Wire rod coiling method

A wire winding method and wire technology, applied in the field of wire winding, can solve problems such as crossing another magnetic pole 1b, limiting the movement range of the wire nozzle 6, and returning to the coil portion 5 side.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

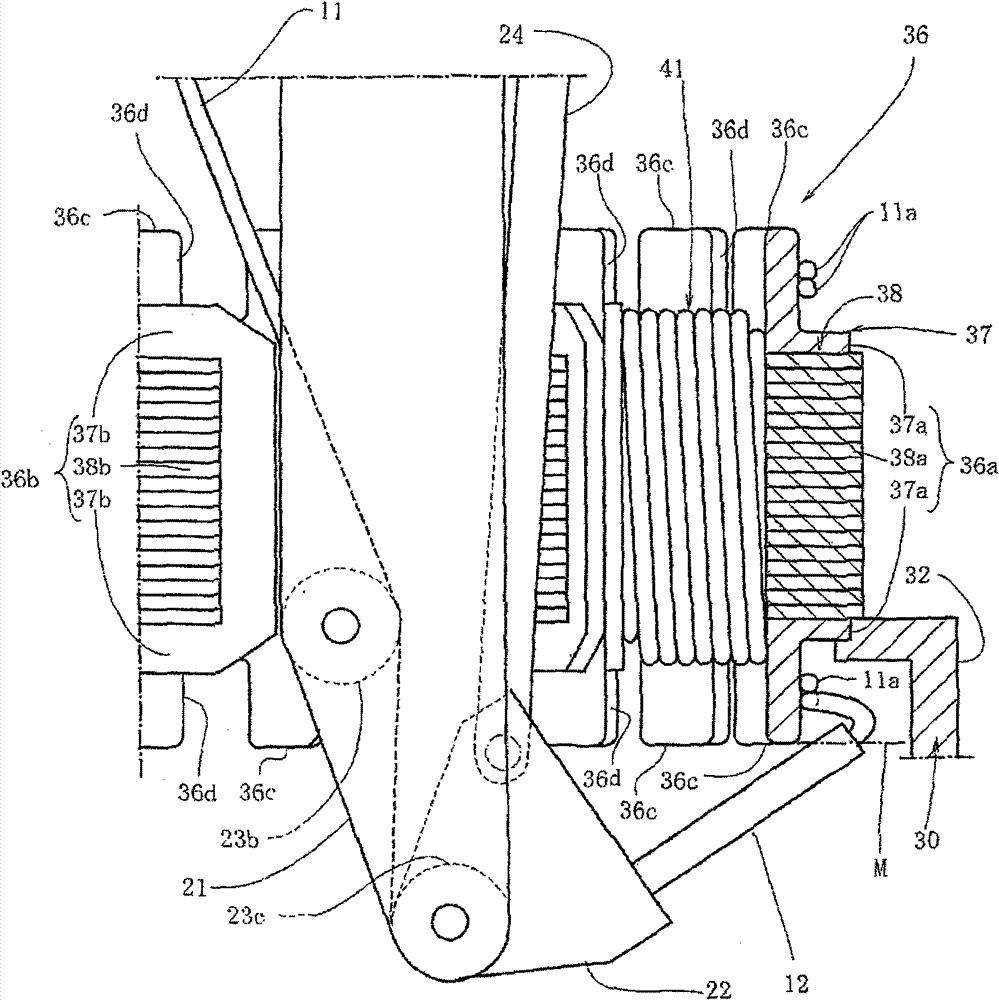

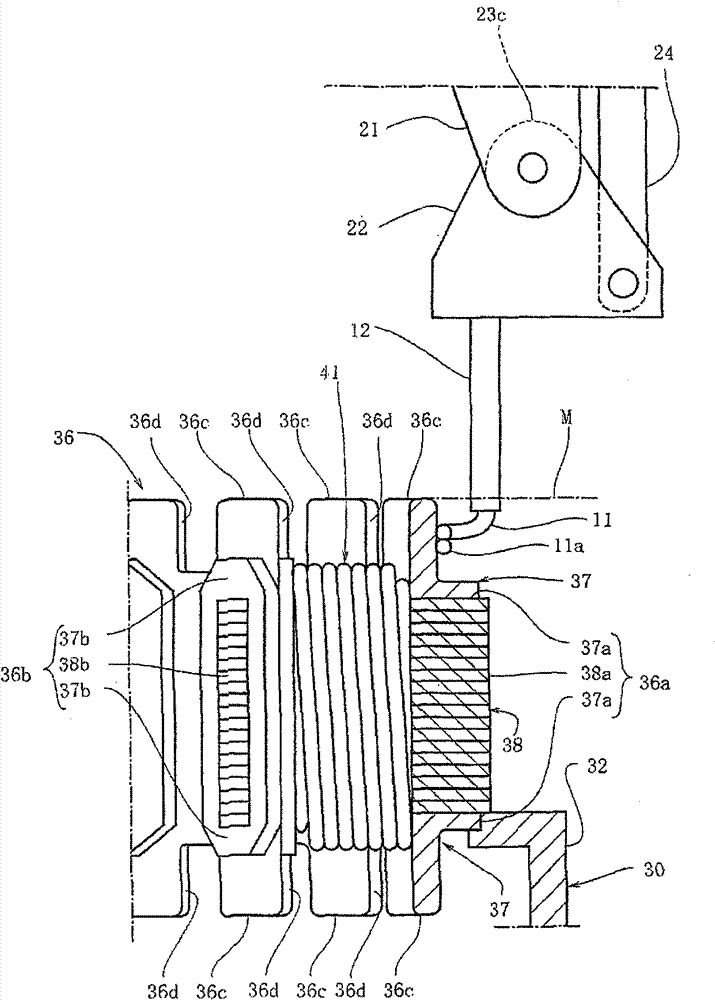

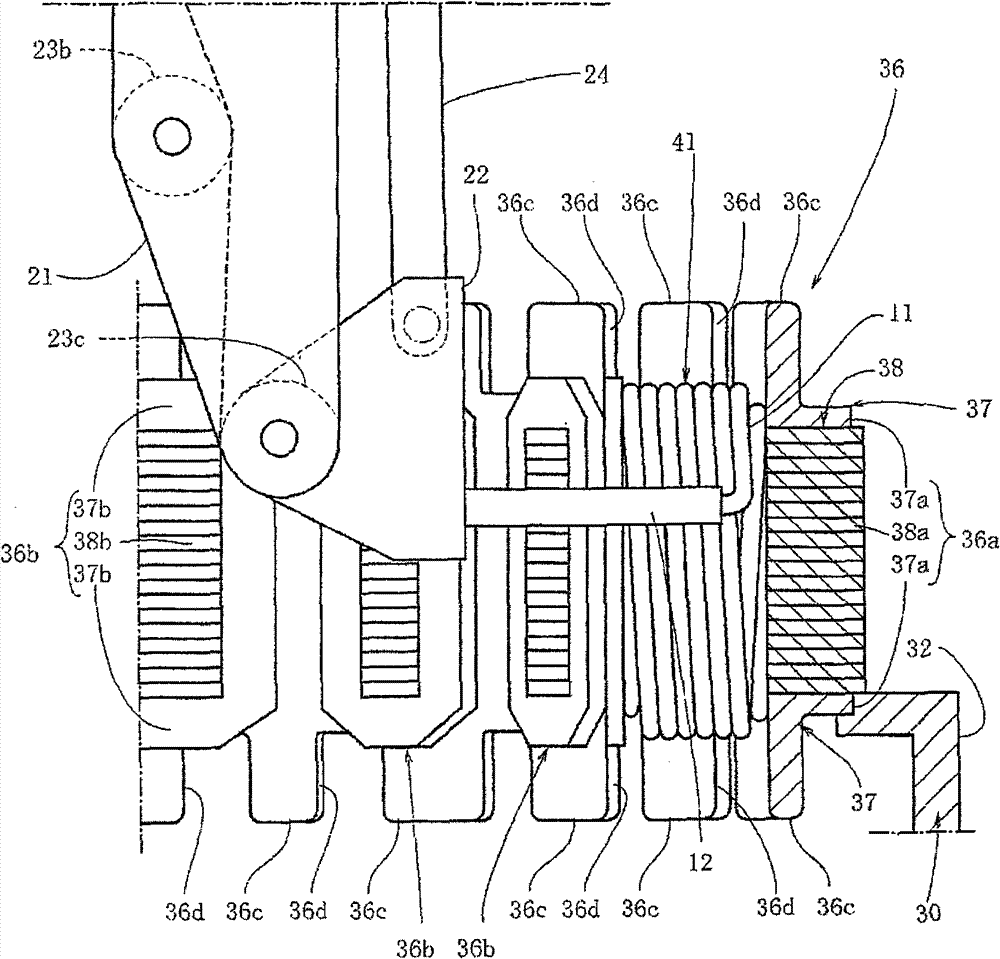

[0024] Next, the best mode for carrying out the present invention will be described with reference to the drawings.

[0025] Figure 5 The winding machine 10 used for the method of this invention is shown. This winding machine 10 is provided with the base 14 provided in the installation place, and the drive unit 13 provided on the base 14 for driving the nozzle 12 which draws out the wire 11. As shown in FIG. The drive unit 13 is composed of drive units 16 , 17 , and 18 in three axial directions, and includes a front-rear direction drive unit 16 , a left-right direction drive unit 17 , and a vertical direction drive unit 18 . The driving units 16 , 17 , and 18 are substantially identical driving mechanisms along the driving directions X, Y, and Z.

[0026] First, the up-down direction drive unit 18 will be described. The up-down direction drive unit 18 is provided with: an up-and-down guide rail 18a arranged along the driving direction Z; Bolts are provided; a vertical movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com