Parallel torch support tower

A technology for supporting towers and torches, applied to towers, building types, buildings, etc., can solve the problems of torch installation and disassembly, large steel consumption, and small lateral rigidity, so as to achieve smooth loading and unloading of torches and reduce steel consumption , reducing the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

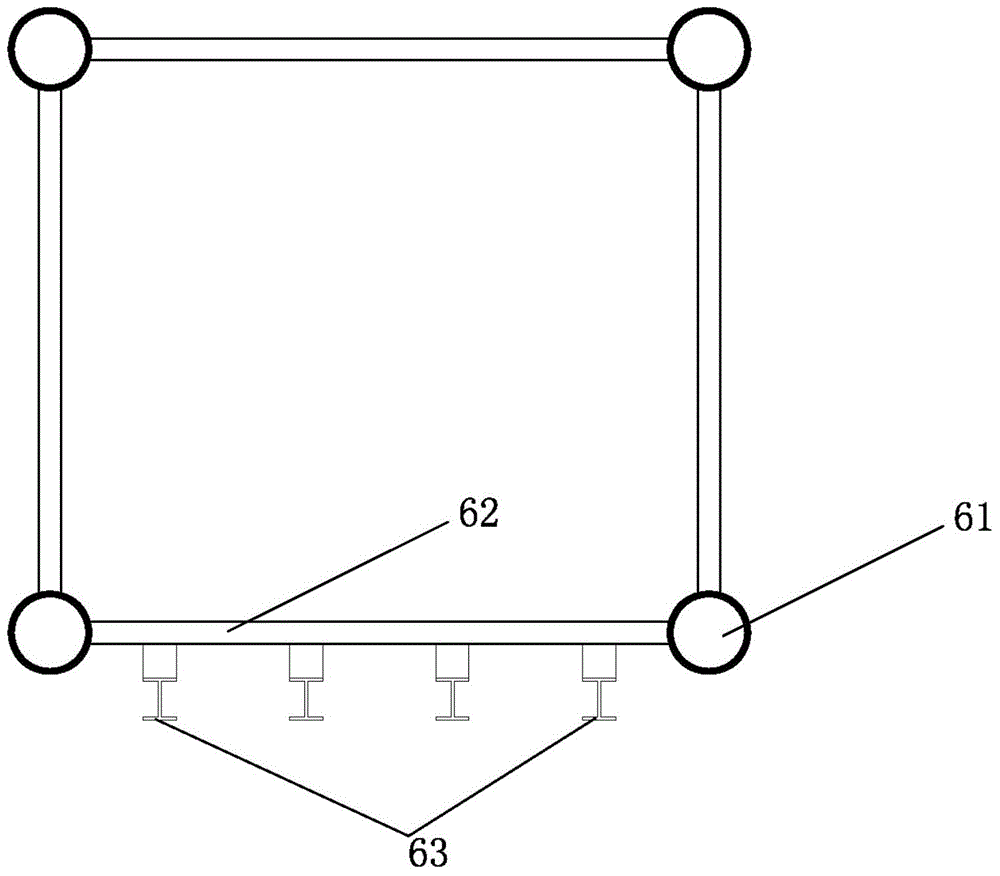

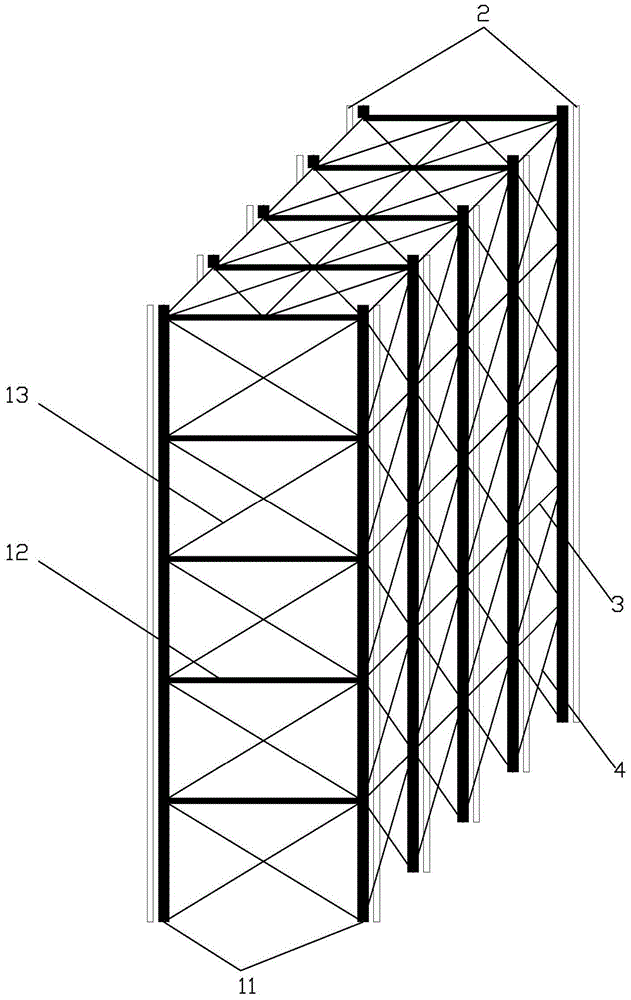

[0033] Such as image 3 , Figure 4 and Figure 5 As shown, the side-by-side torch support tower includes a torch support unit 1, a tower column 11, a horizontal support 12 between columns, a cross support 13 between columns, a torch lifting track 2, a unit connecting cross bar 3, and a unit connecting oblique bar 4 , Unit connection interface 5 . The torch support unit 1 is composed of two sets of tower columns 11 perpendicular to the ground and inter-column horizontal supports 12 and inter-column cross supports 13. The shape of the torch support unit 1 is rectangular.

[0034] Torch lifting rails 2 are installed at both ends of the torch support unit 1 .

[0035] Unit connection interfaces 5 are arranged on both sides of the torch support unit 1, and each group of torch support units 1 is connected into a spatial overall structure through the unit connection cross bar 3 and the unit connection oblique bar 4. The outer reserved unit of the torch support unit 1 is connecte...

Embodiment 2

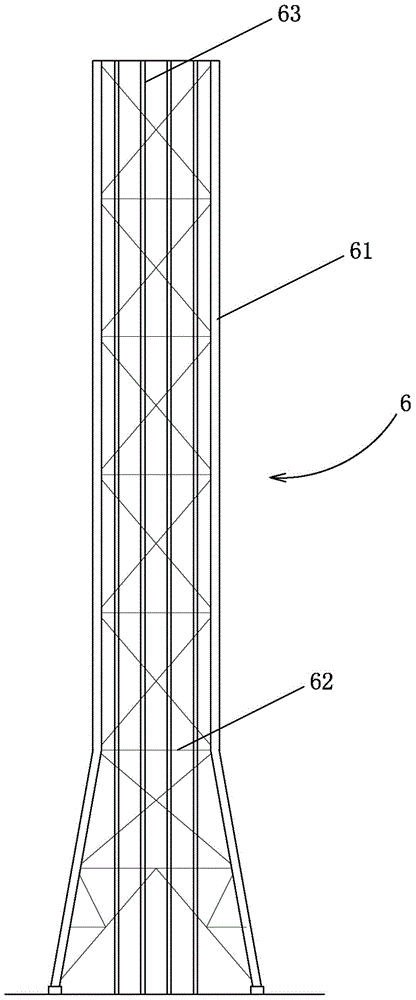

[0040] as attached Figure 6 As shown, the structure and beneficial effects of this embodiment are basically the same as those in Example 1, the difference being that one group of the two groups of tower columns 11 that make up the torch support unit 1 is perpendicular to the ground, and the other group is inclined, and the torch support unit The shape of 1 is similar to a right triangle, and the torch lifting track 2 is installed on the end of the torch support unit 1 perpendicular to the ground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com