Method for knitting single-sided fabric with dense needle sticker

A fabric and single-sided technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve problems such as yarn breakage, time-consuming weaving process, and dirty needle-attached loops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

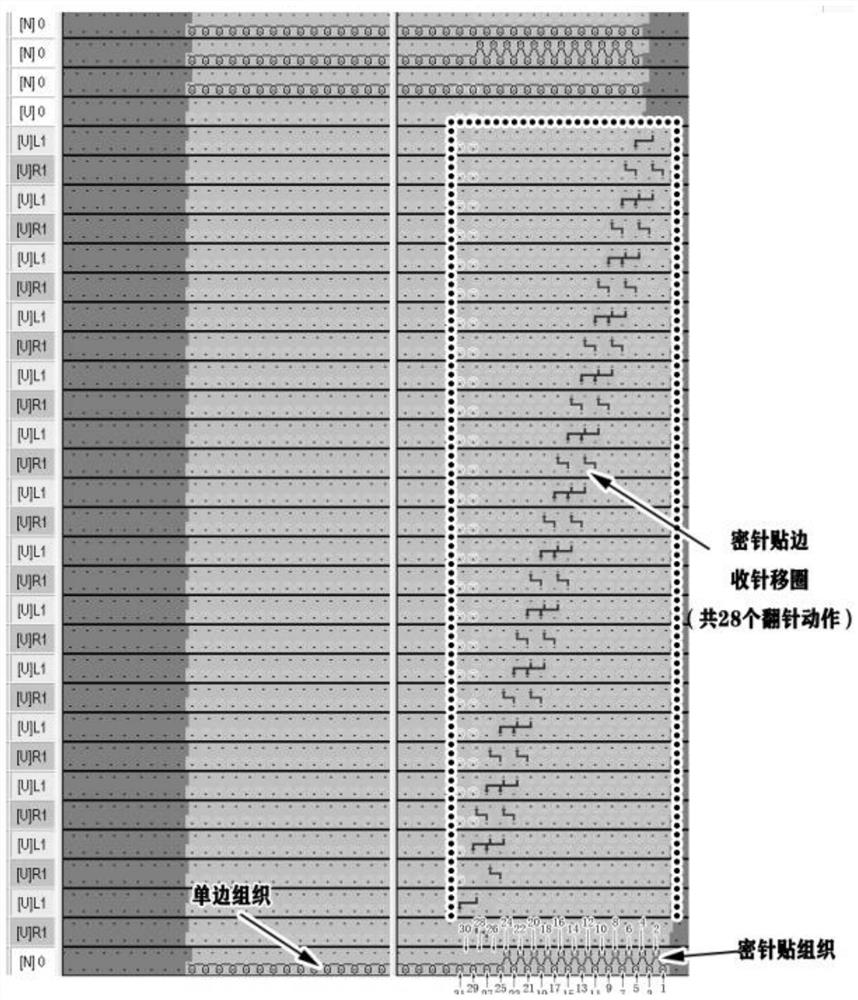

[0060] In the daily knitting process diagram of sweater, it includes all the knitting process of the sweater and the models of each piece, hereinafter referred to as the "first model", which is the conventional knitting model (refer to figure 1 , 5 ). The present invention converts the first model into a new weaving model, hereinafter referred to as "the second model" (refer to figure 2 , 6 ), which is the knitting model after applying the preparation method of the present invention, specifically: the body structure is a unilateral structure, and when the side of the original body of the welt needs to be stitched with "edges" or narrowed, the dense When the needle application meets the need for adding needles, it is converted from welt adding to clamping edge adding, that is, each time adding needles, the dense needle sticking loop remains vertical without any transfer action, and the need for adding needles is changed from a single direction in the clamping edge direction....

Embodiment 2

[0071] Take the front of a common 12-needle V-neck pullover as an example, that is, the dense needle patch is a 12-needle V-neck, and the width of the dense needle patch is 12 pieces, about 2cm (such as figure 1 ). According to the required collar shape, the left and right neck welt narrowing knits are "2 turns - 2 pieces - 19 times", "3 turns - 2 pieces - 11 times", "4 turns - 2 pieces - 3 times", "6 Turn" is complete. Among them, "x turn" is the number of knitting rows ("1 turn"=2 knitting rows), "-y branch" is the number of narrowing ranges, and "-n times" refers to the number of stitches according to the above-mentioned "knitting revolutions" and "needle narrowing ranges". Number" repeat weaving "n times". According to the above requirements, use 12 dense needles to make bordered narrowing.

[0072] The process diagram of the garment piece weaving using the conventional scheme is as follows image 3 As shown, specifically:

[0073] Take the left collar edge sticker as...

Embodiment 3

[0084] Take the front right piece of the common 12-needle cardigan as an example, that is, the dense needle patch is the 12-needle breast edge, and the width of the dense needle patch is 10 pieces, about 1.8cm (such as Figure 5 ). According to the required chest welting requirements, the left and right breast welts are knitted with "4 turns + 1 piece + 8 times", "5 turns + 1 piece + 35 times", and "5 turns" to complete. Among them, "x turn" is the number of knitting rows ("1 turn"=2 knitting rows), "+y branch" is the number of stitches, and "+n times" refers to the number of stitches according to the above-mentioned "knitting turns" and "stretch of stitches". Number" repeat weaving "n times". According to the above requirements, use 10 dense needles to make bordered needles.

[0085] The process diagram of the garment piece weaving using the conventional scheme is as follows Figure 7 As shown, specifically:

[0086]Take the front right piece of a cardigan as an example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com