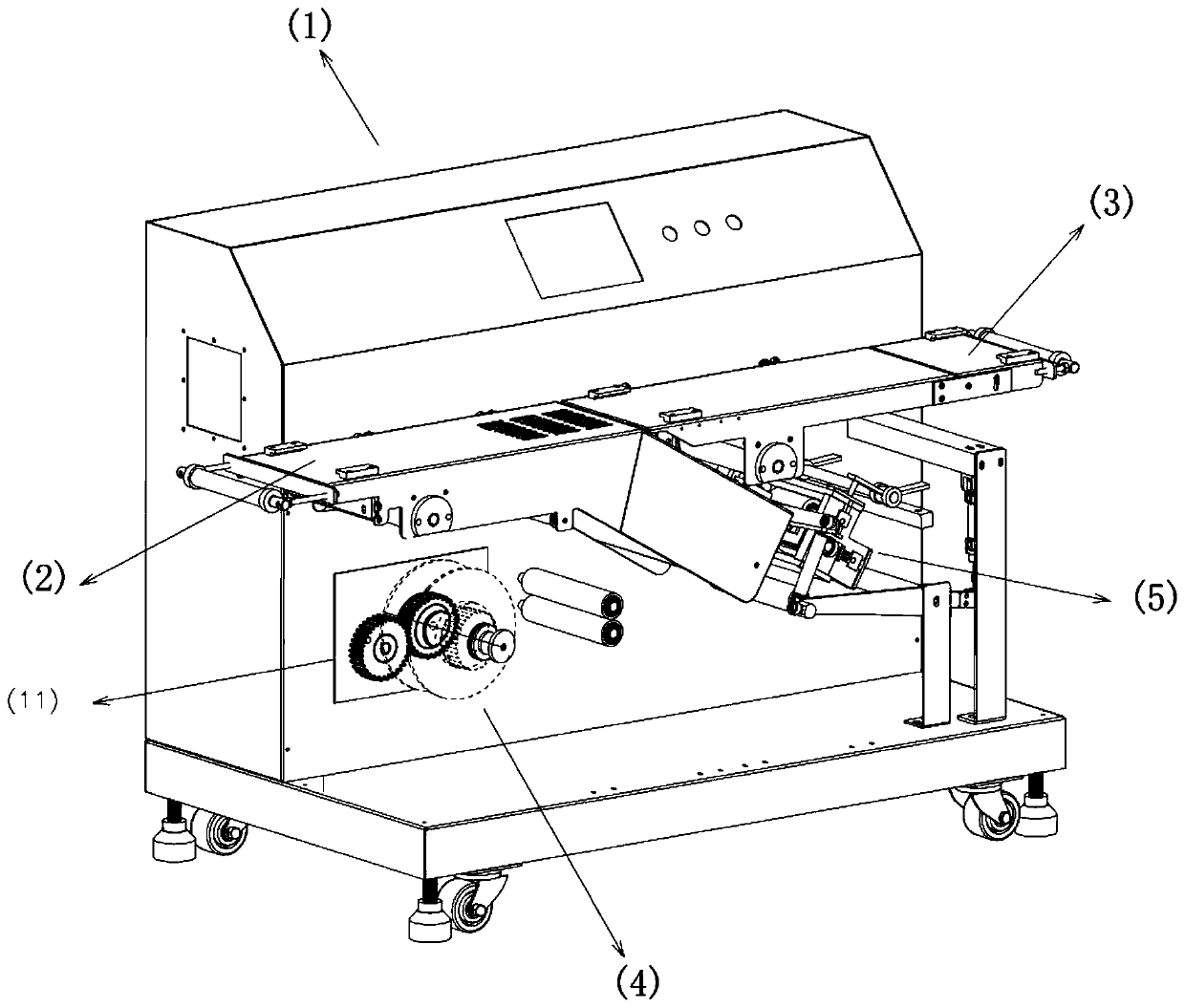

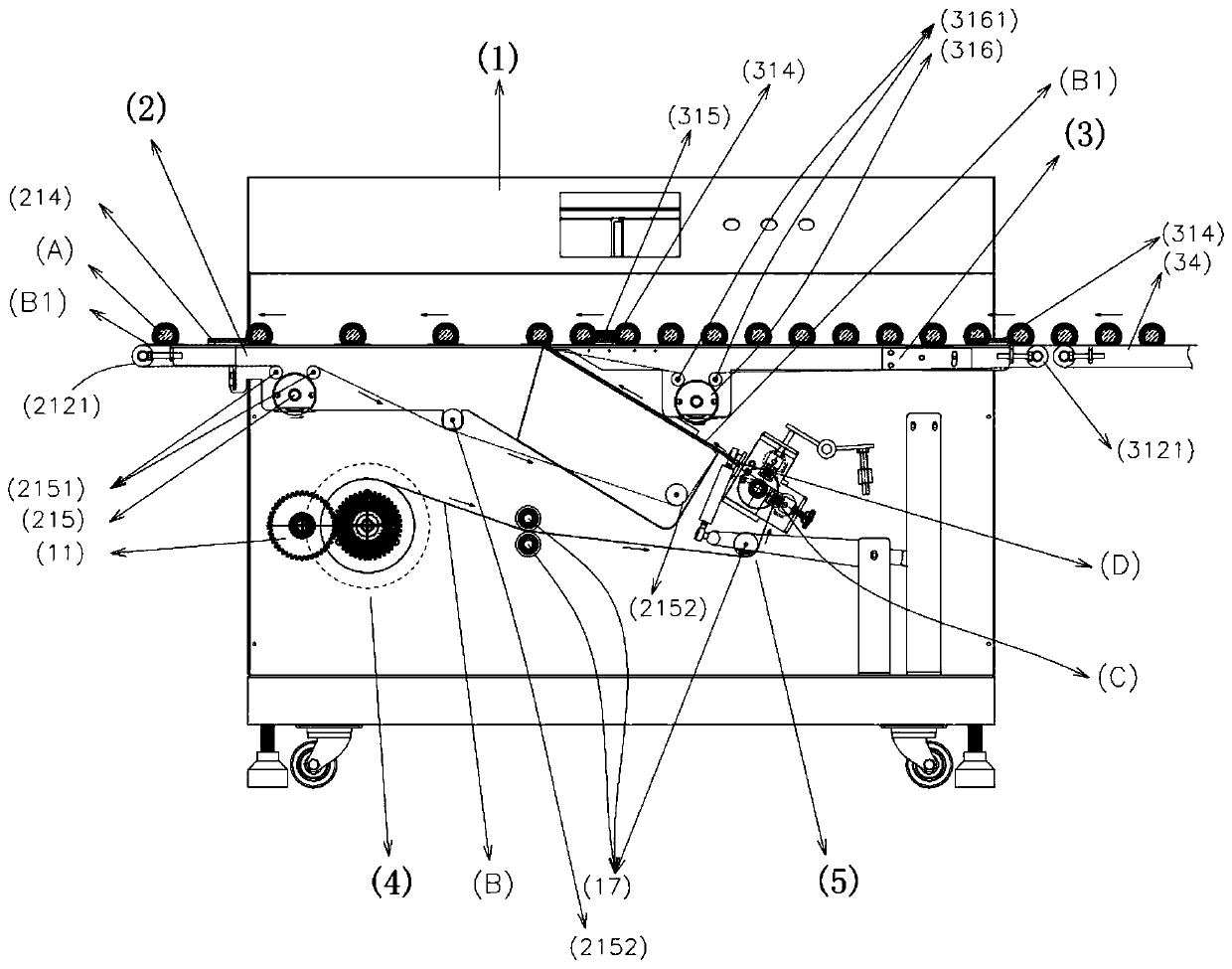

[0086] like figure 1 , figure 2 As shown, a multi-functional high-speed paper pad equipment includes a complete machine platform 1, on which a rear conveying device 2 for conveying edible products A, a front conveying device 3 with an adsorption device, and a Pad paper brake fine-adjustment device 4 for center correction, fine-tuning and braking of the whole bundle of pad paper, pad paper cutting and pinching device 5 for realizing cutting and pinching of pad paper, and multiple pad paper transition pulleys 17 , the rear conveying device 2 has a horizontal conveying surface and a slope conveying surface, the horizontal conveying surface is coplanar with the conveying surface of the rear conveying device 2, and the slope conveying surface is close to the pad paper cutting and pinching device 5.

[0087] like image 3 , Figure 4 and Figure 5 As shown, the rear conveying device includes a rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com