A bow and stern pontoon type shipbuilding platform

A floating box and platform technology, which is applied in the field of bow and stern floating box shipbuilding platforms, can solve the problems of no floating dock, etc., and achieve the effects of convenient hoisting and ship moving, improved construction efficiency, and short travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

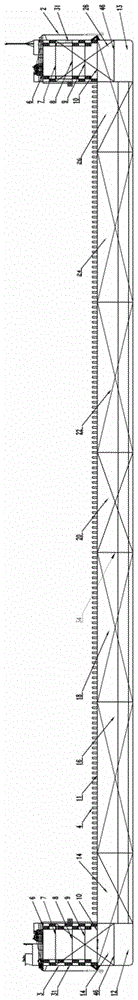

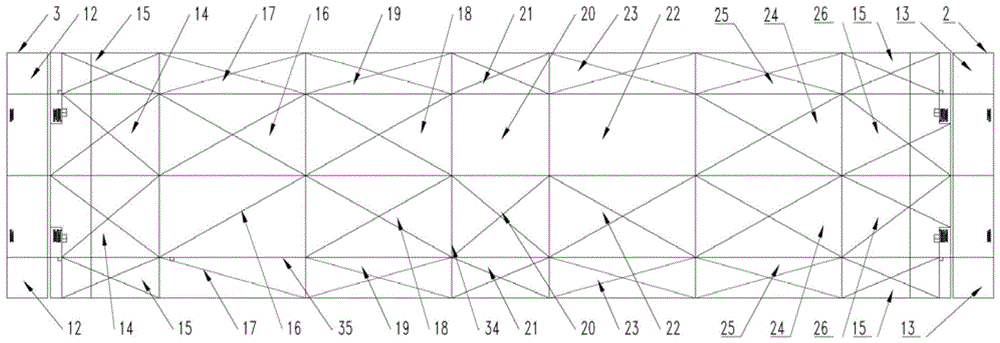

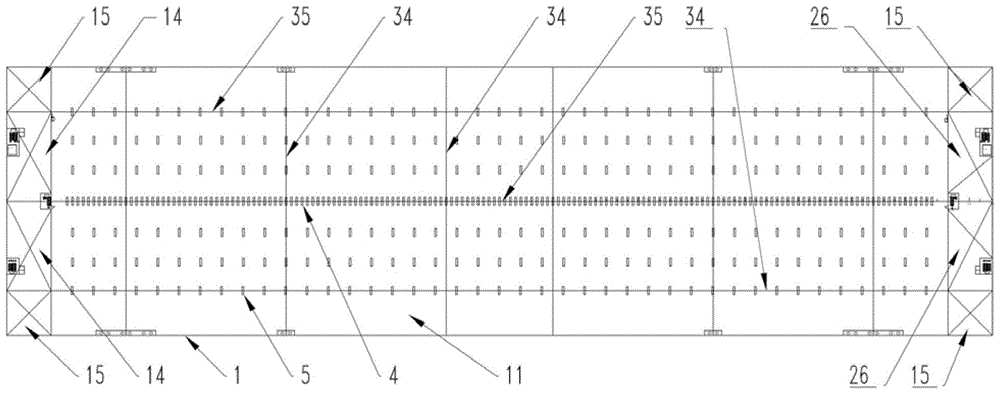

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail, so that those skilled in the art understand:

[0030] Such as Figure 1-5 As shown, the labels represent:

[0031] Main hull 1, bow pontoon 2, stern pontoon 3, middle keel pier 4, side keel pier 5, top deck 6, safety deck 7, third platform deck 8, second platform deck 9, pontoon deck 10, main hull Deck 11, stern pump room 12, bow pump room 13, seventh middle ballast tank 14, trim adjustment water tank 15, sixth ballast middle tank 16, sixth ballast side tank 17, fifth ballast middle tank 18. The fifth side ballast tank 19, the fourth middle ballast tank 20, the heel adjustment water tank 21, the third middle ballast tank 22, the third side ballast tank 23, the second middle ballast tank 24, the Second ballast side tank 25, first ballast middle tank 26, winch hydraulic unit room 27, main switchboard room 28, central control room 29, toilet 30, stairs 31, auxiliary swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com