Bamboo plywood and process for making same

A technology of bamboo plywood and its manufacturing method, which is applied in the jointing of wooden veneers, manufacturing tools, wood processing appliances, etc., and can solve the problems of limited width of bamboo boards, affecting installation quality, splitting of bamboo strips, etc. , to achieve the effects of easy installation, improved installation quality and use effect, and simple and easy production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

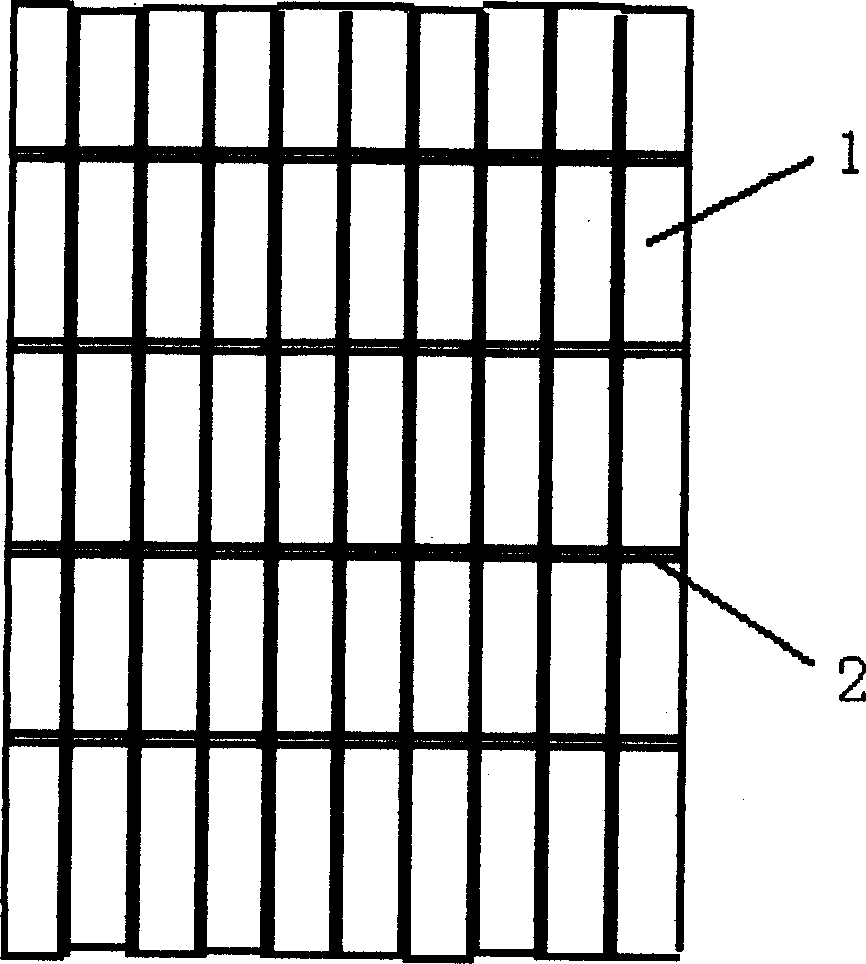

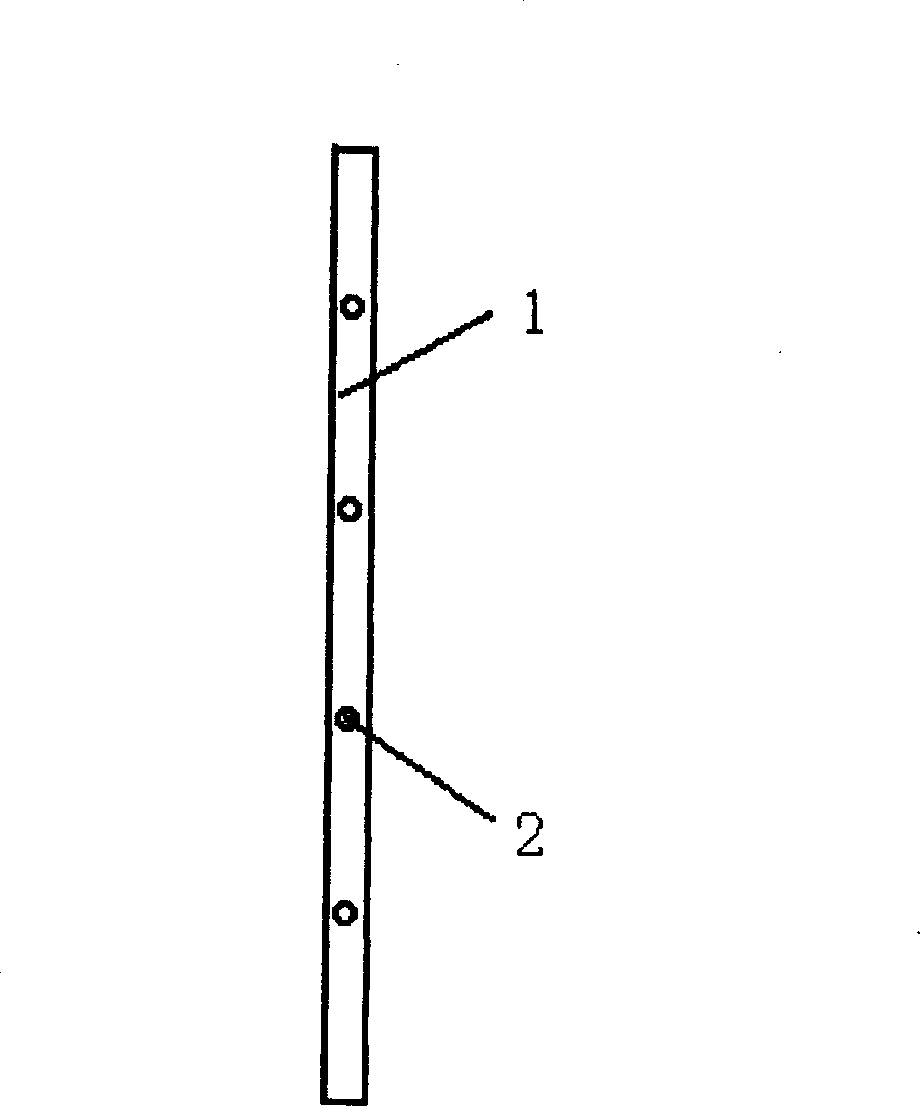

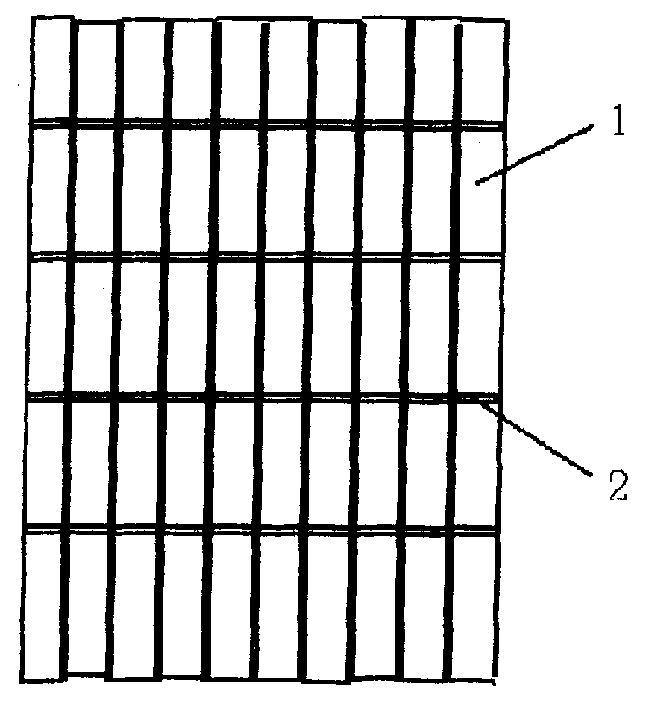

[0016] see figure 1 , figure 2 , the present embodiment is formed by splicing and gluing bamboo strips 1 side by side on a bamboo board, and there are ribs 2 connected in series between adjacent bamboo strips 1 .

[0017] As shown in the figure, in this embodiment, the ribs 2 are arranged through the bamboo board from one side to the other side.

[0018] In order to make the glue connection between the bamboo strips stronger, the tendons 2 can be arranged at intervals along the longitudinal direction of the bamboo strips 1 .

[0019] The specific production process is:

[0020] 1. Open bamboo strips.

[0021] Cut the bamboo into long strips, cut off the outer layer of bamboo green and the inner layer of bamboo springs, and form double-planar bamboo strips;

[0022] 2. Anti-insect treatment.

[0023] Boil the bamboo sticks in insect repellant water for two hours to carry out insect repellent treatment. Then enter the drying room for drying, the time is 6-12 hours, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com