CMOS-MEMS double-sided integrated chip and integration method thereof

A technology of integrated chips and integrated methods, which is applied in the field of micro-electromechanical systems, can solve the problems of complex sensor structure, difficult completion, and increased chip area, and achieve the effect of reducing the overall volume and solving compatibility problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

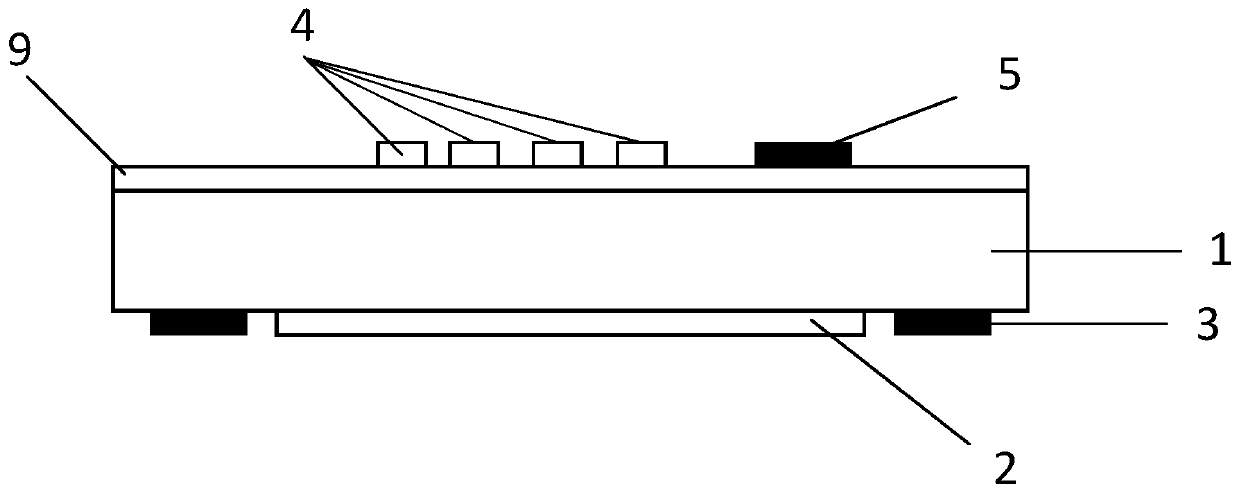

[0044] Such as Figure 5Shown, a kind of CMOS-MEMS double-sided integrated chip comprises substrate 1, CMOS circuit 2, the lead pad 3 of CMOS circuit, MEMS structure 4, the lead pad 5 of MEMS structure, is used for the lead bonding of CMOS circuit The plate 3 leads to the metal via 7 on the surface where the MEMS structure 4 is located. In double-sided boards and multi-layer boards, in order to connect the printed wires between the layers, a common hole is drilled at the intersection of the wires that need to be connected in each layer. , that is, the via hole, and the filling metal in the via hole is the metal via hole. The metal in the metal via hole 7 is one or more of copper, aluminum and gold.

[0045] The substrate 1 in the embodiment of the present invention is a silicon substrate, which is not limited to a silicon substrate in practical applications, and can also be other substrate materials for fabricating MEMS structures and CMOS circuits. The CMOS circuit 2 and th...

Embodiment 2

[0054] Such as Figure 8 As shown, for MEMS, there is also a MEMS structure 4 including a deep cavity 10, so in order to complete the double-sided integration of the MEMS structure 4 including the deep cavity 10 and the CMOS circuit 2, the difference between Embodiment 2 of the present invention and Embodiment 1 is that: The CMOS-MEMS double-sided integrated chip also includes a deep cavity 10, which is opened on the second surface of the substrate 1, and a window 8 is provided on the support layer 9 corresponding to the opening of the deep cavity 10. The depth of the deep cavity 10 is smaller than the thickness of the substrate 1 .

[0055] In practical applications, the window 8 is located in an area other than the MEMS structure 4 on the second surface of the substrate, and the position of the window 8 should not coincide with the position of the MEMS structure 4, so as to avoid accidentally etching off the leads of the MEMS structure 4 to cause circuit failure . Both the...

Embodiment 3

[0058] Corresponding to Embodiment 1 of the present invention, the present invention also provides an integration method of a CMOS-MEMS double-sided integrated chip, the method comprising:

[0059] In order to facilitate the identification of the example diagrams of each process, the steps of the process are identified below, but in practice, the order of the steps is not limited, as long as it meets the process requirements. Such as figure 1 As shown, step a: select a single-throw or double-throw silicon wafer as the substrate 1;

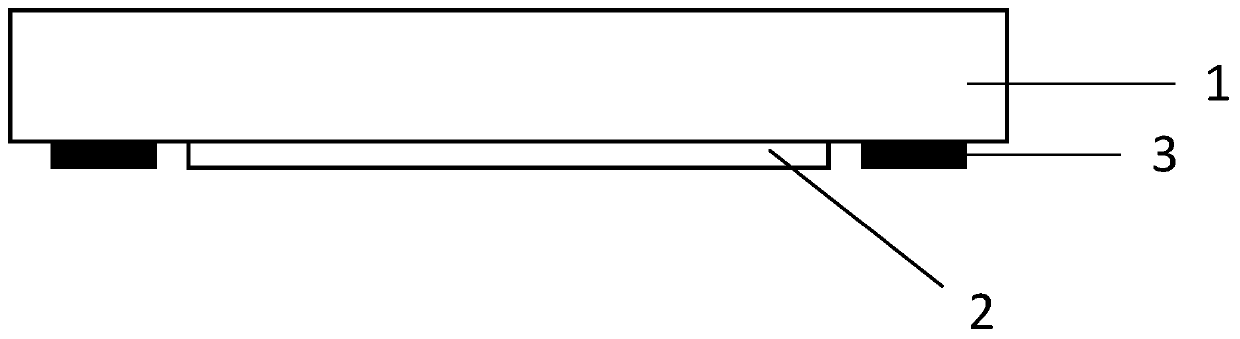

[0060] Such as figure 2 As shown, step b: use the CMOS process to integrate the CMOS circuit 2 and the lead pad 3 of the CMOS circuit on the first surface of the substrate 1; the CMOS process is an existing process flow, including initial cleaning, pre-oxidation, and nitrogen deposition There are dozens of processes such as siliconization, silicon nitride removal, P-well ion implantation, P-well annealing, and oxide layer formation, so I won’t r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com