A vibration experiment platform for fatigue testing of thin-walled components

A thin-walled component, fatigue testing technology, applied in the testing of machine/structural components, vibration testing, measuring devices, etc., can solve problems such as immaturity, lack of established standardized experimental procedures, lack of universal experimental methods, etc. Flexible and convenient use, improved use range, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

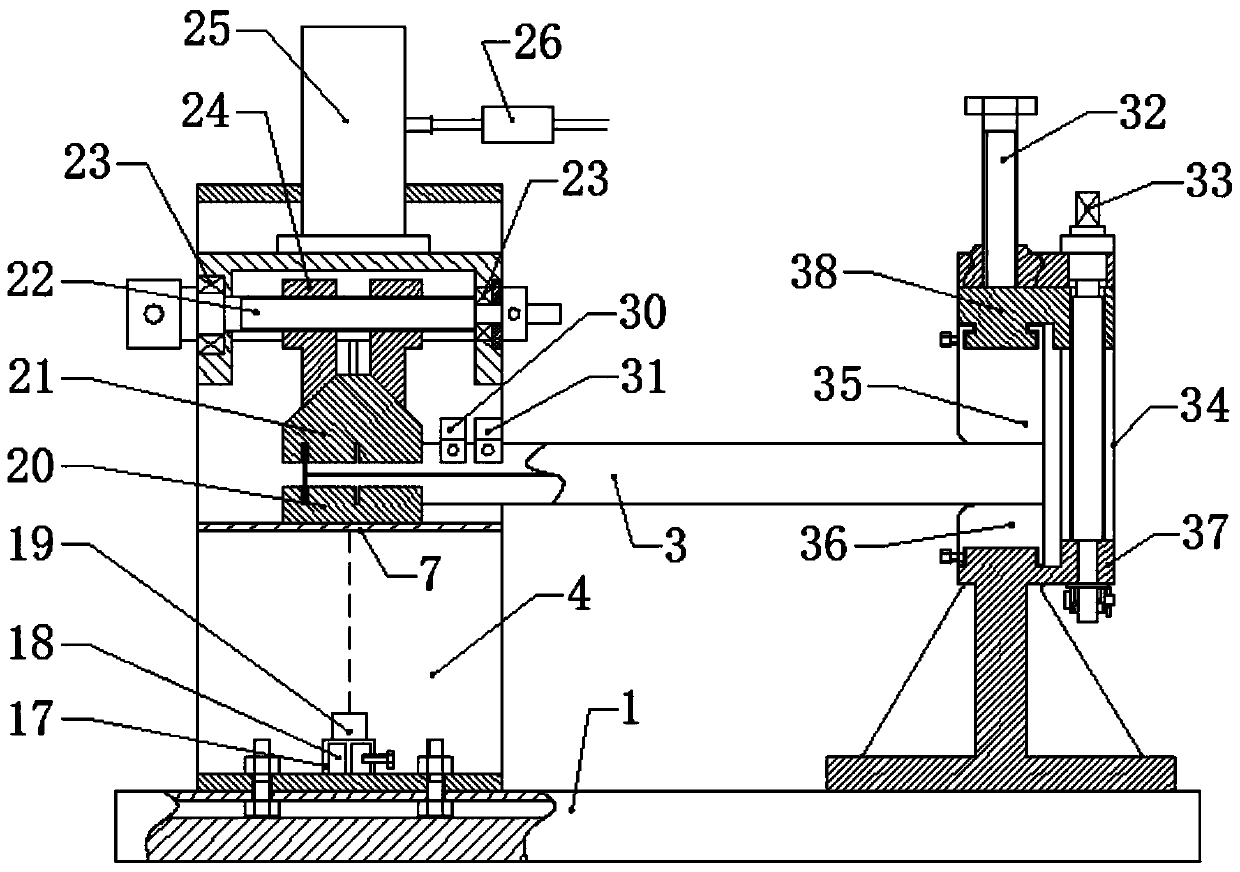

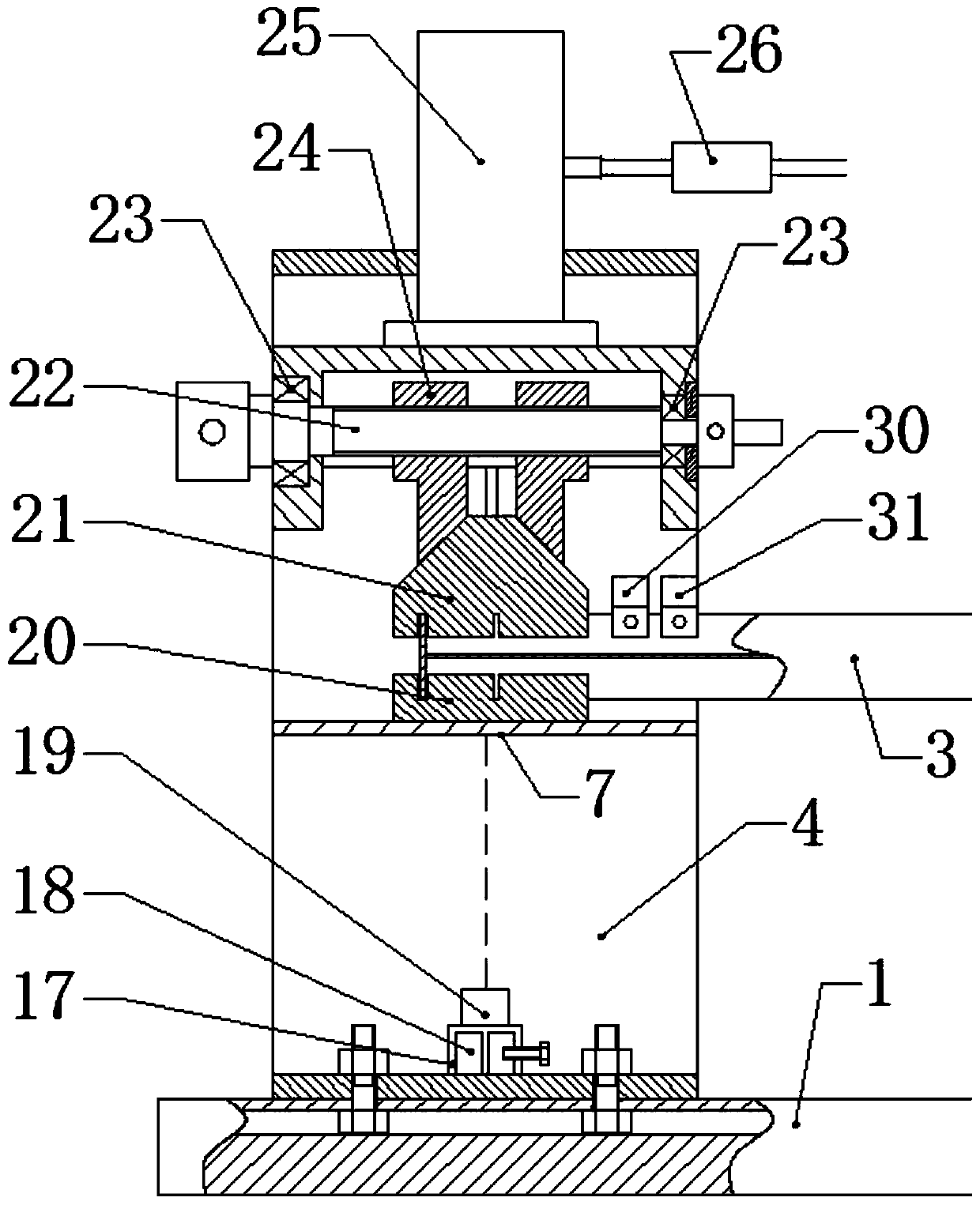

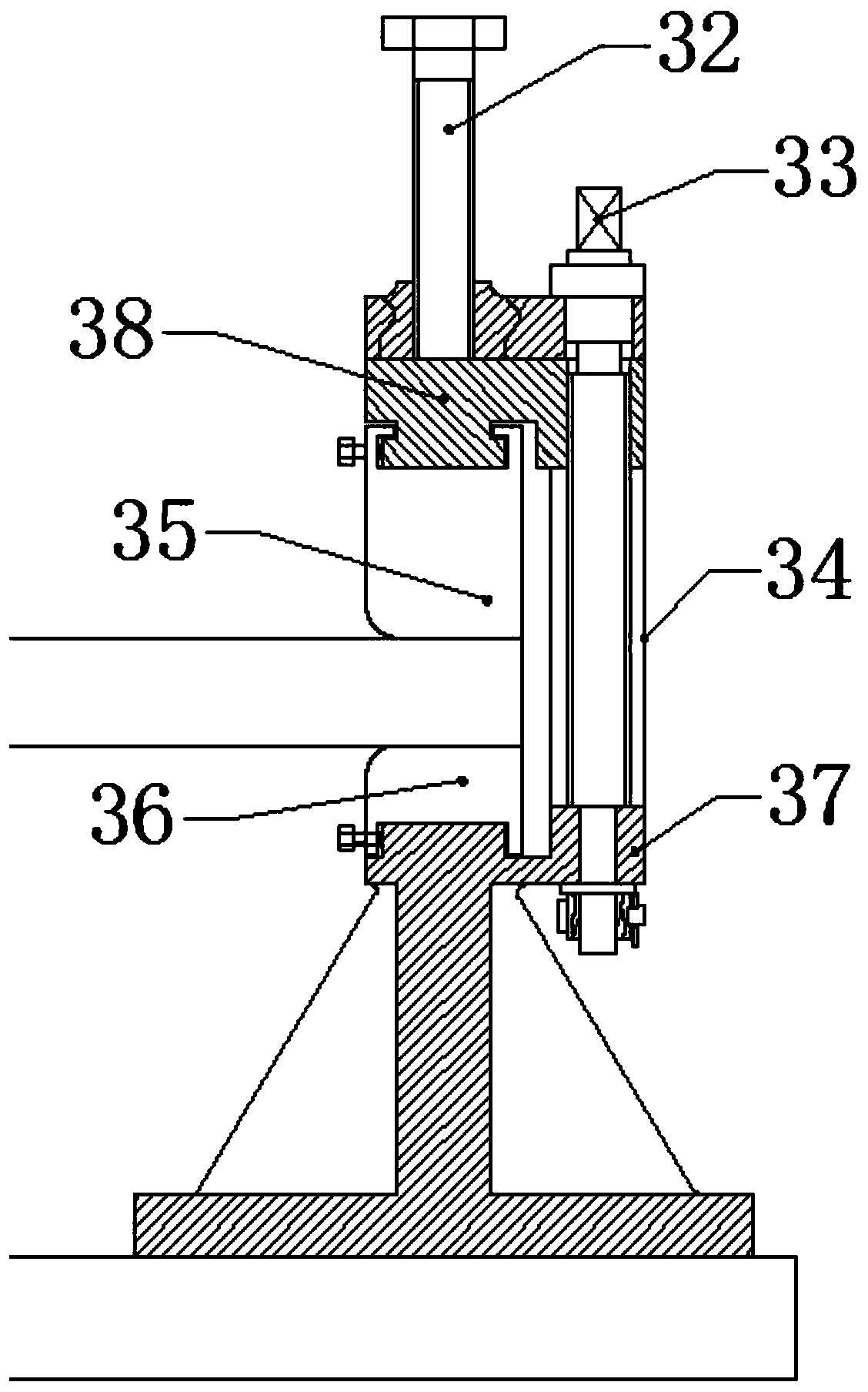

[0046] Laser displacement sensor 19 adopts ZLDS10X laser displacement sensor; speed sensor 30 adopts DH601 magnetoelectric speed sensor; acceleration sensor 31 adopts DH131 piezoelectric acceleration sensor.

[0047] Under normal experimental conditions, the laser displacement sensor 19 is adsorbed by a magnet to the bottom of the bracket in the clamping part of the excitation source, and the speed sensor 30 and acceleration sensor 31 are fixed on a thin-walled member close to the excitation source by bolts. Each sensor measures in real time and transmits the data to the dynamic data acquisition system, and then the system is connected to the PC terminal through the network cable, and the vibration acceleration, vibration velocity, and vibration displacement can be tested and analyzed in the computer operating system. It can also complete the test and analysis of stress and strain by pasting metal strain gauges on the workpiece, and finally complete the real-time storage, real-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com