Device and method for producing large-width ultrathin metal lithium strip

An ultra-thin metal, lithium strip technology, applied in the field of lithium metal, can solve the problems of high cost, difficult preparation of ultra-thin metal lithium strips, poor quality, etc., to achieve easy debugging, improve work efficiency and product quality, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

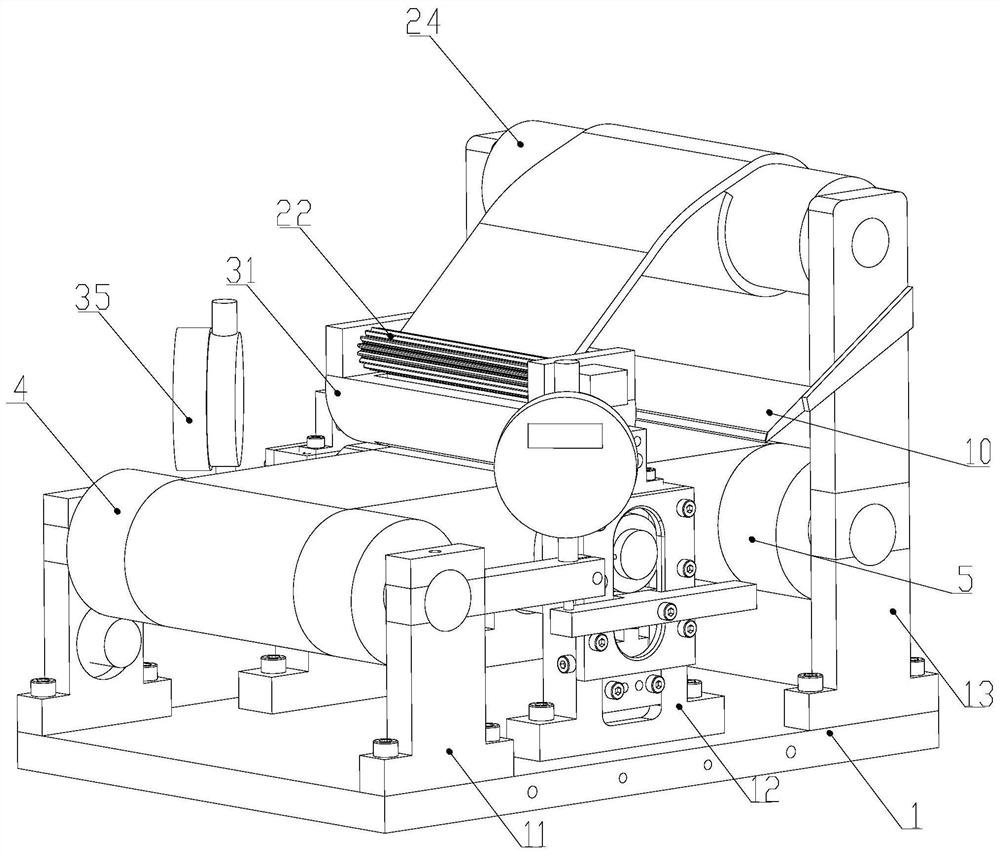

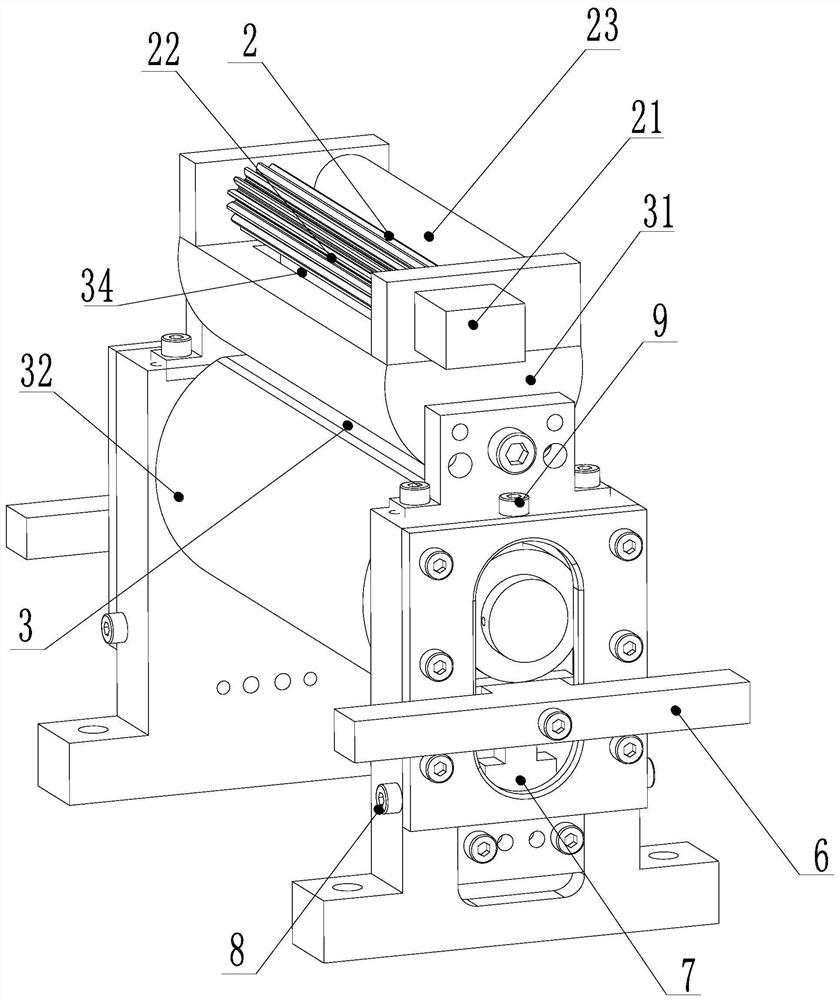

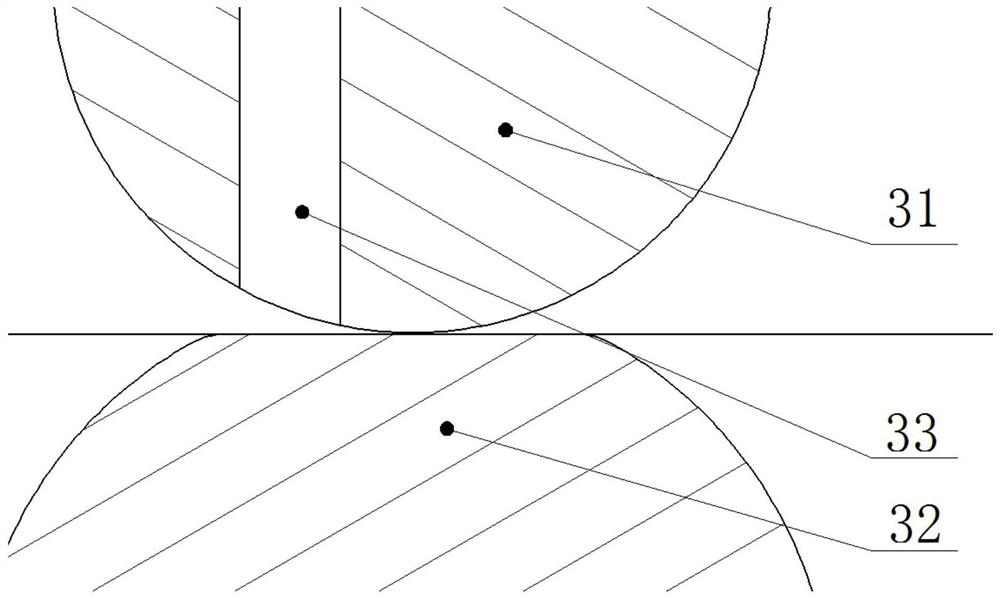

[0026] refer to figure 1 , the device for producing large and wide ultra-thin metal lithium strips according to the present invention, which includes a frame 1, a lithium material feeding device 2, a lithium material melting scraping device 3, a base material unwinding roller 4 and a composite tape winding roller 5. Wherein, frame 1 is used for installing other parts; Lithium material feeding device 2 is used for supplying material to lithium material melting scraping device 3; Lithium material melting scraping device 3 is used for melting metal lithium material and metal on the substrate The lithium liquid is used for scraping; the substrate unwinding roller 4 is used to provide the substrate, and the composite tape winding roller 5 is used to rewind the composite tape and play a tensioning role with the substrate unwinding roller 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com